paddy

Well-known member

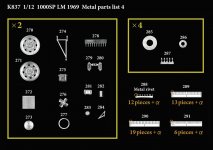

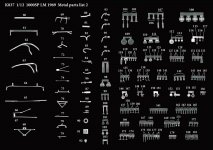

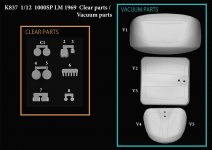

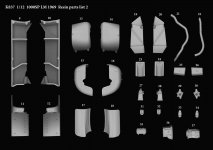

So i am laying the foundations here of my first MFH car build.

Its rather daunting being multi media, white metal, resin, vac form etc, basically a whole new experience for me.

I dont really know what to expect in terms of fit, drilling required and alignment. I guess i will need a good flat plate or i will be building a twisted mess.

Glue is a slight problem, they say you should use CA but i didnt find it very good on white metal, fine in a peg and hole situation but not very good on a surface to surface join.

This is a 1966 Fiat Abarth 1000SP and like all MFH cars now its 1/12. A good scale that ties in nicely with Italeri vintage cars and is big enough for me to see what I am doing .

.

You could be forgiven from this picture for thinking this is a 5 litre (300ci) monster designed to eat up miles in the 24 hour LeMans and you would be half right.

Its actually 1 litre (60ci) 4cyl 105 bhp minnow designed to eat up miles in the 24 hour LeMans

Its only when you see a guy next to it you realise at just under 1000LB its actually quite small

www.stellantisheritage.com

www.stellantisheritage.com

Its rather daunting being multi media, white metal, resin, vac form etc, basically a whole new experience for me.

I dont really know what to expect in terms of fit, drilling required and alignment. I guess i will need a good flat plate or i will be building a twisted mess.

Glue is a slight problem, they say you should use CA but i didnt find it very good on white metal, fine in a peg and hole situation but not very good on a surface to surface join.

This is a 1966 Fiat Abarth 1000SP and like all MFH cars now its 1/12. A good scale that ties in nicely with Italeri vintage cars and is big enough for me to see what I am doing

You could be forgiven from this picture for thinking this is a 5 litre (300ci) monster designed to eat up miles in the 24 hour LeMans and you would be half right.

Its actually 1 litre (60ci) 4cyl 105 bhp minnow designed to eat up miles in the 24 hour LeMans

Its only when you see a guy next to it you realise at just under 1000LB its actually quite small

Fiat Abarth 1000 SP

The Sport designed to turn gentlemen drivers into winners.