Big10

Well-known member

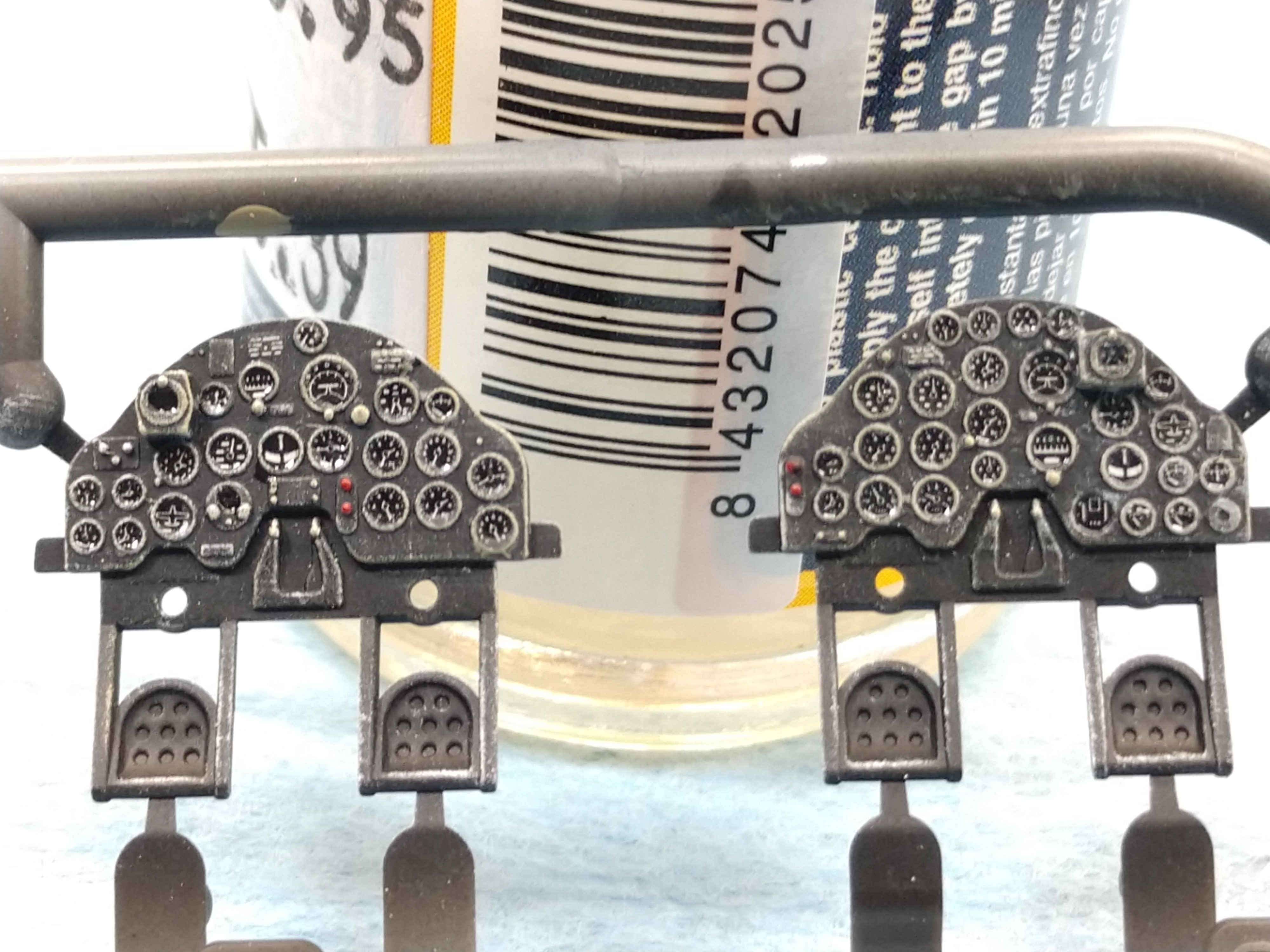

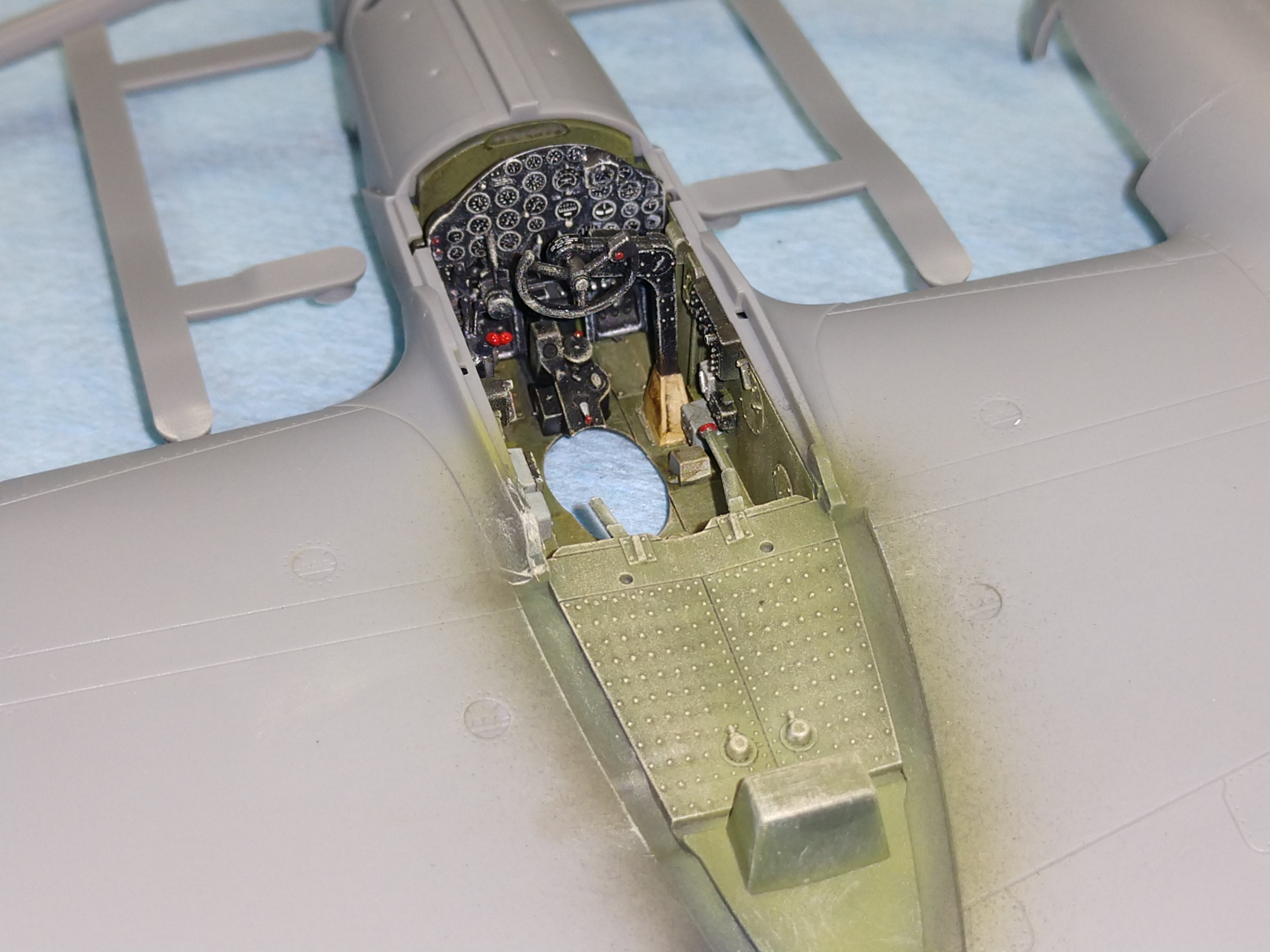

