-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/350 US Coast Guard Reliance class Cutter TLAR Models #723

- Thread starter Rhino

- Start date

Rhino

Super Moderator

1/350 Life raft canisters came today from Model Monkey LLC in North Carolina.

Model Monkey® 3D-printing. Products for Scale Modelers.

Model Monkey Direct Sales Catalog of accurate, highly detailed, 3D-printed products for scale modelers. Products are available in scales 1/4 through 1/1250. Products appearing in this catalog are printed by Model Monkey in gray acrylate resin.

www.model-monkey.com

www.model-monkey.com

Last edited by a moderator:

Nice!

Rhino

Super Moderator

Ok, Men. It's time to 'fess up.

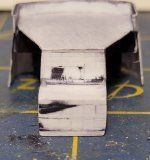

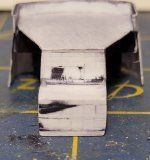

Having captured the basic look of USCGC Dauntless' superstructure, I admit it needs more work. I do NOT wish anyone to think I am some kind of savant or made a deal with the Devil for model Master perfection. I am not and did not. The superstructure was .040" too short (I fixed that), and is .040" too narrow on both sides. The big, angular side spray shields should extend to the edges of the foredeck.

The foredeck and the afterdeck were also .040" too short. This is the corrected freeboard height. I cain't say why every flaw on this Master is a measurement of .040", but that's what the digital caliber measurement is.

My brain gets stuck in 1/700 gear sometimes and everything looks way too big.

The caliper doesn't lie, I just clearly choose NOT to believe it!

It a "Do-Over!" I'm really good at do-over.

This whole project was an experiment. Just to see if I could do it. It's not going so badly.

Thanks again for looking in again!

Having captured the basic look of USCGC Dauntless' superstructure, I admit it needs more work. I do NOT wish anyone to think I am some kind of savant or made a deal with the Devil for model Master perfection. I am not and did not. The superstructure was .040" too short (I fixed that), and is .040" too narrow on both sides. The big, angular side spray shields should extend to the edges of the foredeck.

The foredeck and the afterdeck were also .040" too short. This is the corrected freeboard height. I cain't say why every flaw on this Master is a measurement of .040", but that's what the digital caliber measurement is.

My brain gets stuck in 1/700 gear sometimes and everything looks way too big.

The caliper doesn't lie, I just clearly choose NOT to believe it!

It a "Do-Over!" I'm really good at do-over.

This whole project was an experiment. Just to see if I could do it. It's not going so badly.

Thanks again for looking in again!

You think anyone would notice .04 of an inch???

Rhino

Super Moderator

A lot to time, effort and pride go into making TLAR Models "Just so". My reputation rides on every model. I own the Store!You think anyone would notice .04 of an inch???

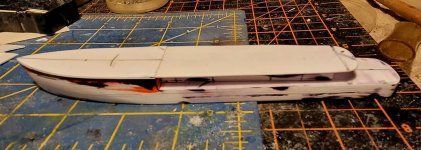

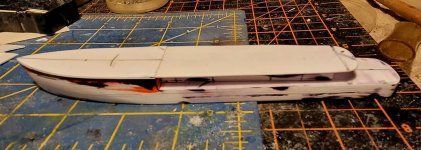

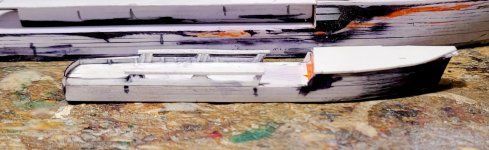

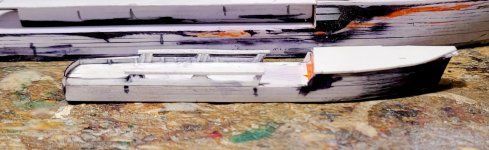

A start was made on the lower hull plate. I usually don't do bottoms, but John asked for a full hull model so this will fill that request.

Now I have a use for all the .040 scraps I made cutting out layers for the solid styrene hull! Waste not, want not!

