OK, still working on this one but the C-123 for the cargo campaign has been stealing me away some.

The Vector engines consumed more time than usual. I only had to grind away about half of the rocker covers to get them to fit the cowlings, I have had to do much worse to others. The push rod tubes guides near the crankcase were a major PITA to clean up and install due to their small size and the made the push rod tube installation a major aggravation as no two end up the same length. I finally ended up drilling a hole through the rocker covers and down and into the guides and inserted them from the top and trimmed them flush. Tedious but easier than trying to measure and cut each one.

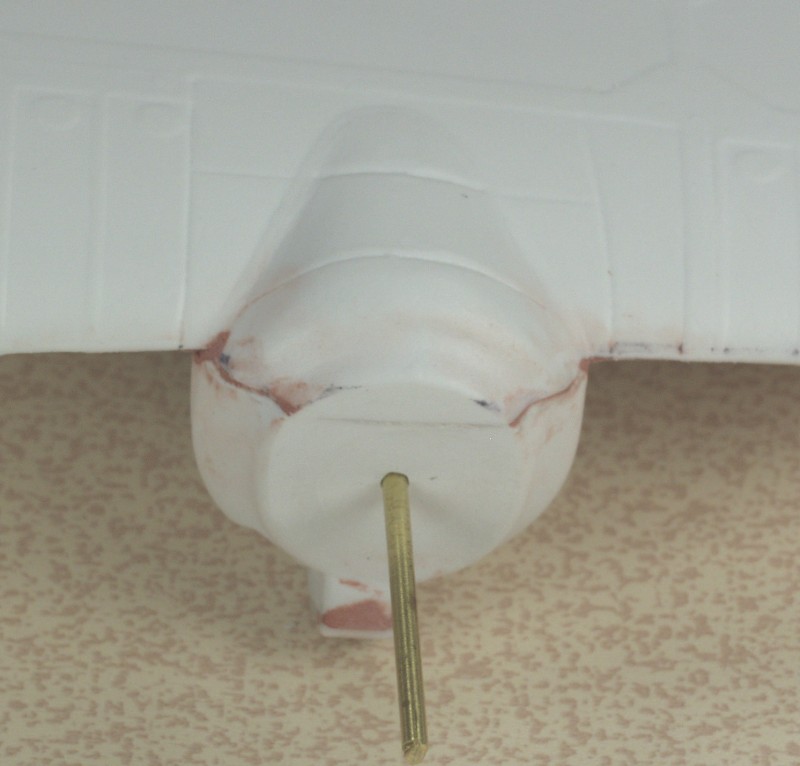

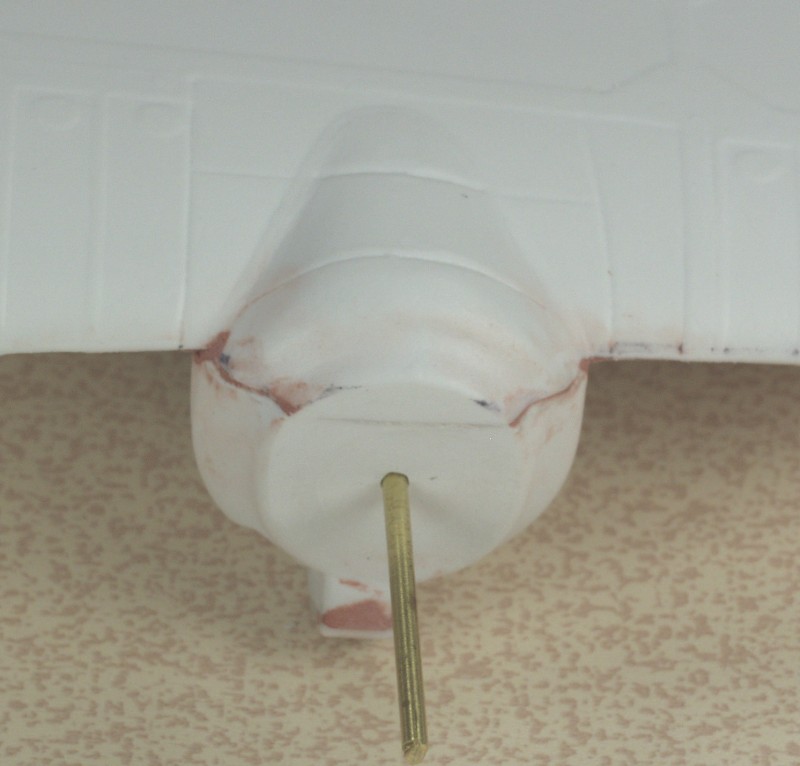

One of the crankshafts had broken off in shipping and both appeared to be too wimpy to support the cast metal props. The props themselves had a rather beefy shaft as part of the casting and drilling a hole that large in the front of the crankcase looked to be a disaster in the making. I end up drilling a 1/16" hole through the engine and cutting off the prop shaft and drilling it out the same size. The area where the engine was to mount had no alignment devises but there was a small dimple in the center of the area so I drilled it out to 1/16" as well. That way my new prop shaft, some 1/16" brass rod, would pass through the engine and into the mounting area correctly positioning the engine. I have secured the brass rod into the cowling but the engines and cowls will be left off till after painting as they will be black it will save masking them.

