-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Latest Acquisitions Revisited!

- Thread starter tomwes

- Start date

Duke Maddog

Well-known member

Latest Acquisitions

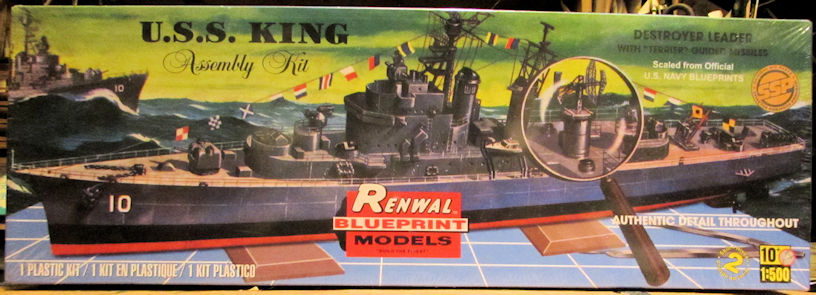

It was one of the raffle prizes at my IPMS meeting. I also got the old Renwal USS Springfield from an IPMS club raffle as well.

Nice old destroyer kit. Where did you find that?

EJ

It was one of the raffle prizes at my IPMS meeting. I also got the old Renwal USS Springfield from an IPMS club raffle as well.

Latest Acquisitions

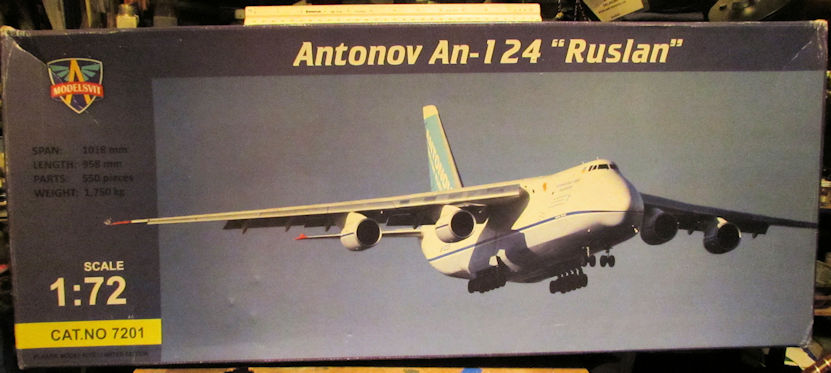

I saw one of those AN 124 up at GSP many years ago, came around the corner, it was parked at the UPS ramp and it dwarfed anything I ever saw.

Nice haul!

I saw one of those AN 124 up at GSP many years ago, came around the corner, it was parked at the UPS ramp and it dwarfed anything I ever saw.

Nice haul!

Latest Acquisitions

Wow, that Antonov is quite the kit Mark!!

Happy Birthday Terry! Excellent choice!

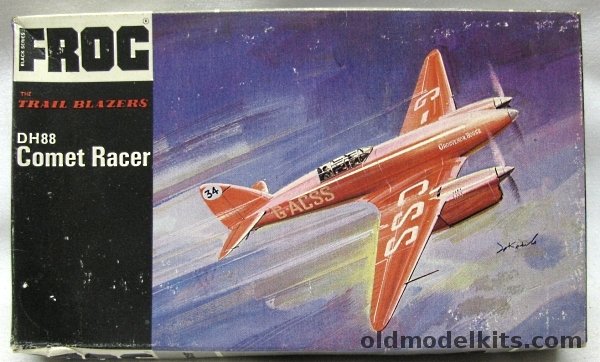

A couple days ago we had our IPMS chapter meeting. I got this in the raffle:

Now since I also have the Renwal USS Springfield, I can build both of these.

Before that however, a friend sold this to me; using up the last of my Christmas money:

That is a white one-foot-long ruler on the top of that box. yes, it is that big. The fuselage seen below is made from fiberglass, as is the wings and tail surfaces. All other parts are injection plastic. The ruler is still there to show size:

Later I also decided to test-fit the wings to see how big this monstrosity is. The tail feathers didn't fit, but I was able to at least balance the vertical stabilizer:

Yeah, that puppy will have to be all done at Hobby Day....

