Wow Jeff, I'll be praying for a swift recovery. I hope you get back to 100% very soon. Glad to see you back on the bench.

Well, I have a lot on the workbench so this will be a pretty long post with tons of pics. Brace yourselves people for a wild ride!

I'll start out with the two F-14's I've been doing for a review. These models are some tough birds to build! This past Hobby Day I decided to try and finish the cockpits/forward fuselage sections. I am only going to show one plane as I go through this as most all of these issues were the same for each aircraft. In the event I need to show differences due to alternate parts for specific variants I'll show the two together.

The first thing I did was I tried to add the instrument panel cowls over the two instrument panels. The forward one managed to fit okay with only some minor adjustment to the instrument panel. The second one required that I break off the instrument panel since it did not fit at all:

So this time, I cemented the instrument panel inside the cowl before adding it back to the cockpit:

That finally fit right. Both cockpit assemblies had this problem and needed to be completed this way.

Another issue I had was when I tried to add the rear cover to the opening behind the second pilot seat. The part would not quite fit the way it was indicated on the instruction sheet below the model:

In order to get that part to fit, you need to push it inside the rear opening as seen above, only push it further back in order to clear the seat. Then, as you are pressing it down, you'll need to also push it forward toward the seat until it snaps into position flat against the fuselage edges like so:

Now it was time to turn these over and complete the assembly by adding the lower panel behind the forward landing gear bay. Once again, I ran into poor fitting parts. I lined up one side flush with the fuselage assembly and found that these panels are too wide:

The solution I came up with was to cement one side and wait for it to dry sufficiently. Then I pressed the other side in until it snapped flush with the fuselage and glued it into place so it was flush on that side as well. Later on I then pressed the forward part down to make it relatively flush along the front join. I figured the shorter step would be easier to sand and be less noticeable that the sanding along the side of the fuselage.

Finally after adding a few more small panels to openings and adding the nose cones, I was able to declare these two forward fuselage assemblies completed:

Now I could move onto the main fuselage parts. I started out with the tail section that holds the tailhook. This went together fairly well so far, considering there are six entire pieces in that assembly:

The steps along the sides are supposed to be there to conform to the main body of the plane when it is assembled. That part on the right side sticking out under the end of the tailhook is one of two different parts. One is for the F-14A and the other for the F-14B. Watch closely to be sure you are adding the right part for the version you are doing.

Next I had to add two side pieces for the main landing gear bays. Why these weren't molded into place I don't know, but I will probably find out later on in this build. They were slightly bent so I needed to glue the one end and then clamped the other end to cement it correctly:

Yes, those are mini clothespins that my wife got me from a local 99-cent store.

Later, after opening the holes I needed to open for the particular weapons system I wanted to load on this; I cemented the two fuselage halves together. These fit pretty well in the front section. At the rear, they fit badly with gaps alongside the L-shaped joint. These joints also stepped unevenly and needed to be adjusted for a flush joint. Putty will be needed to complete the seam repair:

Later I added the tailhook assembly to the rear of this. You can see more clearly here the gap in the rear seam as well:

After all of that frustration with these models, I felt it was time to move onto something else...

I pulled out my F-102 Delta Dagger to get more done on it. I started out finishing a few minor details on the cockpit and then I cemented it inside the two fuselage halves along with the exhaust shroud:

This went together well, I had no seam issues at all. The gap you see on top is because I didn't add cement to the spine of this yet. There is a long opening along the bottom of this that gives no support to the fuselage when pressing it together. So I cemented the ends together and later on when it was dry, I cemented the spine when I could hold it better.

After some time I snapped the wing assembly into the fuselage to see how it fit. This fits like a glove:

That is only dry fit in there!

Later on when I had cemented the spine and let it dry, I then added the nose. Again, the wings are only snapped into place and not glued yet:

Some time after that, I dipped the canopy parts in Future and now they are drying. I should be able to close up the cockpit tomorrow.

Well that's all I got done on my aircraft. Now lets check out my armor work....

Once again, I was a glutton for punishment, trying to make progress on some more difficult models. With all the time I have at Hobby Day to work; Hobby Day weekends are perfect for doing these types of difficult models.

I started out getting the rest of the bogies done on my Sherman with the mineroller mounted. After two and a half more hours, I had these three done and added to the side of the hull:

Another two and a half hours or so later, I finally manage to get all the wheels and bogies mounted on the lower hull. Repeated assembly of these bogies allowed me to get faster with each new one I built:

Next I added the sponson floors to the undersides of the upper hull sides. Afterward I test fit the upper and lower hulls to see how this fit together:

That ain't too bad. I still have to work it a bit, but this will glue together fine. Just for fun, I added the turret and then positioned the mine roller assembly in front of this to see how it was going to look:

This is gonna look cool!

