Old Dog

Well-known member

I have had the itch to build a Japanese aircraft for a while, the last one I did was for the Dave Harper campaign and I've also had the itch to do a vacuform kit so in this thread I hope to scratch both itches. :laugh:

Since the vacuform campaign didn't make the cut this year I'm going to do mine here. Probably better anyway as I really don't want a deadline in this case. Also I'm not intending this to be a tutorial on building vacuforms. Good information on the basics can be found here Walter's Guide to Building Vacuform Models I don't consider myself an expert by any means as I have only done a couple and one that didn't get finished due to an injection molded kit becoming available. No guarantee that won't happen here in which case I would only be too happy to bin this one. :woohoo:

For those not familiar with the type some history:

The Mitsubishi G3M series got it's start from a non-competitive specification that was issued to them on the recommendation of Admiral Yamamoto during the time he was serving with the Naval Bureau of Aeronautics. The specification called for a land based twin engined long range reconnaissance aircraft. The result of this was to serve as an aerodynamic prototype possessing the necessary performance required from a future attack bomber. The resultant aircraft (Mitsubishi designation Ka-9) possessing a clean airframe with a wing featuring flying control surfaces similar to those used by Junker's aircraft of the time, and twin fins and rudders. It demonstrated exceptional manoeuvrability and handling characteristics and achieved a maximum range of 3,265 nautical miles. The results of the flight test program were received with enthusiasm by the Navy which resulted in a new specification being issued to Mitsubishi calling for a fully developed attack bomber.

The resultant aircraft used the wings from the Ka-9 and a new wider fuselage. Corrugated panels on the wings were replaced with smooth skinned panels. The tail surfaces were enlarged and the landing gear simplified and strengthened. As the aircraft was intended to operate in support of naval units, the main offensive weapon was the torpedo, carried under the fuselage with no provisions for an internal bomb bay. This new aircraft (Mitsubishi designation Ka-15) made its first flight in July 1935. It was soon apparent that the aircraft was equal to most foreign aircraft of the time. Within a year twenty additional prototypes were built and despite the loss of one aircraft, the test program progressed smoothly. The prototypes were built in a variety of configurations with different engine and propeller configurations. In June 1936 it was put into production as the Navy Type 96 Attack Bomber Model 11 (G3M1). The production aircraft featured a redesigned canopy and internal equipment changes. Even though the G3M1 exceeded most of the Navy's original requirements, this variant saw only limited service as an improved version of the Kinsei engine allowed a further increase in performance.

Powered by two Kinsei 41 or 42 engines the G3M2 Model 21 differed only in minor internal details and increased fuel capacity. On 14 August, 1937, a week after the start of the second Sino-Japanese conflict a group based in Formosa sent its G3M2s against targets in mainland China and despite poor weather, flew 1,250 miles over water and made the first trans-oceanic bombing raid in aviation history. Soon thereafter the G3M2s were moved to bases on the mainland where they mounted raids deep into mainland China. However, operating beyond the range of their fighter escorts, the bombers suffered heavy losses due to wholly inadequate defensive armament. In 1940 Nakajima began manufacturing the Model 21 under a Navy production contract.

As a result of pressing requests from operational units Mitsubishi designed the G3M2 Model 22 with a much revised defensive armament set up and various equipment changes including a license built Sperry automatic pilot and radio direction finding units. When hostilities with the United States began in December 1941 the Japanese Navy had 204 G3M2s operating in first line units and 54 in second line units. The bombers took part in operations against Wake Island, the Philippines and the Marianas and on 10 December, 1941, sixty G3M2s and 26 G4M1s succeeded in sinking the two British battleships the HMS Prince of Wales and HMS Repulse of Malaya. As Japanese forces moved swiftly through the Southwest Pacific islands, so did the G3M2s. However they had already been replaced on the Mitsubishi assembly lines by the G4M1 leaving Nakajima as the sole manufacturer. By 1943 few of the G3M2s were still operating in their intended roles with most surviving aircraft serving until the end of the war in second line units as glider tugs, bomber trainers and maritime reconnaissance aircraft often fitted with search radar. A total of 1,048 G3Ms were built including prototypes.

