paddy

Well-known member

Hang there Paddy, didnt you build one of these a while back ?

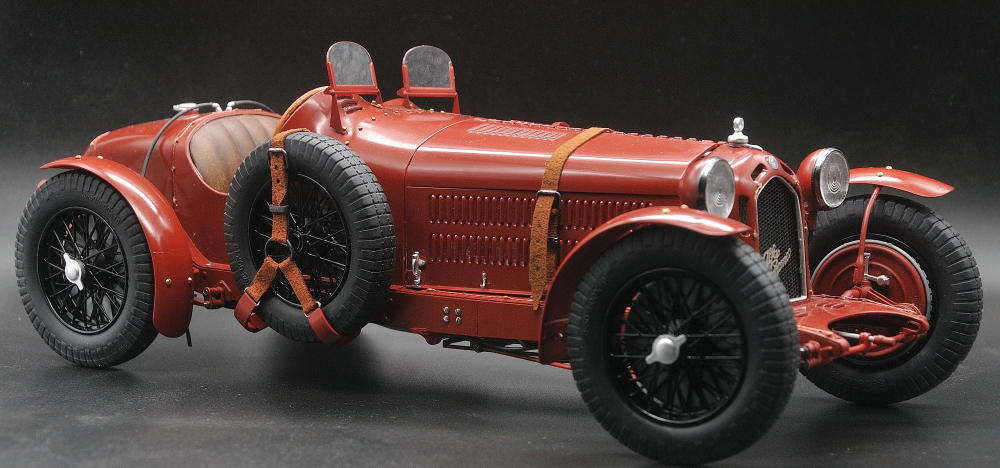

Well yes i did as it happens, but i had problems with shattering parts due to the spirit based washes i used, ill fitting hood, again my fault and i also auctioned it off for Charity so i dont have one of these for myself.

Here is the first attempt

Now i am going to try again to build a model to keep for myself for my retirement collection.

this time it will be a blinged up. I plan to build it as a ferrari badged Alfa in a much brighter Ferrari/ Italian red,

3D printed wheels and a little more chrome. so basically as a Modern restoration rather than a factory fresh finish as before.

Some people don’t know that Enzo Ferrari started out as a racing driver for Alfa Romeo.. Enzo began his relationship with Alfa Romeo in 1920, when he raced in the Targa Florio road race in Sicily. He went on to win several important races and became the director of Alfa Romeo's racing department, Scuderia Alfa Corse. In 1939, Ferrari left Alfa Romeo to establish his own independent racing team. Scuderia Ferrari was Alfa Romeo's official racing team for most of the 1930s. The agreement between Alfa Romeo and Scuderia Ferrari stated that Alfa Romeo would build a certain number of racing cars, and Scuderia Ferrari would participate in all the races

