-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WNW Sopwith Camel F.1 USAS

- Thread starter SdAufKla

- Start date

SdAufKla

Active member

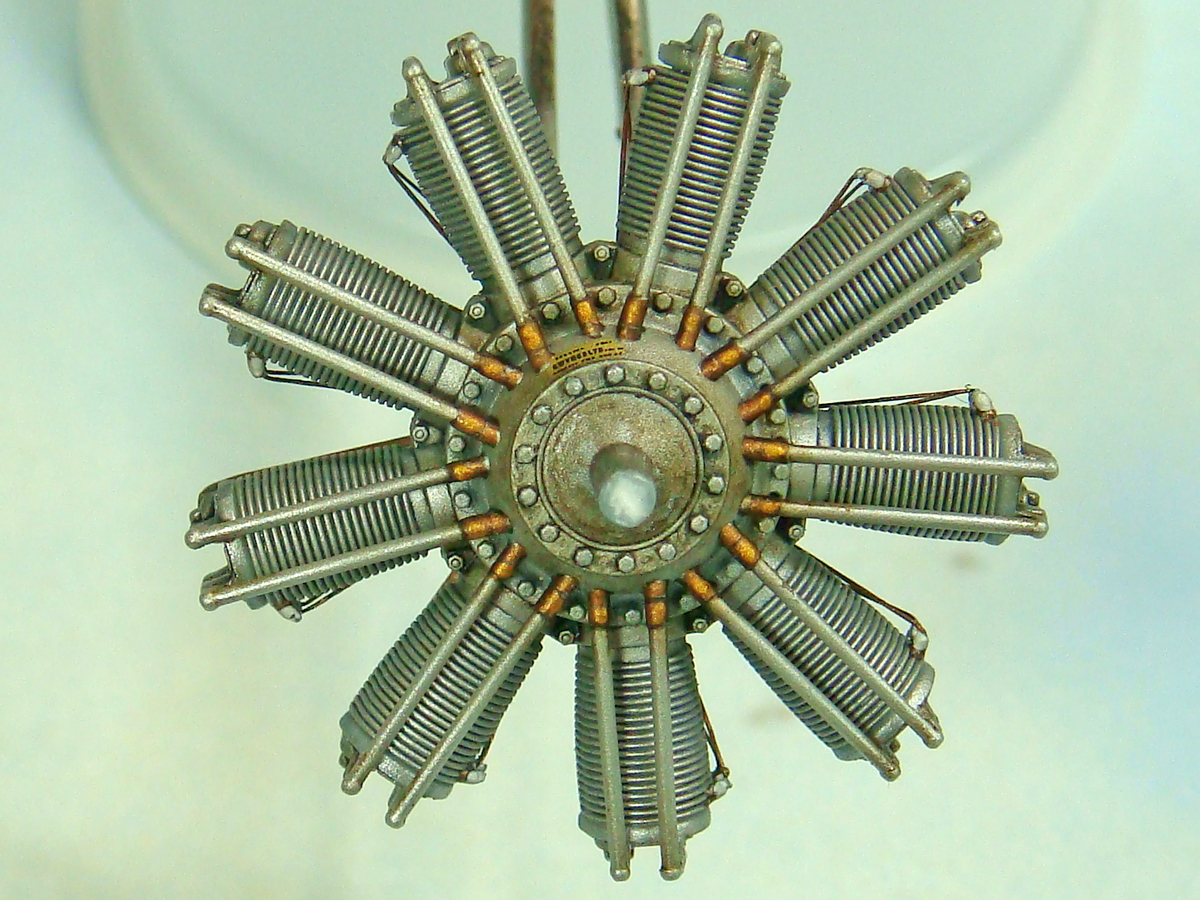