Moving on, I started again on the Russian GAZ fuel truck. Some time before I had slathered on a ton of Mr. Surfacer to fill in the gaps and seams (canyons!) on the sponsons on either side of the tank:

Once that was dry, I carved, sanded and smoothed out this tank, It looks far better now:

While that tank was drying and before I sanded it; I test fit the two parts of the truck cab on the chassis:

Yeah, that is going to take a lot of work to fit right...

For the next hour and a half, I sanded, carved and test-fit that cab together until almost all the gaps disappeared. Finally they were small enough that any gaps left could easily be dealt with easily. Now I added the windows to this cab:

These aren't the best windows ever molded, but they fit fairly well in comparison to the rest of the model. Once they dried, I cemented the two cab parts together and then cemented them onto the chassis. These parts took quite a bit of persuasion to glue correctly:

Finally, when that was dry enough, I added the tank to the rear of this truck:

Now all I have to do is mask the windows, fix the remaining seams and this will be ready for paint. Finally, this is starting to look like a truck!

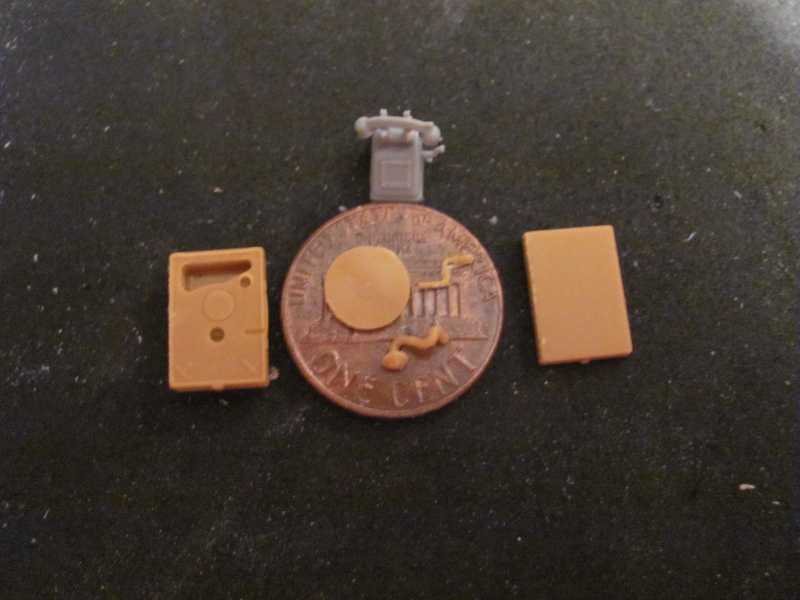

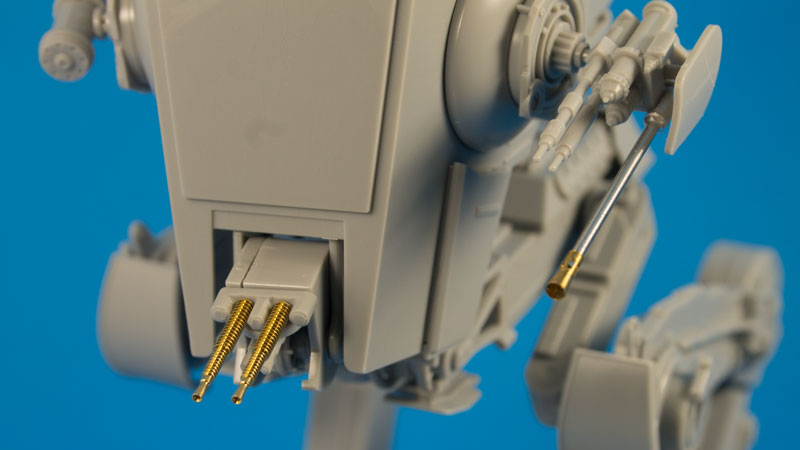

The last model I worked on was my little FWD ammo carrier. I had already painted the camo pattern on this so I took a fine-tipped black marker and drew in all the demarcation lines:

Later on I completed the assembly with all the final detail parts as well as the tilt over the driver's cab:

Now all I have to do is complete the detail painting and then weather this and it'll be done. The next pics you see of this will be completed pics.

Okay, that's all there is happening at Maddog Manufacturing; I hope you enjoyed the factory tour. Thanks all for looking in, comments are welcome.

Stay tuned, more to come.

After all the crap I went through with my late wife years ago I have minimal trust and respect for most medical people. My experience Saturday did nothing to change that.

After all the crap I went through with my late wife years ago I have minimal trust and respect for most medical people. My experience Saturday did nothing to change that.