Thought I'd share what I attempting.

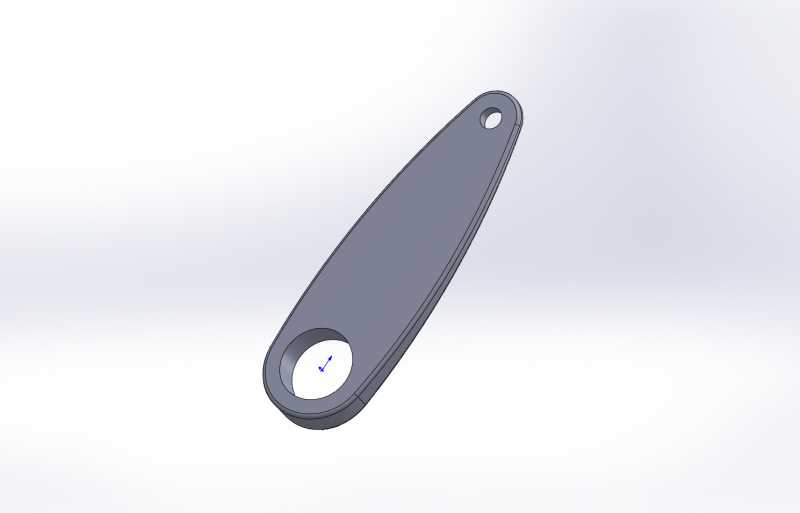

We need brass control horns for these WnW and any other of the ol' WWI aircraft we've been building lately.

No I didn't draw this, our R&D Engineer at work whipped this out in about 10 minutes, my describing it to him slowed him down. He's an old Ultralight pilot (that means he gave it up ) so he knows what a control horn is.

) so he knows what a control horn is.

Top hole is .3mm, plenty big for Ezline or a simulated bolt. Bottom hole is 1mm for the connecting rod.

Send the file off to Shapeways but it's too small. Think I'm going to get him to put like 6-8 of them on a runner and maybe then they can print it.

Whacha think?

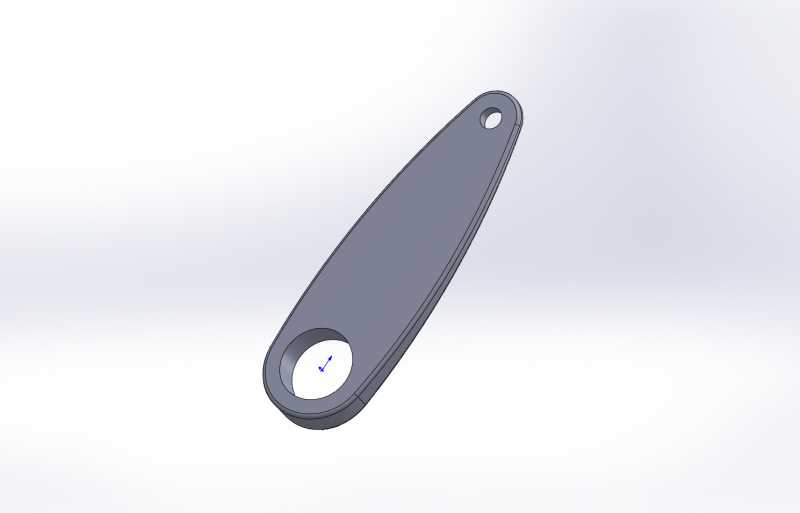

We need brass control horns for these WnW and any other of the ol' WWI aircraft we've been building lately.

No I didn't draw this, our R&D Engineer at work whipped this out in about 10 minutes, my describing it to him slowed him down. He's an old Ultralight pilot (that means he gave it up

) so he knows what a control horn is.

) so he knows what a control horn is.

Top hole is .3mm, plenty big for Ezline or a simulated bolt. Bottom hole is 1mm for the connecting rod.

Send the file off to Shapeways but it's too small. Think I'm going to get him to put like 6-8 of them on a runner and maybe then they can print it.

Whacha think?