It looks like the guys at Todd Shipbuilding used similar profiles for their USCG hulls. The 210 lower hull closely resembles the Point class 82' cutter

below the waterline, but BIGGER!

Take a wild guess, if you will, at what fraction of an inch the lower hull is oversize by?

Just wow!

Brokeneagle

Master at Arms

great model skills!

Rhino

Super Moderator

Thanks Bob & Ian! I contend anyone can do this. Scale drawing, digital caliper, calculator and LOTS of wet-sanding sticks!

Water, music and brain-damage could be assets to the process as well.

In the continuing "waste Not" motif, I filled the inside of the Big 210's afterdeck with plastic trash, stray resin bits and a few drops of C/A glue. the underside of the waterline hull got a similar treatment. If the Masters trap any air at all in the mold, all this is all for nothing!

Hunting Shinies, filling with drops of C/A and wet-sanding takes time. While I fill the undersides of the 1/350 ship, I worked on the 1/700 210's superstructure.

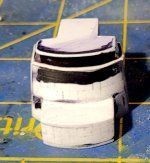

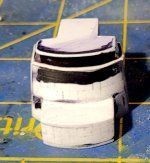

My model eyes like 1/700 best. The Object isn't so grand my brain wanders (more than usual!) Progress is brisk and I have all the P/E parts to detail the smaller WMEC. The 1/700 superstructure does NOT have the accurate open undercuts the 1/350 version does. Molding will not need to be overly complex. See here a properly sized 1/700 Reliance class cutter superstructure!

I fear the 1/700 210' Master suffers from the same mismeasurement her bigger sister did, by 1/2.

The overhead on the afterdeck is .020 too short. A smaller do-over! YAY!

In other ship model news, Back-Aft Models of Millard, NE and TLAR Models are embarking on a joint venture. See here pictures from 2013 of Back Aft's AS-33, USS Simon Lake. USS Simon Lake is just a hair over 11 inches long in 1/700 scale. Molding and casting will NOT be done at my facility. You know, our Kitchen.

10 years ago, the plan was to create a waterline diorama of the US Navy submarine base at Holy Loch, Scotland. Back Aft's 1/700 Los Alamos floating drydock, SSN and SSBN subs made it to production, but AS-33 didn't quite get there. As you can see, Simon Lake's "blacksmithing" is mostly done. I told Carl that my favorite part of Mastering is adding the dinky details.

He shivered a bit when I said that out loud. A Man's faculties may suffer just a bit, as he ages.

I have decided to finish this final Master project from Carl's excellent ship model company and help release Her under his Back Aft Models banner. Mr. Back Aft hisownself will make the molds, pour the castings and write his usual thorough instructions.

I am honored to be asked to finish such a thing by my good friend and resin model mentor.

I think She deserves a BIG finish and I get to have all the fun!

Thanks for enduring another of my lengthy narratives!

Water, music and brain-damage could be assets to the process as well.

In the continuing "waste Not" motif, I filled the inside of the Big 210's afterdeck with plastic trash, stray resin bits and a few drops of C/A glue. the underside of the waterline hull got a similar treatment. If the Masters trap any air at all in the mold, all this is all for nothing!

Hunting Shinies, filling with drops of C/A and wet-sanding takes time. While I fill the undersides of the 1/350 ship, I worked on the 1/700 210's superstructure.

My model eyes like 1/700 best. The Object isn't so grand my brain wanders (more than usual!) Progress is brisk and I have all the P/E parts to detail the smaller WMEC. The 1/700 superstructure does NOT have the accurate open undercuts the 1/350 version does. Molding will not need to be overly complex. See here a properly sized 1/700 Reliance class cutter superstructure!

I fear the 1/700 210' Master suffers from the same mismeasurement her bigger sister did, by 1/2.

The overhead on the afterdeck is .020 too short. A smaller do-over! YAY!

In other ship model news, Back-Aft Models of Millard, NE and TLAR Models are embarking on a joint venture. See here pictures from 2013 of Back Aft's AS-33, USS Simon Lake. USS Simon Lake is just a hair over 11 inches long in 1/700 scale. Molding and casting will NOT be done at my facility. You know, our Kitchen.

