SdAufKla

Active member

So… I haven’t built a fully rigged biplane model since I was about 9 or 10 years old when I built the old Monogram Wright Flyer. Molded in color, IIRC, the rigging was done by lacing black sewing thread through the molded on rigging holes in the struts and wings. Well, that was back around 1970, so it’s been a while, to say the least.

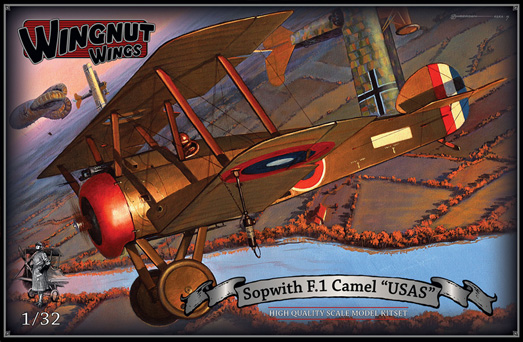

I generally build armor, but occasionally I’ll do something else, either for the challenge, to learn some new skills or techniques or just because the subject is one that I’ve developed an interest in. In the case of this project, the WNW Sopwith Camel USAS, it’s a bit of all of the above.

I’ve got a mate in our local IPMS chapter who grew up in the upstate of South Carolina. Among his stories are some about a gent, Elliot White Springs, and his family. Not to stray too far from the topic of modeling, it’s enough to say that E.W. Springs was a WWI ace who started the war flying with the British in the S.E.5 and later transferred to the US Air Service where he flew in the Camel F.1. He was credited with about 17 kills (the exact number depends on the official source and how the kills were counted differently by the British and Americans).

After the war, he went on to author a number of novels on WWI and early aviation, and he was quite well known for this back in the interwar years. Later on, E.W. Springs took over his family’s textile firm, and for a long time in the '40s, '50s and '60s, he and his company were even more well known for their risque (for the times) advertising campaign that featured the “Spring Maid” girls (a play on their original slogan, “Spring Made”). Buxom, short skirts, very cheese cake, the “Spring Maids” were what every housewife wanted to be if she made up her beds using the sheets and pillow cases from the Springs textile mills.

Anyways, with a resume like that, how could I resist the home team ace and entrepreneur, E.W. Springs’ Sopwith Camel F.1?

I’m no experienced WWI aircraft modeler, so I’ll avoid any attempt at adding to the many good reviews of the Wing Nut Wings kit. A simple 5 minute search online will turn up plenty of information about this kit and all of their other offerings. It really is too bad, though, that WNW has gone out of business. However, I suppose there’s hope that their kits will eventually be released. Clearly there’s demand and the kits are so well designed and engineered that they deserve to continue on.

At any rate, I started with the kit a few weeks ago. Unfortunately, since I’m no experienced aircraft modeler, I was too focused on trying to both learn some new techniques and materials while at the same time trying to figure out the best construction and finishing sequences. In sort, I was just to engaged with the work to stop and take any in-progress photos.

I did pretty much follow the sequence and build suggestions by the many WWI biplane modelers out there, so the work illustrated follows, I believe, the conventional approach used by others.