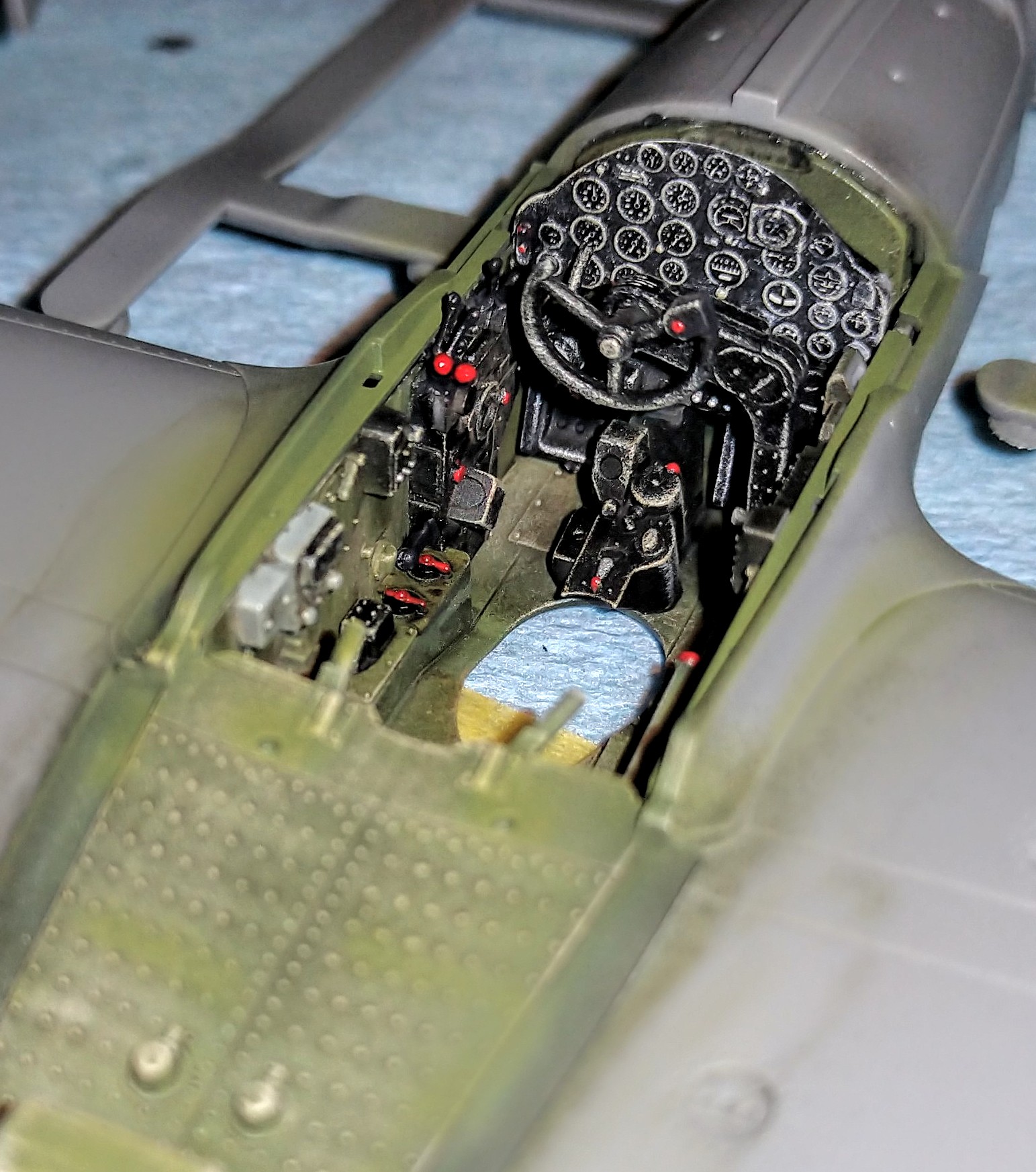

Time for a break from Mustangs for a bit. Gonna take a crack at Tamiya's P-38. I ended up using their decals for the IP panel that did not turn out too bad.

