-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

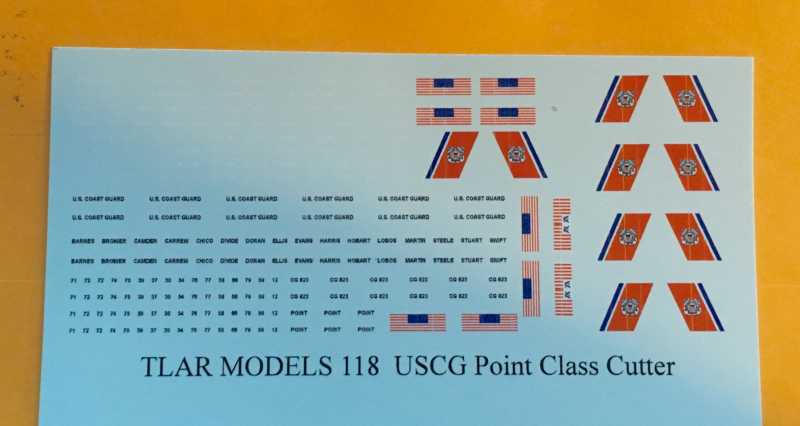

1/350 USCG Full Hull Vietnam Point Class Cutter

- Thread starter Rhino

- Start date

Cookin'

Duke Maddog

Well-known member

That last line says it all: "Lots of imagination, music, and laughter!" That's what makes watching this Thread so fantastic!

Very sharp!

Rhino

Super Moderator

Lower hull plate for the waterline version of the Big Cutter in progress!

I made an impromptu mold with leftover RTV and got a really lousy casting. LOTS of shaping & sanding to do yet.

A better businessman would have just cut the bottom off a full-hull model. :idonno :stinker

Duke Maddog

Well-known member

Wow, those kind of days overflowing with modeling mojo are the best ever! Brilliant work overall! Way to go man.

Rhino

Super Moderator

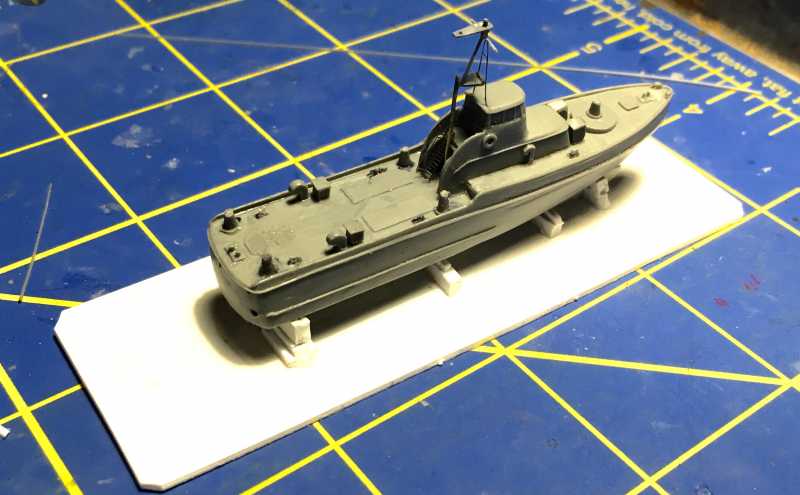

Construction underway! :frantic

Using a #80 drill, the closed chocks up forward are open, the smaller bollard plates get 2 holes each, for dinky bits of stretched sprue. I highlighted the bollard plates with black, so's I kin see to drill them lil' deevils better! Weps pedestals are going on. If you mount a 20mm, leave the arms on the pedestals. This WPB will sport the Mk.29 mount forward, and .50's on the after deck.

Thanks for looking in!

:salute

Heavens Eagle

Well-known member

That looks really good Chris! The detail is quite sharp and clean! Excellent!

That looks sharp!