So you see its not too far fetched and here are a couple with ferrari badges

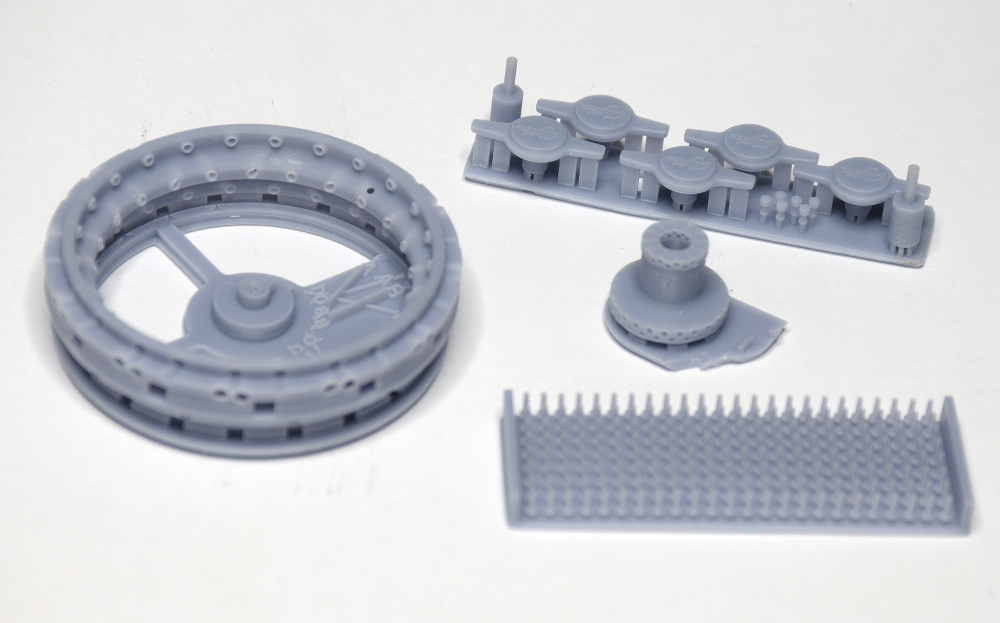

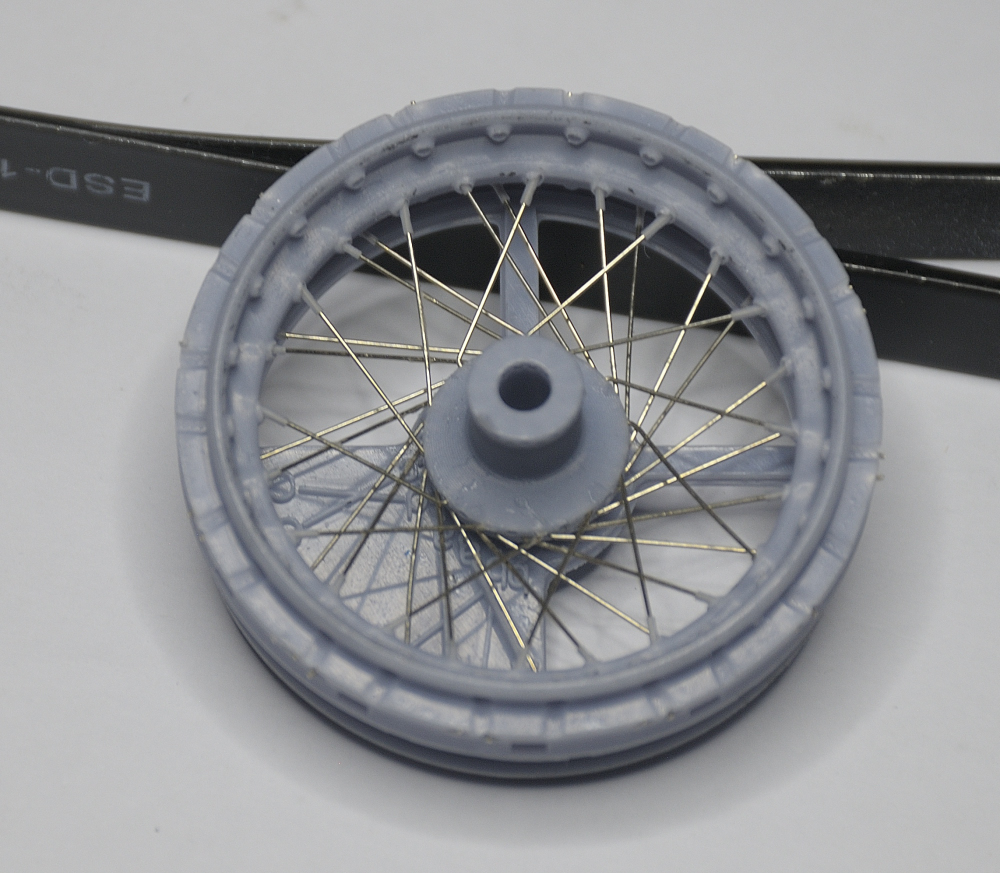

Resin wheels are from a guy who is 3D printing them in the UK, these allow you get more accurate spoke sizes of about 7-8 mm rather than the kit sizes of 12mm to scale