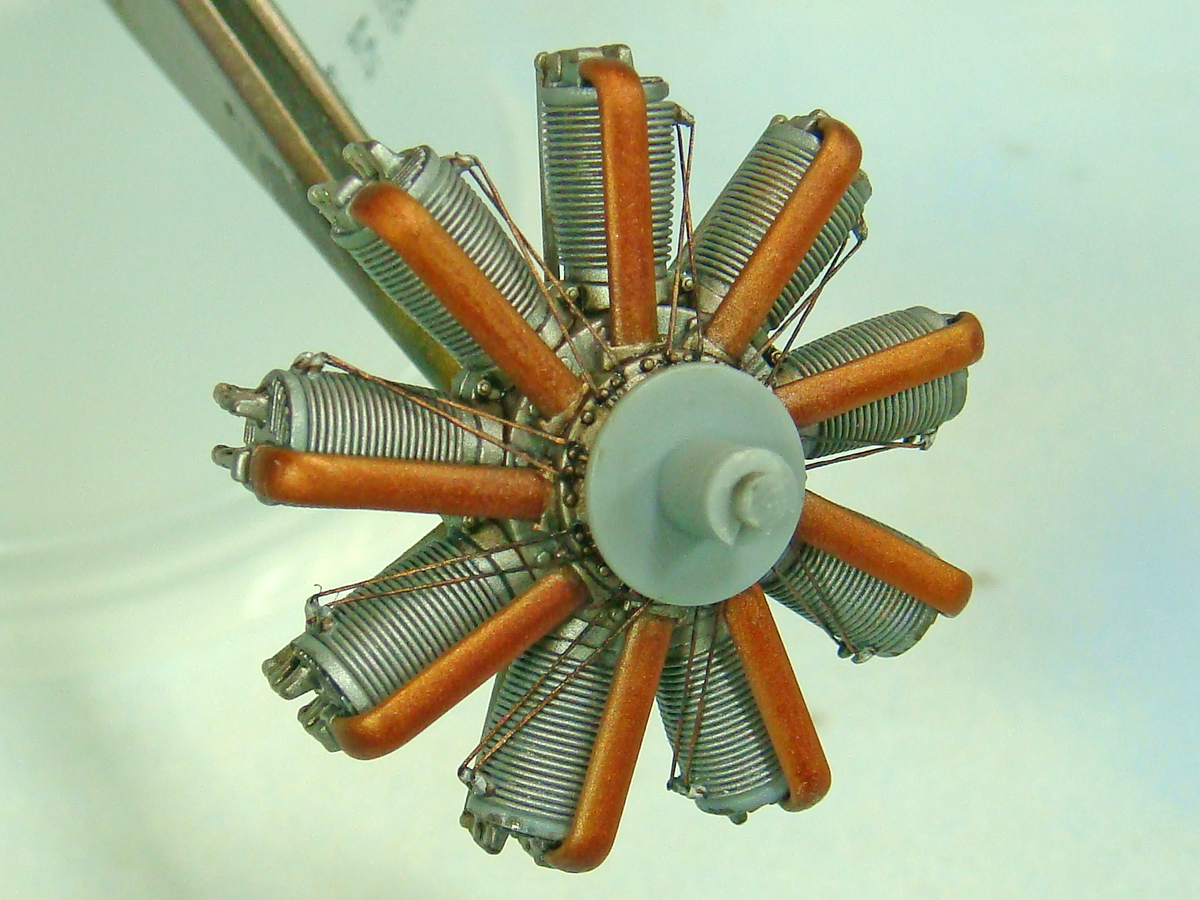

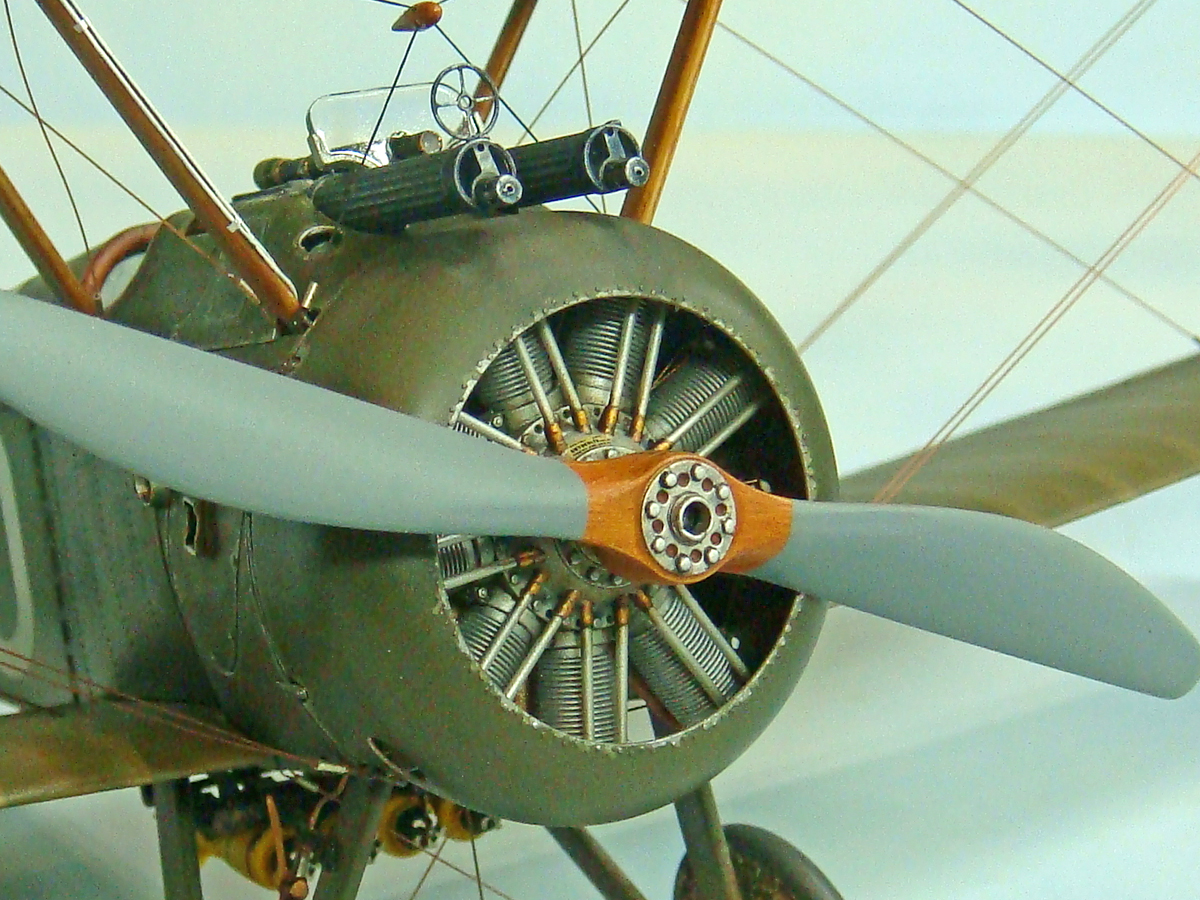

So, a quick little update. I've finished the Clerget 9B rotary engine and the prop.