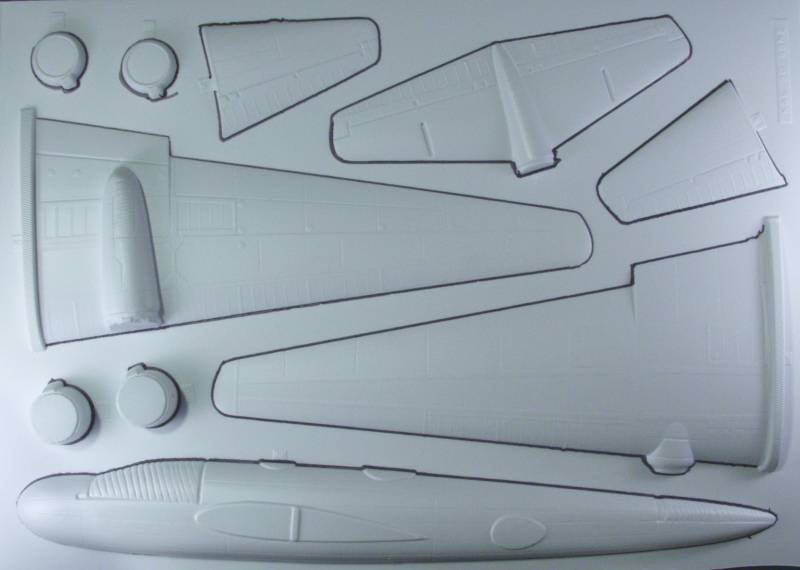

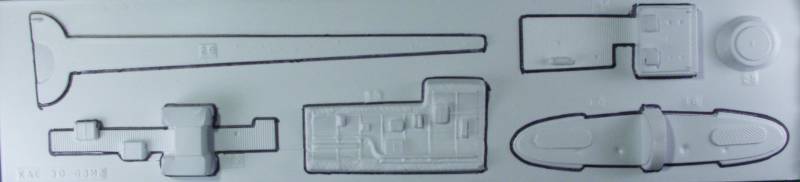

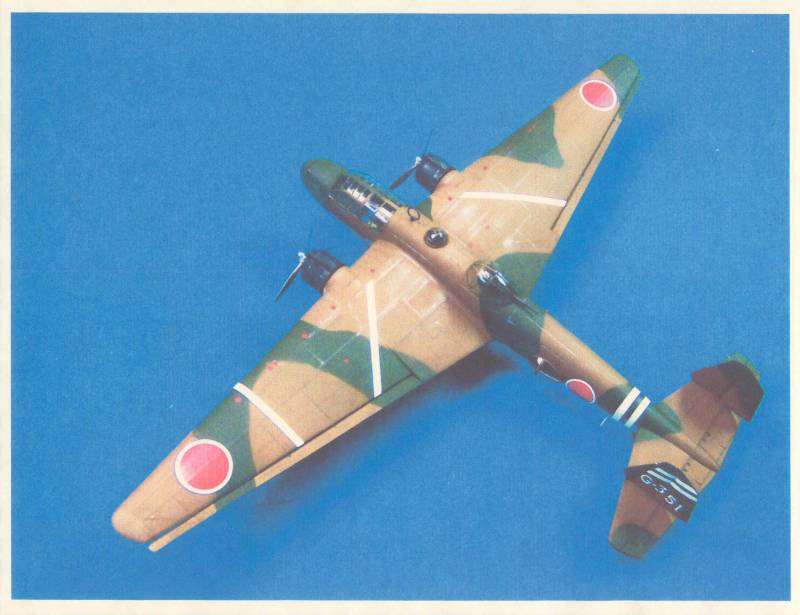

Although some vacuform kits only include the basic airframe parts and expect the builder to scratch the rest the Koster kit is quite complete. This is what comes in the box...

