-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Italeri Bugatti 1/12 FINISHED

- Thread starter paddy

- Start date

Could always wreck it if they don't come through.

Piet

Well-known member

Same hereItaleri has been very good about selling me "Extra Parts".

Keep Calm and Model On.

Heavens Eagle

Well-known member

Congratulations! That is how it works, had it happen on me twice last weekend, and managed to find the last lost part in the process. The hard part sometimes is just having the patience to let it happen.

That looks a lot better than what I was able to print out. Since I have been working with so many super tiny parts on my Ju87A, I have been keeping everything in several small containers so as not to loose them.

That looks a lot better than what I was able to print out. Since I have been working with so many super tiny parts on my Ju87A, I have been keeping everything in several small containers so as not to loose them.

paddy

Well-known member

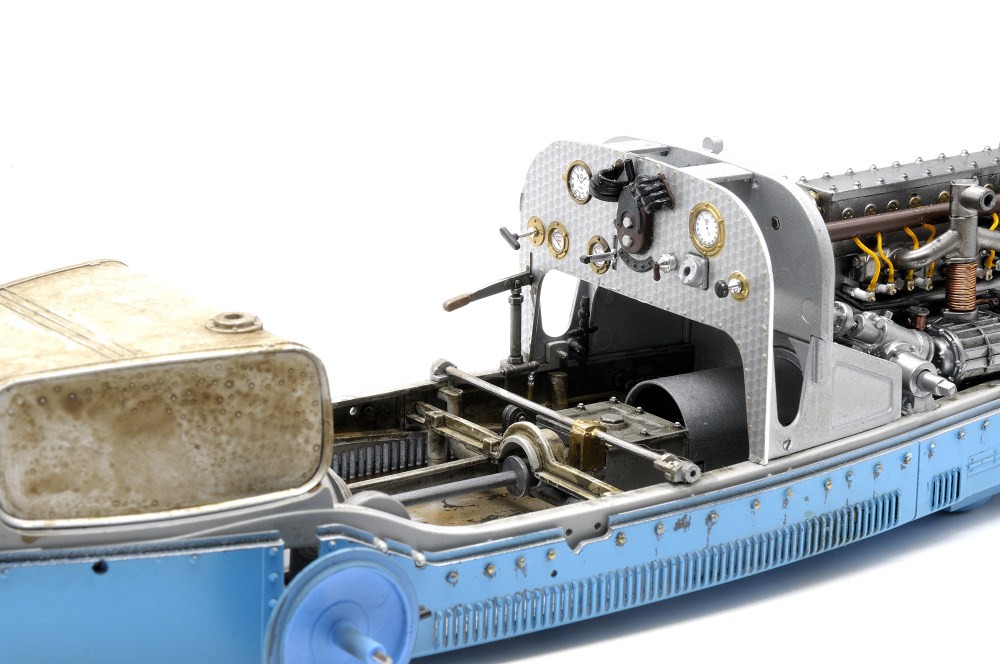

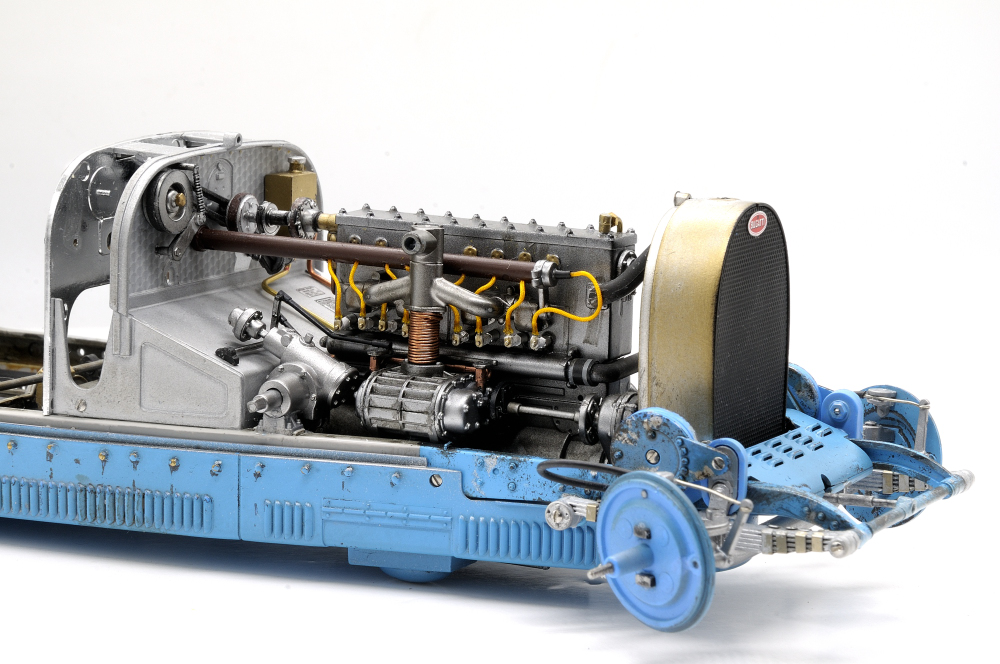

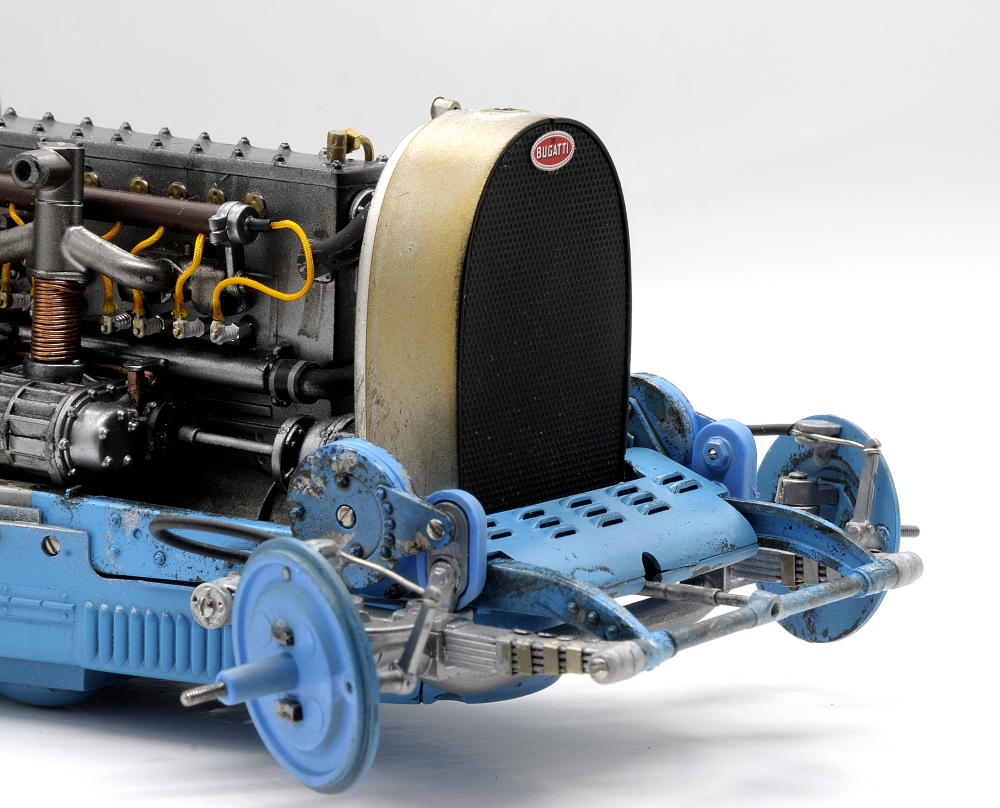

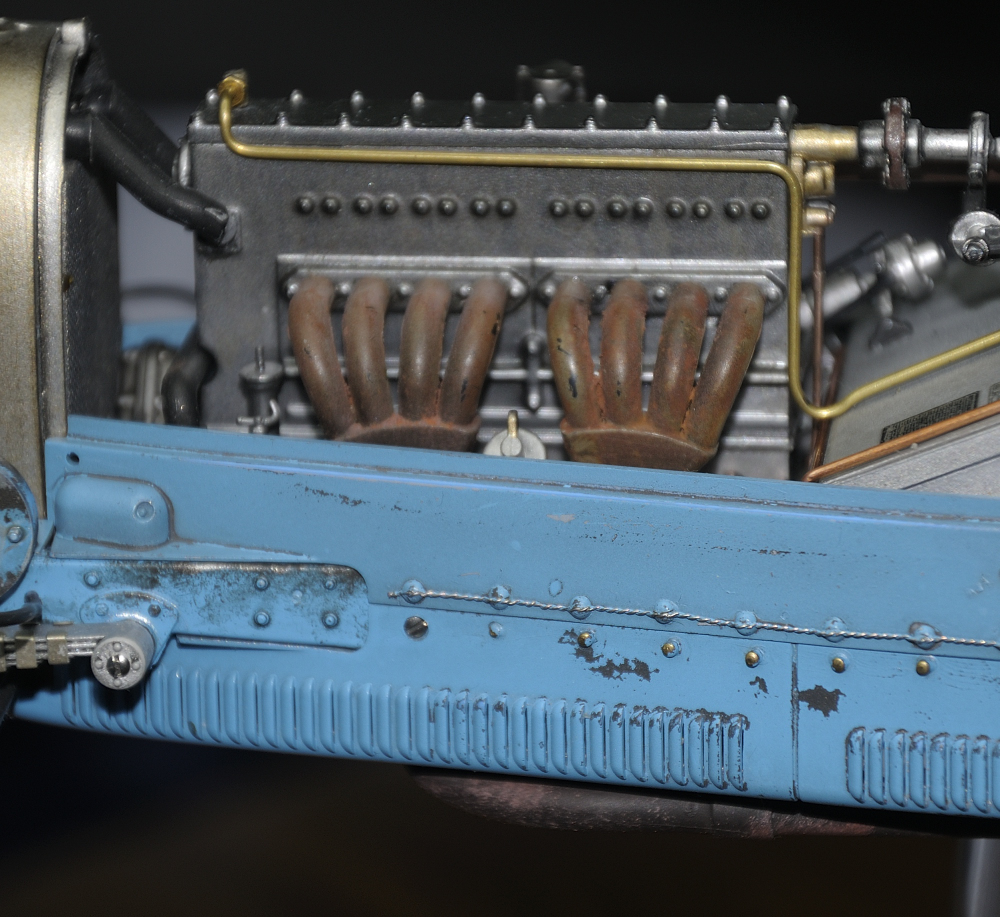

So i seem to be doing loads of different things here, out of step and out of order as i wait for replacement parts

To that end i have had a tidy up and look at where i have got to.

I added the under try and the front bodywork in front of the Rad. The car doesn't really have a floor just the under try so the prop shaft is whizzing round under the seat and oil and such is flowing back under your feet from the engine bay

and i fitted the missing badge but there is a stone guard to go in front of it eventually.

but there is a stone guard to go in front of it eventually.

To that end i have had a tidy up and look at where i have got to.

I added the under try and the front bodywork in front of the Rad. The car doesn't really have a floor just the under try so the prop shaft is whizzing round under the seat and oil and such is flowing back under your feet from the engine bay

and i fitted the missing badge

Heavens Eagle

Well-known member

I am quite impressed Paddy!