That's it for now. I have four Brookhurst gift cards; prizes from my AMPS meetings so I may have some more to show after the Spruefest show. Stay tuned.

Wow, that Antonov is quite the kit Mark!!

Duke Maddog

Well-known member

Latest Acquisitions

Thanks Bob! I would love to see one of these AN-124's in person someday. You are one lucky guy!

Sharkman thanks! It is quite the kit and assembly looks pretty fast and straightforward. I will have some issue sanding the seam on the dorsal spine, but I'll be careful. I do need to find a way to cut fiberglass so I can do the cockpit area well.

Thanks Bob! I would love to see one of these AN-124's in person someday. You are one lucky guy!

Sharkman thanks! It is quite the kit and assembly looks pretty fast and straightforward. I will have some issue sanding the seam on the dorsal spine, but I'll be careful. I do need to find a way to cut fiberglass so I can do the cockpit area well.

Heavens Eagle

Well-known member

Latest Acquisitions

Cutting fiberglass, use carbide cutters, and diamond files for the edges. I suspect that the surface of the fuse is a resin coating so you can have the surface detail. HPH does this with their giant size kits. Give me a shout and I can visit with you about it a little. I used to make prototype PC boards by hand so have a bit of experience with fiberglass.

Cutting fiberglass, use carbide cutters, and diamond files for the edges. I suspect that the surface of the fuse is a resin coating so you can have the surface detail. HPH does this with their giant size kits. Give me a shout and I can visit with you about it a little. I used to make prototype PC boards by hand so have a bit of experience with fiberglass.

Tankbuilder

Active member

Latest Acquisitions

And please be sure to wear a QUALITY respirator when cutting or sanding fiberglass.

Cheers

Cutting fiberglass, use carbide cutters, and diamond files for the edges. I suspect that the surface of the fuse is a resin coating so you can have the surface detail. HPH does this with their giant size kits. Give me a shout and I can visit with you about it a little. I used to make prototype PC boards by hand so have a bit of experience with fiberglass.

And please be sure to wear a QUALITY respirator when cutting or sanding fiberglass.

Cheers

Duke Maddog

Well-known member

Latest Acquisitions

Thanks Paul. I appreciate that. When I get ready to start this, I'll let you know so we can chat. Yes, it has a resin coating on it; very smooth, but the seam still has a slight step in it that needs to be reduced.

TB, I will. I have just the thing that I use for my house painting, air-less paint sprayer. In addition to that, I have two fans: one in the window blowing outside; and the other behind me at an angle to blow the debris to the fan in the window.

Now to find some carbide cutters; I think I need a saw of some type too since there are a couple curves I need to cut. Or I can cut them straight and sand in the curves.....

Thanks Paul. I appreciate that. When I get ready to start this, I'll let you know so we can chat. Yes, it has a resin coating on it; very smooth, but the seam still has a slight step in it that needs to be reduced.

TB, I will. I have just the thing that I use for my house painting, air-less paint sprayer. In addition to that, I have two fans: one in the window blowing outside; and the other behind me at an angle to blow the debris to the fan in the window.

Now to find some carbide cutters; I think I need a saw of some type too since there are a couple curves I need to cut. Or I can cut them straight and sand in the curves.....

jknaus

Administrator

Latest Acquisitions

James

Something else that could help is pushing a plastic bag into the fuselage and then putting some expanding foam in. Dont over fill, just enough to add strength while you are cutting. That way the fuse wont flex on you. Then when done pull the bag out. Of course if its a really rigid kit you probably wont need that. Again just not too much foam so you dont distort the fuse. And a mentioned a good respirator. Fiberglass can be very nasty if it gets in your lungs or eyes etc.Thanks Paul. I appreciate that. When I get ready to start this, I'll let you know so we can chat. Yes, it has a resin coating on it; very smooth, but the seam still has a slight step in it that needs to be reduced.