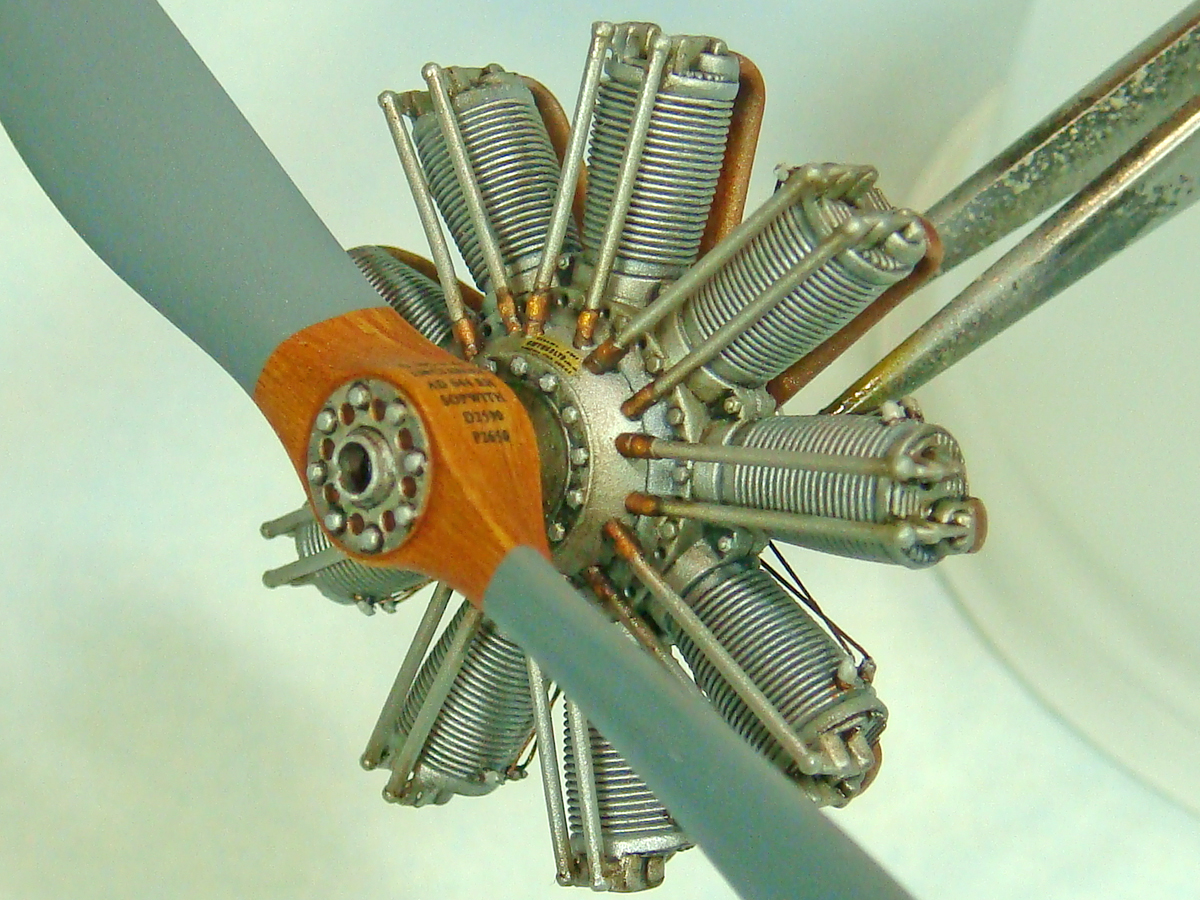

Not a huge lot to say about either, really. The prop came out pretty nice, and the kit data decal is a very nice little touch. (There're actually two decal options, one for the Clerget and the other for the Rhone engine which are, themselves kit options - i.e. two complete engines provided.)

I had some imaginings of doing some detail work on the engine, but as it turned out, I just built it out of the box. The only additions are the ignition wires (illustrated in the instructions). I added these using fine EZ Line. The rest of the engine is OOTB. The brass engine data plate decal was another very nice WNW touch!

