-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

E-Type jag, Scale = big.

- Thread starter paddy

- Start date

paddy

Well-known member

Thanks James, glad you like the thread

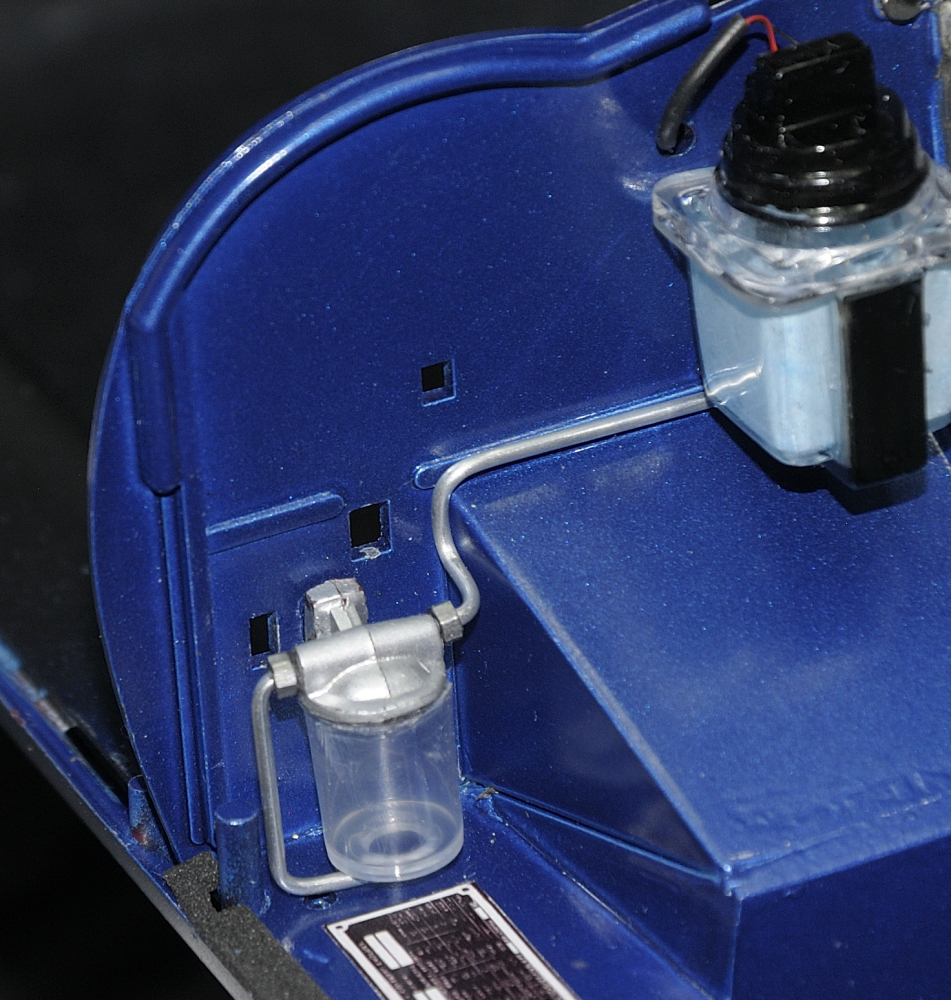

For some reason Revell moulded the glass filter bowl in red plastic, odd because the washer bottle and others are in clear ? anyway i scratched my head for a couple of days wondering what i could use and my eyes settled on the nozzle on my super glue bottle

So i cut the red plastic bowl off painted the top silver and glued a section of the the nozzle to it. That's when i found out you cant super glue the plastic they use for the nozzles They are super glue proof......who knew ?

They are super glue proof......who knew ?

update

Italeri have said they will send another body shell for the Bugatti....first one never arrived...

For some reason Revell moulded the glass filter bowl in red plastic, odd because the washer bottle and others are in clear ? anyway i scratched my head for a couple of days wondering what i could use and my eyes settled on the nozzle on my super glue bottle

So i cut the red plastic bowl off painted the top silver and glued a section of the the nozzle to it. That's when i found out you cant super glue the plastic they use for the nozzles

update

Italeri have said they will send another body shell for the Bugatti....first one never arrived...

Last edited:

That's what great about this scale, common items can be used for parts.

paddy

Well-known member

You are right Steve TBH if i couldn't do the scratch building i probably wouldn't build at all.

This is great stuff

It self adhesive cloth meant for model seats but works well as a carpet

Its one of those jobs where you have remind yourself to breath as you fit it it has an adhesive back that if it touches anything, just will not let go so get it wrong and it stretches before it comes unstuck and is ruined

it has an adhesive back that if it touches anything, just will not let go so get it wrong and it stretches before it comes unstuck and is ruined

The hardest bit was making card templates to cut the material to shape. I will bring the carpet up the sills however i need to work out where the door sits first to see if i have room for the thickness etc.

This is great stuff

It self adhesive cloth meant for model seats but works well as a carpet

Its one of those jobs where you have remind yourself to breath as you fit it

The hardest bit was making card templates to cut the material to shape. I will bring the carpet up the sills however i need to work out where the door sits first to see if i have room for the thickness etc.

So what radio would be in a Jag?

Carpet looks great!

Carpet looks great!

paddy

Well-known member

I thought it would have valves  but it looks a bit 1970's to me..

but it looks a bit 1970's to me..

Nice, 70s was a great decade for radio.

paddy

Well-known member

I solved it bob

the E-type had a radio operator position in the back. He also served as a rear gunner in car chases.

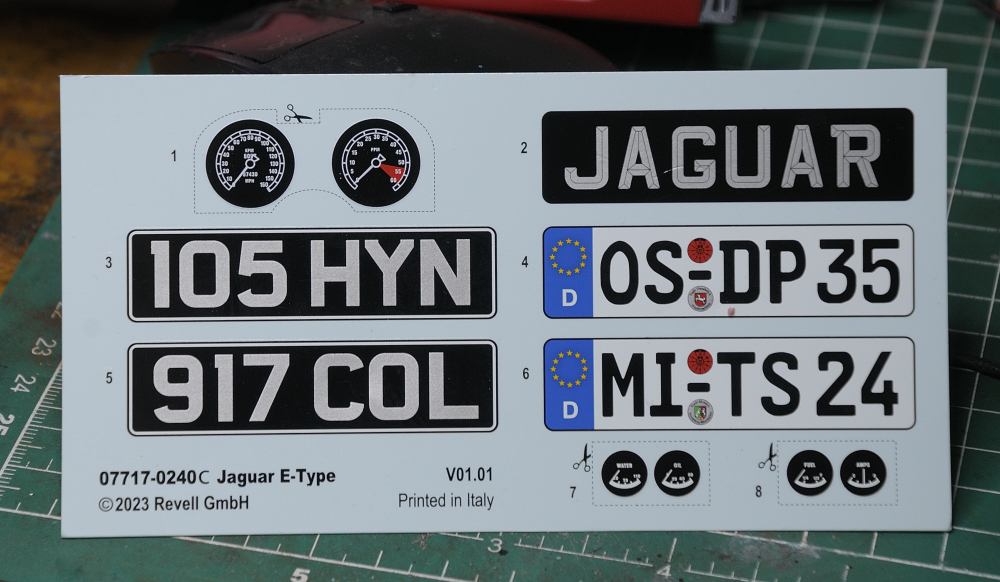

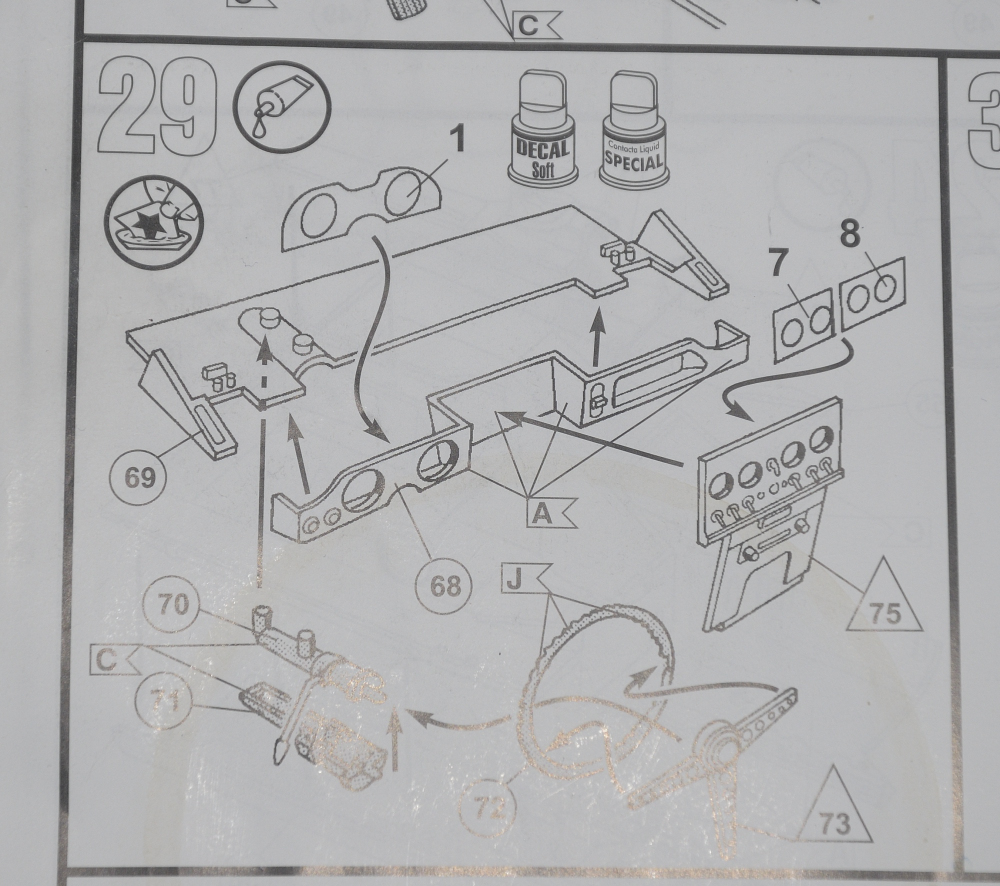

Here's a mystery then

these are the decals...

note the clocks have a cut out scissor dotted line ?

This is the dash board

There is no back to the clocks and no glass, just a pair of holes.... so do you cut the decals out, dont use water just stick them in place with glue on the enlarged cutting area ?

These are water slide, the instructions show a bottler of decal softener next to the clock faces.

I am completely stumped. ??

note 1-7-8 are decal numbers not part numbers

the E-type had a radio operator position in the back. He also served as a rear gunner in car chases.

Here's a mystery then

these are the decals...

note the clocks have a cut out scissor dotted line ?

This is the dash board

There is no back to the clocks and no glass, just a pair of holes.... so do you cut the decals out, dont use water just stick them in place with glue on the enlarged cutting area ?

These are water slide, the instructions show a bottler of decal softener next to the clock faces.

I am completely stumped. ??

note 1-7-8 are decal numbers not part numbers

this calls for a job for Scratch Builder!

We'll only accept "Smiths" branded instruments if you please.

We'll only accept "Smiths" branded instruments if you please.

Yes, they expect you to simply cut it out and paste it directly. Obviously, someone else would use the cut out shape to cut out a white styrene backing, apply the decals to said white styrene backing, and cover with a matching clear sheet shape, before attaching.There is no back to the clocks and no glass, just a pair of holes.... so do you cut the decals out, dont use water just stick them in place with glue on the enlarged cutting area ?

Heavens Eagle

Well-known member

I ran into this backward decal application craziness with the clear instrument panel option on the Ho-229 that I was building. Only difference was the decals didn't look good at all. Someone did a FUBAR.

That's so cool, we having fun yet?