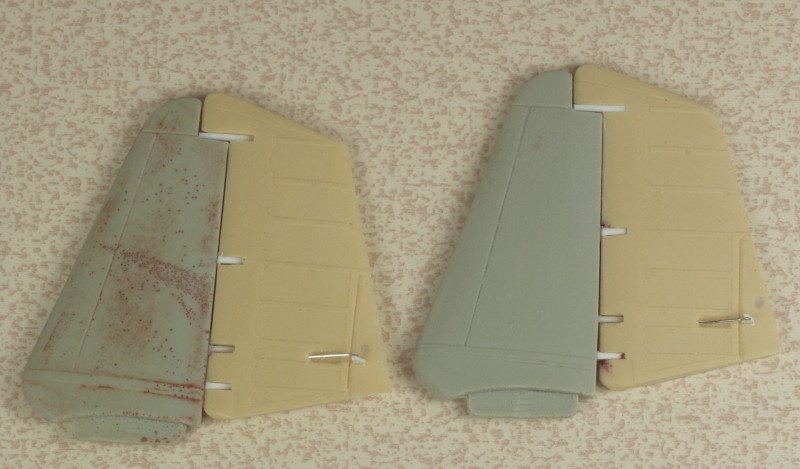

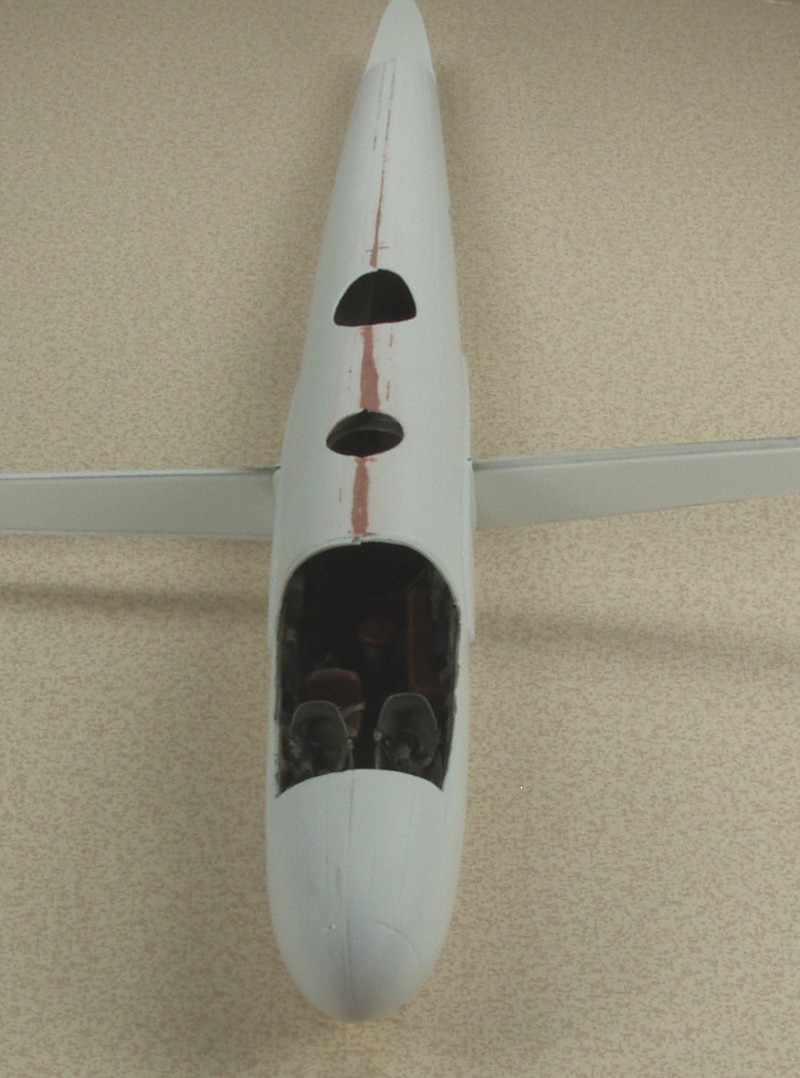

The engines...

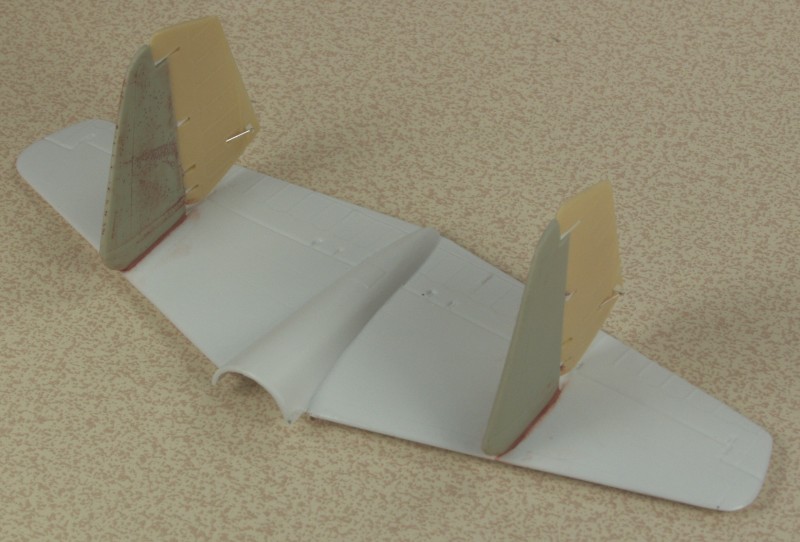

