JRGlasoe

Beginner

Hi All Modelers of the Alliance:

I started sailing in Northern Minnesota and, due to the long winters, took up modeling my dreams. Hand crafted from 2x4s or any flotsam to float by, I got hooked. Back then, without the internet, I literally had no idea there were kits let alone experts or "hobbyists."

Years later, living in Coronado, CA allowed me to sail nearly year round; it was then, 20+ years ago, that I built my first Dumas Lightning. My real-world sailing was done on Chrysler O'Days, Hobie Cats and Wayfarers. The Wayfarer is what I consider the British equivalent of an American Lightning. Hence, I had a model that looked like my Wayfarer. She was called My Big Red Woody - much to the delight of my sons and chagrin of their mother. And to push the point, I had a matching red Volvo, who's licence plate holder said, "If you thought the car was Red, wait until you see my Woody." Living in Coronado, you're surrounded by Navy.

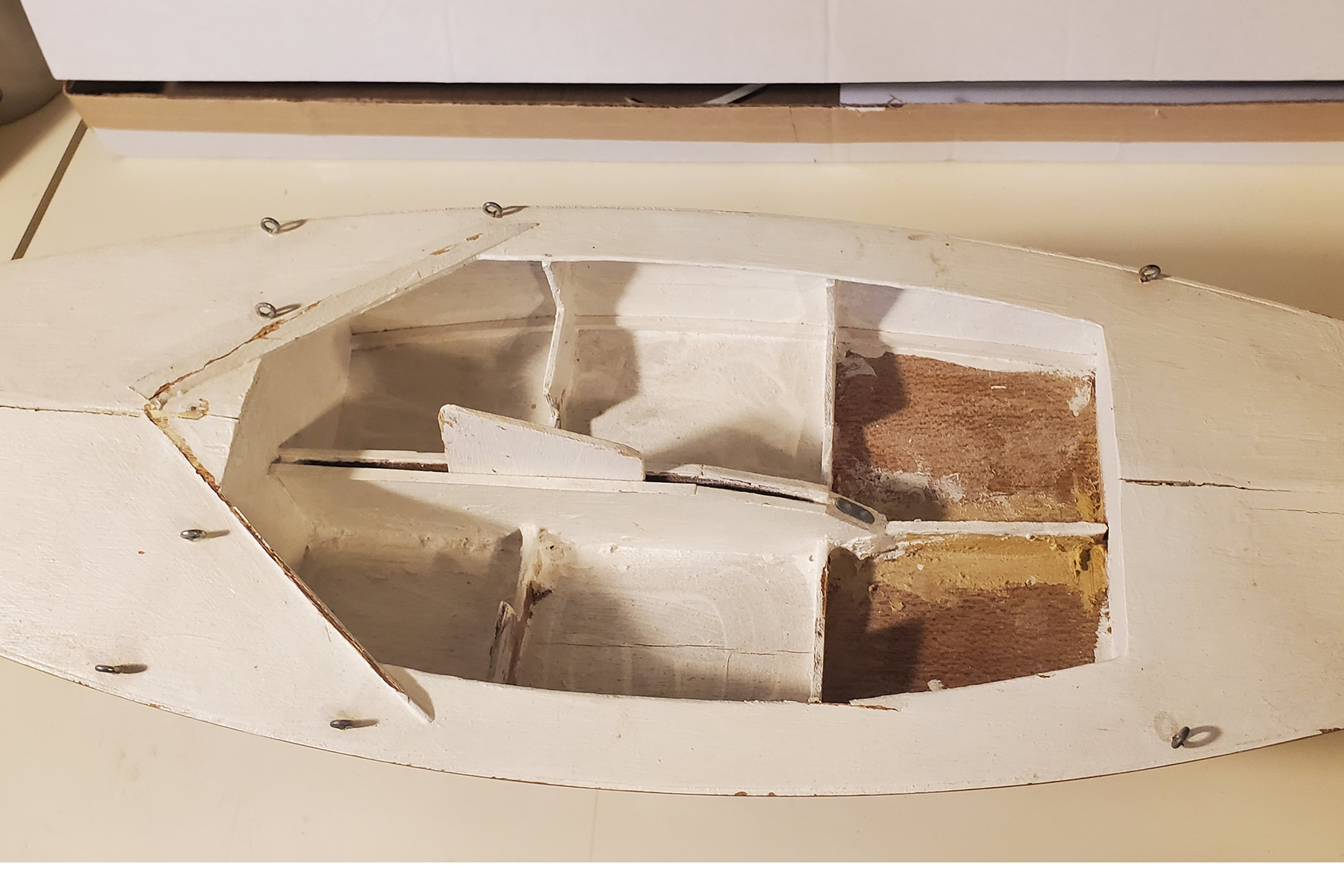

All the remains is the hull (see pics 1-3) and my embarrassment since they reflect my skills at the time) but I keep it around for the memories and now, after reviewing MM2CVS9's efforts on his Lightning, I was challenged to bring her back to life and learn from those "skills" as I correct the mess.