TB, I will. I have just the thing that I use for my house painting, air-less paint sprayer. In addition to that, I have two fans: one in the window blowing outside; and the other behind me at an angle to blow the debris to the fan in the window.

Now to find some carbide cutters; I think I need a saw of some type too since there are a couple curves I need to cut. Or I can cut them straight and sand in the curves.....

James

Duke Maddog

Well-known member

Latest Acquisitions

Thanks Paul for the excellent suggestion. I will consider that, but as you said; the fuselage is pretty firm. Still, I believe in utilizing all possible resources to avoid any pitfalls.

Thanks Paul for the excellent suggestion. I will consider that, but as you said; the fuselage is pretty firm. Still, I believe in utilizing all possible resources to avoid any pitfalls.

Heavens Eagle

Well-known member

Latest Acquisitions

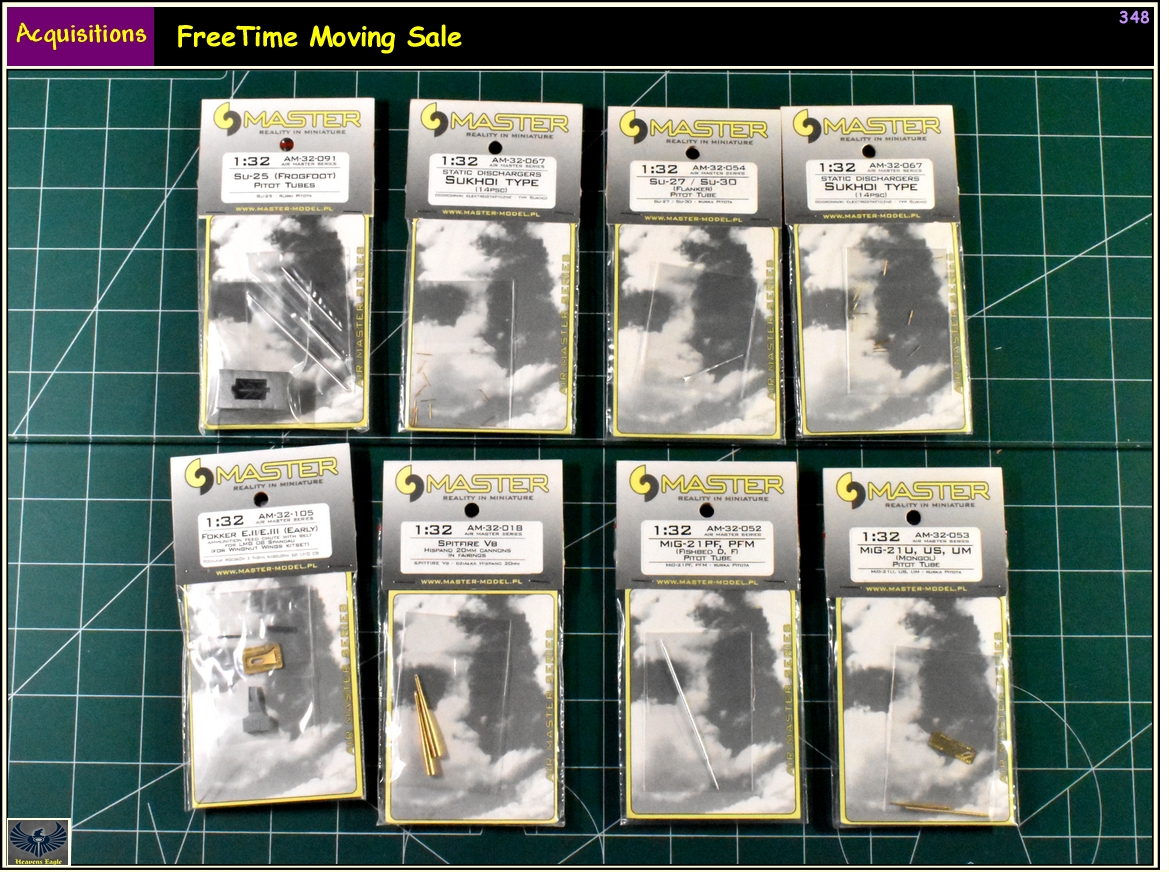

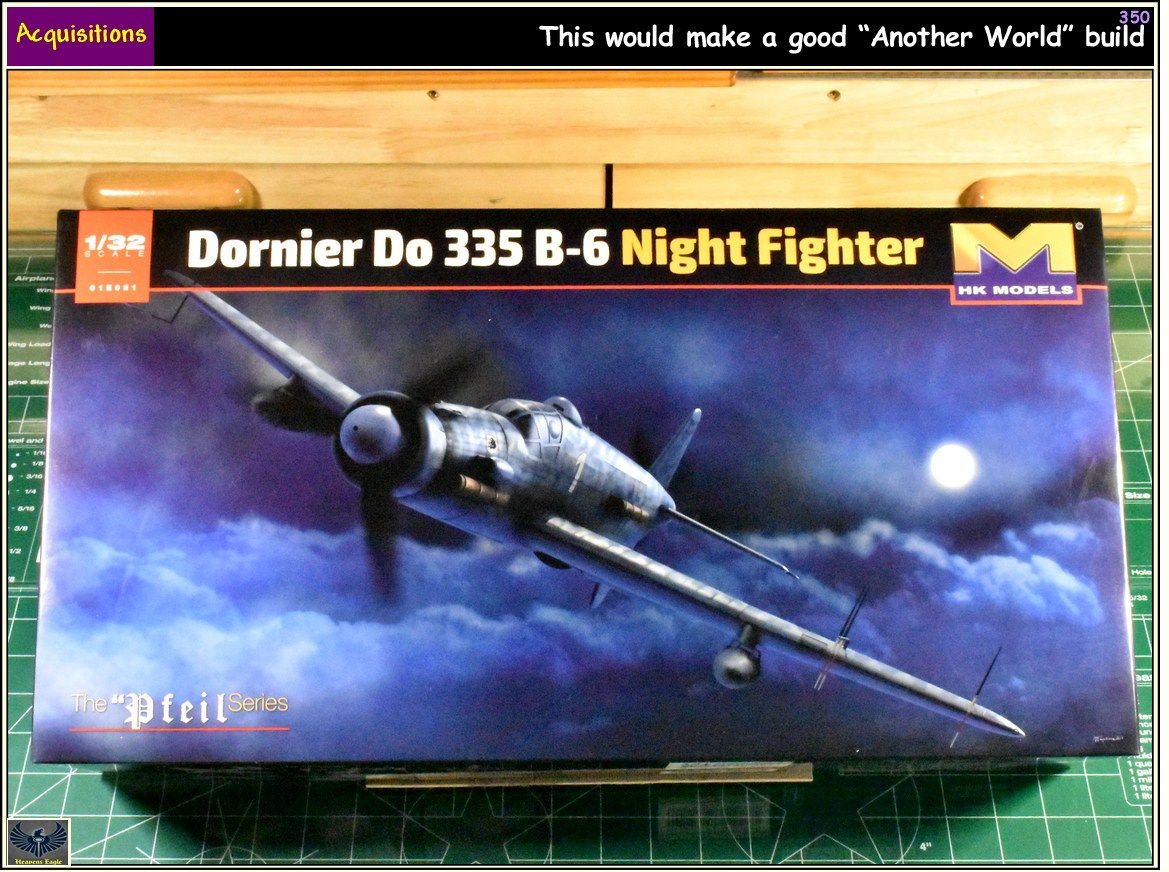

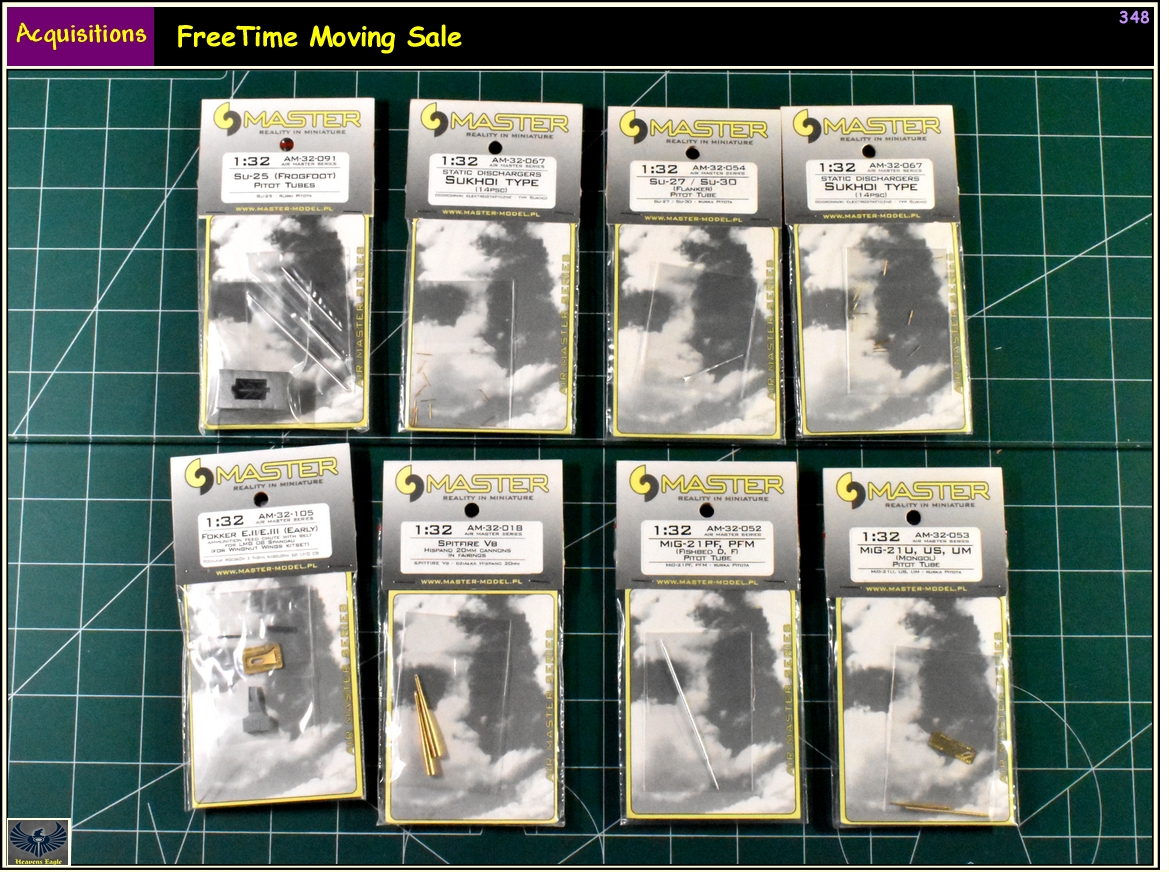

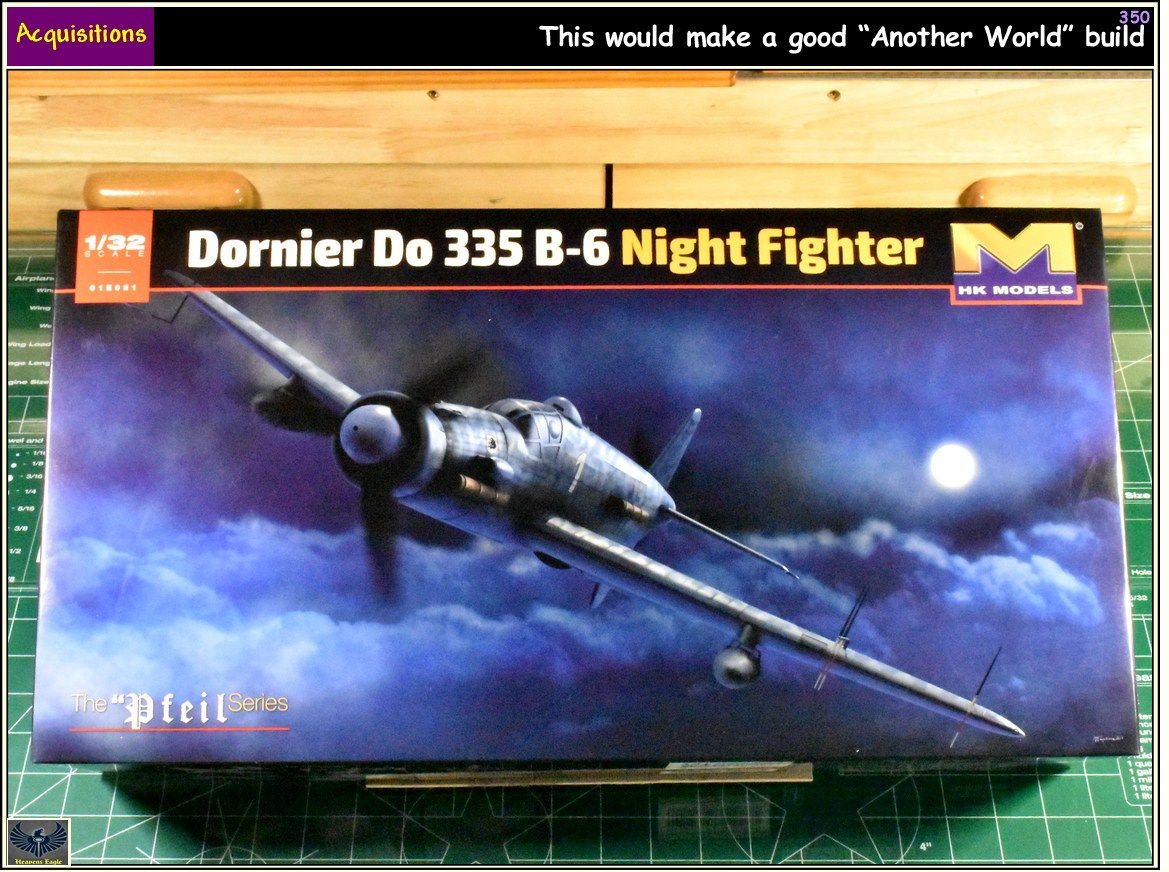

I got a few items in this week as Birthday presents to me. Free Time is on their final moving sale day(s) and in looking through the stuff I ran across the D0335 Night Fighter for an excellent price. The other items were about 1/2 off (or more) so I added them to the order. (Made another smaller order tonight of some other goodies)

I got a few items in this week as Birthday presents to me. Free Time is on their final moving sale day(s) and in looking through the stuff I ran across the D0335 Night Fighter for an excellent price. The other items were about 1/2 off (or more) so I added them to the order. (Made another smaller order tonight of some other goodies)

Latest Acquisitions

Sweet!

Sweet!

jknaus

Administrator

Latest Acquisitions

got some more kits and stuff in today but no pics. I just wanted to put a heads up out there for anyone thinking of buying the new Dragon combo kit with the Stug III Ausf B and the Sd.Kfz. 252. They are both nice kits but I was really disappointed to find that all they have done is stuck 2 kits in the 1 box. I wrongly assumed they would put some new decals in so you can post they both together. Instead each kit has different markings from different Regiments or Zugs within a Regiment. So now to look for some decals. Star makes some nice ones so will research the units and decide.

James

got some more kits and stuff in today but no pics. I just wanted to put a heads up out there for anyone thinking of buying the new Dragon combo kit with the Stug III Ausf B and the Sd.Kfz. 252. They are both nice kits but I was really disappointed to find that all they have done is stuck 2 kits in the 1 box. I wrongly assumed they would put some new decals in so you can post they both together. Instead each kit has different markings from different Regiments or Zugs within a Regiment. So now to look for some decals. Star makes some nice ones so will research the units and decide.

