Rhino

Super Moderator

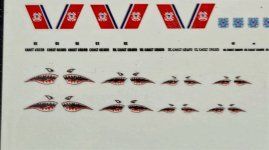

I bought 3D printed 1/350 HH-52A Seaguard "Flying Lifeboat" helicopters for early WMEC builders. I like this ol' rescue egg-beater.

USCGC Active will have an HH-65C Dolphin.

Both early and late superstructures must be built for writing instructions. I used an old model airplane trick on the smokestack gap. I soaked styrene in Tamiya thin glue and schmooshed the plastic into the gap. A little wet-sanding and you're golden!

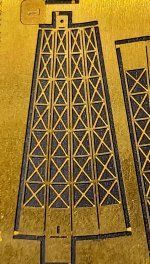

The mast is done except for a few small (?!) radar antennas. Well, and no paint yet. This assembly installs last.

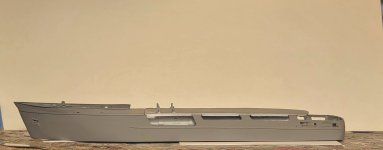

For those of you that like a nicely shaped bottom, Here ya go!

A great stopping place for one day. Boat cradles, ventilators, and upgraded superstructure filled, sanded and ready for primer.

Thanks for looking in and for your prayers for our own "little Tough Guy".