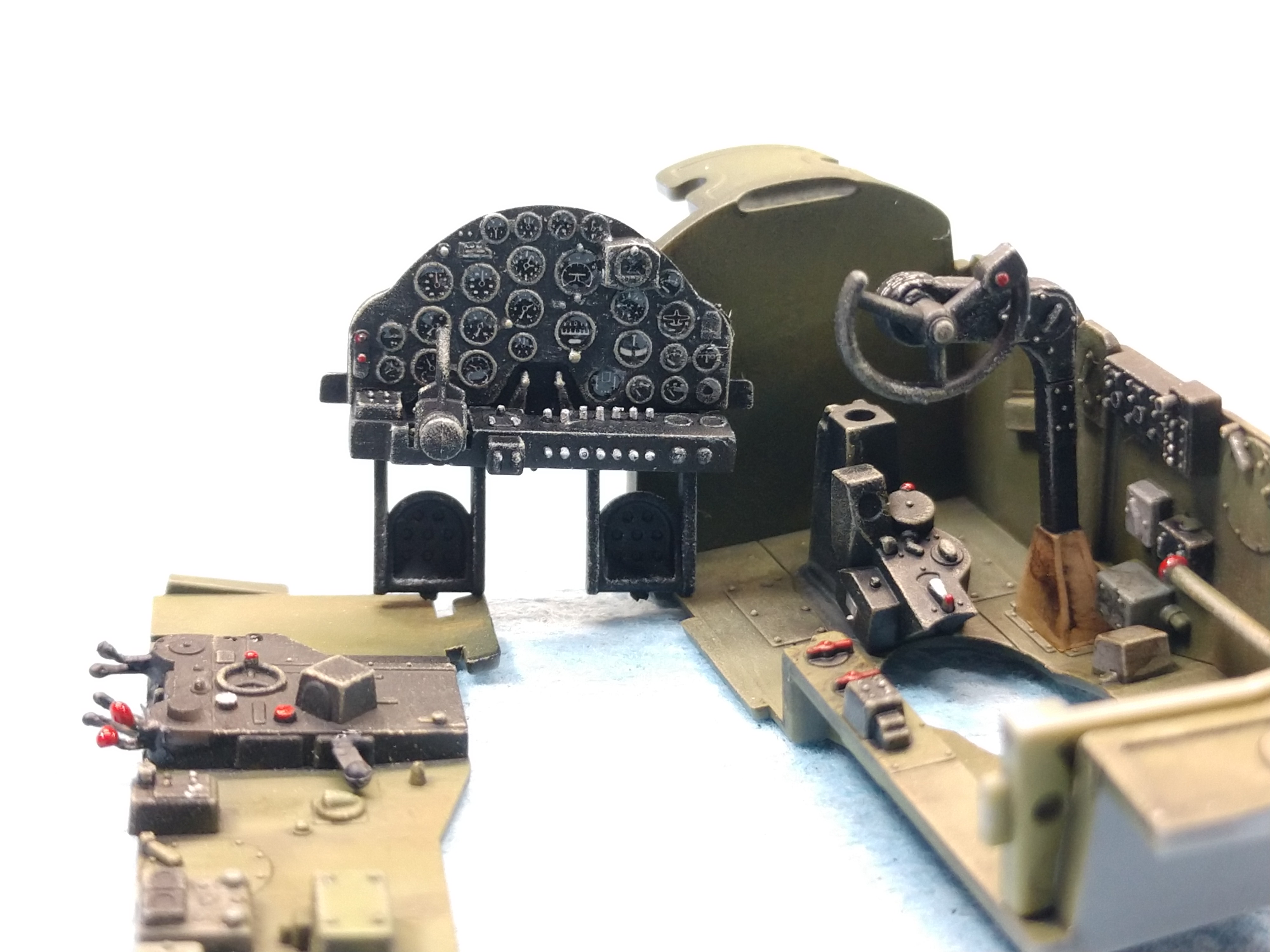

I also removed what is the prop, mixture, throttle quadrant and replaced with my own doing. Took some small diameter brass rod and smashed flat, them trim to fit. Added knobs with glue build up on the ends and painted.

IP's with stock decals applied. Not too shabby, Eduard Look IP would be a great improvement.