paddy

Well-known member

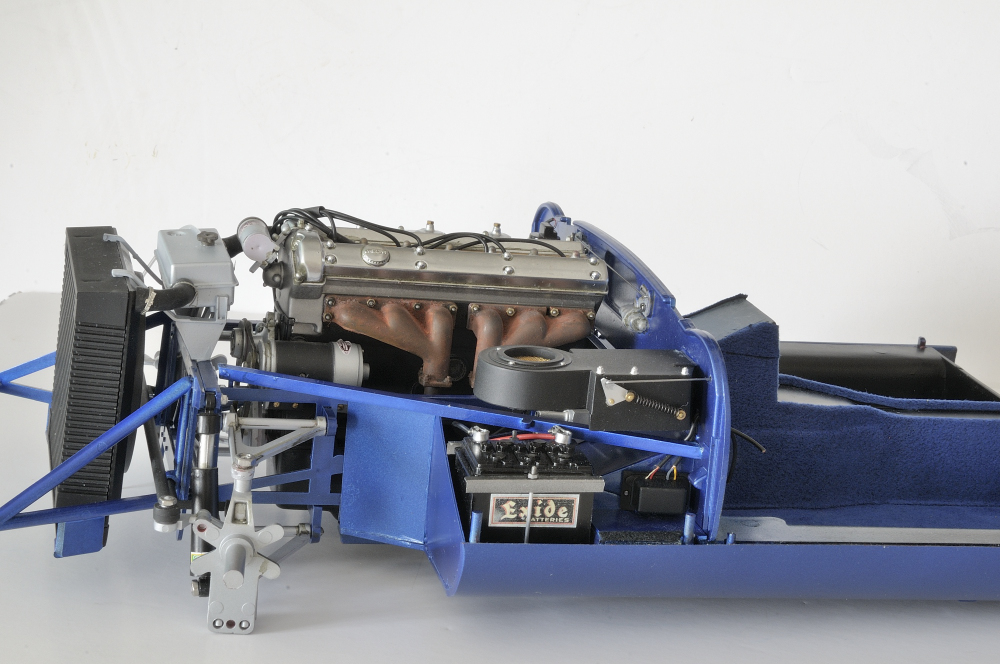

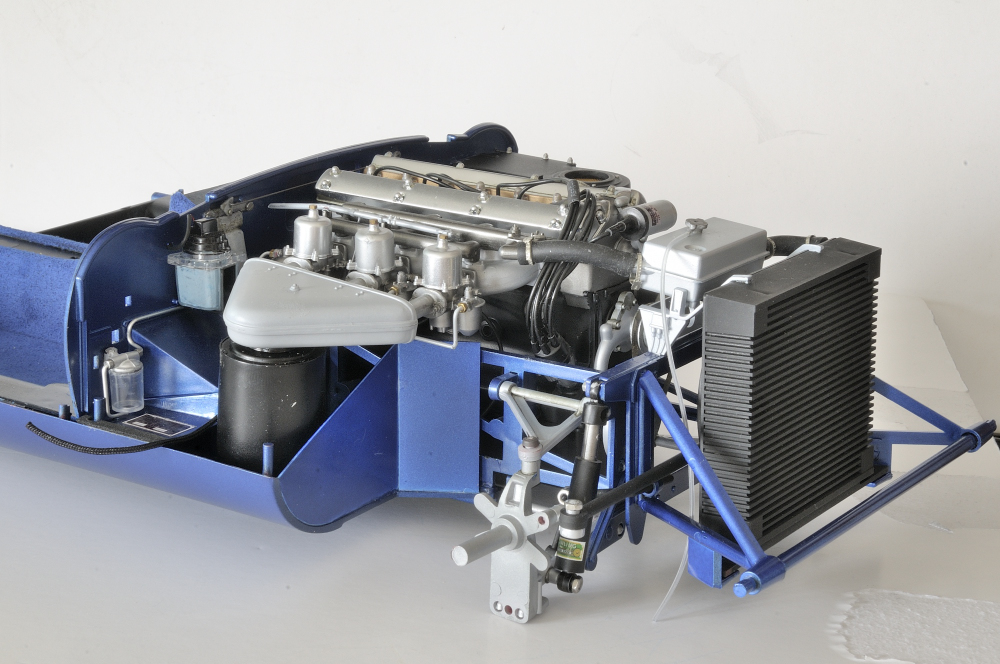

Engine now attached to the fire wall with no major drama's  still; not done the brake pipes as i can only get copper pipe in 1mm and i cant solder alloy tube however i have some 0.8mm brass which i suppose i could paint...

still; not done the brake pipes as i can only get copper pipe in 1mm and i cant solder alloy tube however i have some 0.8mm brass which i suppose i could paint...

Starting to look forward to some weathering as its looking too much like a toy car at the moment

Starting to look forward to some weathering as its looking too much like a toy car at the moment

Last edited:

Well aren't they all just toys anyway?