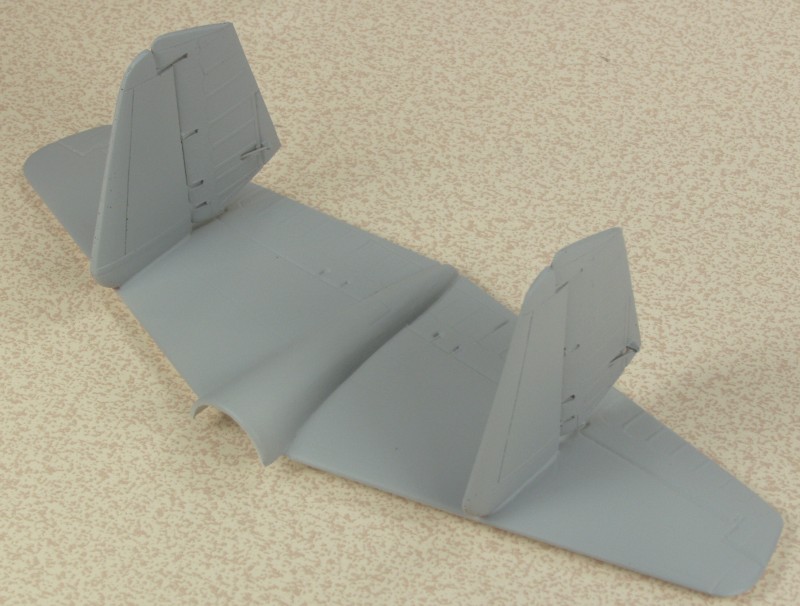

The opening in the cowls were cut out and the insides painted black...