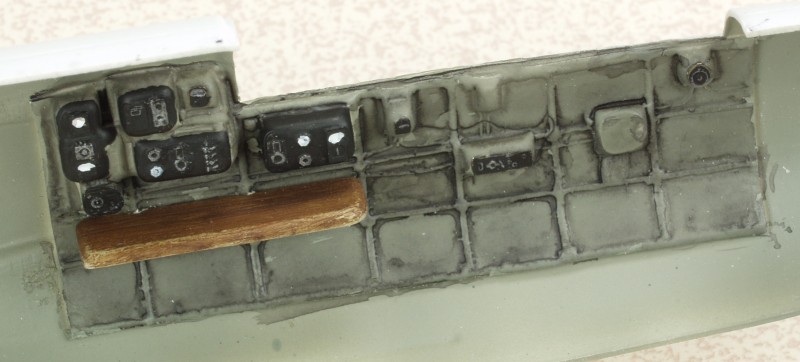

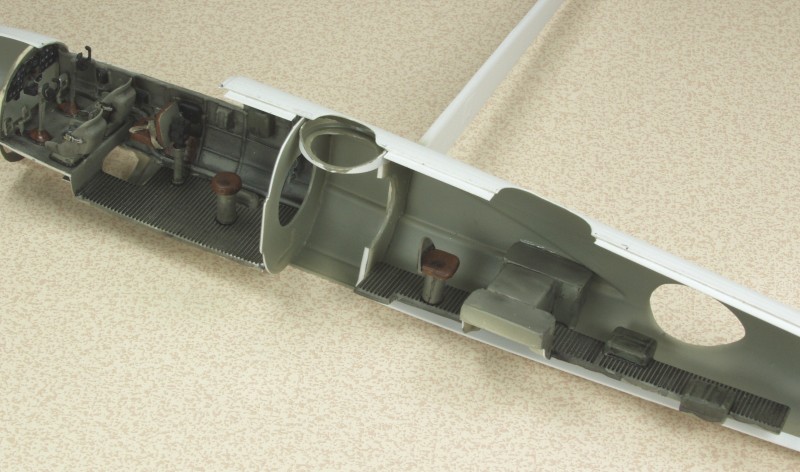

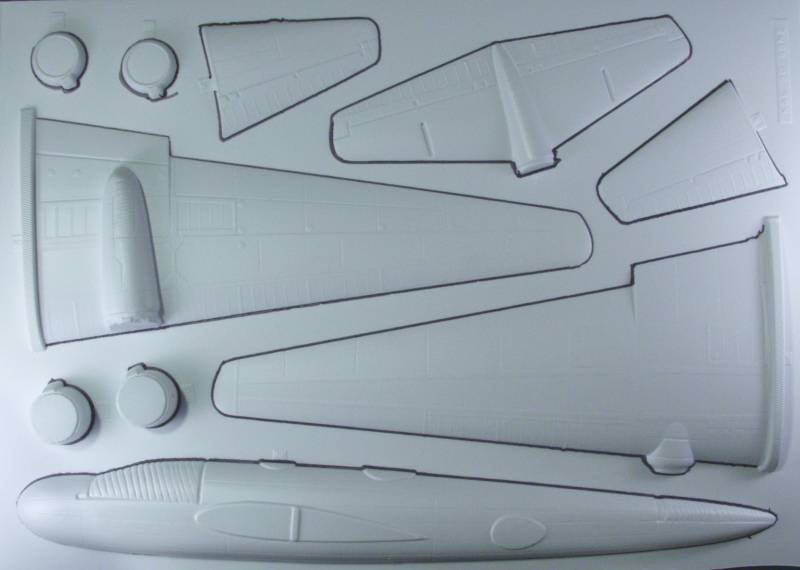

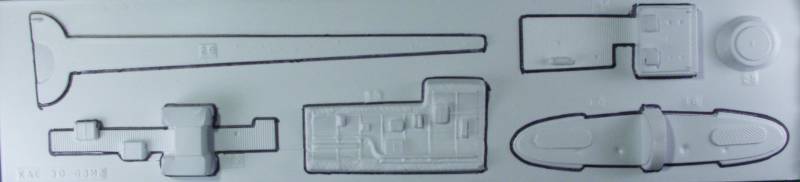

The photo above is included inside the box along with three sheets of vacuformed parts. Also included in the box is a pair of cast metal propellers, a zip lock bag of additional cast metal parts, a zip lock bag full of cast resin parts and a vacuformed set of clear glazings. Koster uses heavier plastic than many makers of these types of kits which makes for a bit sturdier construction. Two of the three sheets are good sized and have the primary airframe parts, a bulkhead, one wing spar, torpedo, engine cowlings and some internal side wall detail. A smaller third sheet has the other wing spar and some additional internal details. In spite of the heavier gage plastic used the surface detail is very nice with recessed panel lines a raised detail as appropriate. While the detail is not up to the standard expected with injection molding it is some of the nicest I have seen on a vacuformed kit. The fabric control surfaces are a bit overdone to my eye but no worse than many injection molded kits. As is the case with many vacuformed kits invariably the plastic gets stretched very thin in some places especially on very detailed parts and such is the case here and on some parts some additional strengthening may be needed. The internal side pieces are a mixed bag, the one has so much detail that most of it ended up being rather soft and lacking detail while the other turned out much better. Still a little soft but probably acceptable once installed inside the fuselage. I suspect I'll will be temped to cut the detail away on one side and replace it with some scratch built parts with sharper edges and more defined details. In the photos below I have outlined the parts with a magic marker not only to make them stand out more but as the first step in preparing the parts.

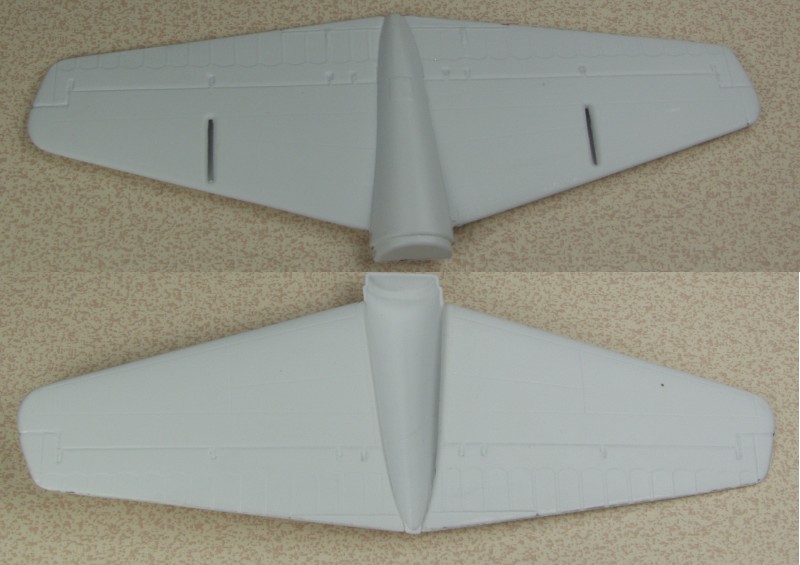

The G3M series aircraft were equipped with flying control surfaces on the wings much like those used on Junkers aircraft like the Ju 52 and Ju 87. These would be tough to do as a vacuform part and in this kit these are supplied as a resin part. The castings were quite good in my kit with few if any casting defects although both are a bit warped. Once removed from their casting blocks a warm water dip should take care of the warps.