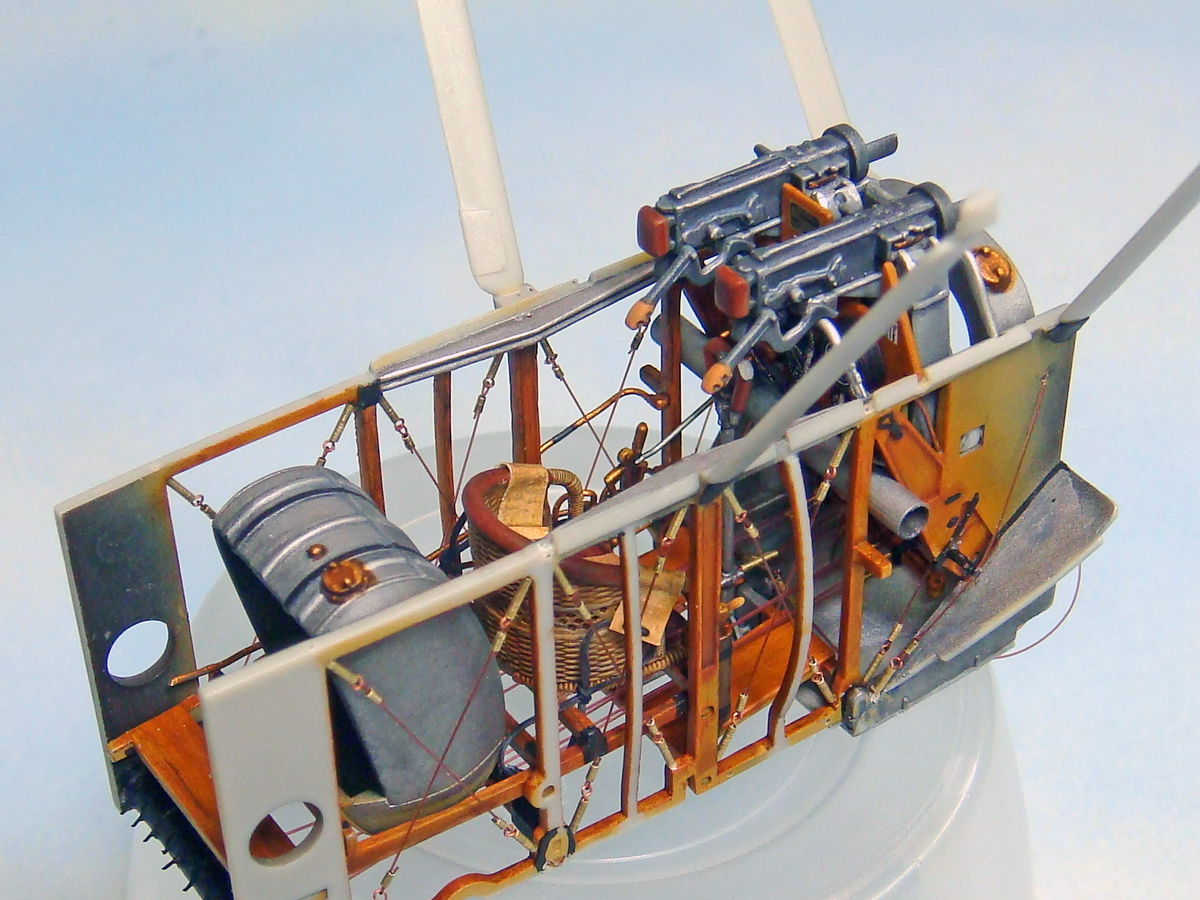

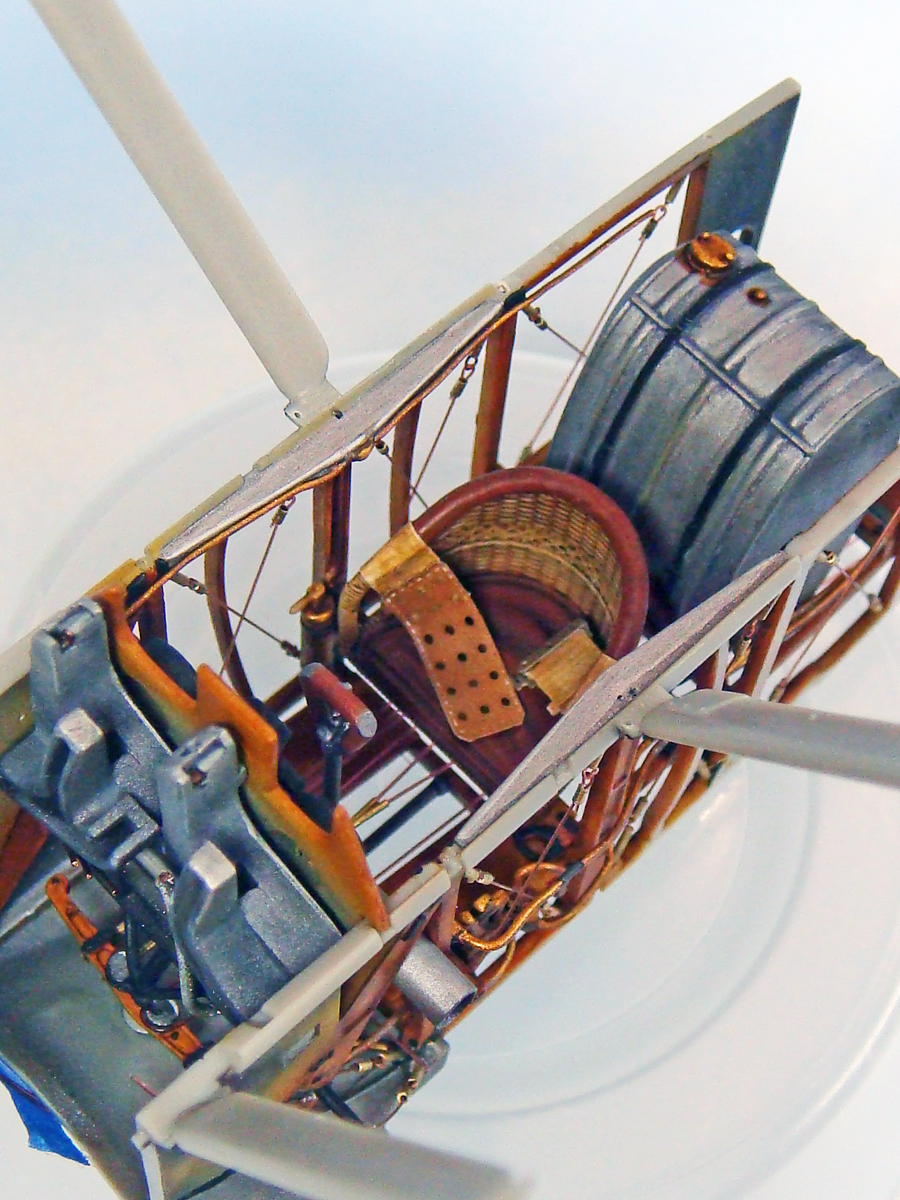

The bracing wires were done with 2# monofilament fishing line. The clevises were cut from .5 mm Albion brass tube. The eyelets were twisted from fine, approx 32 ga. copper wire.

