I guess it's really about time that I update this thread. I admit that I'm a really slow builder, and this project seems even slower than many since I spend about as much time trying to figure out what and how to do things as I do actually doing them. LOL!

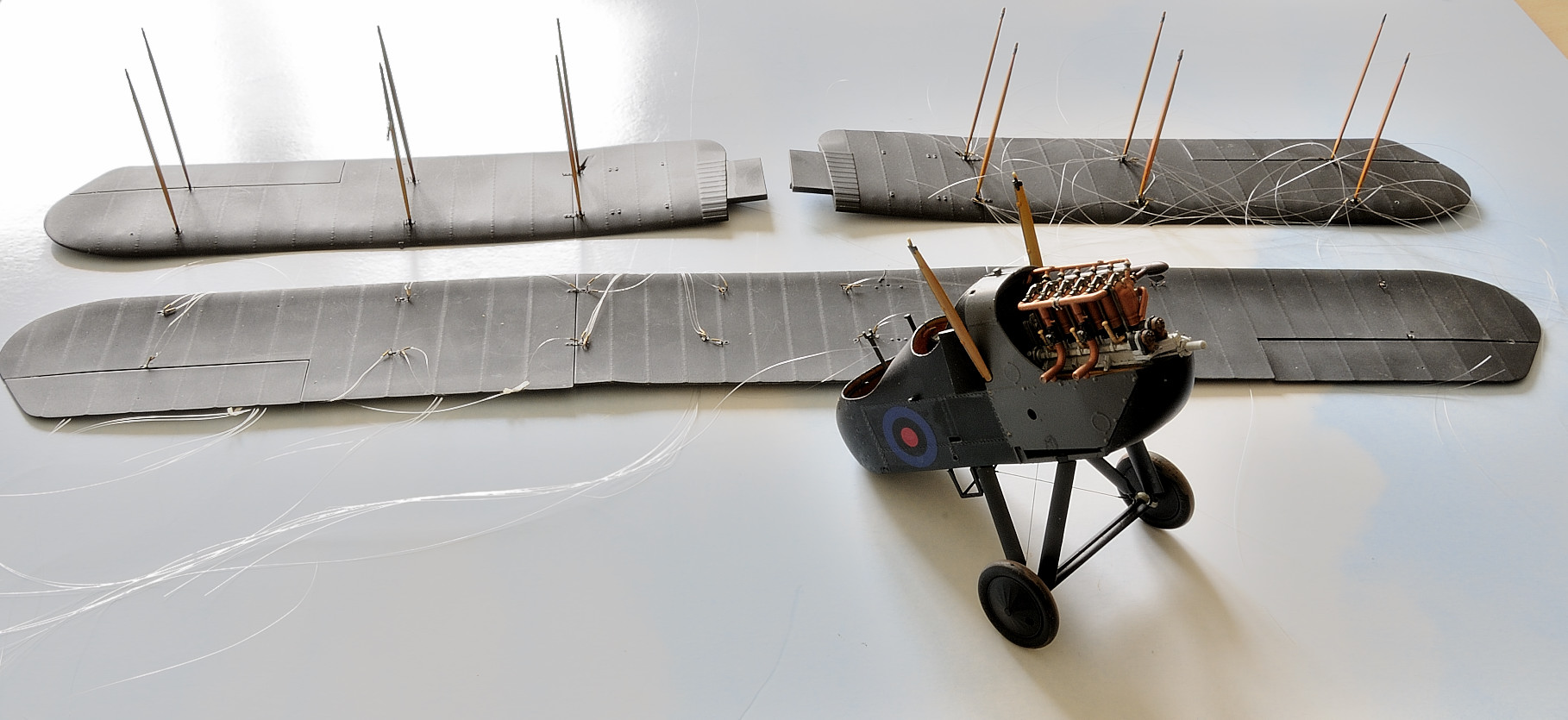

At any rate, I've finally finished up the fuselage except for some more weathering (particularly on the bottom) after the bottom wing and landing gear get added to it.

I really like this shot because it shows just how the fuselage colors can look radically different just because of the angle of the light on them. The rear fuselage from the cockpit back, sides and top, is the same color. However, just like the photos of the actual aircraft, in most lighting it looks like two entirely different colors - a much darker one on the sides and a lighter one on the top.

I did use a slightly darker shade of this on the birch plywood and aluminum panels around the engine and cockpit because there seems to be another difference in how these smooth, hard surface areas reflectively contrast with the doped linen areas. There also seems to be a large difference in the sheen, where these areas seem to be semi- to gloss and the doped linen areas seem much duller. Any hoo... just my take on it.

I'm still tidying up some of the control cables for the tail. I broke off the elevator horn on the still loose cable and I'm still waiting for it to dry in these photos. The rigging is a combination of #2 lb. monofilament fishing line and elastic EZ Line. The ferrules were cut from .5 mm diameter nickel-silver Albion tubing. All pretty standard materials and techniques, I think.

I used the kit decals for everything except the rudder. That was just simpler to mask and paint. It was conveniently 18 mm wide and I just happened to have a role of 6 mm wide Tamiya tape. "Serendipity," as the lizard on TV says...

The cockpit interior, of course, is much more difficult to see, but if you do bother to shine a light into it, it's surprising how much can be seen.

Examples of the Camel that had the field-expedient cut-away decking around the Vickers MG receivers would naturally show more of the instrument panel. Unfortunately (for me...) the USAS plane I'm building wasn't so modified.

One of the details missing from the WNW kit are the lines running from the pitot tubes to the airspeed indicator. My references suggest that these were made of white rubber tubing. According to a Windsock pub that I have, the WNW's kit designer made a deliberate decision to leave these off the cabane strut because they would have just been a blobby and indistinct shape because of the limitations of the molding process.

I made mine from .3 mm dia. lead wire and replicated the clips holding them in place with tiny bits of Bare Metal Foil. I went back over them with artist matt medium as an adhesive to reinforce the strength of the little drops of CA glue used to hold the tubes in position and the adhesive on the back of the Bare Metal Foil (the bits are so small that there's almost no surface to them for their self-adhesive).

The fuselage framing on the bottom showing through the clear doped linen (CDL) was just painted on using Tamiya flat earth before I sprayed Deck Tan for the CDL color. There's a lot more weathering to do here. Apparently the total oil loss system used on the rotary engines made an absolute mess of the bottom of the aircraft. Basically, these engines have no oil sump such as is found on most other engines, so castor oil (water-soluble and which would not dissolve in the fuel) was injected into the carbureted air-fuel mixture to provide cylinder lubrication and to lubricate the inside of the crankcase (remember - no oil sump for the connecting rods, etc. to splash around in). Most of this oil was not actually burned with the fuel and was exhausted straight into the air from the cylinder heads as they rotated around to near bottom dead center. All this exhaust gas and castor oil then just flowed along the bottom of the fuselage...

Interestingly enough, when castor beans and castor oil are burned, they release the poison ricin, so pilots of rotary engined aircraft often experienced horrible headaches from the fumes.

And that's all, folks!

Happy modeling!