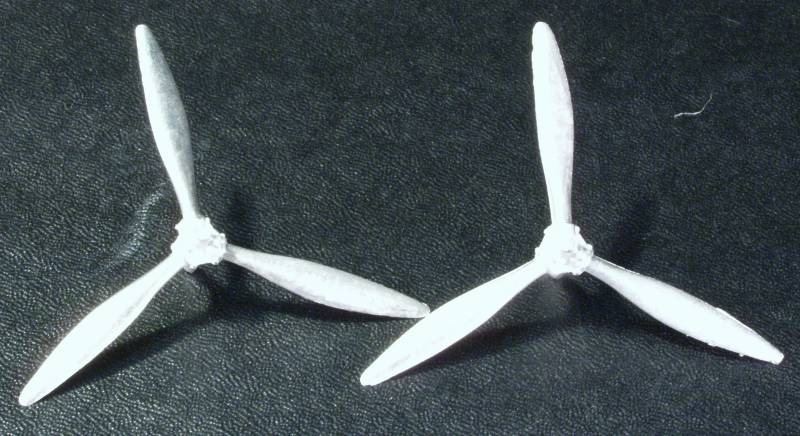

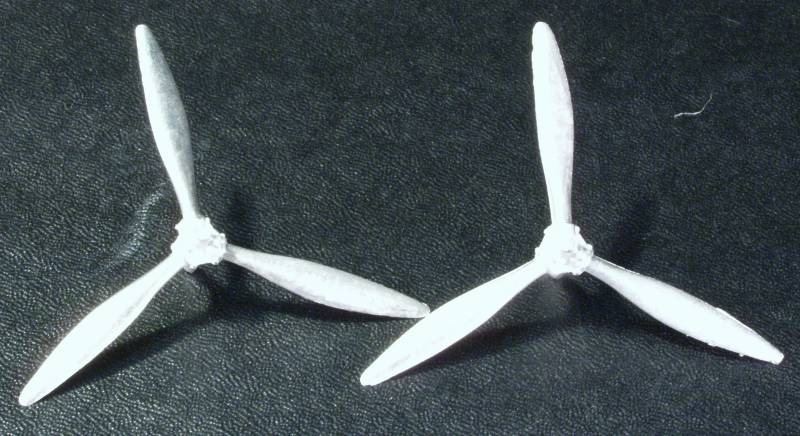

The propellers are provided in cast soft metal and look quite nice needing only some light clean up of flash.

The landing gear is also done in metal and again is quite nice. Like many cast metal part some of them may need to be tweaked a bit to get them straightened out.

The balance of the metal parts are for the guns, an ammo drum, DF loop, antenna, pitot tube, trim wheel, control wheels, rudder pedals and all those 'V' shaped parts which are intended to be the push rods for the resin engines. Those must have been a pain to cast and look to be even more of a pain to clean up and install. These parts are for the most part nice and shouldn't be that hard to clean up and straighten. The guns would probably look better with some hypodermic tubing for barrels.

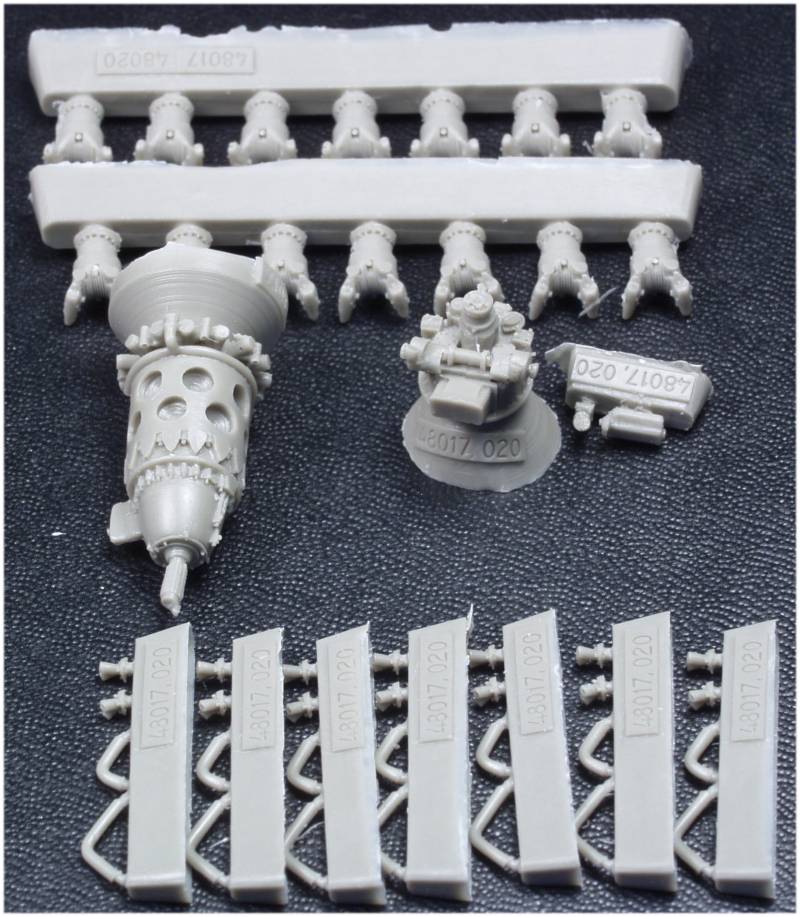

The resin parts shown below are some what of a mixed bag. Molded in three different colors of resin. The engines which at first glance didn't look too bad but mine were marred with a numerous air bubbles on the front side. Once painted and buried in the cowlings they might be passable but I would recommend replacing them with quality resin replacements from Vector. The wheel assemblies are a bit rough and to my eye a bit too flat. The Prop spinners are good. The fins and rudders are nice but do have a few bubbles to fill. The oxygen tanks are nice as are the seats but again the seats will require a bit of bubble filling. The exhaust stubs are nice as are the gear doors and the bulkhead with the instrument panel but they will require a bit of clean up. The wedge shaped parts are the mounting parts for the flying control surfaces and these look like they could be a challenge both to clean up and install. The other two parts are the control columns.