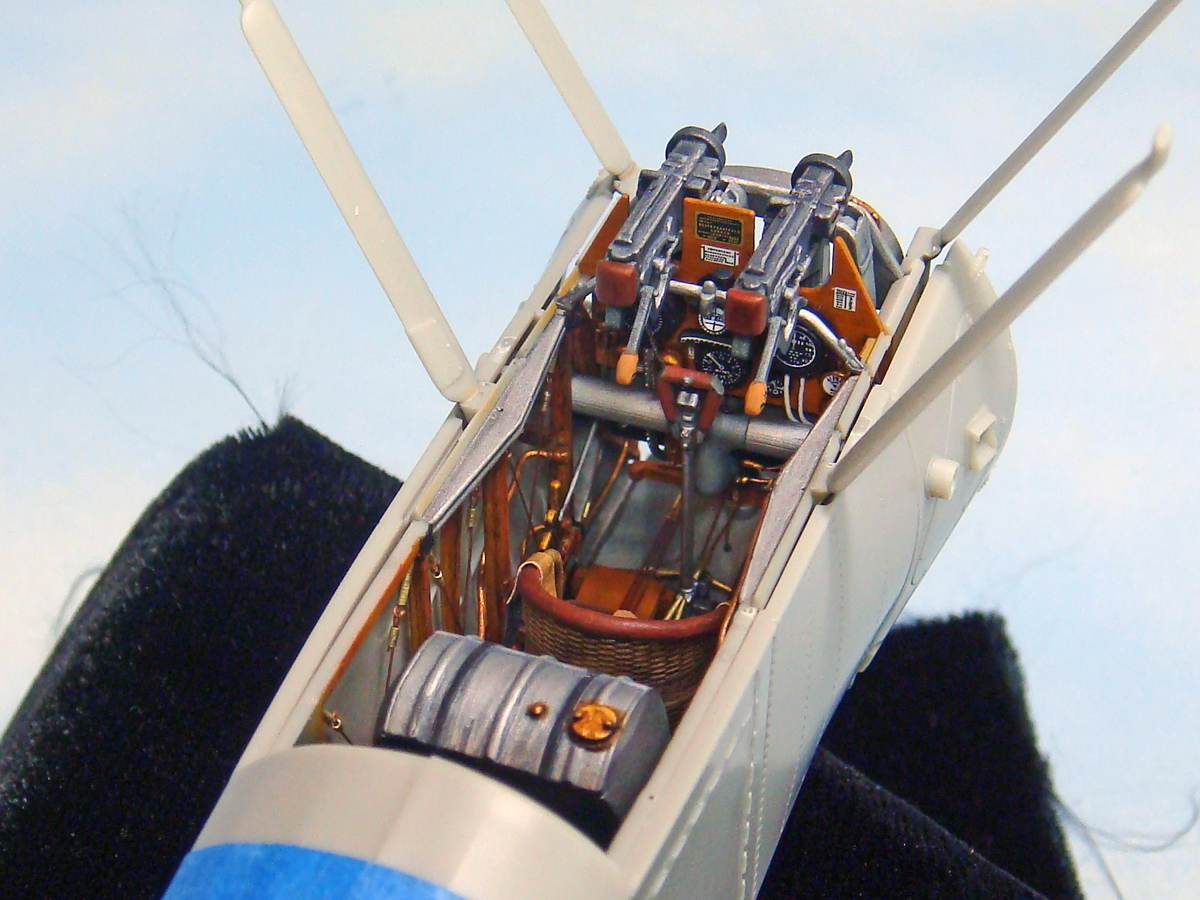

The control wires were made with 3# monofilament fishing line with .4mm Albion tubing for the ferrules. I think if I was to do this again, I’d use Easy Line or the 2# monofilament for these. Although the instructions show the control lines as thicker in diameter than the bracing wires, the visual difference isn’t enough and the thicker mono was much harder to tension and work with.

The seat belts are the HGW laser cut “fabric” belts. They’re really nice and easy to work with, but honestly, they don’t really look any better than the kit provided PE belts. So another lesson learned: Next time I’d just anneal, paint and use the PE belts.

