-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/48 Lockheed CP-140 Aurora

- Thread starter chrispisme

- Start date

Flyingbabydoc

Well-known member

This is a huge project. I would never dare. You are going to need a whole lot of bags of Studenten Futter (you call it trail mix right)

Good luck!

Alex

Good luck!

Alex

chrispisme

Well-known member

Sharp eye my friend.Nice! What were those flaps designed for? 1/48 Herc?

I’ve bought these (AttackSquadron?- now Brengun? flaps) for Italeri’s C-130 (Well they’re both Lockheed products) 2 sets of resin “reskit” wheels for E2C Hawkeye, 2 sets of quickboost props, also for the the Hawkeye. SAC metal landing gear for (again) the E2C and a set for the Grayhound (some fitment adjustments to be decided upon once they arrive. This is the second time I’ve tried ordering the SAC stuff, the first shipment came without them. The pylons (if I remember right) are for a Mohawk...? Does that make it a multimedia kit? Ooorrr just a bastardized kit?

chrispisme

Well-known member

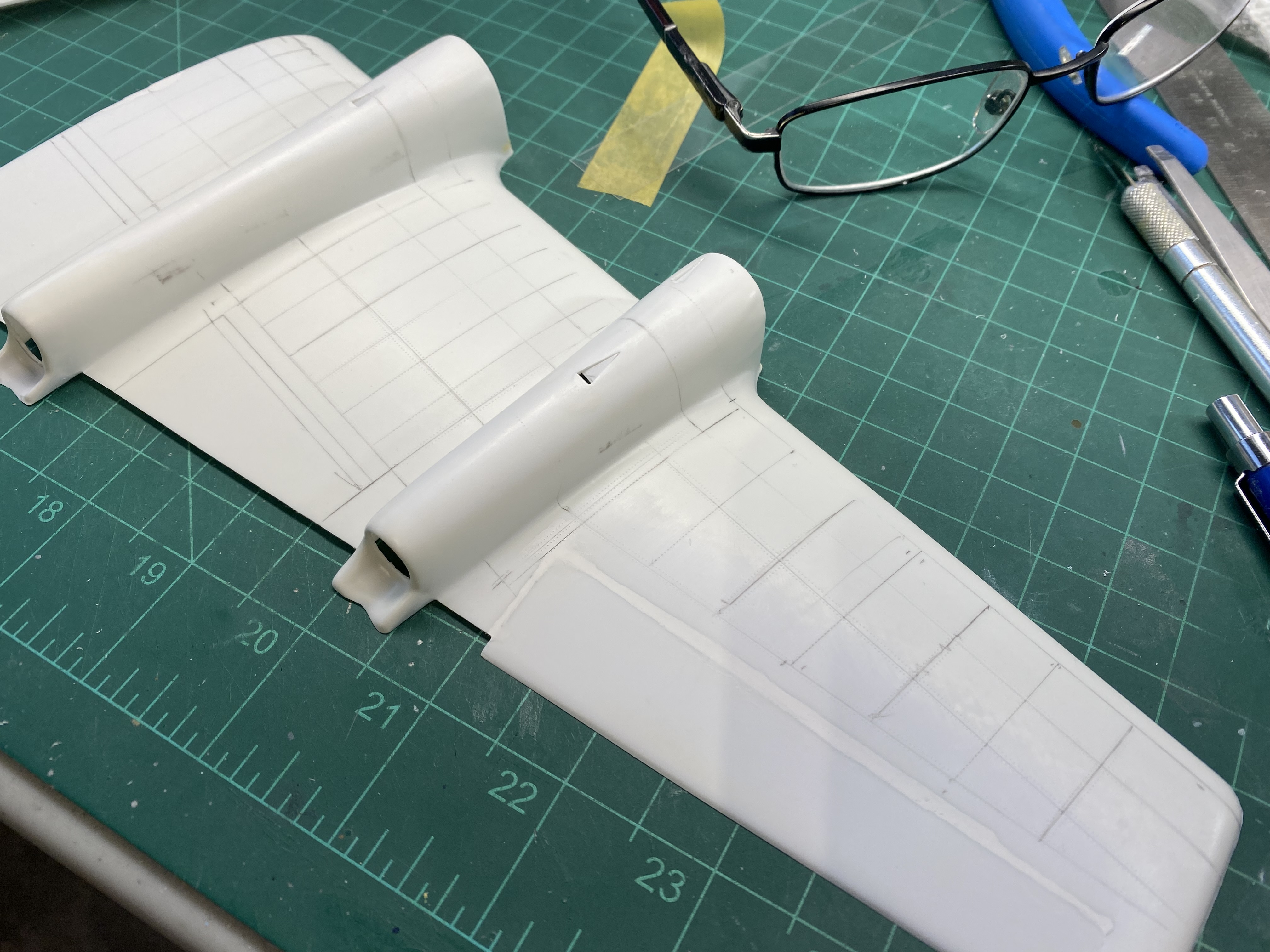

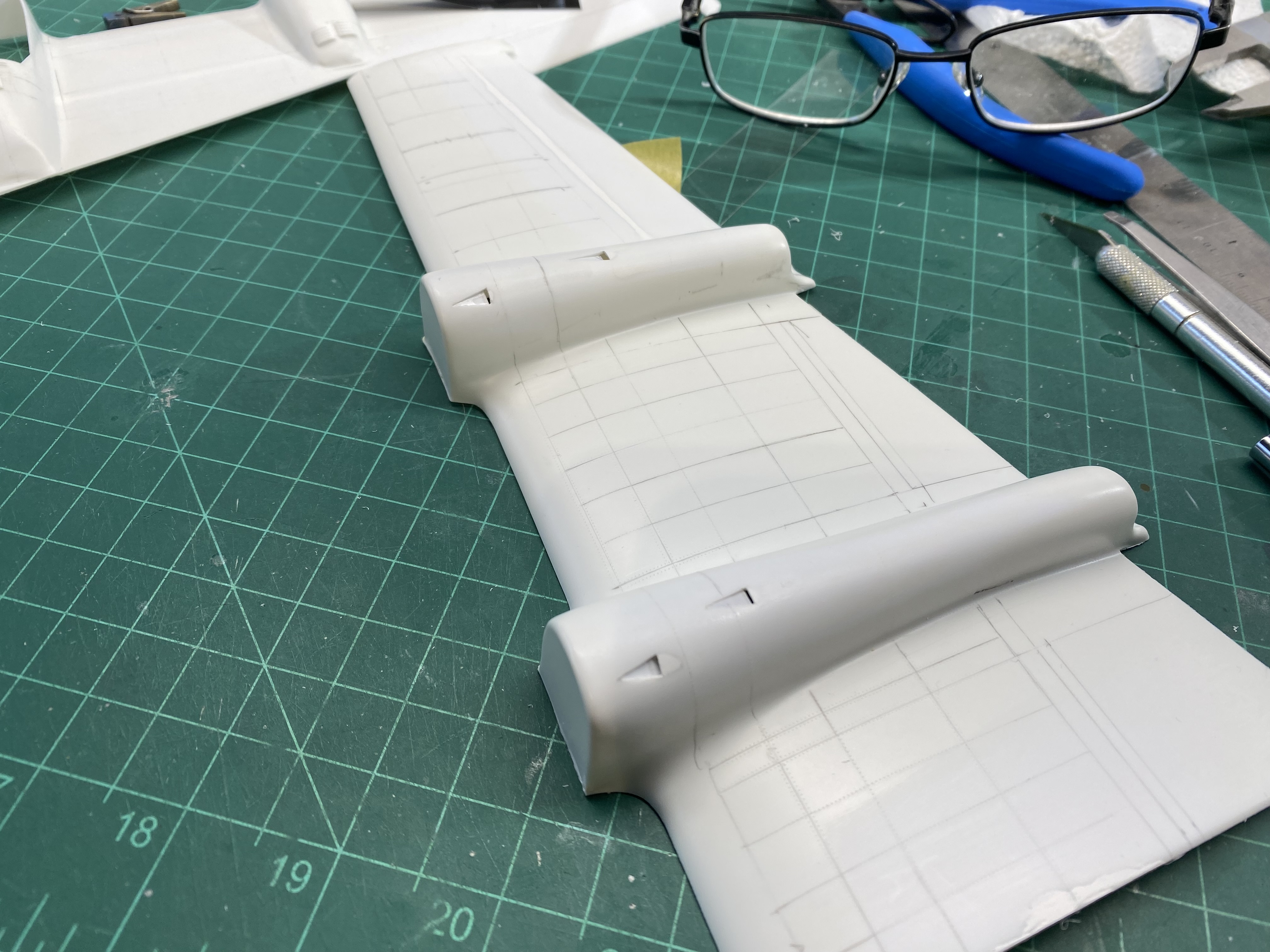

A little more dry fitting/ farting around going on...the devil finding work and all that.