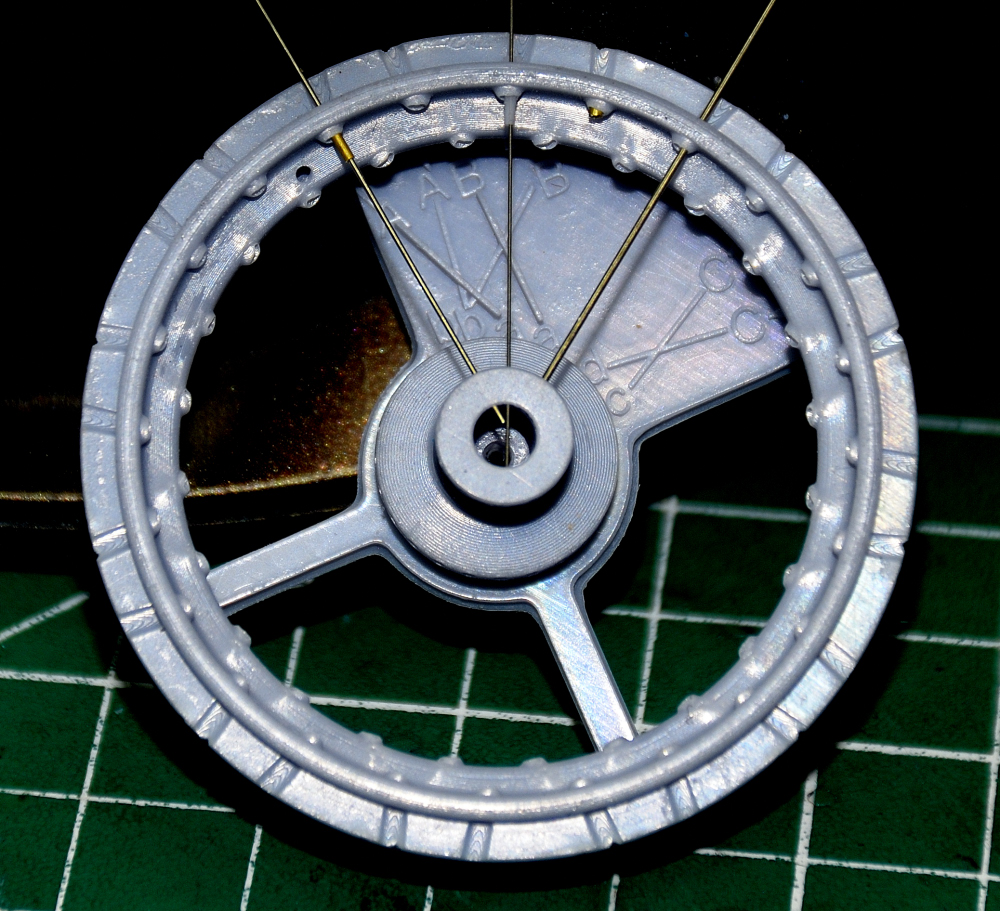

You will need to make your own spokes but you can buy suitable 0.3mm wire on e-bay and in most model shops from albion alloys.

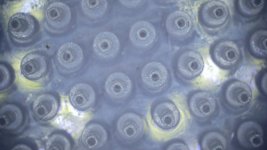

The rim has a frame on the back, its shows where to thread the first spoke for each row and also has a centre (that you cut off later) to hold the hub

Half way

And completed

These are approx 1.5 inches dia and there is 6ft of wire in each one.

One of the problems i had with the first bild was parts that were screwed together where the screws used (self tapping) tended to expand and burst there holes. The other problem was nearly all the external body fixings were lock wired and this was extremely difficult to replicate in this scale however the guy that makes the wheels also makes some 3D printed square head bolts with a hole through them for wiring

We shall see how i get on with these , my only reservation at this point is how fragile these will be if you tighten a wire through them ?

Well yes i did as it happens, but i had problems with shattering parts due to the spirit based washes i used, ill fitting hood, again my fault and i also auctioned it off for Charity so i dont have one of these for myself.

Here is the first attempt

Now i am going to try again to build a model to keep for myself for my retirement collection.

this time it will be a blinged up. I plan to build it as a ferrari badged Alfa in a much brighter Ferrari/ Italian red,

3D printed wheels and a little more chrome. so basically as a Modern restoration rather than a factory fresh finish as before.

Some people don’t know that Enzo Ferrari started out as a racing driver for Alfa Romeo.. Enzo began his relationship with Alfa Romeo in 1920, when he raced in the Targa Florio road race in Sicily. He went on to win several important races and became the director of Alfa Romeo's racing department, Scuderia Alfa Corse. In 1939, Ferrari left Alfa Romeo to establish his own independent racing team. Scuderia Ferrari was Alfa Romeo's official racing team for most of the 1930s. The agreement between Alfa Romeo and Scuderia Ferrari stated that Alfa Romeo would build a certain number of racing cars, and Scuderia Ferrari would participate in all the races

So you see its not too far fetched and here are a couple with ferrari badges

Resin wheels are from a guy who is 3D printing them in the UK, these allow you get more accurate spoke sizes of about 7-8 mm rather than the kit sizes of 12mm to scale

You will need to make your own spokes but you can buy suitable 0.3mm wire on e-bay and in most model shops from albion alloys.

The rim has a frame on the back, its shows where to thread the first spoke for each row and also has a centre (that you cut off later) to hold the hub

Half way

And completed

These are approx 1.5 inches dia and there is 6ft of wire in each one.

One of the problems i had with the first bild was parts that were screwed together where the screws used (self tapping) tended to expand and burst there holes. The other problem was nearly all the external body fixings were lock wired and this was extremely difficult to replicate in this scale however the guy that makes the wheels also makes some 3D printed square head bolts with a hole through them for wiring

We shall see how i get on with these , my only reservation at this point is how fragile these will be if you tighten a wire through them ?