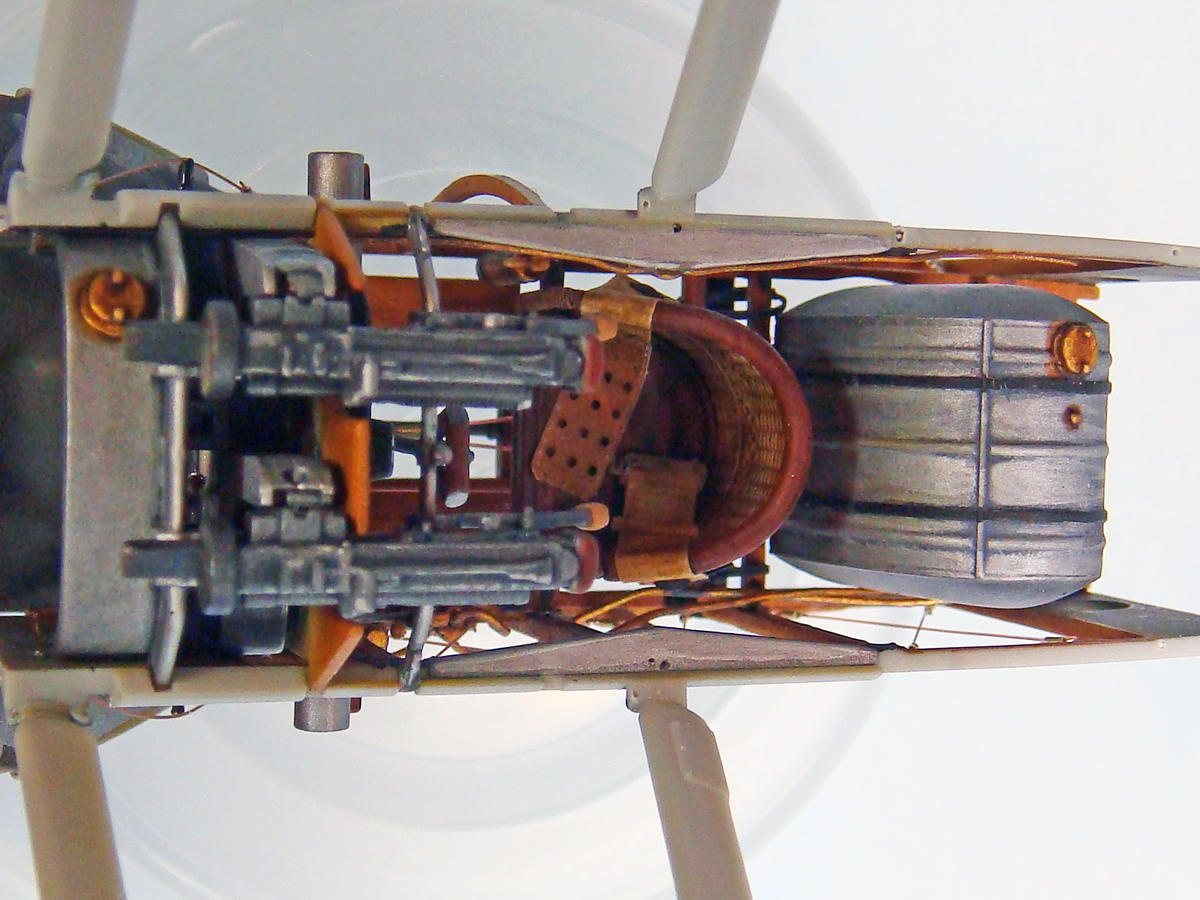

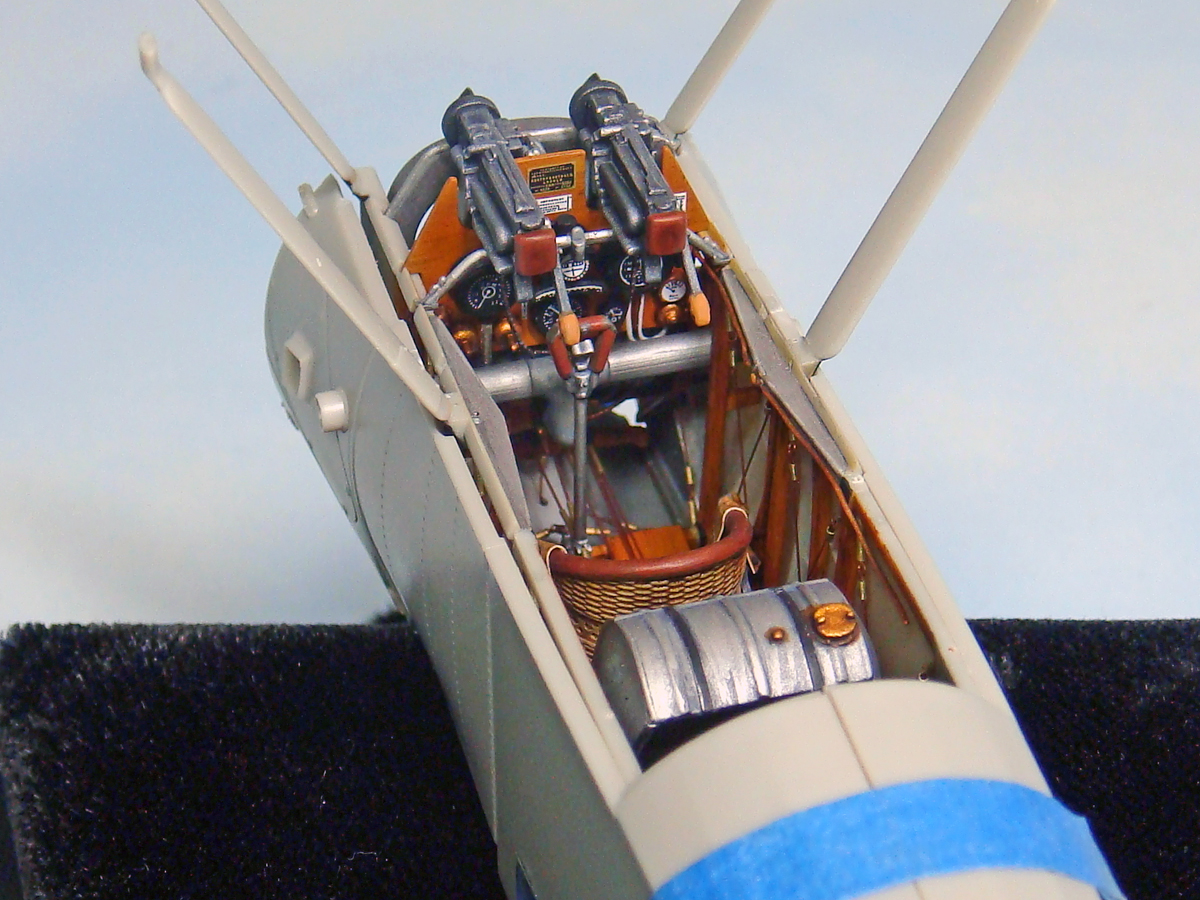

The kit’s Cartograph instrument decals were a perfect fit into the injection molded gages. No trimming needed at all. I did add the switch levers for the magnetos. I also replaced the lines to the airspeed indicator and pulsometer with wire. I have a piece of clear stretched sprue that I’ll add for the pulsometer bulb when I add some Future to the instrument faces.