wing spar added I'll notch and add dihedral soon

fitting the flap inserts;

Thanks for looking

wing spar added I'll notch and add dihedral soon

fitting the flap inserts;

Thanks for looking

chrispisme

Well-known member

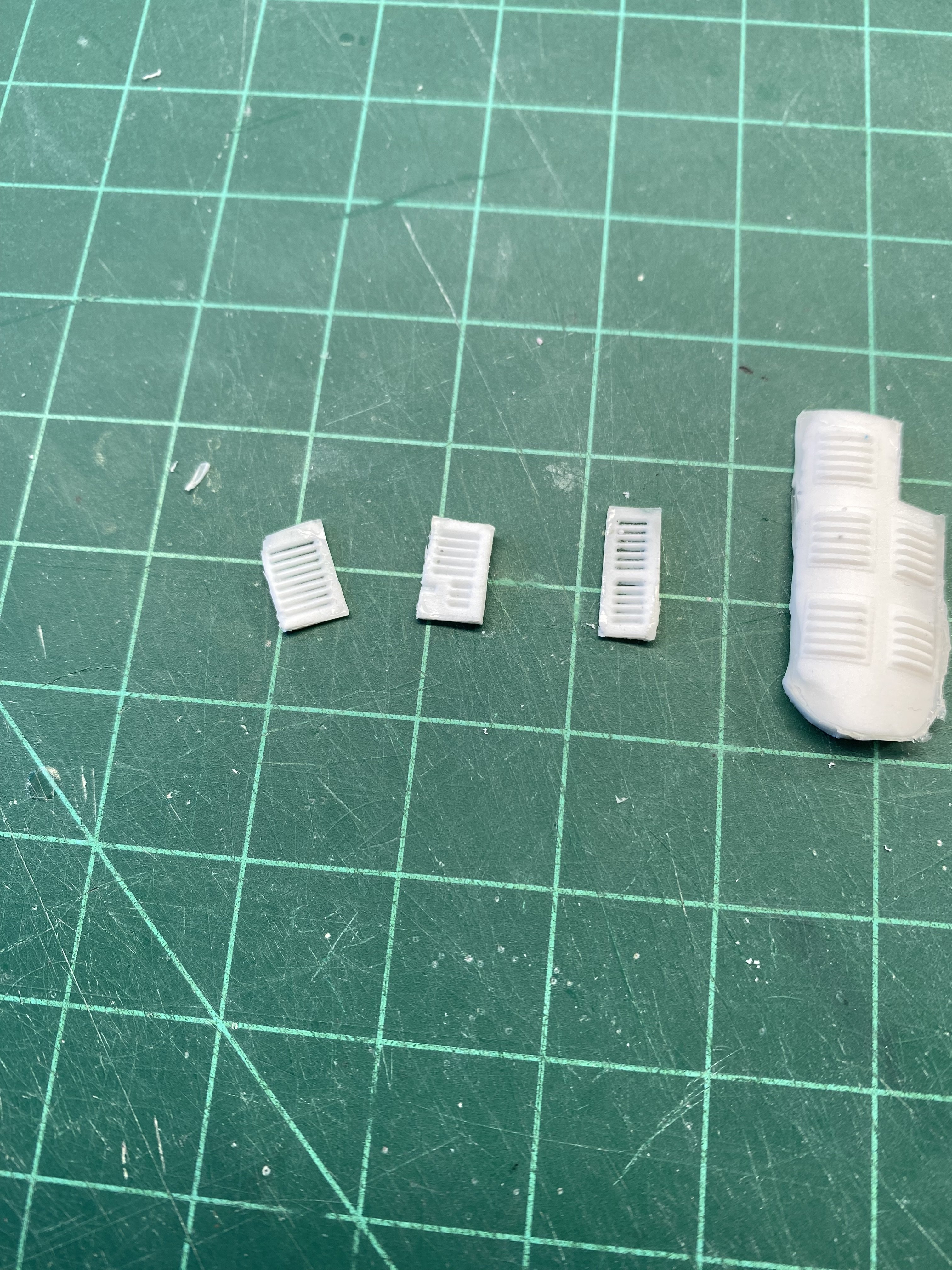

nacelle louvers, silicon and resin copied from a 1/72 Russian helicopter sanded down and test fitting in place

