Greg Kimsey

Well-known member

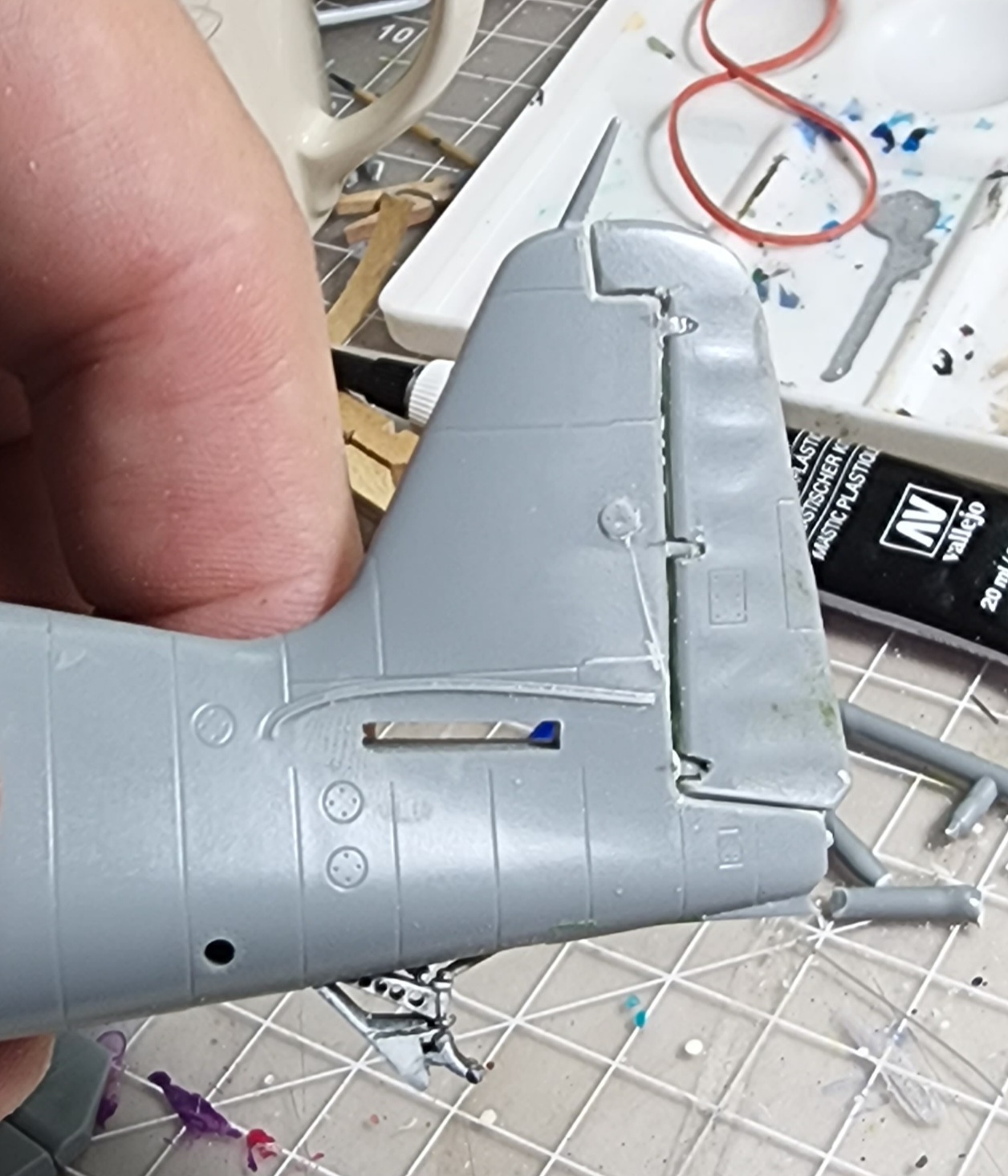

So, I have the butchery on the rudder and rear flaps puttied and sanded. I made little pins for the hinges

I drilled holes in the tail wings and fin then glued the pins in place. After a little fine tuning with a sanding stick, the flaps are ready to be glued on.

You can see where the knife slipped and gouged the plastic. It is puttied and sanded. I will know more after the black primer.

I drilled holes in the tail wings and fin then glued the pins in place. After a little fine tuning with a sanding stick, the flaps are ready to be glued on.

You can see where the knife slipped and gouged the plastic. It is puttied and sanded. I will know more after the black primer.