-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/350 US Coast Guard Island class 110' Cutter. TLAR Models #425

- Thread starter Rhino

- Start date

Rhino

Super Moderator

Here's a dandy snap of CGC Orcas. Her afterdeck is a busy place, indeed! This will help with placement of details as the ship nears molding.

No, I won't be making any bloody 1/350 Wheelie-bins. Orcas looks as if she is standing out to sea for a cruise of some length.

(Credit to Military magazine)

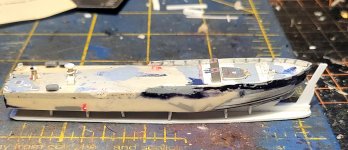

I frame/support my Masters. The "Big Dogs" of resin ship model making make a flat mold and pour them much more rapidly and efficiently than I do, but then you have to wet sand the leftover resin wafer away perfectly to make a good fit. My method creates lots more waste resin, (that my customers never see) but simplifies the clean-up to assembly process. I think nautical objects have bottoms.

Quality, simplicity of assembly and model fun are tantamount at TLAR Models.

After the framework is on, more delicate details can be added without fear of knocking them off the Master on the way to the mold box. Handrails and firefighting hose racks are glued on with Tamiya X-22 clear, or Future. I'll add the piping to to the hose racks when I'm sure the acrylic clear has cured completely. I can still do SOME plumbing!

This project is going much better this go than she did before.

Thanks for looking in!

Rhino

Super Moderator

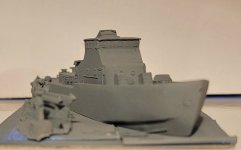

CGC Knight Island in a well-lit daylight snap! Not near as much firefighting plumbing to do on her portside.

I've got the hull pretty much the way I want it. It looks a mess now, bur she'll be much more pleasing to the eye when she's cast in cool gray LPP. I'm hoping the life raft canisters stay level and plumb. Sometimes, as X-22 cures, attached details "squirm" just a bit. I ordered fairleads for the stern, but installed the 3 I made up early this morning. She's in the mold box on the window sill for safe keeping.

She may go to mold before Halloween! Just a few more bits to fabricate and frame up! Yippee!!

Thanks again for looking in!

So many nautical terms...confused. Good luck with the casting!

Heavens Eagle

Well-known member

Practice makes perfect and improves the skills Chris. I always like to watch you build your masters.

Rhino

Super Moderator

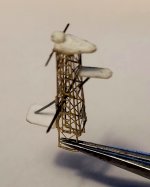

1/350 scale USCG Island class WPB major assemblies, Cape Island lobster boat, 25' MSB, and Mk. 38 cannon. The round mold contains my Dad's old 16' Larsen ski boat, the cutter's rescue boat and outboard, SATCOM domes, extra equipment lockers, and a few scale 55 gallon barrels.

You always get bonus accessories in my model kits.

RTV coming up, as soon as I finish the crane components. Base, arm and cradle.

This was a very productive Sunday.

Rhino

Super Moderator

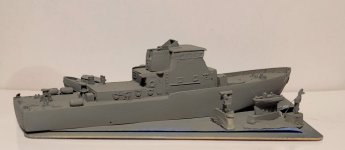

I am well pleased with how the 1/350 Island class cutter molds cast. I went to work on the box art model right away. I'll give her a bath and spray the reefer gray primer yet tonight. The dome antenna mold from the 210' kit will be returned to service for the WPB kit as production goes forward. Assembly of the LPP parts isn't overly complex. Fixing the P/E cage mast will be the most fiddly bit. My Dad's old Larsen ski boat is particularly noice!

Rhino

Super Moderator

Primer job on the 1/350 USCG Island class WPB, rescue boat and 25mm gun, and Cape Island lobster boat. You can see how nicely capillary action pulled the Future into the teeny gap between the hull and superstructure of the 110. She'll rest overnight before any more paint work is done, but the primer really shows the details of the cutter model. I Mastered her at speed, on the step, with someplace to go. Sand her hull flat another .040 for dockside display

Heavens Eagle

Well-known member

That ship looks really good Chris. I will be looking forward to seeing it in paint.

Rhino

Super Moderator

Initial flat white paint for the 1/350 USCG Island class cutter kit. This is the "Leave it alone until the paint cures." part that I'm really not good at! There are a few tiny flaws in the hull, but rather than striving for the perfect cutter, I chose to focus on the fun of building this kit.

Unlike the 1/700 version of this iconic Coast Guard vessel, the 1/350 kit will not include islands, lighthouse and keepers cottage.