10 years ago, the plan was to create a waterline diorama of the US Navy submarine base at Holy Loch, Scotland. Back Aft's 1/700 Los Alamos floating drydock, SSN and SSBN subs made it to production, but AS-33 didn't quite get there. As you can see, Simon Lake's "blacksmithing" is mostly done. I told Carl that my favorite part of Mastering is adding the dinky details.

He shivered a bit when I said that out loud. A Man's faculties may suffer just a bit, as he ages.

I have decided to finish this final Master project from Carl's excellent ship model company and help release Her under his Back Aft Models banner. Mr. Back Aft hisownself will make the molds, pour the castings and write his usual thorough instructions.

I am honored to be asked to finish such a thing by my good friend and resin model mentor.

I think She deserves a BIG finish and I get to have all the fun!

Thanks for enduring another of my lengthy narratives!

Rhino

Super Moderator

I am searching for P/E that has enough huge cranes to make a decent model of the Old Lady. Not so unlike TLAR Models, Back Aft Models makes/made subjects nobody else does. I hope them Friggin' Froggies at Black Cat don't make a 1/350 USCG Reliance class in their scavvy 3D printer for $200.00 before I finish my kit!

The 1/700 ship got her .020 upgrade to scale freeboard. I extended the aft bulwarks to fit the after/flight deck with .030 worth of evergreen strip.

This gives her a stake bed pick-up look. I will trim off the unnecessary parts that span the bulwark before She goes to mold.

"Daddy, will I have the Smokestack option like you do one day?"

"Well, M'boy, you'll have get quite a bit bigger before I'll allow you to smoke."

Reliance class 210's sported 2 different pilot houses post 1987 overhaul. The Big Cutter kit will include both.

USCGC Active, WMEC-618 has her smokestack mod, but retained Her original Sturgeon Bay, WI 1966 pilothouse.

Thanks again for looking in!

The 1/700 ship got her .020 upgrade to scale freeboard. I extended the aft bulwarks to fit the after/flight deck with .030 worth of evergreen strip.

This gives her a stake bed pick-up look. I will trim off the unnecessary parts that span the bulwark before She goes to mold.

"Daddy, will I have the Smokestack option like you do one day?"

"Well, M'boy, you'll have get quite a bit bigger before I'll allow you to smoke."

Reliance class 210's sported 2 different pilot houses post 1987 overhaul. The Big Cutter kit will include both.

Thanks again for looking in!

Greg Kimsey

Well-known member

Cool video!

Heavens Eagle

Well-known member

A wee widdo boat.

Rhino

Super Moderator

The Barnegat class served as seaplane, PT boat tenders, Coast Guard cutters and submarine tenders. Along with this ASR, the possibilities seem boundless, do they not? Said "Wee Widdo Boat" are my favorites to model, unless some Communist sumbitch already makes a better ship model.

They never do. Wonkers! Pracks!

They never do. Wonkers! Pracks!

Rhino

Super Moderator

Pouring the voids in the bow of the lower hull with resin worked fairly well. Milliput was to chunky, Tamiya putty would have taken a long time to cure and would been very expensive. I put some scrap evergreen in the stern half of the lower hull and inclined the bottom to keep the resin from running out astern. Making this part of the master is tedious, indeed.

More to come!

Rhino

Super Moderator

I'm spending almost as much time working on the lower hull as I did the rest of the Cutter. The price a Man pays for being unable to accept mediocrity, I suppose. Hunt shinies, dab c/a glue, wait. Sand, black sharpie, hunt shinies. repeat

This is getting very tedious.

The modern day 210' will carry 2 Mk.2 24-foot OTH (Over The Horizon) RHI boats. Seating for 5, helm, GPS, Radar and a bow mounted light machine gun. The Mk.2 is jet driven and inboard diesel powered.

This is a whole different kind of tedious. A welcome diversion from the Bottom I don't like to do.

Thanks again for looking in!

Similar threads

- Replies

- 70

- Views

- 7K

- Replies

- 41

- Views

- 6K

- Replies

- 36

- Views

- 7K