-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

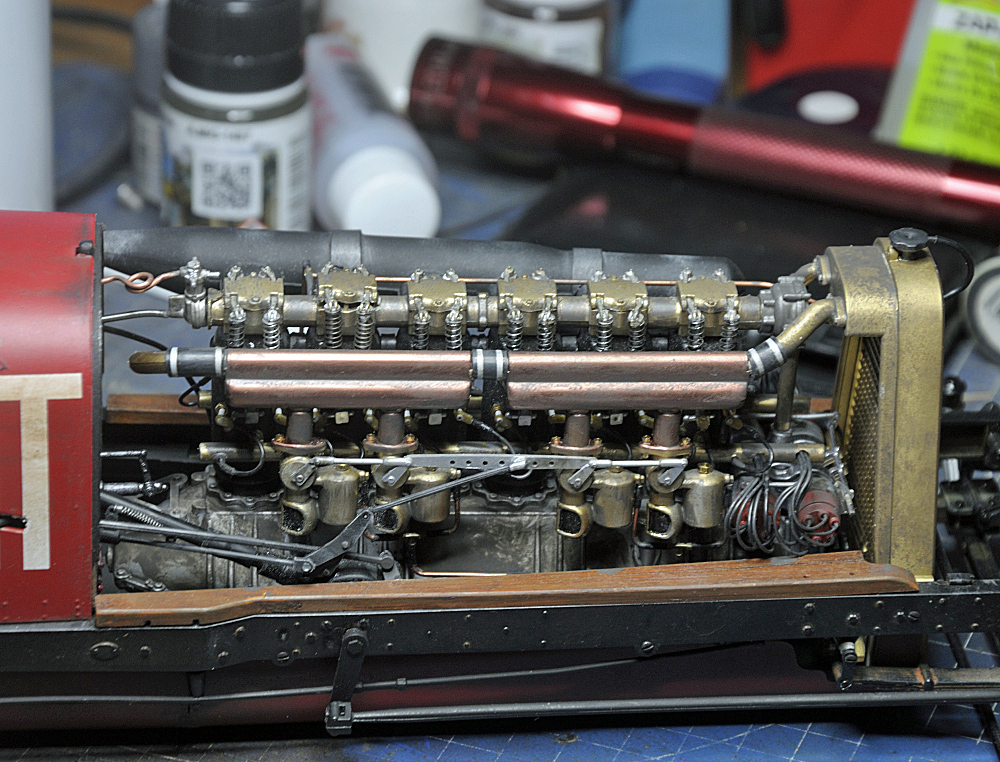

Beware the Mephistopheles FINISHED

- Thread starter paddy

- Start date

Nice Paddy, looks like it could take wings.

mustang1989

Well-known member

DANG Paddy!!! You build so darn quick and precise!! It would take me a half a year or better to make it this far with all the upgrades you've added here!!!! WOW!!!!!!!

That's insane!

mustang1989

Well-known member

The details man....the DETAILS!!! WOW!!!!

paddy

Well-known member

now i am in trouble. this thing was chain drive on both sides and the kit chain is about 500 pieces about 2mm long assembled with a hot soldering iron. that would not be so bad if i had assembled the first half in the right order. Finally the totally useless instructions have beaten me .

i am a bit stuck now ? Tamiya do a PE type chain in1/12 for their motorcycles but its nearly £40.00 and i would need 3. Cheaper to buy a whole new car kit... thinking cap on.

i am a bit stuck now ? Tamiya do a PE type chain in1/12 for their motorcycles but its nearly £40.00 and i would need 3. Cheaper to buy a whole new car kit... thinking cap on.

paddy

Well-known member

hmm, glad i checked, i have 1/12 and 1/6 bikes on the shelf and although the car is 1/12 the chain is the same size as a 1/6 bike chain.

These are a little cheaper than 1/12 and longer so i would need 2 not 3, still £60.00 though better than the £120 for 1/12.

I will sleep on it and see if i can salvage what i have first.......

These are a little cheaper than 1/12 and longer so i would need 2 not 3, still £60.00 though better than the £120 for 1/12.

I will sleep on it and see if i can salvage what i have first.......

Good luck Paddy.

Heavens Eagle

Well-known member

Paddy, in a pinch I would be willing to bet I could disassemble the chain if it is just soldered together. Might try fine tweezers and an alcohol lamp to heat and pull the parts apart. The alcohol burns hot and clean and shouldn't overheat the parts. Any kind of torch would end up being too hot and could burn or melt the parts. A candle flame would coat the parts with soot.

paddy

Well-known member

Hi Paul

If only it was that straight forward despite this being a 2015 release the chain is plastic and is held together my melting each pin in the chain, 2 per link with a soldering iron, It gives a totally useless finish for a high detail kit like this anyway as the chain just looks like melted bits of plastic.

despite this being a 2015 release the chain is plastic and is held together my melting each pin in the chain, 2 per link with a soldering iron, It gives a totally useless finish for a high detail kit like this anyway as the chain just looks like melted bits of plastic.

I know this looks like i made a pigs ear of it and i did and given another chance i could do a lot better but remember these pins are 0.5mm and melt before soldering iron even get near to touching them and my soldering iron has adjustable temp control.

I did this under 10x magnification and still made a mess of it

I really think that a re-box of an ancient kit like this could do with a little PE if you are going to charge in excess of £160.00 ($190USD)

If airfix can turn out their new 1/24 spit for £90.00 then this is a £60.00 kit.

anyway i have ordered Tamiya's 1/6 motorcycle chain at great expense in an effort to save the build but the chances of the pitch etc being correct for the sprockets is slim TBH

I have added some oil stains to the engine . its a compromise between an oily mess and retaining some detail. In reality i think it would have been a huge black oily mess, 90% blackened and wet and leaking from every gasket with its total loss oil feed s however models are all about compromise i think. ( thats my excuse )

)

If only it was that straight forward

I know this looks like i made a pigs ear of it and i did and given another chance i could do a lot better but remember these pins are 0.5mm and melt before soldering iron even get near to touching them and my soldering iron has adjustable temp control.

I did this under 10x magnification and still made a mess of it

I really think that a re-box of an ancient kit like this could do with a little PE if you are going to charge in excess of £160.00 ($190USD)

If airfix can turn out their new 1/24 spit for £90.00 then this is a £60.00 kit.

anyway i have ordered Tamiya's 1/6 motorcycle chain at great expense in an effort to save the build but the chances of the pitch etc being correct for the sprockets is slim TBH

I have added some oil stains to the engine . its a compromise between an oily mess and retaining some detail. In reality i think it would have been a huge black oily mess, 90% blackened and wet and leaking from every gasket with its total loss oil feed s however models are all about compromise i think. ( thats my excuse

Paddy you need to get an iron that has variable temperature control.

I have not done this yet but I've wondered if I could lower the temp on this station to simulate weld beads.

BTW, that motor looks freakin real!

Hakko FX888D Soldering Station

HAKKO FX888D Intro Over the years I have been back and forth over getting a resistance soldering station but I just could not pull the trigger on $400+ for something I may not use that often. Biggest problem I have had with soldering is the...

modelersalliance.org

I have not done this yet but I've wondered if I could lower the temp on this station to simulate weld beads.

BTW, that motor looks freakin real!

Not sure how cool it'll get. I'll fire it up this afternoon and see.Got one Bob but that was the lowest it will go but still way too hot. that digital one might go down to zero ?

According to the website this is the temp range. 50 to 480℃

mustang1989

Well-known member

Where does the details end here? So much to learn in this thread.

Heavens Eagle

Well-known member

I never use a soldering iron for this, I have a nail head that is polished that I use. With practice you can learn to heat it just enough to melt the plastic a little and then cool. Then the plastic part pops loose and you have a lot nicer finish on the melted part.

The problem is that in addition to the temperature of the iron, it also never cools off so it mangles the plastic. Maybe take a piece of brass strip, set it on the parts to "melt", heat it with the iron until you feel it give, then remove the iron and cool it. Then pop the part loose.

The problem is that in addition to the temperature of the iron, it also never cools off so it mangles the plastic. Maybe take a piece of brass strip, set it on the parts to "melt", heat it with the iron until you feel it give, then remove the iron and cool it. Then pop the part loose.

Blast! These things happen on these bigger jobs.

Blast! These things happen on these bigger jobs.