paddy

Well-known member

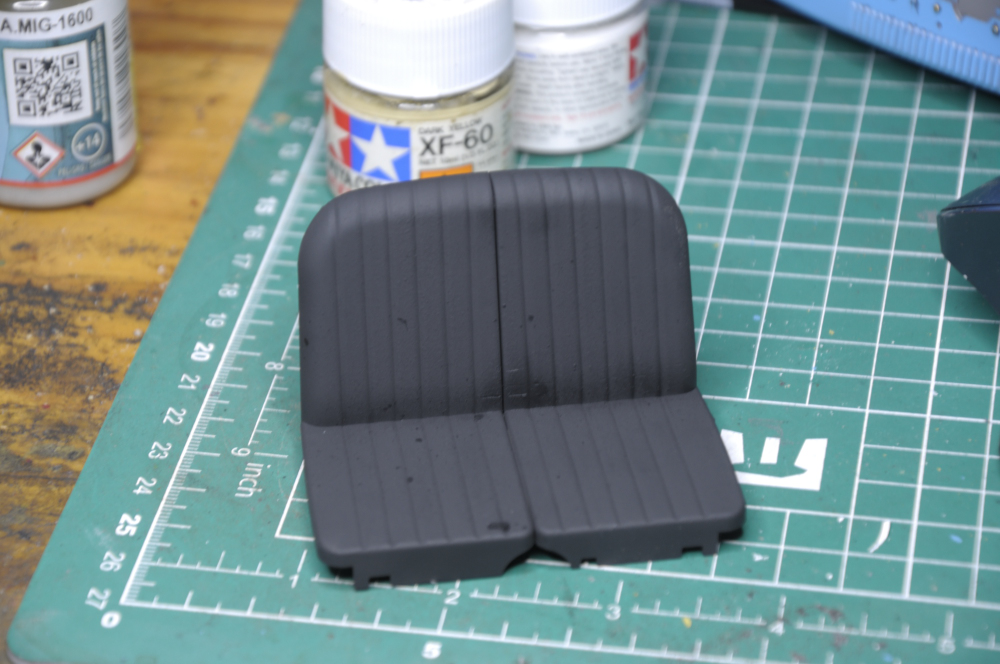

ha ha don't ha ha don't look to me for leather, never have mastered it , Red or brown is easier but Black is hard

Black rubber base coat

Then white and rust pigments for brown leather showing through , some silver and loads of scratches to replicate cracks.

This the best i could do

Black rubber base coat

Then white and rust pigments for brown leather showing through , some silver and loads of scratches to replicate cracks.

This the best i could do

Heavens Eagle

Well-known member

Looks like worn leather to me!

That's what's cool about leather. There's so many ways to get the effect, who's the say it's wrong.

paddy

Well-known member

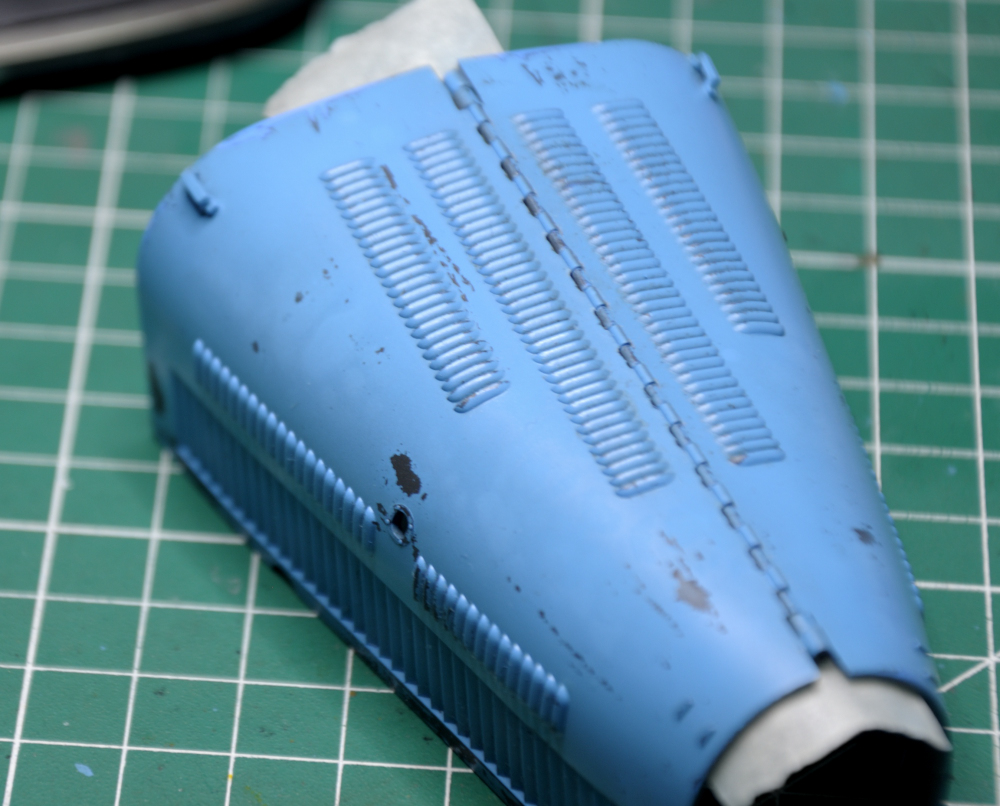

This is another experiment with lock wire using round head screws which are smaller than cheese head

I have also been experimenting with "weathered paint" This i a spray template for a mottled effect available from lots of places, this one is AK, its plastic and washable.

the effect is subtle and difficult to see in a pic but a little more prominent in real life, i just added a small amount of white to the base blue.

I have also been experimenting with "weathered paint" This i a spray template for a mottled effect available from lots of places, this one is AK, its plastic and washable.

the effect is subtle and difficult to see in a pic but a little more prominent in real life, i just added a small amount of white to the base blue.

paddy

Well-known member

Still waiting for my spare part but i thought i would have a look at fixing the wheels..

