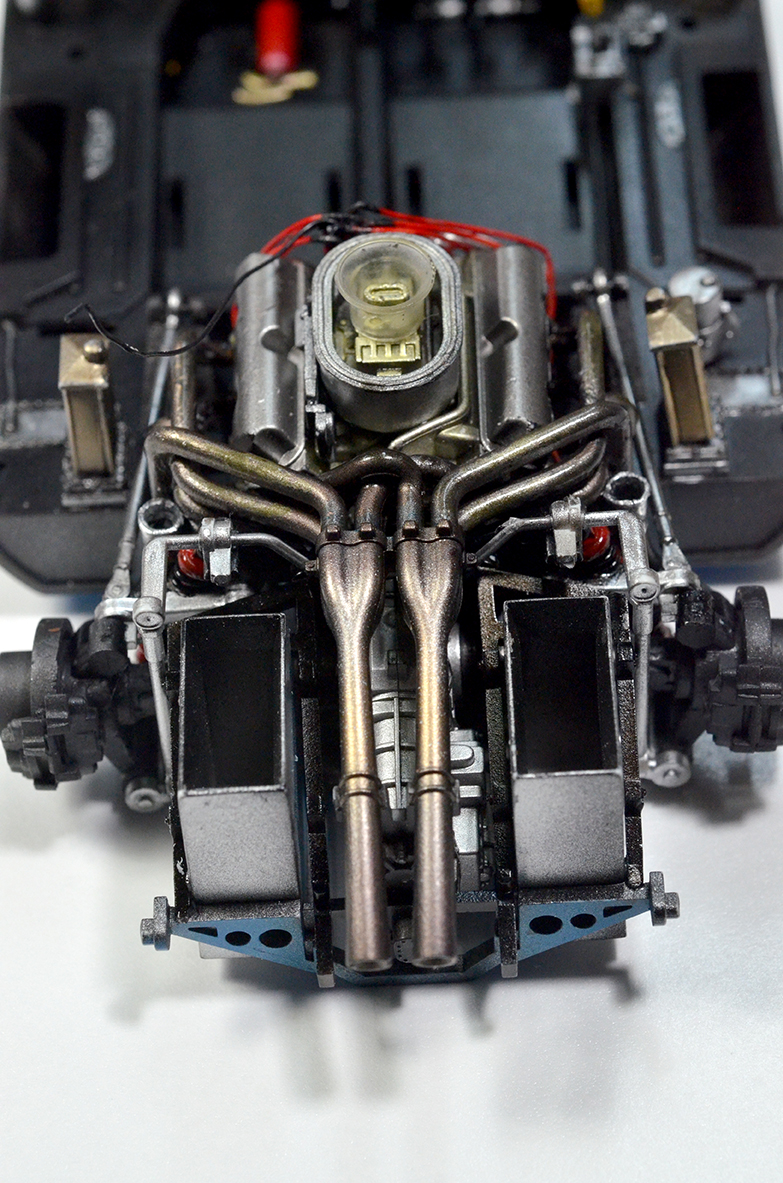

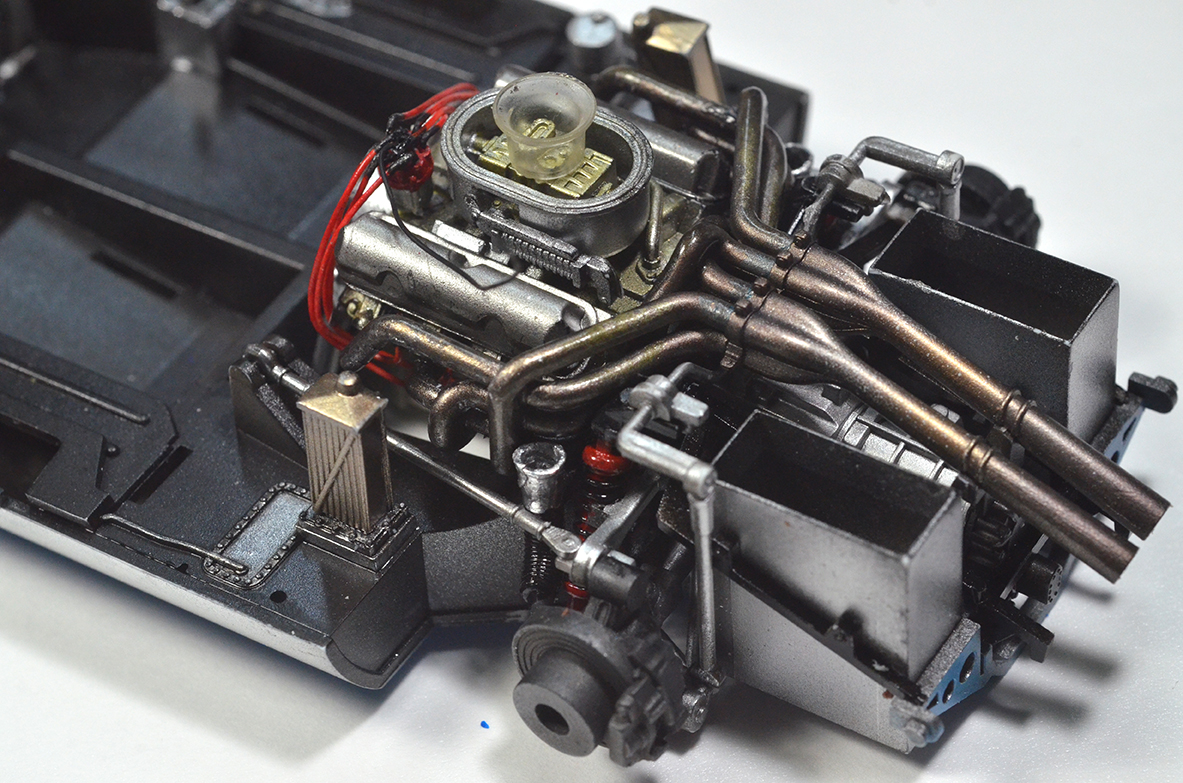

It has been a minute since I posted about this build. I have been busy building! But I have been taking photos as I go. Let's see...where was I? The engine had been wired. I had to decide how to proceed. Should I put the exhaust on the top part of the engine, then put everything on, or put the top part of the motor on in case of any fiddling needed to fit, then glue on the exhaust. I went with the latter. Turns out, unnecessarily. Put the exhaust on first,, then put the top of the motor in place. I put the exhaust pieces together and painted them. I used various colors of metallic paints, adding blues and purples to show different degrees of heat. It turned out OK. It looks better in person than it does in this photo, that's for sure. This is a very tight fitting configuration with little or no wiggle room at all.

