Duke Maddog

Well-known member

I'm at a loss for words to express how incredible this is. Way to go and I wouldn't change a thing. That is very smart of you to keep it as is.

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

I'm at a loss for words to express how incredible this is. Way to go and I wouldn't change a thing. That is very smart of you to keep it as is.

Man, I'm overwhelmed! This is far and away higher quality and skill than I could ever dream of doing!

You are the Master!

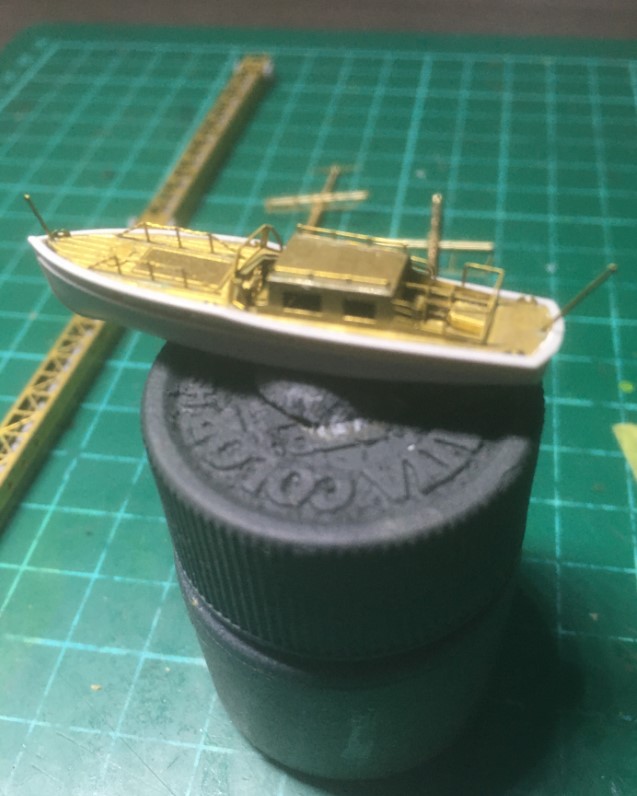

Wow, that is amazing, Laurence!

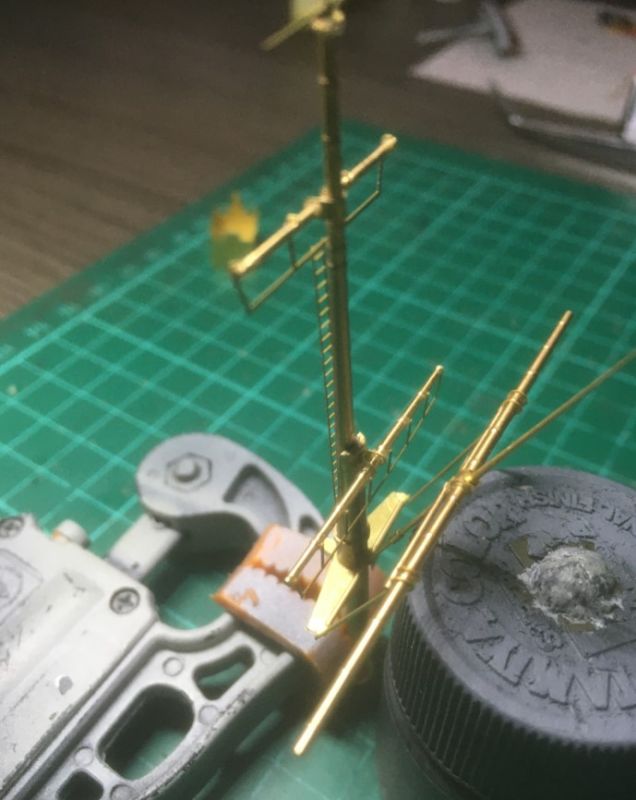

Man, soldering thin brass on thick can be tricky, right Eric?

Man, soldering thin brass on thick can be tricky, right Eric?

Good luck, looking sharp so far.

Man, soldering thin brass on thick can be tricky, right Eric?

That it is!!...

...man Laurence that mast is off the hook!!!

Fantastic Laurence!

This is such a really cool build! It makes me want to build one!

Bob

The trick to soldering tiny parts to each other is to pre-tin both parts. Then all you have to do is hold them together and heat them till the pre-tin flows and bonds. There are quite a number of soldering units available for around $100 that have the capability to solder with hot air. That will work with pre-tinning and solder paste.

This is just freaking amazing Lawrence! Nice work.

I am inclined to use two parts epoxy resin - a very small amount, around the joint, for that extra strength that is always good to have.

Laurence