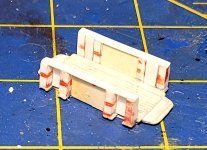

Finishing the Pontoon Drydock 2.0 with runners under the outrigger tanks to let the air out of the mold when casting. I get the idea that the walkways on top of the ballast tanks were wooden, but not the idea they were precisely planked. I took a stab at the pictured gas-powered generator on one side of the dock.

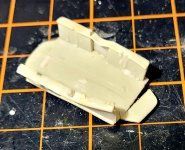

Both 1/700 drydock Masters are ready to mold. They are each in their own handy little cup mold.

See here the improved, enlarged, finished YS/YR barge. Rubberbabybuggybumpers and everything! On the actual model masts will hold SO and SCR-517 radar antennas for tuning. A few other stray boats were cabbaged on to for filling the mold.

They will be included as a bonus in TLAR Models 122D set. Drydock, Barge, (PT) Bottom and Boats.

122E will be docks and piers. Leftover bits of wood deck stuck on to scrap plastic. Not much goes to waste in the Nut Department.

I hope there isn't an "F" to all these PT boat base accessory sets. 5 seems like plenty!

What? No flying boat set?

Skywave 1/700 P-boats are still readily available.

MARS? PBM? Pan Am Clipper? C'mon man.

Shush!

Thanks again for looking in again and again and again.................