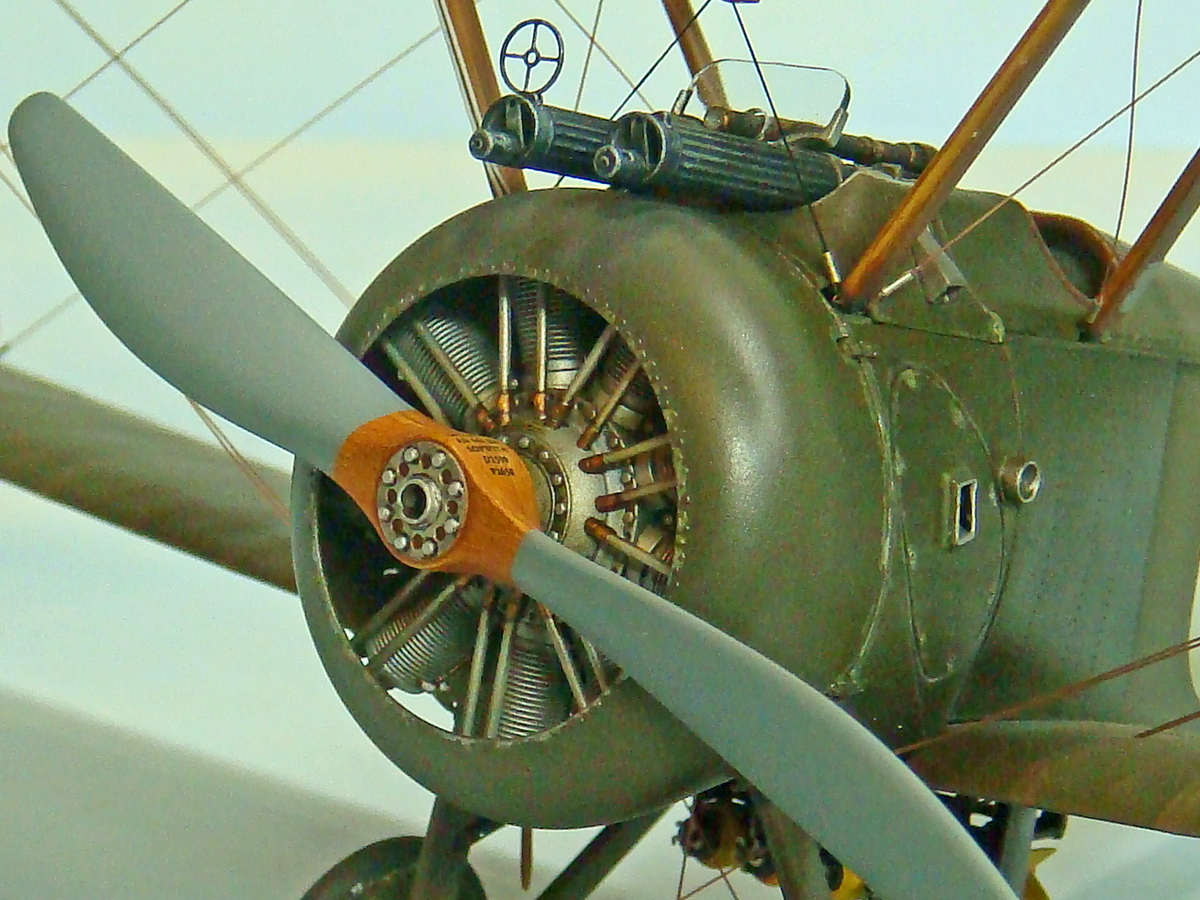

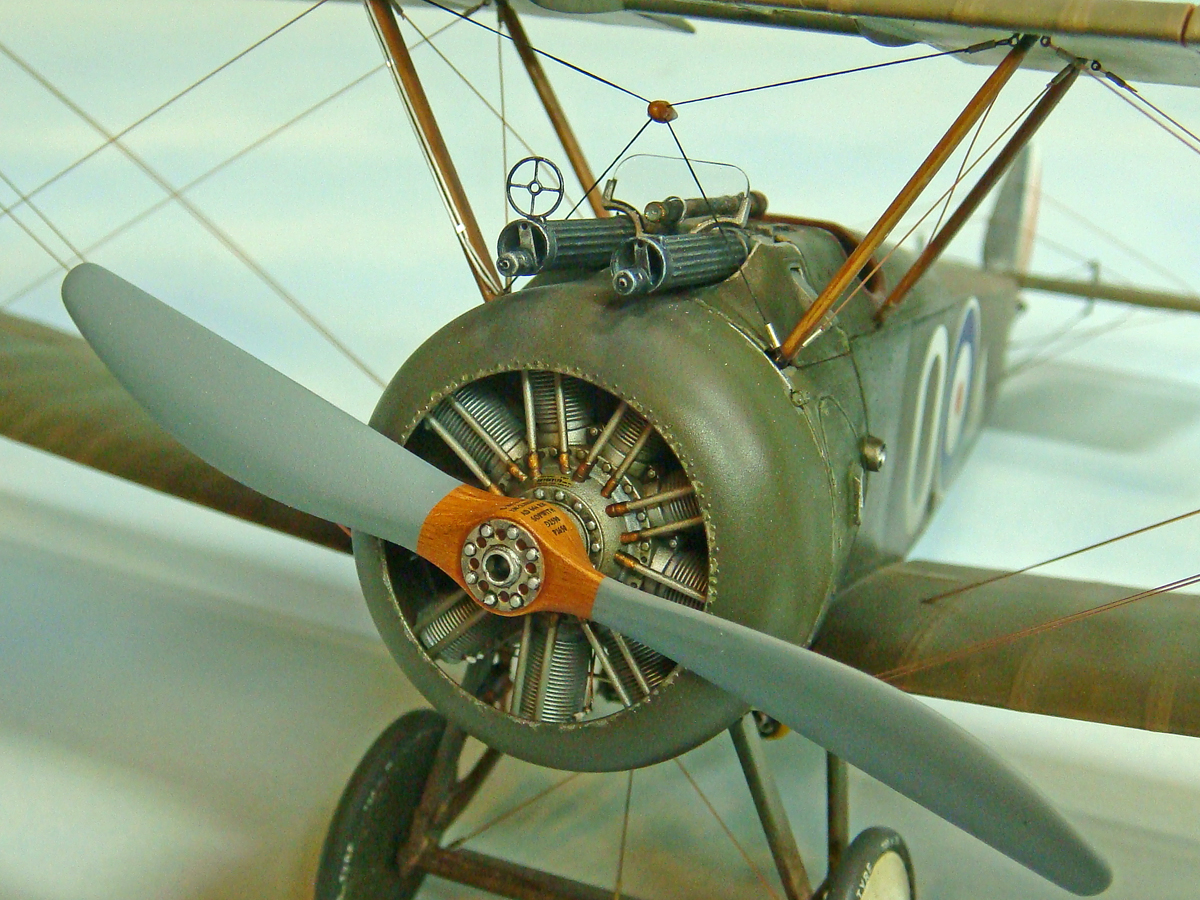

I did run into an unexpected problem, though, trying to fit the engine cowling over the finished engine. So, the engine is designed and kitted at its correct, accurate overall diameter. Good, right? And the cowling is also designed and kitted at its correct and accurate overall OUTSIDE diameter. Yea, baby!

However, the real engine fits into the real cowling with very, very little clearance between the rocker arms and the inside of the cowling. The real cowling is also made of pressed-stamped aluminum that's probably only maybe 1.5mm thick... You can see where I'm going with this, right?

The kit cowling, while very thinly molded is still about a scale 1-1/2" thick, or perhaps about a scale 3" too small on its INNER diameter. The engine being properly kitted at its correct overall diameter simply will not fit inside the cowling. Something has to give. My first choice was to thin the cowling with the intention of getting the engine to fit with enough clearance to actually be rotated. Alas, I simply lacked the courage to keep grinding away at the inside to make this happen. I got real close, and the modified cowling does fit over the engine, but there is still some rubbing of the rocker arms on the inside of the cowling....

Another option would have been to sand down the rocker arms on the cylinder heads that are tucked up into the cowling. IF I had caught this problem earlier, I might have gone that route. The engine's static and unmovable either way, really.

(Unless you're a better man than I Gunga Din, and you do keep thinning that cowling down! It's probably doable, but risky... Although there are two other cowling options provided, so in the event of a catastrophic failure, you could probably manage an acceptable bailout.)

Of course, I had already painted and finished the cowling, so it was also back to paint for it after all of the work. I had kind of expected to be able to photograph the engine installed, cowling added, MG barrels in place along with the prop. Unfortunately, while I do have all of these glue ups done, I was too discouraged to take pictures of the taped on and wedged in place bits. Once the glue has dried and I've removed all of the props, then I'll take some "happy snaps."