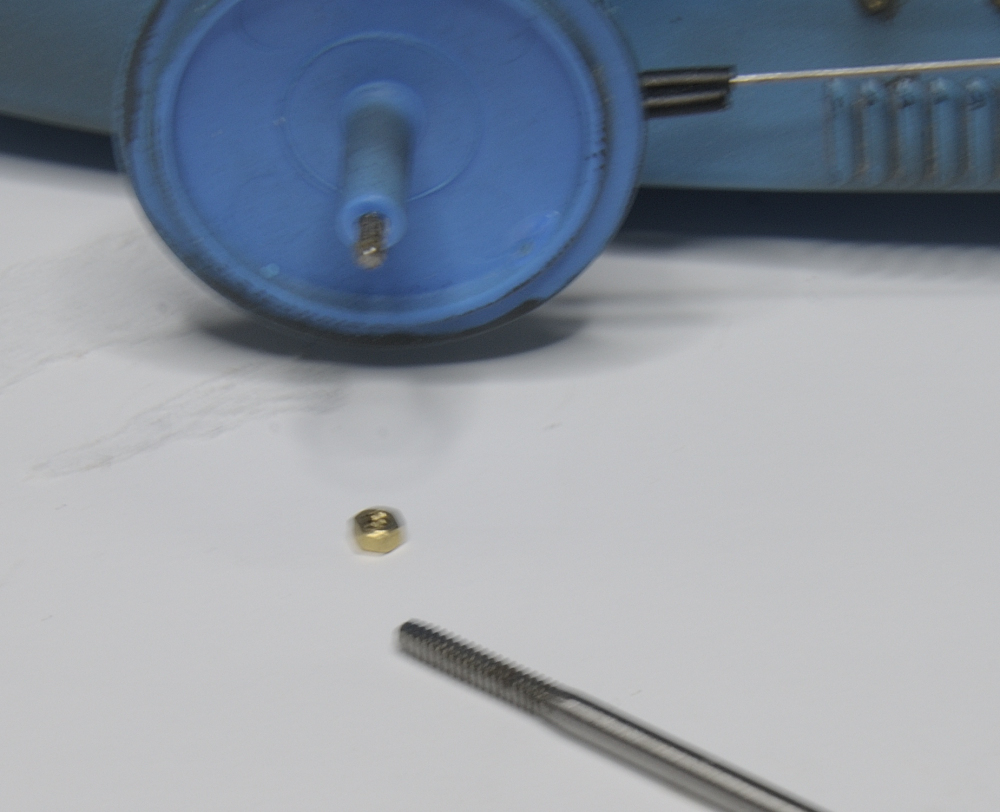

Now my moans about Italeri's obsession with screws and nuts and bolts is probably boring people by now but.....

the wheels are held on to the axel buy a nut and a screw fitted to the wheel hub during construction. the Nut is recessed down a hole and is a tight fit

The nut is 1.4mm so its small. You need tweezers to pick it up....so of course 2 of the 4 nuts supplied pinged out of the tweezers into another dimension, never to be seen again. So now i have 4 wheels and 2 nuts. Next problem is the plastic socket spanner they supply just rounds off because the wall thickness is only 0.5mm in order for it to fit into the wheel nut recess.