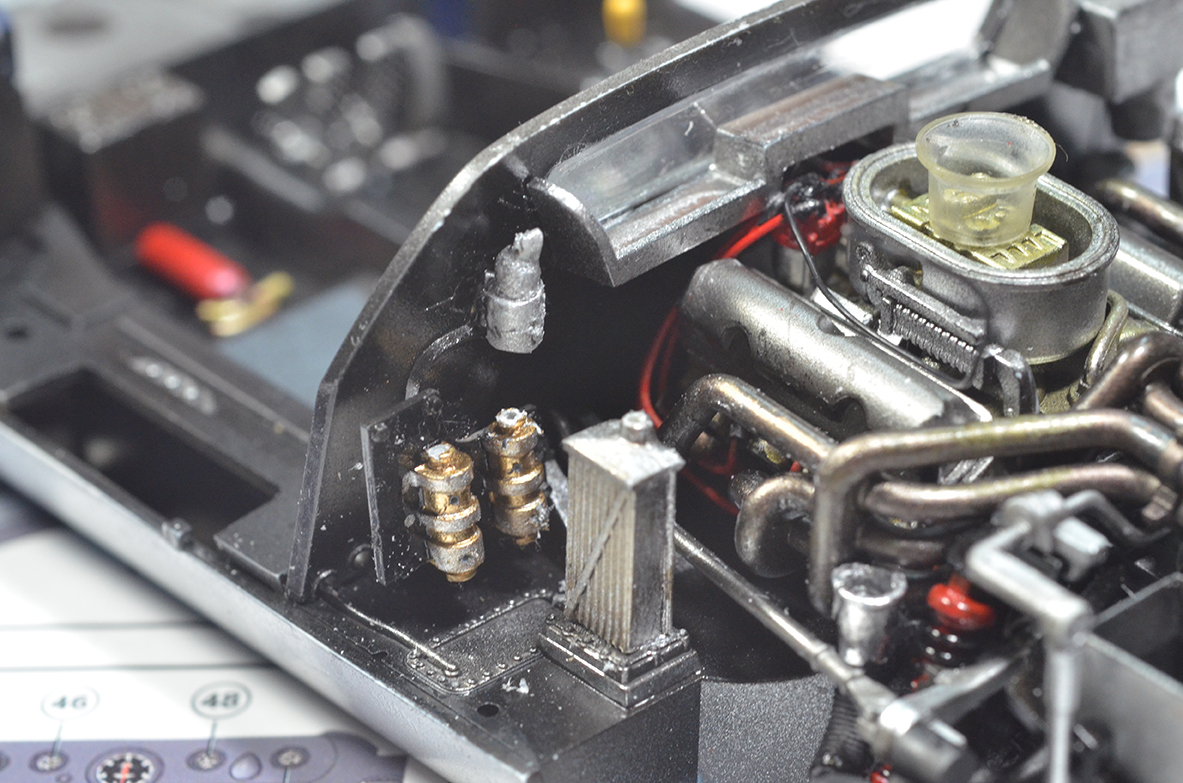

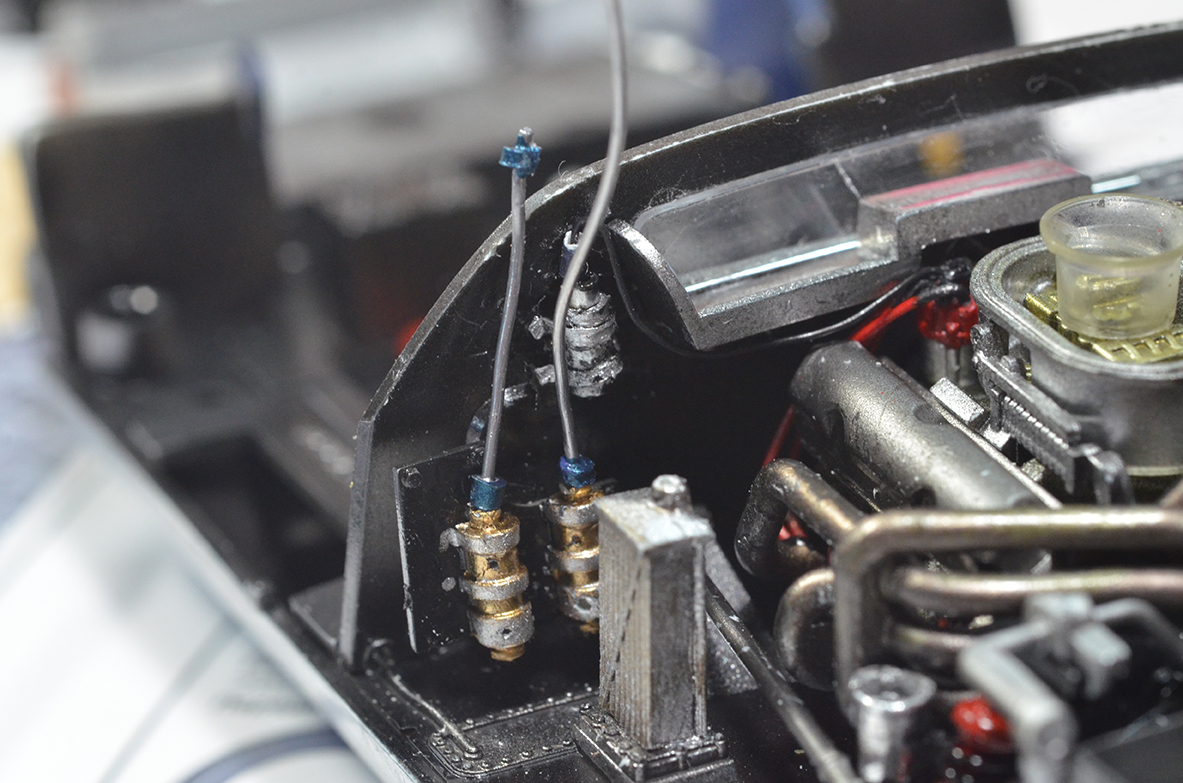

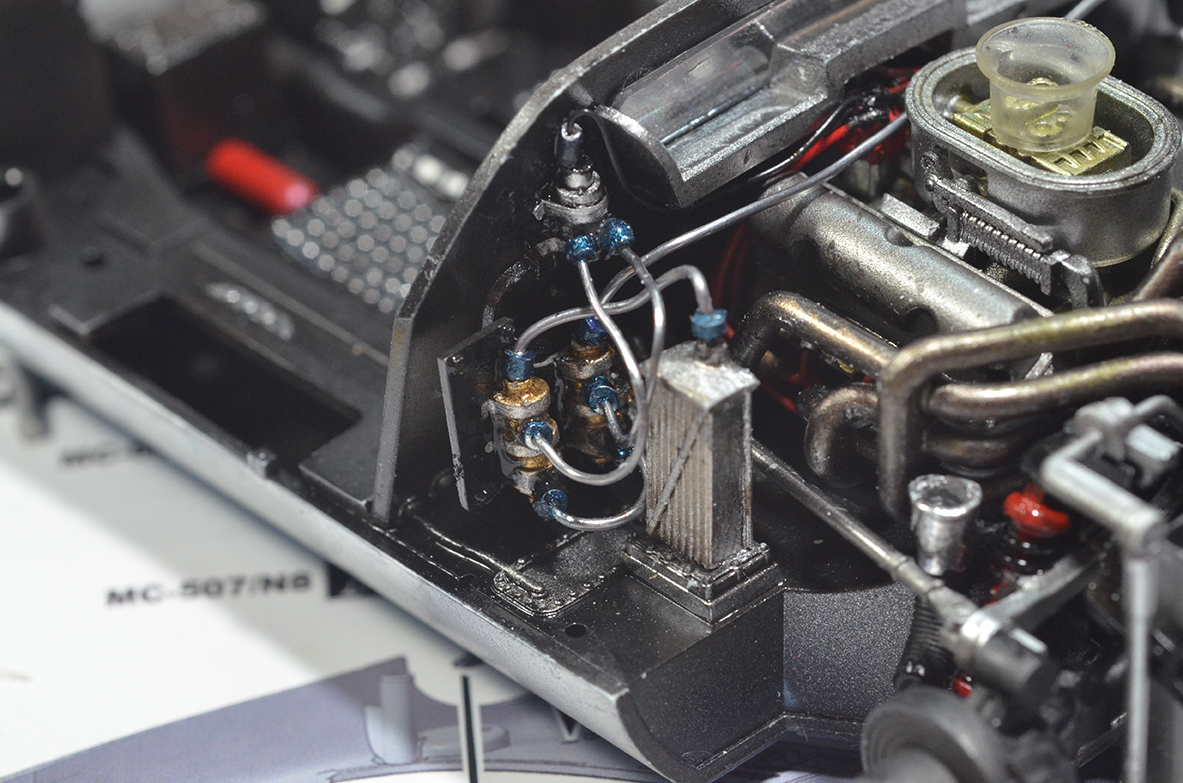

I researched the coil as much as I could and really never could find the exact information I was looking for. It seems that the ignition wire goes to a coil relay, and there are two coil packs, with each of those going to those vertical tower things on each side of the motor. I have no idea what they are. I found some decent photo of wire/tubing/pipe routing. Honestly, the best photos I found were from a custom built 1:10 model in the Ford museum. I thought they were photos of a real car until I read about it. Almost defied belief. So, I used those as reference for the coil routing. I used lead wire, since I don't have the braided hose with blue fittings. It will be fine I think. The coil relay is not included in the kit. I made something to resemble it. You can see in the second photo that I scratched the first one and built another. I drilled all of the holes and