Rhino

Super Moderator

If you liked the USCG aircraft decals,

You'll REALLY like this! There are different 1/350 decals for Early and late, modern Reliance WMEC's. At one point I considered releasing the Early Cutter, with an upgrade kit for the modern ship. (Big bridge, smokestack & parts, Mk.2 and Mk.4 OTH boats and cranes, Mk. 38 Chain gun and round gun platform, and a forest of SATCOM domes) I hesitate to further complicate an already complex kit. Yeah. Me.

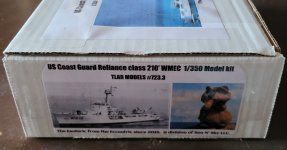

The size of the decal sheet determined the size of the package, so they lay flat in the box. U-Line S-159 boxes should fit the decals nicely.

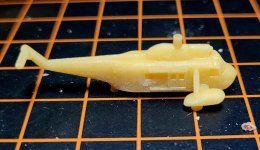

Oh! And that other stuff that comes with the model too!

"Hey, that's cool! I can actually read them!" Teresa, my biggest cheerleader!

You'll REALLY like this! There are different 1/350 decals for Early and late, modern Reliance WMEC's. At one point I considered releasing the Early Cutter, with an upgrade kit for the modern ship. (Big bridge, smokestack & parts, Mk.2 and Mk.4 OTH boats and cranes, Mk. 38 Chain gun and round gun platform, and a forest of SATCOM domes) I hesitate to further complicate an already complex kit. Yeah. Me.

The size of the decal sheet determined the size of the package, so they lay flat in the box. U-Line S-159 boxes should fit the decals nicely.

Oh! And that other stuff that comes with the model too!

"Hey, that's cool! I can actually read them!" Teresa, my biggest cheerleader!