In the mean time, here's the completed engine and prop.

Happy modeling!

Not a huge lot to say about either, really. The prop came out pretty nice, and the kit data decal is a very nice little touch. (There're actually two decal options, one for the Clerget and the other for the Rhone engine which are, themselves kit options - i.e. two complete engines provided.)

I had some imaginings of doing some detail work on the engine, but as it turned out, I just built it out of the box. The only additions are the ignition wires (illustrated in the instructions). I added these using fine EZ Line. The rest of the engine is OOTB. The brass engine data plate decal was another very nice WNW touch!

I did run into an unexpected problem, though, trying to fit the engine cowling over the finished engine. So, the engine is designed and kitted at its correct, accurate overall diameter. Good, right? And the cowling is also designed and kitted at its correct and accurate overall OUTSIDE diameter. Yea, baby!

However, the real engine fits into the real cowling with very, very little clearance between the rocker arms and the inside of the cowling. The real cowling is also made of pressed-stamped aluminum that's probably only maybe 1.5mm thick... You can see where I'm going with this, right?

The kit cowling, while very thinly molded is still about a scale 1-1/2" thick, or perhaps about a scale 3" too small on its INNER diameter. The engine being properly kitted at its correct overall diameter simply will not fit inside the cowling. Something has to give. My first choice was to thin the cowling with the intention of getting the engine to fit with enough clearance to actually be rotated. Alas, I simply lacked the courage to keep grinding away at the inside to make this happen. I got real close, and the modified cowling does fit over the engine, but there is still some rubbing of the rocker arms on the inside of the cowling....