I still have the bracing wires for the first two bays of the floor to add along with the clear parts and gloss on the gages, but these last two shots show the cockpit module test fitted into the fuselage haves. The gaps between the top edge of the fuselage opening and the interior framing are cause by some slight warping of the fuselage parts. These parts are molded pretty thin, though, and the gaps will close up with just a little finger squeeze. The famous WNW reputation for excellent parts fit is well deserved.

So… My hat’s off to all the guys and girls out there who regularly build fully-rigged biplanes! I was looking for a bit of a challenge and something new, and I can say that this rigging stuff is a “whole 'nuther kind of model building nuttiness”!

Now onto the fuselage interior…

I generally build armor, but occasionally I’ll do something else, either for the challenge, to learn some new skills or techniques or just because the subject is one that I’ve developed an interest in. In the case of this project, the WNW Sopwith Camel USAS, it’s a bit of all of the above.

I’ve got a mate in our local IPMS chapter who grew up in the upstate of South Carolina. Among his stories are some about a gent, Elliot White Springs, and his family. Not to stray too far from the topic of modeling, it’s enough to say that E.W. Springs was a WWI ace who started the war flying with the British in the S.E.5 and later transferred to the US Air Service where he flew in the Camel F.1. He was credited with about 17 kills (the exact number depends on the official source and how the kills were counted differently by the British and Americans).

After the war, he went on to author a number of novels on WWI and early aviation, and he was quite well known for this back in the interwar years. Later on, E.W. Springs took over his family’s textile firm, and for a long time in the '40s, '50s and '60s, he and his company were even more well known for their risque (for the times) advertising campaign that featured the “Spring Maid” girls (a play on their original slogan, “Spring Made”). Buxom, short skirts, very cheese cake, the “Spring Maids” were what every housewife wanted to be if she made up her beds using the sheets and pillow cases from the Springs textile mills.

Anyways, with a resume like that, how could I resist the home team ace and entrepreneur, E.W. Springs’ Sopwith Camel F.1?

I’m no experienced WWI aircraft modeler, so I’ll avoid any attempt at adding to the many good reviews of the Wing Nut Wings kit. A simple 5 minute search online will turn up plenty of information about this kit and all of their other offerings. It really is too bad, though, that WNW has gone out of business. However, I suppose there’s hope that their kits will eventually be released. Clearly there’s demand and the kits are so well designed and engineered that they deserve to continue on.

At any rate, I started with the kit a few weeks ago. Unfortunately, since I’m no experienced aircraft modeler, I was too focused on trying to both learn some new techniques and materials while at the same time trying to figure out the best construction and finishing sequences. In sort, I was just to engaged with the work to stop and take any in-progress photos.

I did pretty much follow the sequence and build suggestions by the many WWI biplane modelers out there, so the work illustrated follows, I believe, the conventional approach used by others.

The bracing wires were done with 2# monofilament fishing line. The clevises were cut from .5 mm Albion brass tube. The eyelets were twisted from fine, approx 32 ga. copper wire.

The control wires were made with 3# monofilament fishing line with .4mm Albion tubing for the ferrules. I think if I was to do this again, I’d use Easy Line or the 2# monofilament for these. Although the instructions show the control lines as thicker in diameter than the bracing wires, the visual difference isn’t enough and the thicker mono was much harder to tension and work with.

The seat belts are the HGW laser cut “fabric” belts. They’re really nice and easy to work with, but honestly, they don’t really look any better than the kit provided PE belts. So another lesson learned: Next time I’d just anneal, paint and use the PE belts.

The kit’s Cartograph instrument decals were a perfect fit into the injection molded gages. No trimming needed at all. I did add the switch levers for the magnetos. I also replaced the lines to the airspeed indicator and pulsometer with wire. I have a piece of clear stretched sprue that I’ll add for the pulsometer bulb when I add some Future to the instrument faces.

I still have the bracing wires for the first two bays of the floor to add along with the clear parts and gloss on the gages, but these last two shots show the cockpit module test fitted into the fuselage haves. The gaps between the top edge of the fuselage opening and the interior framing are cause by some slight warping of the fuselage parts. These parts are molded pretty thin, though, and the gaps will close up with just a little finger squeeze. The famous WNW reputation for excellent parts fit is well deserved.

So… My hat’s off to all the guys and girls out there who regularly build fully-rigged biplanes! I was looking for a bit of a challenge and something new, and I can say that this rigging stuff is a “whole 'nuther kind of model building nuttiness”!

Now onto the fuselage interior…

Last edited: