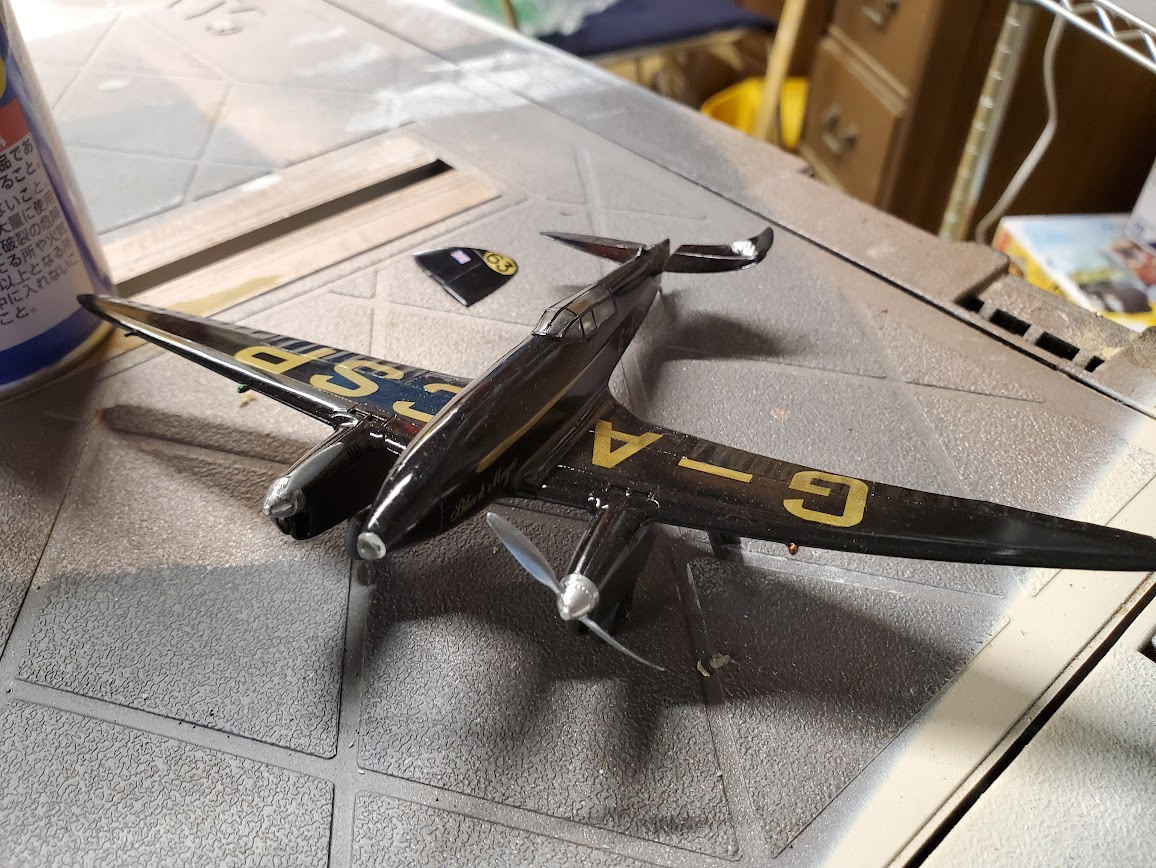

Or... DH88 Restoration.

Black Magic was one of the last build I finished at the old house. Seen here with G-ACSS The Orphan

So when we packed up and moved I had to put the models in storage for a spell. I suspect that the heat got to the resin and warped.

Black Magic suffered worse and since I've played with some painting stuff on it. It's too far gone to restore I think.

The Orphan wasn't as damaged but that's a huge bend. this photo was literally a year ago from this posting. dated Aug 16 2022

The other day I looked at The Orphan again and notice that the wing had recovered slightly.

check it

You tell me, hasn't that wing restored a bit?

I remember reading here on our forum about hot water and resin so I figure give it a go. I text @Rhino to confirm rather boiling water should be used or what. He told me hot tap water. I tried running hot water over the surface, then I let it sit in a hot water bath. Pulled it out and this is the result.

Hard for me to tell, better?

What can I do to get instant gratification!

If I can save this I probably will strip it and paint it in the original red Grosvenor House scheme for my MacRobertson Air Race takeoff day scene I want to do.

Black Magic was one of the last build I finished at the old house. Seen here with G-ACSS The Orphan

So when we packed up and moved I had to put the models in storage for a spell. I suspect that the heat got to the resin and warped.

Black Magic suffered worse and since I've played with some painting stuff on it. It's too far gone to restore I think.

The Orphan wasn't as damaged but that's a huge bend. this photo was literally a year ago from this posting. dated Aug 16 2022

The other day I looked at The Orphan again and notice that the wing had recovered slightly.

check it

You tell me, hasn't that wing restored a bit?

I remember reading here on our forum about hot water and resin so I figure give it a go. I text @Rhino to confirm rather boiling water should be used or what. He told me hot tap water. I tried running hot water over the surface, then I let it sit in a hot water bath. Pulled it out and this is the result.

Hard for me to tell, better?

What can I do to get instant gratification!

If I can save this I probably will strip it and paint it in the original red Grosvenor House scheme for my MacRobertson Air Race takeoff day scene I want to do.

Last edited: