While working on the diorama base - made of wood by yours truly, found some time to put other little things together.

The intention was to make good on all the camo stripes on the hull and superstructure, line them up nicely, but, given the heavy rain and winds over the past few days, painting on the balcony has been impossible. As such, I worked on other areas.

Sea planes - Bismarck had four Arado 196. The MK detail kit gives the option to show the planes with folded wings too, so, I will be showing one plane on the catapult, ready to be stowed away in the hangars, and one or two planes with folded wings, already in the hangars. There were three hangars on the Bismarck 2 x 1 plane each, 1 x 2 planes.

That's what it looks like in 1/200th scale - cockpit is PE too, the dash is not in yet, also PE. Everything else cockpit (except for the MG) is already there and impossibly small - there are 8 pieces of PE there in the photo for the stuff that goes in the cockpit. This will obviously be one plane with folded wings.

Two planes, I will show one being pulled from the catapult, getting ready to be stowed away.

More PE bits showing here.

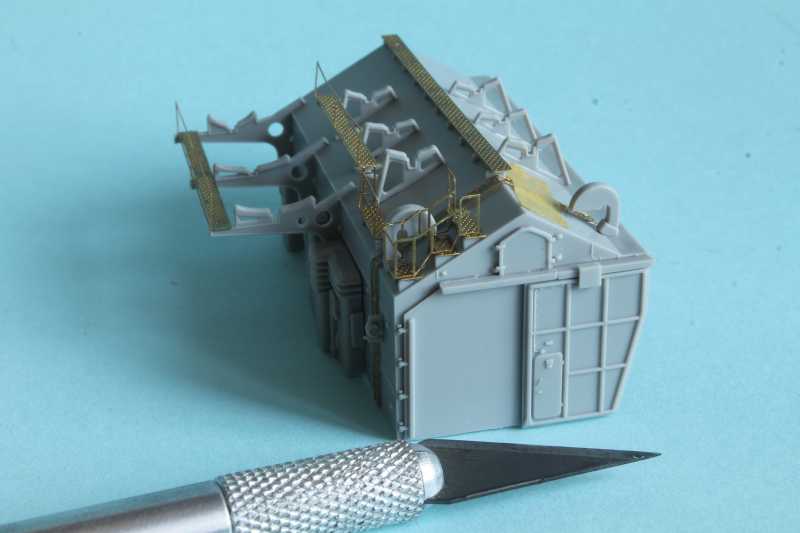

These are parts of the smoke stack - there is a ton of PE. When done, the smoke stack will have over 150 pieces of plastic and PE. That's over 10% of the whole kit AND MK1 detail kit. Madness.

Thanks for watching.