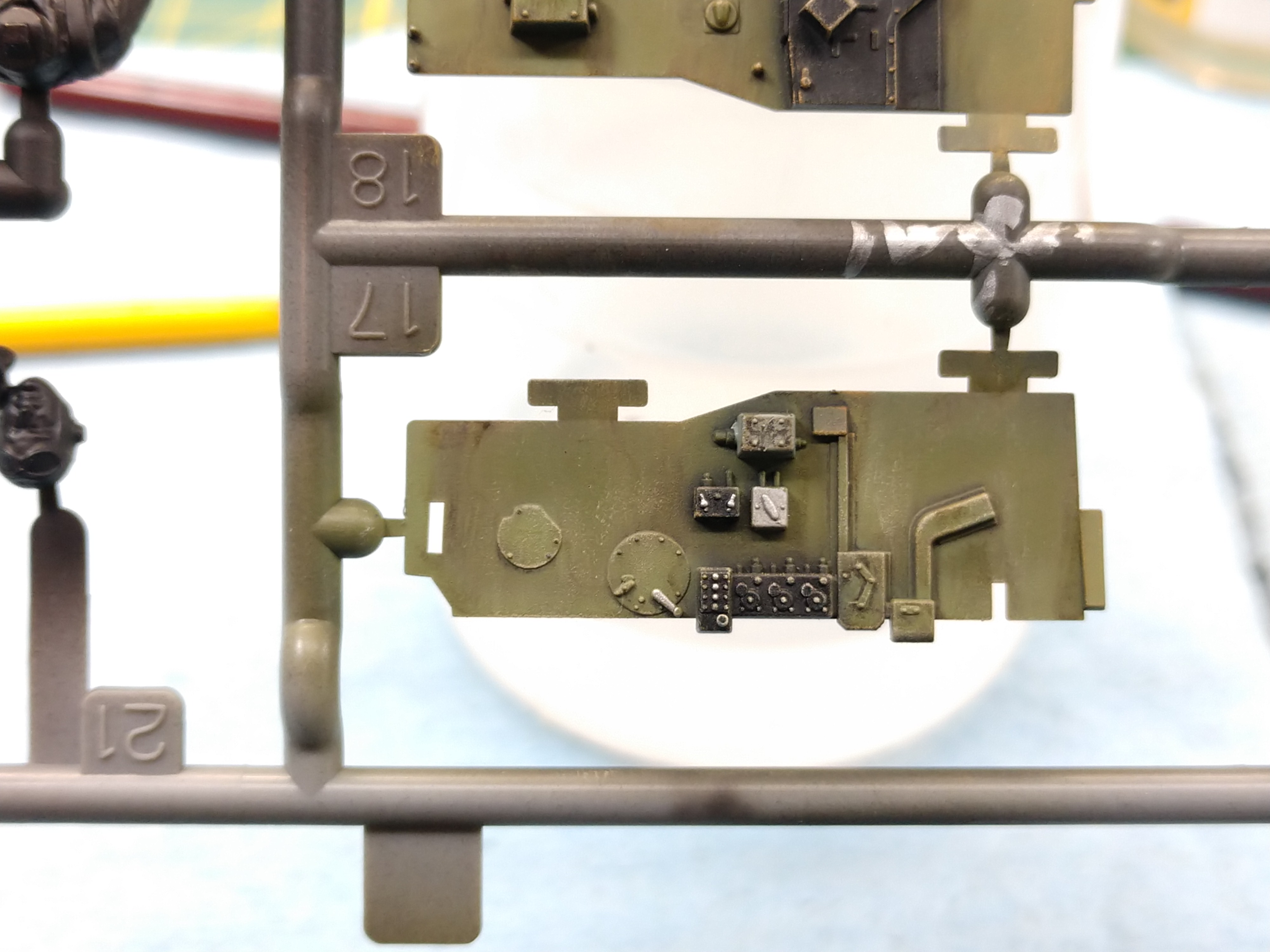

Throttle quadrant stock look before I removed the levers.