Rhino

Super Moderator

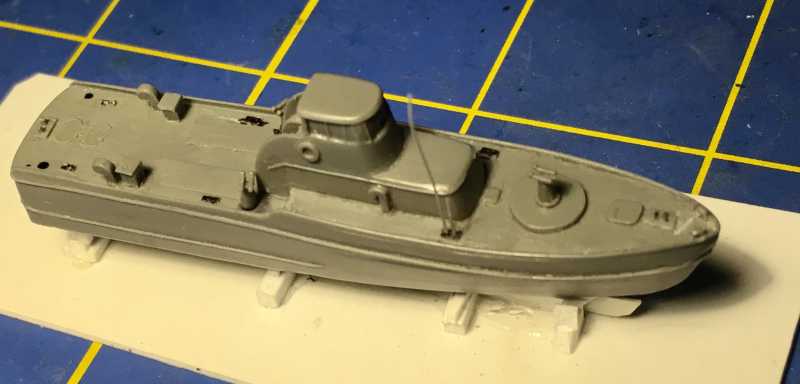

This is the short version of an inexorable story.

Another soggy day on the Island of Peegi-Peegi. Rain means MODELING! :yipee

Ready ammo lockers in place. There is a hatch on the front of each one, so care must be taken not to install them backwards. Starboard side box is a good example of how far NOT to sand them, since they cast from the top down.

.50 pedestals installed. One more bollard left to pin. Cabin hatch, crane post and bridge ladder installed!

The "Start" and "Finish" of said main deck house hatch. This I did NOT sand this too far. It required a bit of fitting to get it in place. The block on the front of each is the cast-on "handle" so a Guy can grip it with tweezers to sand/grind/cuss the hatch to the proper thickness. Just clip it off & c/a glue it to the Cutter!

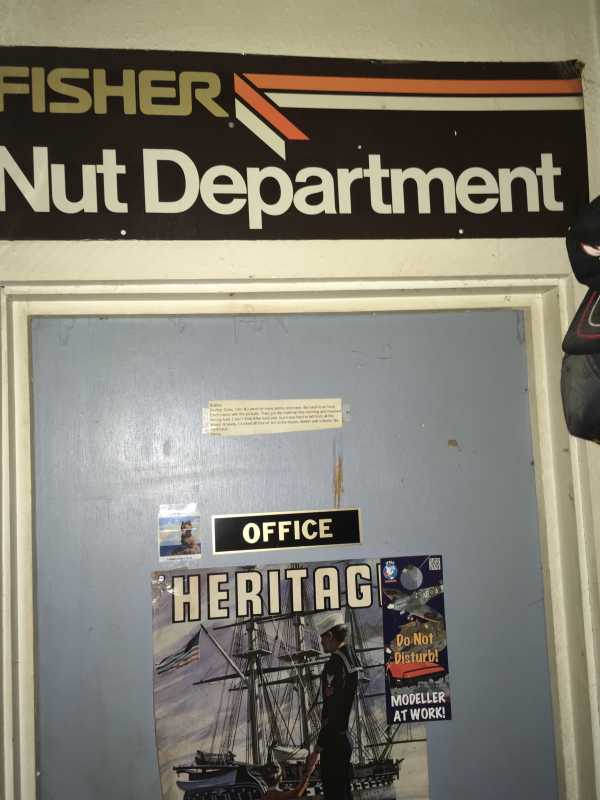

It T'were a Fine day in the Nut Department here on My Island!

Thank you Men, for your kind words and attention!

:salute

ldguy

ldguy

:captain

Another soggy day on the Island of Peegi-Peegi. Rain means MODELING! :yipee

Ready ammo lockers in place. There is a hatch on the front of each one, so care must be taken not to install them backwards. Starboard side box is a good example of how far NOT to sand them, since they cast from the top down.

.50 pedestals installed. One more bollard left to pin. Cabin hatch, crane post and bridge ladder installed!

The "Start" and "Finish" of said main deck house hatch. This I did NOT sand this too far. It required a bit of fitting to get it in place. The block on the front of each is the cast-on "handle" so a Guy can grip it with tweezers to sand/grind/cuss the hatch to the proper thickness. Just clip it off & c/a glue it to the Cutter!

It T'were a Fine day in the Nut Department here on My Island!

Thank you Men, for your kind words and attention!

:salute

:captain

:captain

The barrel will be a tad thin don't you think?

Similar threads

- Replies

- 70

- Views

- 7K

- Replies

- 133

- Views

- 13K

- Replies

- 34

- Views

- 5K

- Replies

- 276

- Views

- 35K