made the "fittings" from brass tubing painted Vallejo Gunmetal blue. As hard as I try, I cannot build clean. It seems there is crap in the paint, or glue drips, or something causing it to look sloppy. When I try to fix it, it just gets worse!

Ok, so as you can see, the firewall is in, so I turned to the seats. There are supposed to be silver rings with a black center for the buttons. I tried every technique I could think of to set silver into the indentions, but the results were severely inconsistent with one good one for every five bad; so I ditched that effort to just make silver dots, and that turned out pretty clean. The seatbelt material provided was nice, but the long, precut belts are too short. Fortunately, the remaining belt material is enough to make longer belts, so know that going in.

I installed the seats

Next I went to work on the dashboard. It wasn't terribly difficult, and I found some decent reference for it.

The original car looked like it had red Dymo tape with raised lettering telling what each button was. I didn't have any red decal stripes so I did my best to hand paint little red "labels" under each switch. With the dash installed, the whole thing reminds me of the Tumbler from Batman Begins.

It's time to start work on the body. Here is where I get a little scared I won't be up for the task. I wanted to finish the inside of the body first, which involved closing up a bunch of ejector pin divots, and I am getting rid of the Meng logo just in case:

The back hood needs to be matte back inside, so that will be easy.

The outside of the hood has a piece of glass installed and some scoops. The J will get painted separate then installed later.

Primed and sanded, and reprimed, and ready for my close up.

It turns out the color is WAY too dark. I though it would be close enough to use. I have to lighten that up considerably!!

That's it. I will make a new batch of blue that is hopefully closer to the correct color tomorrow after this dries overnight.