James

Duke Maddog

Well-known member

Latest Acquisitions

Happy belated Birthday Ian! Nice haul!

Happy belated Birthday Ian! Nice haul!

Duke Maddog

Well-known member

Latest Acquisitions

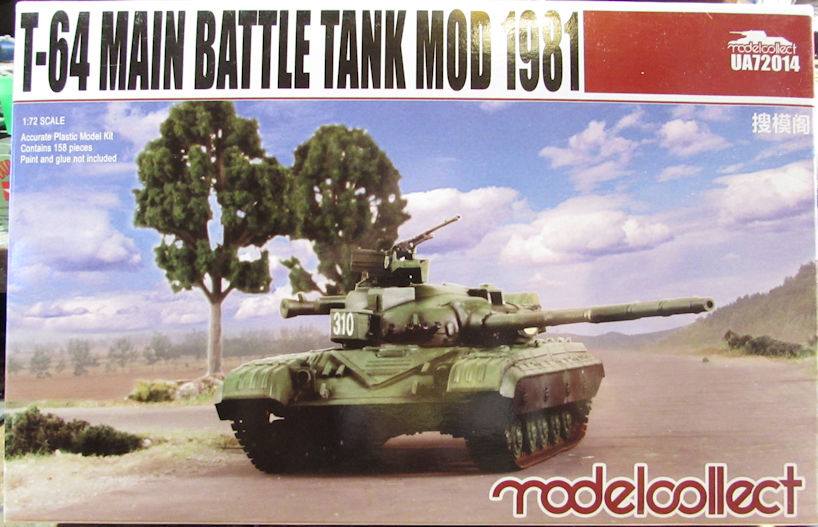

At Spruefest last weekend, I was able to pick these up from Brookhurst during their show sale:

I also got a bunch of glue, paint, filler and Solvaset but didn't shoot pics of it.

At Spruefest last weekend, I was able to pick these up from Brookhurst during their show sale:

I also got a bunch of glue, paint, filler and Solvaset but didn't shoot pics of it.

Duke Maddog

Well-known member

Latest Acquisitions

Thanks Luiz!

Thanks Luiz!

Heavens Eagle

Well-known member

Latest Acquisitions

Nice kits Mark!

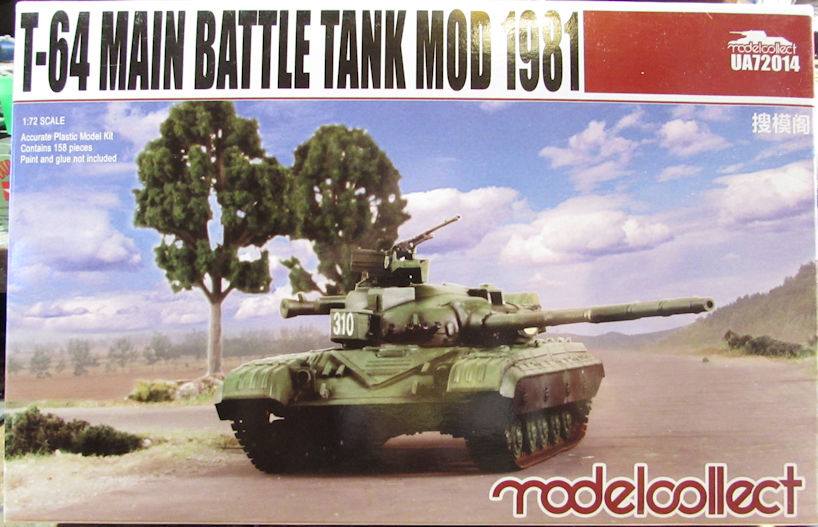

I just received the rest of my birthday order.

Nice kits Mark!

I just received the rest of my birthday order.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 62

- Views

- 14K