The clear parts are quite clear and since they are molded out of heavier material than is the norm they are a bit more sturdy and easier to work with in my opinion. Although it doesn't show well in my photograph the frame lines are pretty well registered and shouldn't be that hard to mask.

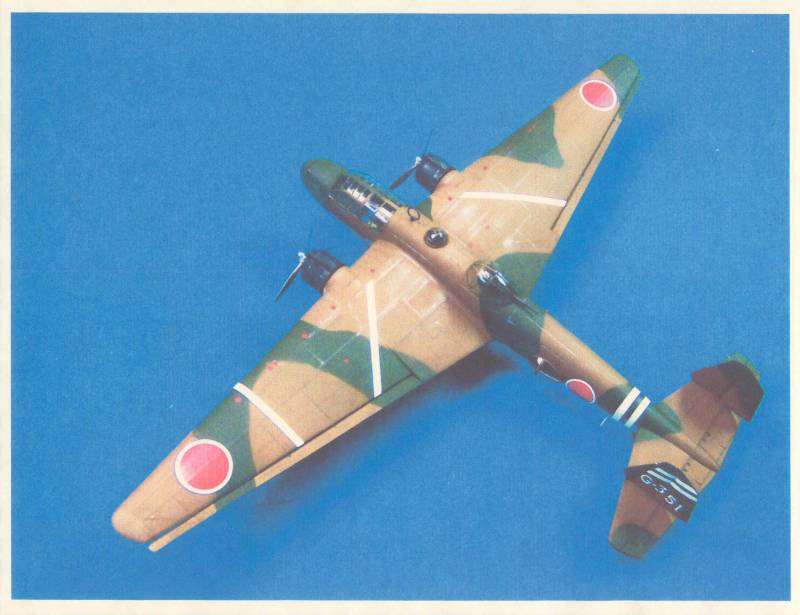

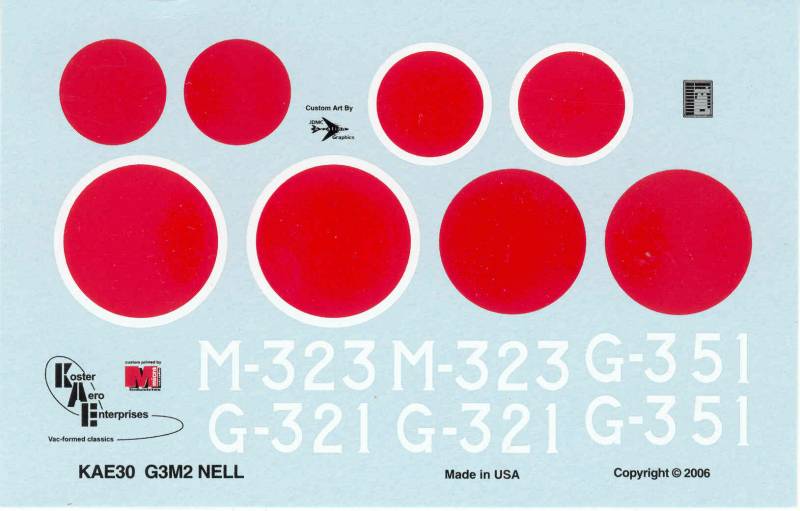

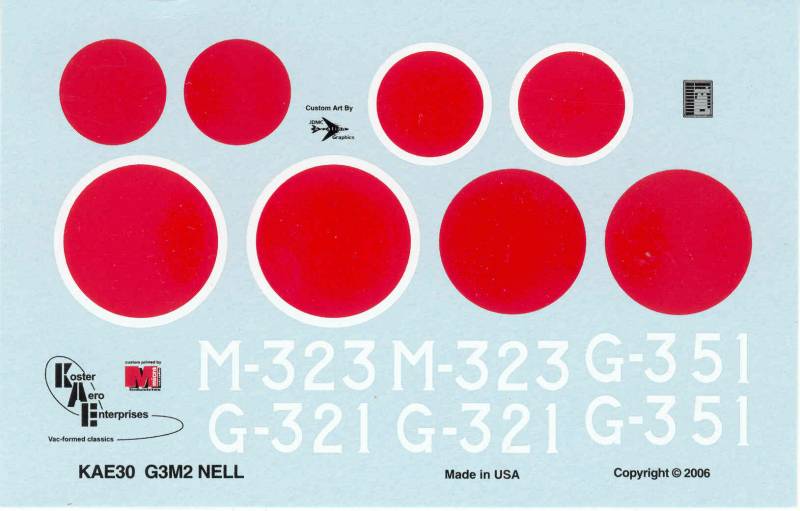

The decals appear thin and are well registered. I have used a few of the decals supplied by Koster before and have not had any issues with them. They appear opaque. Markings are supplied for three aircraft with similar but slightly different paint schemes.

Since the engines were pretty crappy I decided to go with a Vector engine

Don't expect any immediate progress on this as before construction can begin the vacuform parts must be cut out from the base sheet and the thickness of the base sheet sanded from edges of the mating parts. This tends to be a bit tedious and no doubt is what discourages many from doing vacuform kits. It's a good background task that can be done while waiting for paint to dry or decal setting solution to work and that is how I plan on doing it. While not a tutorial as such I may show some progress on this and my way of doing some things. So if you grab an adult beverage to enjoy this you may end up like this before you see much :drunk

Since the vacuform campaign didn't make the cut this year I'm going to do mine here. Probably better anyway as I really don't want a deadline in this case. Also I'm not intending this to be a tutorial on building vacuforms. Good information on the basics can be found here Walter's Guide to Building Vacuform Models I don't consider myself an expert by any means as I have only done a couple and one that didn't get finished due to an injection molded kit becoming available. No guarantee that won't happen here in which case I would only be too happy to bin this one. :woohoo:

For those not familiar with the type some history:

The Mitsubishi G3M series got it's start from a non-competitive specification that was issued to them on the recommendation of Admiral Yamamoto during the time he was serving with the Naval Bureau of Aeronautics. The specification called for a land based twin engined long range reconnaissance aircraft. The result of this was to serve as an aerodynamic prototype possessing the necessary performance required from a future attack bomber. The resultant aircraft (Mitsubishi designation Ka-9) possessing a clean airframe with a wing featuring flying control surfaces similar to those used by Junker's aircraft of the time, and twin fins and rudders. It demonstrated exceptional manoeuvrability and handling characteristics and achieved a maximum range of 3,265 nautical miles. The results of the flight test program were received with enthusiasm by the Navy which resulted in a new specification being issued to Mitsubishi calling for a fully developed attack bomber.

The resultant aircraft used the wings from the Ka-9 and a new wider fuselage. Corrugated panels on the wings were replaced with smooth skinned panels. The tail surfaces were enlarged and the landing gear simplified and strengthened. As the aircraft was intended to operate in support of naval units, the main offensive weapon was the torpedo, carried under the fuselage with no provisions for an internal bomb bay. This new aircraft (Mitsubishi designation Ka-15) made its first flight in July 1935. It was soon apparent that the aircraft was equal to most foreign aircraft of the time. Within a year twenty additional prototypes were built and despite the loss of one aircraft, the test program progressed smoothly. The prototypes were built in a variety of configurations with different engine and propeller configurations. In June 1936 it was put into production as the Navy Type 96 Attack Bomber Model 11 (G3M1). The production aircraft featured a redesigned canopy and internal equipment changes. Even though the G3M1 exceeded most of the Navy's original requirements, this variant saw only limited service as an improved version of the Kinsei engine allowed a further increase in performance.

Powered by two Kinsei 41 or 42 engines the G3M2 Model 21 differed only in minor internal details and increased fuel capacity. On 14 August, 1937, a week after the start of the second Sino-Japanese conflict a group based in Formosa sent its G3M2s against targets in mainland China and despite poor weather, flew 1,250 miles over water and made the first trans-oceanic bombing raid in aviation history. Soon thereafter the G3M2s were moved to bases on the mainland where they mounted raids deep into mainland China. However, operating beyond the range of their fighter escorts, the bombers suffered heavy losses due to wholly inadequate defensive armament. In 1940 Nakajima began manufacturing the Model 21 under a Navy production contract.

As a result of pressing requests from operational units Mitsubishi designed the G3M2 Model 22 with a much revised defensive armament set up and various equipment changes including a license built Sperry automatic pilot and radio direction finding units. When hostilities with the United States began in December 1941 the Japanese Navy had 204 G3M2s operating in first line units and 54 in second line units. The bombers took part in operations against Wake Island, the Philippines and the Marianas and on 10 December, 1941, sixty G3M2s and 26 G4M1s succeeded in sinking the two British battleships the HMS Prince of Wales and HMS Repulse of Malaya. As Japanese forces moved swiftly through the Southwest Pacific islands, so did the G3M2s. However they had already been replaced on the Mitsubishi assembly lines by the G4M1 leaving Nakajima as the sole manufacturer. By 1943 few of the G3M2s were still operating in their intended roles with most surviving aircraft serving until the end of the war in second line units as glider tugs, bomber trainers and maritime reconnaissance aircraft often fitted with search radar. A total of 1,048 G3Ms were built including prototypes.

Although some vacuform kits only include the basic airframe parts and expect the builder to scratch the rest the Koster kit is quite complete. This is what comes in the box...

The photo above is included inside the box along with three sheets of vacuformed parts. Also included in the box is a pair of cast metal propellers, a zip lock bag of additional cast metal parts, a zip lock bag full of cast resin parts and a vacuformed set of clear glazings. Koster uses heavier plastic than many makers of these types of kits which makes for a bit sturdier construction. Two of the three sheets are good sized and have the primary airframe parts, a bulkhead, one wing spar, torpedo, engine cowlings and some internal side wall detail. A smaller third sheet has the other wing spar and some additional internal details. In spite of the heavier gage plastic used the surface detail is very nice with recessed panel lines a raised detail as appropriate. While the detail is not up to the standard expected with injection molding it is some of the nicest I have seen on a vacuformed kit. The fabric control surfaces are a bit overdone to my eye but no worse than many injection molded kits. As is the case with many vacuformed kits invariably the plastic gets stretched very thin in some places especially on very detailed parts and such is the case here and on some parts some additional strengthening may be needed. The internal side pieces are a mixed bag, the one has so much detail that most of it ended up being rather soft and lacking detail while the other turned out much better. Still a little soft but probably acceptable once installed inside the fuselage. I suspect I'll will be temped to cut the detail away on one side and replace it with some scratch built parts with sharper edges and more defined details. In the photos below I have outlined the parts with a magic marker not only to make them stand out more but as the first step in preparing the parts.

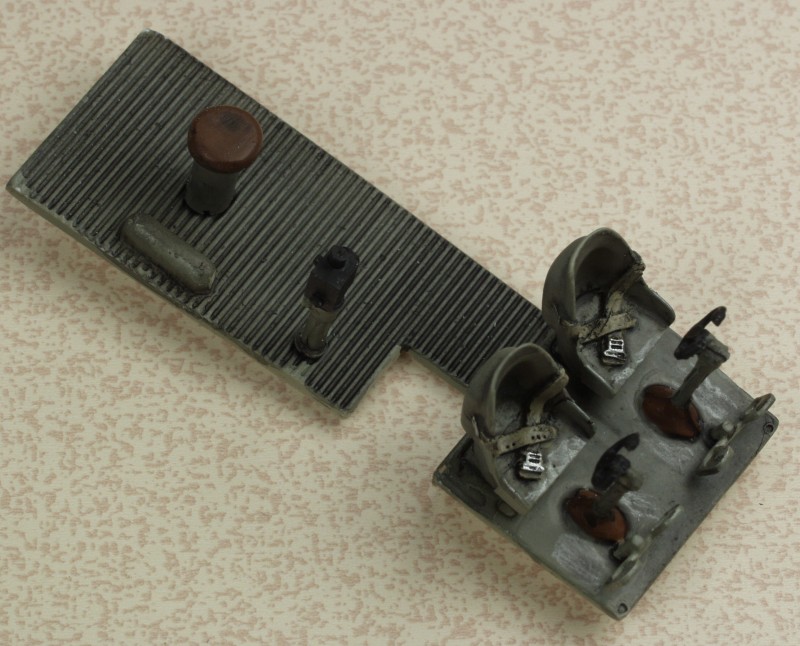

The G3M series aircraft were equipped with flying control surfaces on the wings much like those used on Junkers aircraft like the Ju 52 and Ju 87. These would be tough to do as a vacuform part and in this kit these are supplied as a resin part. The castings were quite good in my kit with few if any casting defects although both are a bit warped. Once removed from their casting blocks a warm water dip should take care of the warps.

The propellers are provided in cast soft metal and look quite nice needing only some light clean up of flash.

The landing gear is also done in metal and again is quite nice. Like many cast metal part some of them may need to be tweaked a bit to get them straightened out.

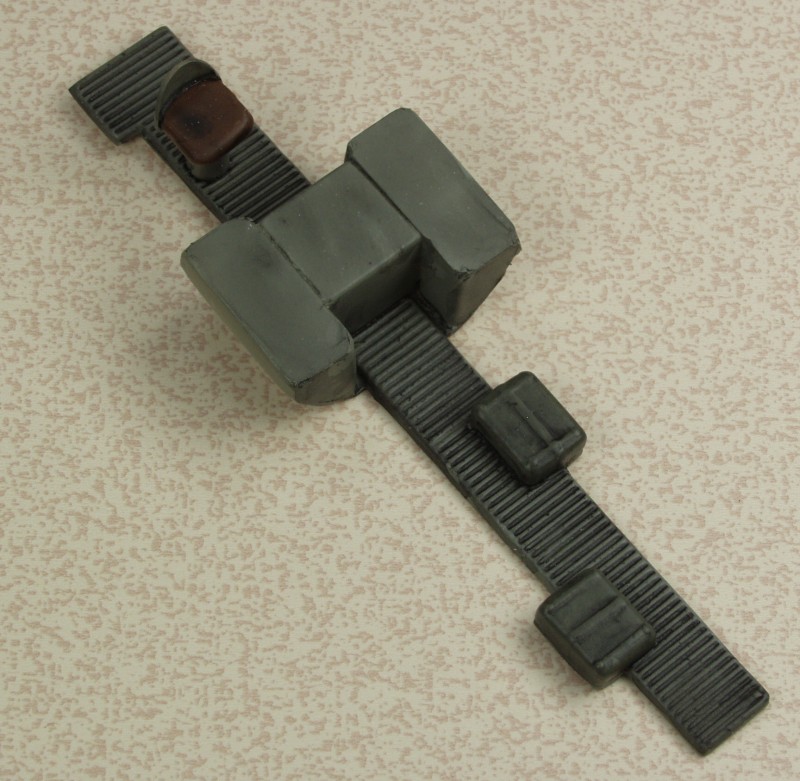

The balance of the metal parts are for the guns, an ammo drum, DF loop, antenna, pitot tube, trim wheel, control wheels, rudder pedals and all those 'V' shaped parts which are intended to be the push rods for the resin engines. Those must have been a pain to cast and look to be even more of a pain to clean up and install. These parts are for the most part nice and shouldn't be that hard to clean up and straighten. The guns would probably look better with some hypodermic tubing for barrels.