The "Diorama-in-a-box" is reserved for waterline scale modelers.

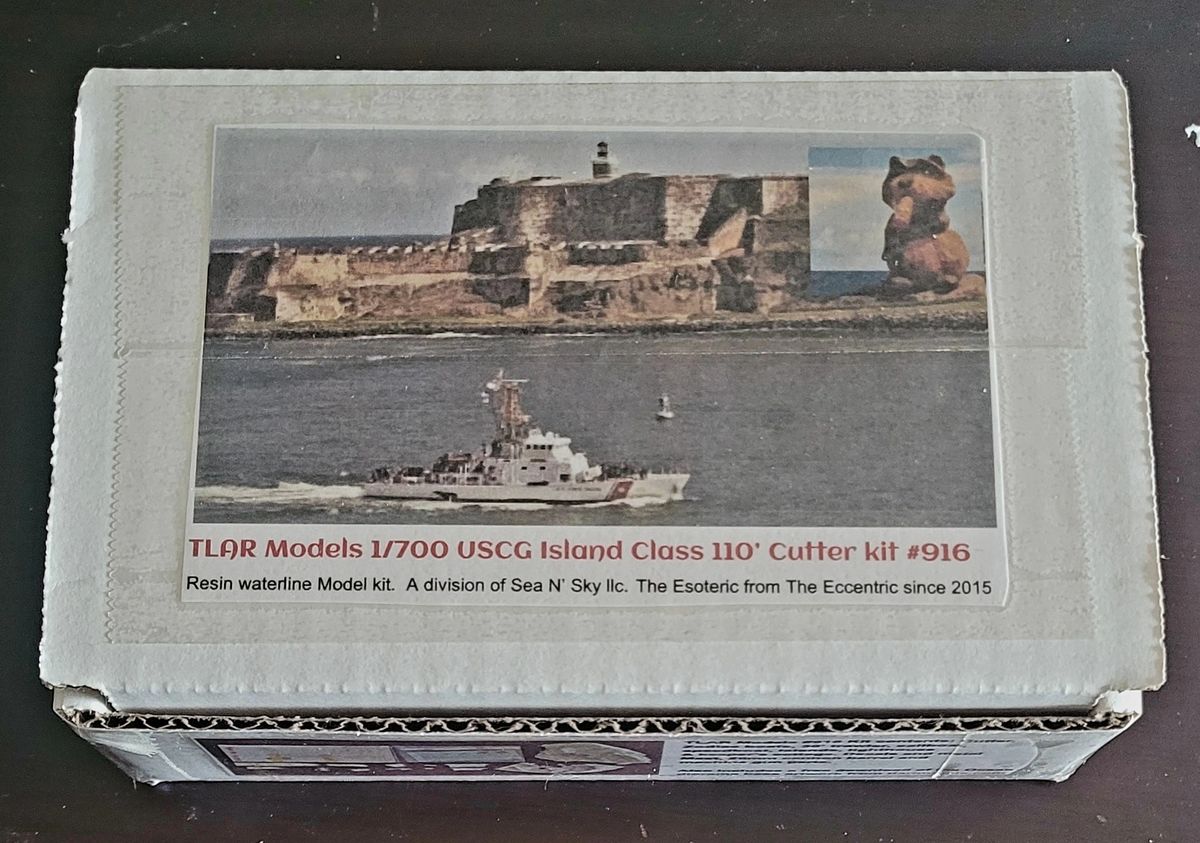

1/700 Resin USCG Island class 110' Cutter Set TLAR Models #916

TLAR Models 2025 re-issue of my very popular 2016 1/700 scale waterline US Coast Guard Island class 110' Cutter set #916. A " US Coast Guard Diorama in a Box"! New Box! New Island class 110' WPB model! New Islands! New lighthouse! New trawler! An Island class Cutter deserves and Island...

tlarmodels.com

tlarmodels.com

Rhino

Super Moderator

It was a very productive Cutter Tuesday! I figger it's time to start working on decals.

My kit mast will not fit the way the actual one does, and mine is one section too tall, but it will have to serve. The idea is to have fun building rather than pursuing perfection nobody truly ever achieves. If I add enough electronical antennical gadgets, it should look very interesting!

That's sharp!

Rhino

Super Moderator

It's easy in 1/350 scale!That's sharp!

Similar threads

- Replies

- 41

- Views

- 6K

- Replies

- 276

- Views

- 34K

- Replies

- 130

- Views

- 13K