Another option would have been to sand down the rocker arms on the cylinder heads that are tucked up into the cowling. IF I had caught this problem earlier, I might have gone that route. The engine's static and unmovable either way, really.

(Unless you're a better man than I Gunga Din, and you do keep thinning that cowling down! It's probably doable, but risky... Although there are two other cowling options provided, so in the event of a catastrophic failure, you could probably manage an acceptable bailout.)

Of course, I had already painted and finished the cowling, so it was also back to paint for it after all of the work. I had kind of expected to be able to photograph the engine installed, cowling added, MG barrels in place along with the prop. Unfortunately, while I do have all of these glue ups done, I was too discouraged to take pictures of the taped on and wedged in place bits. Once the glue has dried and I've removed all of the props, then I'll take some "happy snaps."

In the mean time, here's the completed engine and prop.

Happy modeling!

Last edited:

SdAufKla

Active member

It was kind of a surprise, but I can understand it. If the model is displayed with the cowling off, then the engine is dead-nuts correct size-wise. If the cowling is added, then trimming down the cylinder heads (just the rocker arms, really) would allow it to fit easily, and the obliterated detail is hidden.Other than that, Mrs Lincoln, how did you like the play?

Wow, this is such an epic build, it really bites that the kit is so out of whack size wise. Sending all theI can.

I really think that had I know about this earlier in the build, I would have pushed the envelope and thinned down the cowling enough to allow the engine to rotate freely. There are two other cowlings that could be modified to replace the correct one if it got messed up. Alternatively, I might have vacuum formed a new cowling using the kit part as master to mold a negative form over. There is some very fine rivet detail on the front that would have to be added, but I think some of the 3D rivet decals might work for that (or scavenge the details from the kit part).

A slight disappointment and a bit of an aggravation (with having to go back and repaint the cowling), but certainly not a "mission stopper." I think by this stage I'm ready to get this one finished, so my tolerance for even small issues is pretty low. LOL! Argh...

I"m trying to remember the Sopwith Pup but I don't think I had any issue with the cowl. I know on the Eindecker I used some aftermarket cowls that were paper thin.

Engine does look great Mike, so how are ya going to proceed?

Engine does look great Mike, so how are ya going to proceed?

SdAufKla

Active member

Thanks! At this stage in the build I'm just going to accept that the engine can't be made to rotate freely and assemble the front end of the plane, basically calling it "gee" for good and "dee" for done. I'm really out of motivation and enthusiasm for anymore extensive work with this build. I'm to the stage where I'm working out the layout and composition of the display base and just cruising through the final bits on the actual model.... Engine does look great Mike, so how are ya going to proceed?

The grinding and thinning of the cowling wasn't entirely wasted effort. It did improve the fit, so nothing needs to be modified on the engine now. It does fit inside the cowl but with about one paint layer thickness of interference. It's tight, too tight to rotate freely, but not so tight that it won't go together. "Gee" for good, "dee" for done!

All in all, it's been a great project and, for my goals, a great success. I'm pretty pleased with how it's coming out, especially considering this is the first rigged biplane I've build since about 1970. Heck, I might even build another one sometime! LOL!

SdAufKla

Active member

Thanks! It's right out of the box, so WNW should get the credit.damn, that engine looks really nice

The only additions I made are the ignition wires (as shown in the instructions). It's really a surprisingly simple assembly design that WNW came up with. There are only four main parts (not counting the cylinder heads). The push rods and air induction pipes are each molded on one of the four main parts. Two other parts make up the crankcase and cylinders. There are a few other bits for mounting on the fire wall, and the prop, of course. Overall, though, it's quick and easy to put together.

The bronze-brass push rod lifters were carefully trimmed on their backsides to create full-round cylindrical shapes (part E1). They're molded with a "U" shaped profile that's flat on the rear. A molding simplification that takes just a bit of rework during the mold seam cleanup stage to improve. I also pre-drilled the holes to thread the fine EZ Line "ignition wires" into. On the rear crankcase part (part E10) these holes are located at the ends of the molded on wires ("V" shaped relief details). On the crankcase-cylinder subassembly (parts E6 and E8), the holes were drilled down at an angle through the molded on spark plugs.

During final assembly, I threaded the EZ Line through the holes on the rear crankcase part (E10) and glued them in place from behind (actually using just one long piece threaded through each pair of holes). Once I glued that part to the center crankcase-cylinder subassembly (parts E6 and E8), I then threaded the lines into each sparkplug and out through the tops of the cylinders. I then snugged the line and glued it with CA applied to the tops of the cylinders. Once this had cured, I trimmed the excess line away and smoothed off the tops of the cylinders. The cylinder head parts (parts E3) where then glued on followed by the crankcase front with the pushrods (E1).

For the finish, I cleaned up all the parts and assembled the front and back halves of the crankcase-cylinders and then pre-painted the base colors (after pre-drilling the ignition wire holes, as described above).

For pre-painting, the silver is Tamiya X-32 Titanium Silver. The copper on the air intake tubes is Tamiya X-34 Metallic Brown followed with XF-6 Copper. I used Citadel metallic colors for the bronze-brass lifters on the pushrods on the crankcase front part and for the molded on ignition wires on the rear crankcase part that also has the air induction tubes. After final assembly, I added the brass data plate decal.

A couple of washes from artist oil paints - Paynes gray and ABT 501's "Engine Grease" - were then followed up with some Tamiya X-19 Smoke airbrushed on the tops of the cylinder heads. The final touch was some Testors Dull Coat selectively airbrushed on to modulate the sheen from flat to egg shell in most places leaving a few chosen spots glossy-greasy.

SdAufKla

Active member

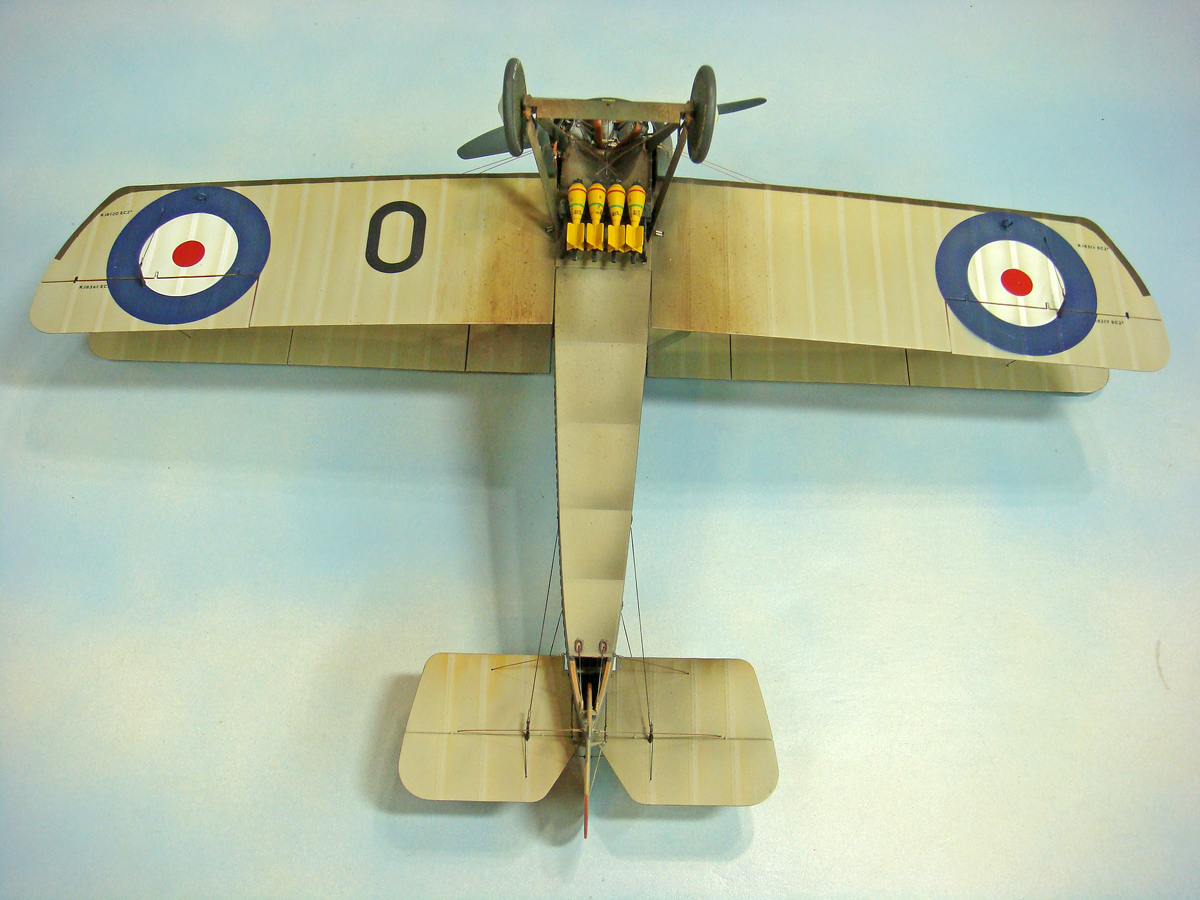

Well, time to wrap this one up. I still have the display base and figure to do, so I suppose there will be one final-final last update. However, for now the Camel is completely finished.

First up are a couple of glamor shots of the engine, prop and cowling. I meant to post these up yesterday, but got busy and forgot. Better late than never, though, so here ya go...

And for the rest...

The pitot tubes were made from sections of Albion Metals .04 mm OD aluminum tubing. Sorry for the poor focus here. Maybe I'll take another when I do the final-final update...