I bought a 1.4mm tap and some 12BA brass nuts and taped the threads out to 1.4mm

the tap is out of focus but it still worked

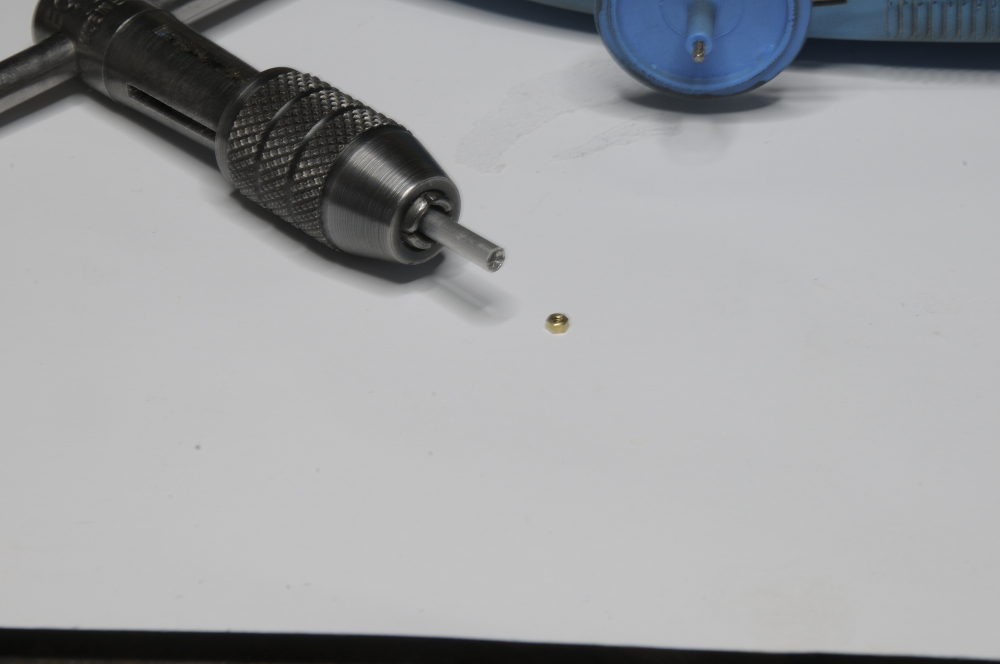

I then had to make a very thin wall socket to fit the nut and still fit in the wheel out of some 3mm alloy tube drilled out 2.3mm and then using a spare nut to press out the hex head shape.

after all that i could fit a wheel

You can just see how little room there is between the wheel nut recess and the wheel nut

Now Italeria ,what was the point of any of this ? A plastic stub axel and a plastic cap glued on the end to retain the wheel would be better, stronger and easier ? in fact the whole thing is so fragile like this there is no point at all in allowing the wheels to rotate on a static model.

I would go so far as to say that on a lot of the model having slotted screws holding the suspension on for example is actually less realistic than a moulded hex head in the part.

In truth this is not really a moan but the point of doing a public thread/build is to allow others to see the good and the bad so i would be failing in not pointing these sorts of things out.

Now my moans about Italeri's obsession with screws and nuts and bolts is probably boring people by now but.....

the wheels are held on to the axel buy a nut and a screw fitted to the wheel hub during construction. the Nut is recessed down a hole and is a tight fit

The nut is 1.4mm so its small. You need tweezers to pick it up....so of course 2 of the 4 nuts supplied pinged out of the tweezers into another dimension, never to be seen again. So now i have 4 wheels and 2 nuts. Next problem is the plastic socket spanner they supply just rounds off because the wall thickness is only 0.5mm in order for it to fit into the wheel nut recess.

I bought a 1.4mm tap and some 12BA brass nuts and taped the threads out to 1.4mm

the tap is out of focus but it still worked

I then had to make a very thin wall socket to fit the nut and still fit in the wheel out of some 3mm alloy tube drilled out 2.3mm and then using a spare nut to press out the hex head shape.

after all that i could fit a wheel

You can just see how little room there is between the wheel nut recess and the wheel nut

Now Italeria ,what was the point of any of this ? A plastic stub axel and a plastic cap glued on the end to retain the wheel would be better, stronger and easier ? in fact the whole thing is so fragile like this there is no point at all in allowing the wheels to rotate on a static model.

I would go so far as to say that on a lot of the model having slotted screws holding the suspension on for example is actually less realistic than a moulded hex head in the part.

In truth this is not really a moan but the point of doing a public thread/build is to allow others to see the good and the bad so i would be failing in not pointing these sorts of things out.

Man that's Nuts...get it...

Heavens Eagle

Well-known member

Excellent rework on the nuts Paddy!

I also noticed something in the last photo. The outer parts of the wheel are dirty, but the back of the wheel on the other side, shouldn't it be a bit on the dirty side as well? It looks clean and shiny in the photo.

As to Italiari, I am even less impressed with them than with Trumpeter. So, sorry you are having to deal with the poor assembly ideas they have put you through.

I also noticed something in the last photo. The outer parts of the wheel are dirty, but the back of the wheel on the other side, shouldn't it be a bit on the dirty side as well? It looks clean and shiny in the photo.