temporary tacked in place

Thanks for looking

temporary tacked in place

Thanks for looking

chrispisme

Well-known member

I've finished adding the vents to the wing lower surfaces, thinking I was getting close to closing the wing halves I figured it's time to do that all important panel line detailing on the wings, I have one wing half scribed and riveted, I'll need to add some access panels but that can be done down the road.

and adding some "wiring harness" to the gear bays;

I'll paint the bays before adding the cabling just to ease painting work. I'm making it in such a way as to be able to add after the wings are built and close up...if that ever happens

Thanks for looking

and adding some "wiring harness" to the gear bays;

I'll paint the bays before adding the cabling just to ease painting work. I'm making it in such a way as to be able to add after the wings are built and close up...if that ever happens

Thanks for looking

It is a gift isn't it!

chrispisme

Well-known member

Gift?…..curse? Tomato Tomato?

now working on an idea I have to re-create the forward upper roof line in order to re-profile the front windshield (it’s too steep making the windshield look flat faced (the included clear part is exactly the same but, clear) I’m thinking I’ll use the kit clear part as a mold, cast it in resin, sand the profile to allow the windshield to slope more and attach it as a “roof” section. A buddy suggests it’s genius…I think it’s more a brain fart unless/until it works….if it pans out I may do the same thing for the lower rear sonobuoy launcher with those sixty million holes in it.

now working on an idea I have to re-create the forward upper roof line in order to re-profile the front windshield (it’s too steep making the windshield look flat faced (the included clear part is exactly the same but, clear) I’m thinking I’ll use the kit clear part as a mold, cast it in resin, sand the profile to allow the windshield to slope more and attach it as a “roof” section. A buddy suggests it’s genius…I think it’s more a brain fart unless/until it works….if it pans out I may do the same thing for the lower rear sonobuoy launcher with those sixty million holes in it.

chrispisme

Well-known member

yup that helps all right.The windscreens are all flat on the Aurora and I would imagine the P-3s. I've replaced a few. If thats of any help.

James

My concern is that the front (forward facing) windshield is almost vertical with very little rearward slope as it angles up to the roof line, the roof line is technically wrong when laid over a general arrangement drawing as well being too flat...but it is a vac. kit and one should expect issues, one wing is longer than the other, the engines further outboard on one wing than the other and so on. I'm not a perfectionist by any stretch but if it's something I may be able to deal with or within my abilities and not going to stall the build I'll give fixing it a try.

Thanks again

chrispisme

Well-known member

Damned Sharkmouth contributing to my delinquency. Posted images of Master static wicks on another thread...had to hunt some down and order them. It's only money right?