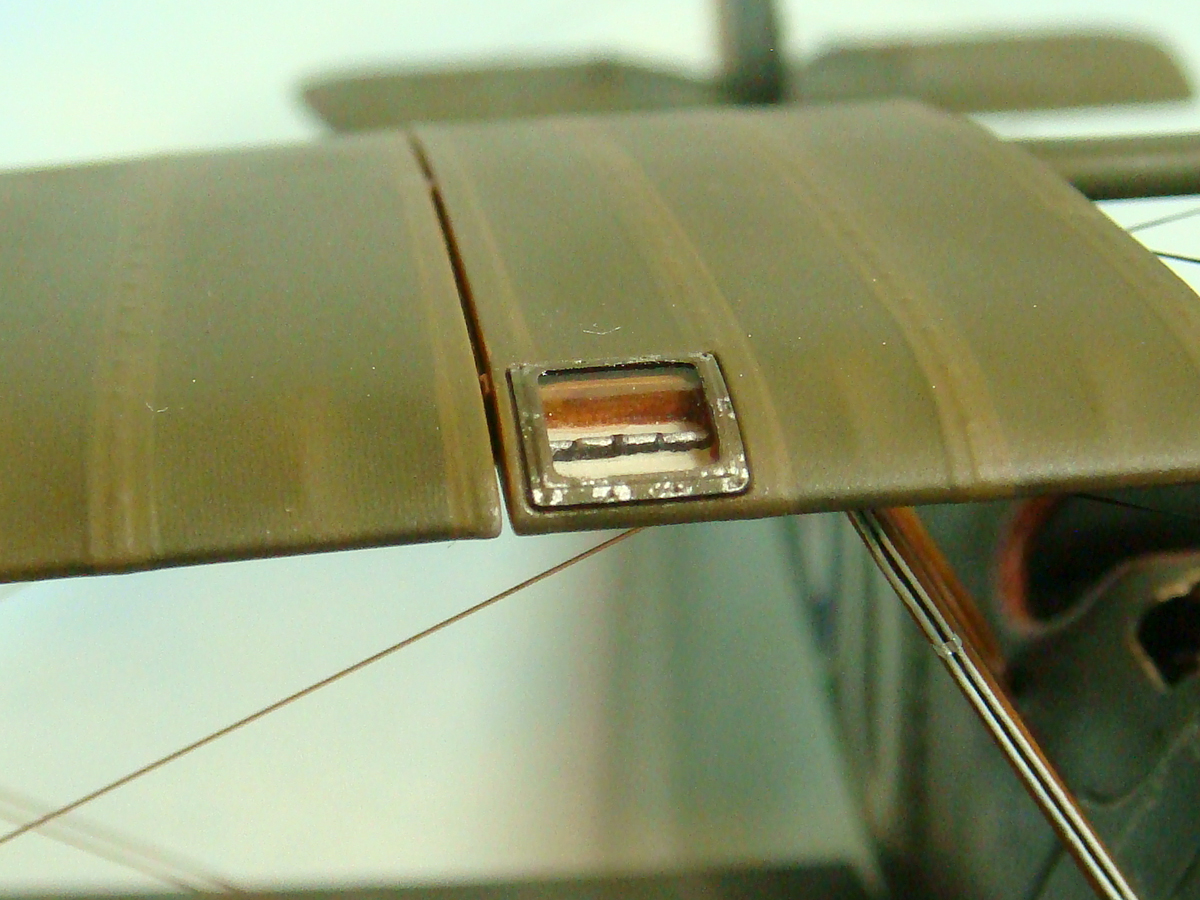

This shot of the top wing's center aileron control cable inspection and maintenance port shows the clarity of the WNW clear parts. I did think they were a bit too thick, but once painted and installed they look pretty good. They also still show off the internal details.

So, this is E.W. Springs' CPT, USAS mount circa late Summer early Autumn 1918. He scored eight of his 16 credited victories flying 08250 as the "B" flight leader, 148th Squadron. FWIW, my novice WNW builder's appreciation is that this is a great kit. Not without a couple of minor issues (no doubt some of which were of my own doing, so not the "prefect" kit, but certainly about as close to that as any kit I've ever built.

Great fun and highly recommended. Take your time and believe and respect its reputation for very close fit tolerances, and it will reward you!

First up are a couple of glamor shots of the engine, prop and cowling. I meant to post these up yesterday, but got busy and forgot. Better late than never, though, so here ya go...

And for the rest...

The pitot tubes were made from sections of Albion Metals .04 mm OD aluminum tubing. Sorry for the poor focus here. Maybe I'll take another when I do the final-final update...

This shot of the top wing's center aileron control cable inspection and maintenance port shows the clarity of the WNW clear parts. I did think they were a bit too thick, but once painted and installed they look pretty good. They also still show off the internal details.

So, this is E.W. Springs' CPT, USAS mount circa late Summer early Autumn 1918. He scored eight of his 16 credited victories flying 08250 as the "B" flight leader, 148th Squadron. FWIW, my novice WNW builder's appreciation is that this is a great kit. Not without a couple of minor issues (no doubt some of which were of my own doing, so not the "prefect" kit, but certainly about as close to that as any kit I've ever built.

Great fun and highly recommended. Take your time and believe and respect its reputation for very close fit tolerances, and it will reward you!

Last edited by a moderator:

Outstanding finish Mike, pulled this off like a champ!

Skinny_Mike

Well-known member

Just went through the whole thread, really amazing work!

Duke Maddog

Well-known member

And another magnificent masterpiece rolls off your workbench! Man, that is out of this world!