With retirement around the corner and the pandemic, I thought I'd try again... I built my second one just this last month and I got hooked all over again. While I understand the quality of the materials for the kit isn't "furniture" grade, the mahogany won me over (see pics 4-6) . And, again, seeing the detailed documentation (thank you MM2CVS9!) and his ability (completely unwittingly) to address my questions before I even know to ask them, I figured this alliance was going to be not only productive, but very rewarding. I'm redoing the rigging on my second one, including the sails (lesson learned: don't have paint anywhere near sails.)

My boat plans always include the answer to the question where is this thing going to displayed? I have little room. So now all models must have a home before I begin. So, with that in mind, all my brothers are getting Viking ships at some point, two sets of grandsons (ie, two sets of brothers) get a Lightning, each, and I'd like to do a Dragen Yacht for myself. That should keep that "modeling" bug of I-wonder-if-I-can-do-this busy.

Goals: 1- become more competent about rigging, 2 - Learn the craft/art of planking, 3 - Study color/varnish/finishes.

I've read all 21 O'Brian Aubrey/Maturin books in the series and would love to actually sail on a "brigantine" (or equivalent), my interests lie in the direction of Vikings (long family of Norwegians, here) and Yachts. But, I like those books so much, I'm going also listen to them while I work.

Looking forward to engaging, documenting and assisting as needed.

Jon

I started sailing in Northern Minnesota and, due to the long winters, took up modeling my dreams. Hand crafted from 2x4s or any flotsam to float by, I got hooked. Back then, without the internet, I literally had no idea there were kits let alone experts or "hobbyists."

Years later, living in Coronado, CA allowed me to sail nearly year round; it was then, 20+ years ago, that I built my first Dumas Lightning. My real-world sailing was done on Chrysler O'Days, Hobie Cats and Wayfarers. The Wayfarer is what I consider the British equivalent of an American Lightning. Hence, I had a model that looked like my Wayfarer. She was called My Big Red Woody - much to the delight of my sons and chagrin of their mother. And to push the point, I had a matching red Volvo, who's licence plate holder said, "If you thought the car was Red, wait until you see my Woody." Living in Coronado, you're surrounded by Navy.

All the remains is the hull (see pics 1-3) and my embarrassment since they reflect my skills at the time) but I keep it around for the memories and now, after reviewing MM2CVS9's efforts on his Lightning, I was challenged to bring her back to life and learn from those "skills" as I correct the mess.

With retirement around the corner and the pandemic, I thought I'd try again... I built my second one just this last month and I got hooked all over again. While I understand the quality of the materials for the kit isn't "furniture" grade, the mahogany won me over (see pics 4-6) . And, again, seeing the detailed documentation (thank you MM2CVS9!) and his ability (completely unwittingly) to address my questions before I even know to ask them, I figured this alliance was going to be not only productive, but very rewarding. I'm redoing the rigging on my second one, including the sails (lesson learned: don't have paint anywhere near sails.)

My boat plans always include the answer to the question where is this thing going to displayed? I have little room. So now all models must have a home before I begin. So, with that in mind, all my brothers are getting Viking ships at some point, two sets of grandsons (ie, two sets of brothers) get a Lightning, each, and I'd like to do a Dragen Yacht for myself. That should keep that "modeling" bug of I-wonder-if-I-can-do-this busy.

Goals: 1- become more competent about rigging, 2 - Learn the craft/art of planking, 3 - Study color/varnish/finishes.

I've read all 21 O'Brian Aubrey/Maturin books in the series and would love to actually sail on a "brigantine" (or equivalent), my interests lie in the direction of Vikings (long family of Norwegians, here) and Yachts. But, I like those books so much, I'm going also listen to them while I work.

Looking forward to engaging, documenting and assisting as needed.

Jon

Arrrr matie, welcome aboard the Good Ship Lolly Pop... We are a fine bunch of folks, plus an Efrikan Savage (SA Dave). We are very helpful and occasionally insightful.

Arrrr matie, welcome aboard the Good Ship Lolly Pop... We are a fine bunch of folks, plus an Efrikan Savage (SA Dave). We are very helpful and occasionally insightful.  Model On!

Model On!