As to Italiari, I am even less impressed with them than with Trumpeter. So, sorry you are having to deal with the poor assembly ideas they have put you through.

paddy

Well-known member

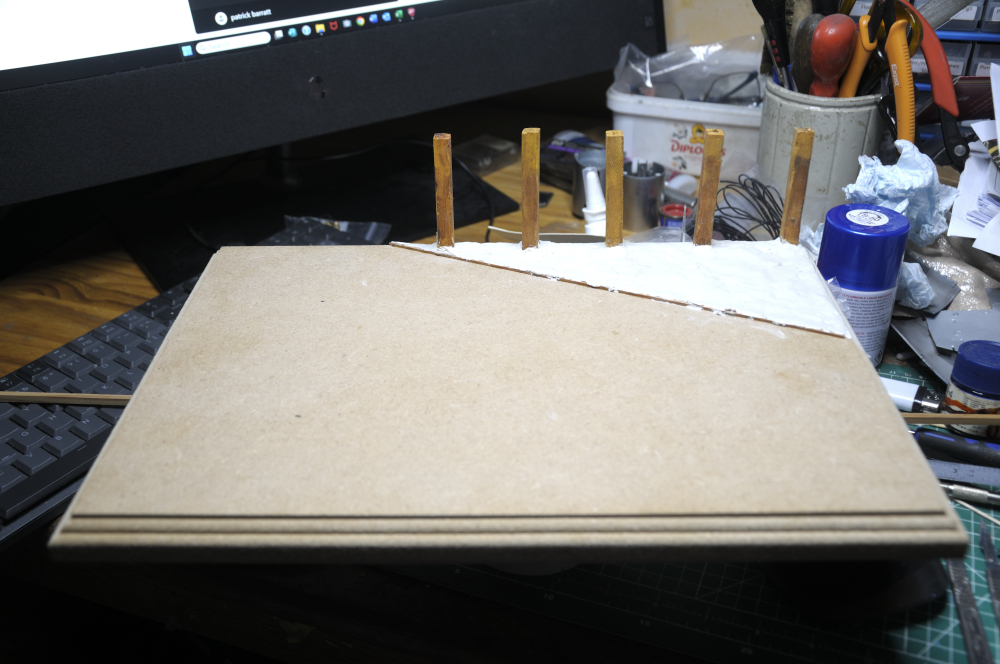

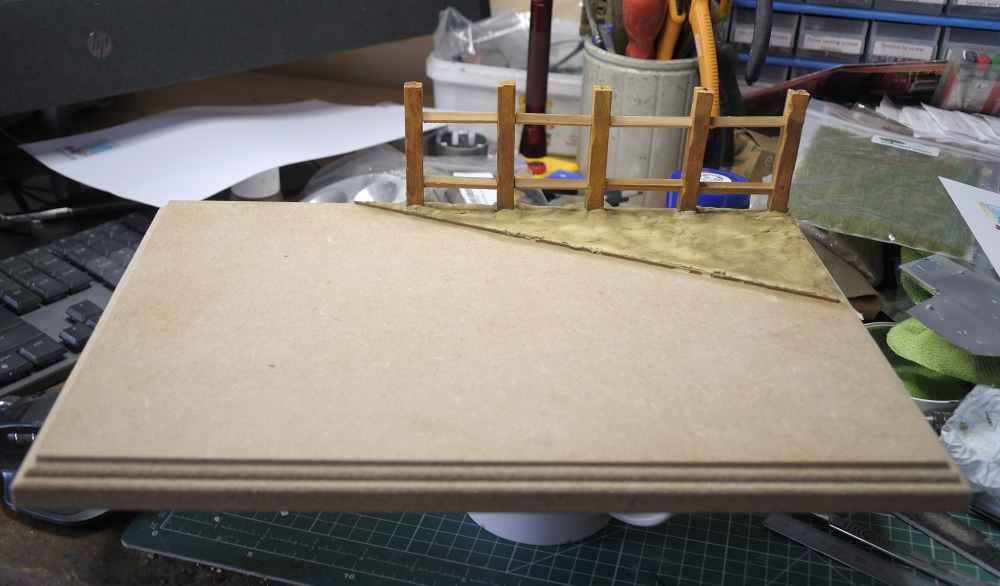

While i "still" wait for a spare part i have started on a base

I am making it up as i go along as i am no good at envisaging things

I am thinking cobbled road and some posters on the fence and i have a 1/.12 toolbox i bough for another build which might find its way here as well.

I am making it up as i go along as i am no good at envisaging things

I am thinking cobbled road and some posters on the fence and i have a 1/.12 toolbox i bough for another build which might find its way here as well.