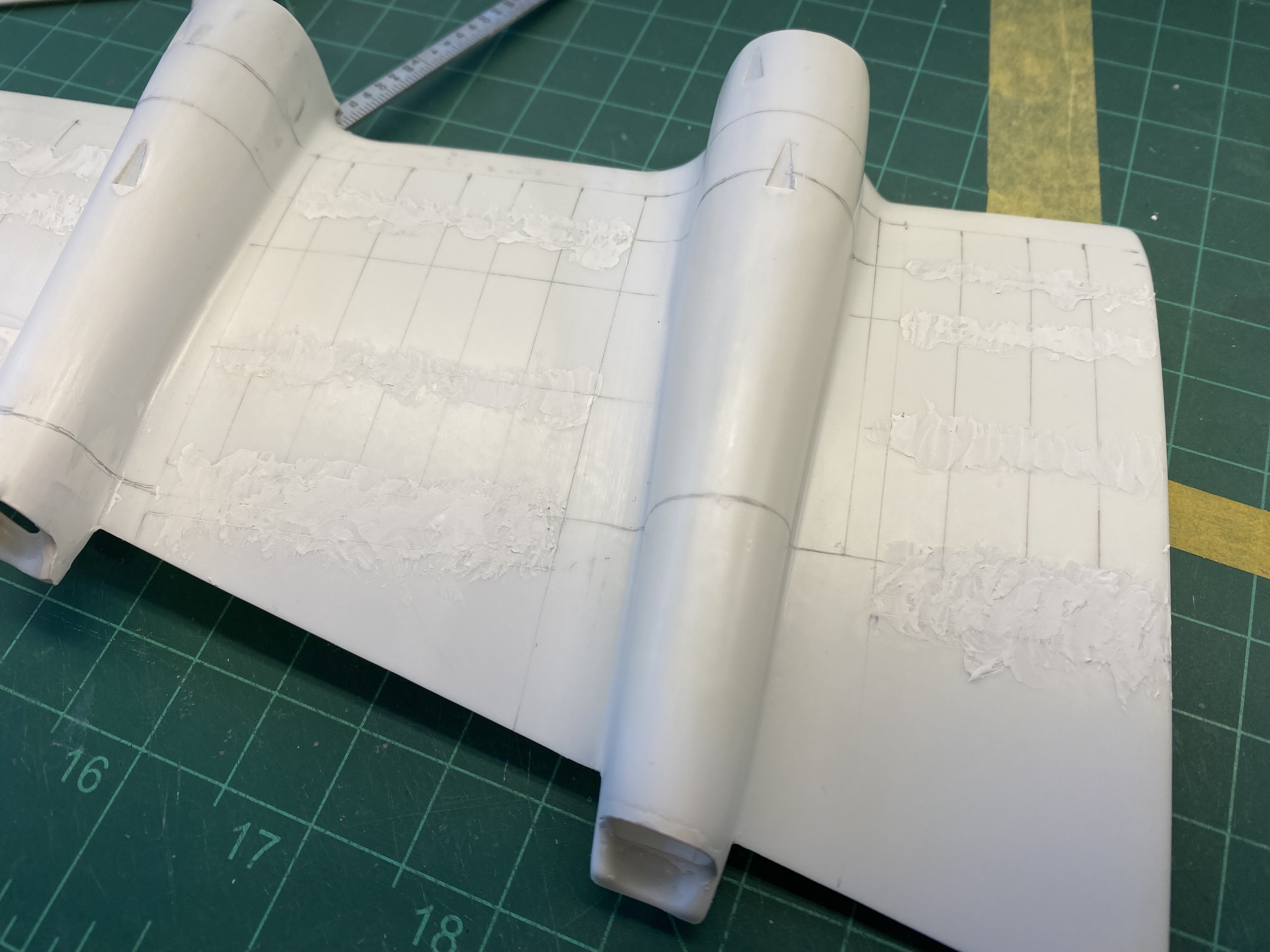

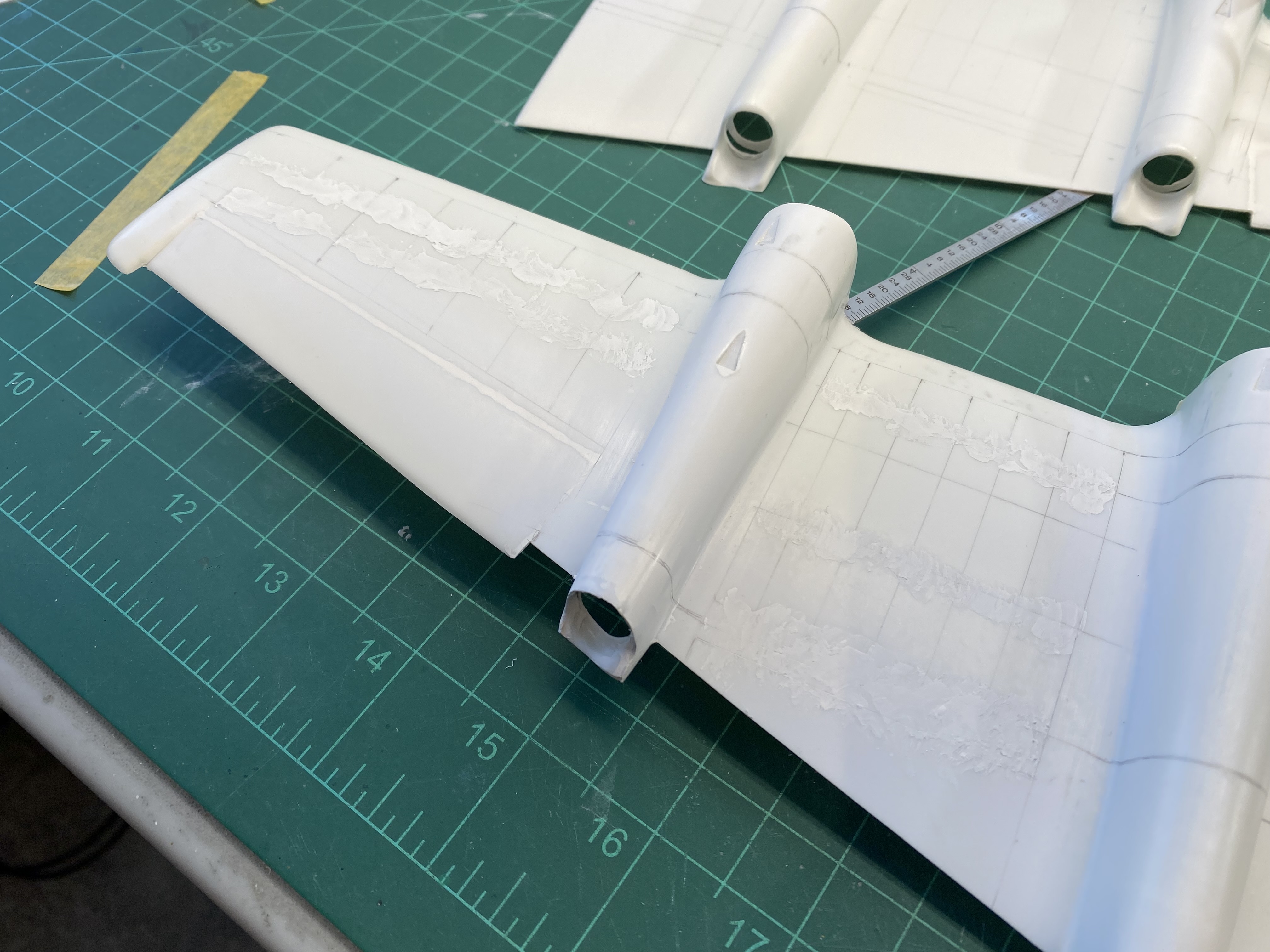

Back on topic, I was scribing panel lines onto the wings finished the long lines when I realized I was following the leading edge not the datum line so my lines are (were) all parallelogram shaped...my dilemma, live with it or putty, sand re-scribe;

Starting over.

Thanks for looking

Back on topic, I was scribing panel lines onto the wings finished the long lines when I realized I was following the leading edge not the datum line so my lines are (were) all parallelogram shaped...my dilemma, live with it or putty, sand re-scribe;

Starting over.

Thanks for looking

By the way, I am not insisting anyone gets them but simply stating they exist.

Damned Sharkmouth contributing to my delinquency. Posted images of Master static wicks on another thread...had to hunt some down and order them. It's only money right?

After all you spent on spinners and flaps... the static dischargers are a drop in the huge bucket of love you're sharing here! Also, I did state my post was to prove they exist!

I'm betting you fill and correct.

chrispisme

Well-known member

You know me too well dude...I'm betting you fill and correct.

The panel line detail and riveting is mostly completed on the main planes, the wing tips will be...modified to represent the sensors and doodads on them. The ailerons will be cut out after the wing upper and lower halves are joined. I thought about cutting them out pre-assembly but the hinge line representations are all different sizes widths/ lengths shapes, the hinge lines aren't even straight for that matter.

I've begun work on the stabilizers now.

Thanks for looking

Heavens Eagle

Well-known member

You might consider placing a strip of plastic between the top and bottom parts in the aileron seam areas before putting the top/bottom halves together. Then pick a line to cut and drill fine holes through to help keep the cutting consistent. This will strengthen the part and you should have a lot less trouble cutting the parts off.

chrispisme

Well-known member

I've "riveted" and scribed the panel lines on the horizontal stabilizers and a first for this project...glued some kit parts together. adding sheet stock allows me to fill the rounded over soft look to the part and add filler to get a much sharper appearance;

Thanks for looking

Thanks for looking

Similar threads

- Replies

- 53

- Views

- 7K

- Replies

- 138

- Views

- 28K