And the prop shaft/engine mount...

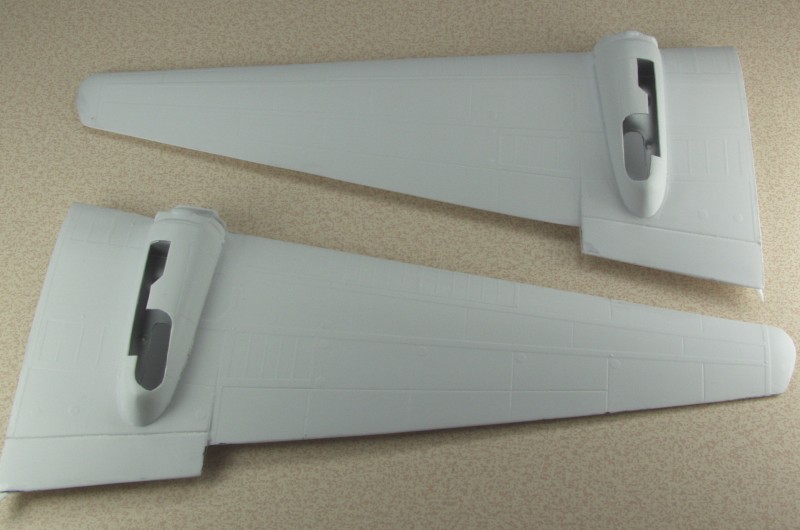

One of the issues sometimes encountered with vacuform kits are areas where the plastic when it is formed over the mold gets stretched to paper thinness. On this kit this occurred on the cowling part that is under the wing. There is a scoop there for the engine oil cooler and the area was so thin that it crumpled when you tried to do anything with it. To deal with this I used some Magic Sculpt, similar to Milliput, and filled in the area behind it forcing the area to take the shape intended. When it had hardened I was able to sand and shape the area as needed but it left me with just a flat area where the opening as supposed to be and no easy way to make one without carving away at the Magic Sculpt. While looking through my supply of styrene I found I had some very small 1/4 round stock. I used this to form an frame around where the opening should be and then used putty to fair this in. Once that was done I cut a couple pieces of 100 x 100 brass screen to simulate the oil cooler. Not sure how close this is to the prototype as the photos I have this area is in the shadows and difficult to see but it works for me...

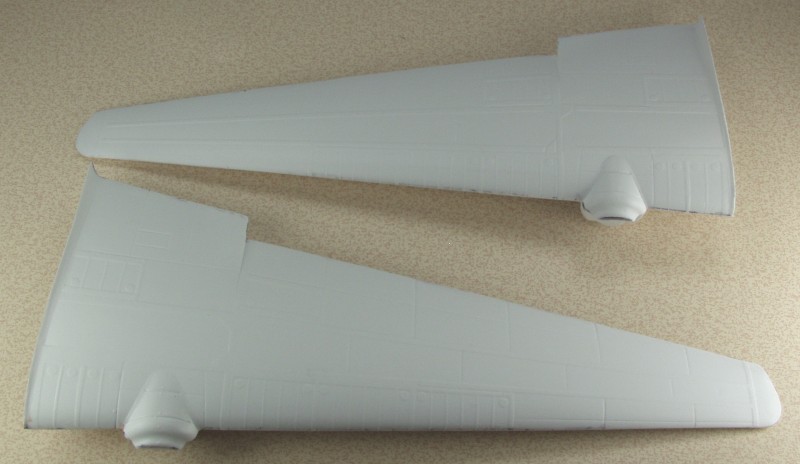

Still need to get all the clear parts to fit and masked and then the wings can go on but I need to finish the 123 first. Thanks for looking !

Nice work!! Gary S.

Nice work!! Gary S.