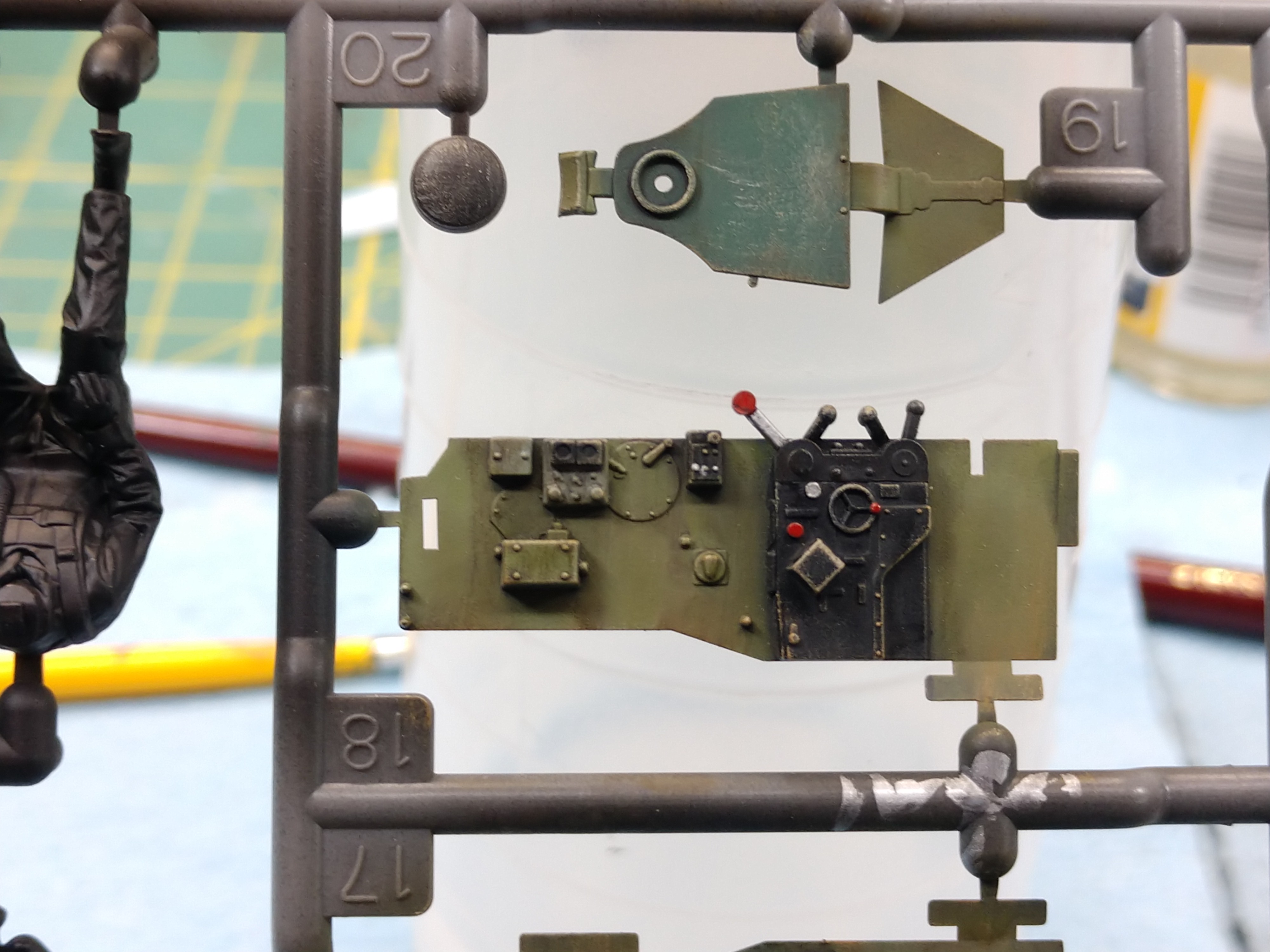

Flatend brass rod

Looks better

It has been a while since I have built a Tamiya kit, I only wish they would add rivet detail like Eduard does.

I also removed what is the prop, mixture, throttle quadrant and replaced with my own doing. Took some small diameter brass rod and smashed flat, them trim to fit. Added knobs with glue build up on the ends and painted.

IP's with stock decals applied. Not too shabby, Eduard Look IP would be a great improvement.

Throttle quadrant stock look before I removed the levers.

Flatend brass rod

Looks better

It has been a while since I have built a Tamiya kit, I only wish they would add rivet detail like Eduard does.