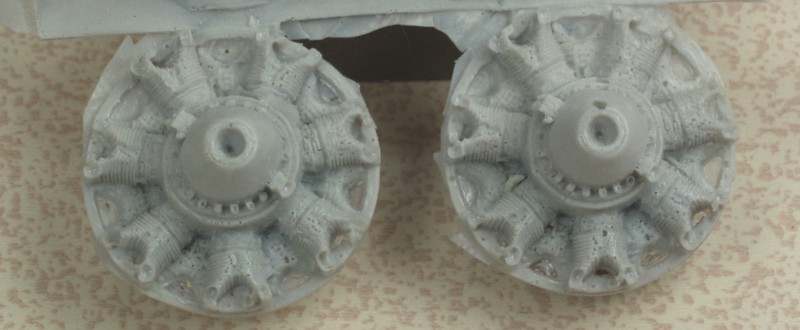

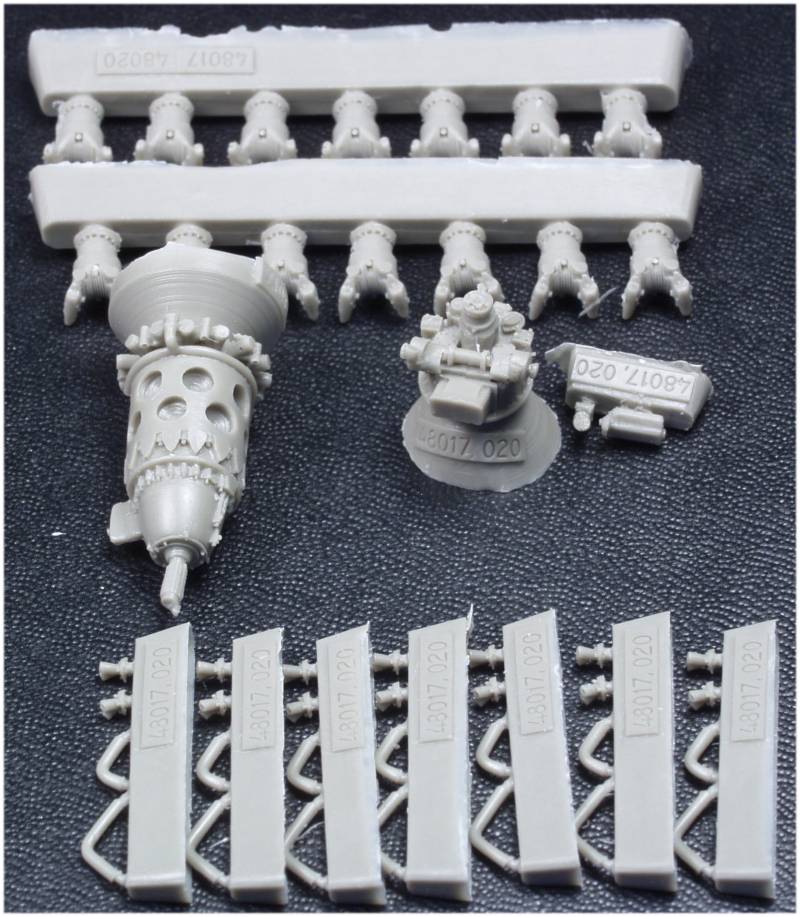

The resin parts shown below are some what of a mixed bag. Molded in three different colors of resin. The engines which at first glance didn't look too bad but mine were marred with a numerous air bubbles on the front side. Once painted and buried in the cowlings they might be passable but I would recommend replacing them with quality resin replacements from Vector. The wheel assemblies are a bit rough and to my eye a bit too flat. The Prop spinners are good. The fins and rudders are nice but do have a few bubbles to fill. The oxygen tanks are nice as are the seats but again the seats will require a bit of bubble filling. The exhaust stubs are nice as are the gear doors and the bulkhead with the instrument panel but they will require a bit of clean up. The wedge shaped parts are the mounting parts for the flying control surfaces and these look like they could be a challenge both to clean up and install. The other two parts are the control columns.

The clear parts are quite clear and since they are molded out of heavier material than is the norm they are a bit more sturdy and easier to work with in my opinion. Although it doesn't show well in my photograph the frame lines are pretty well registered and shouldn't be that hard to mask.

The decals appear thin and are well registered. I have used a few of the decals supplied by Koster before and have not had any issues with them. They appear opaque. Markings are supplied for three aircraft with similar but slightly different paint schemes.

Since the engines were pretty crappy I decided to go with a Vector engine

Don't expect any immediate progress on this as before construction can begin the vacuform parts must be cut out from the base sheet and the thickness of the base sheet sanded from edges of the mating parts. This tends to be a bit tedious and no doubt is what discourages many from doing vacuform kits. It's a good background task that can be done while waiting for paint to dry or decal setting solution to work and that is how I plan on doing it. While not a tutorial as such I may show some progress on this and my way of doing some things. So if you grab an adult beverage to enjoy this you may end up like this before you see much :drunk