Heavens Eagle

Well-known member

Bob, Hippy Ed says :smack

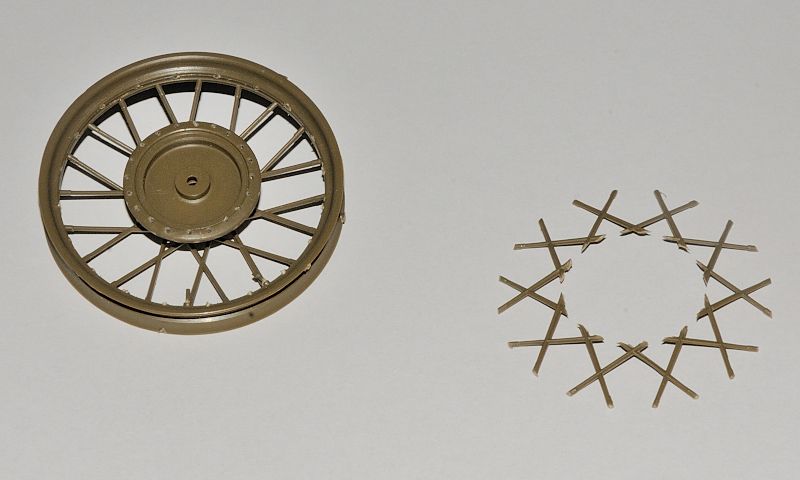

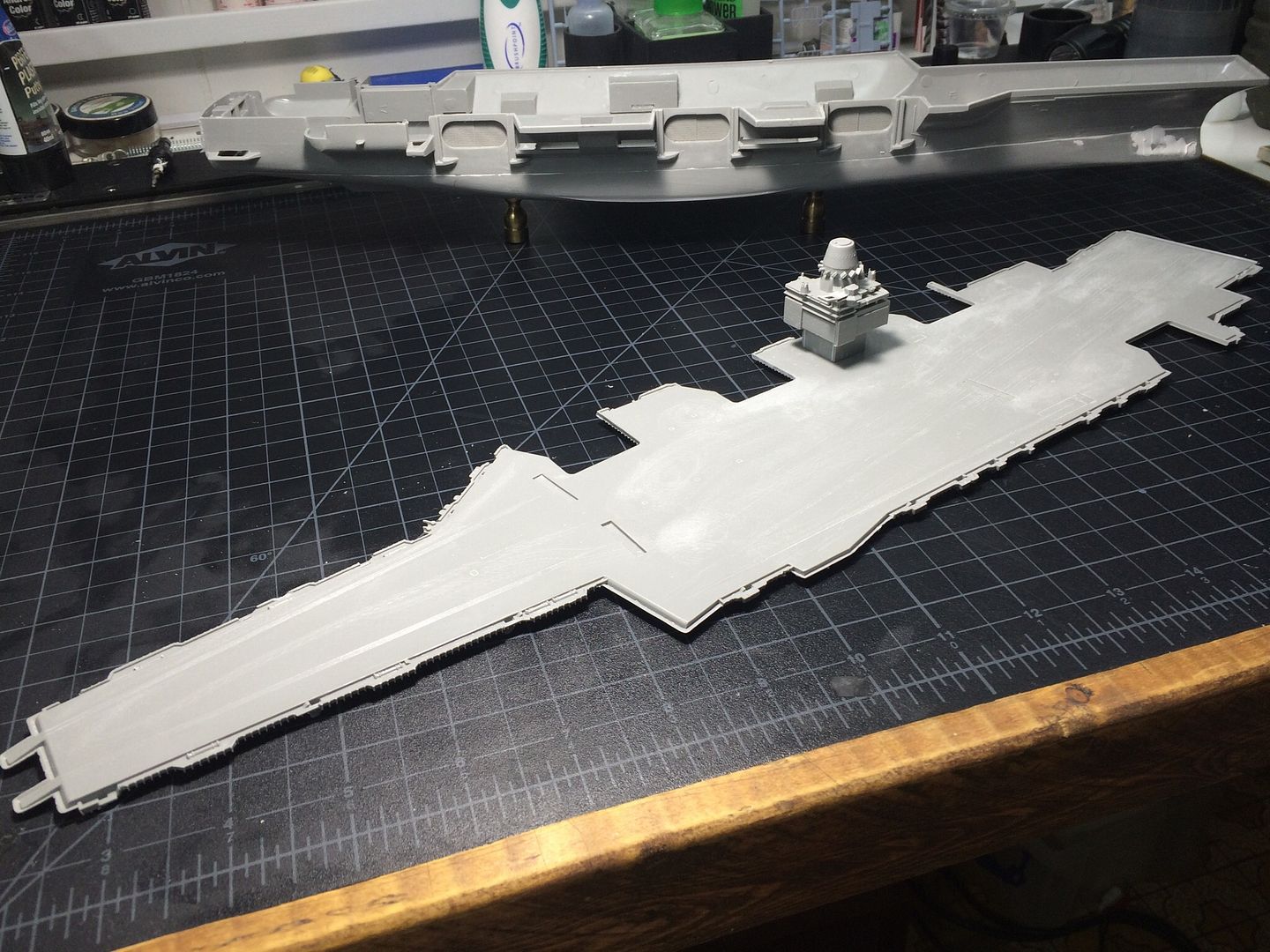

I have started in working on my T-90 again. As the one I chose to do was the lead tank in the squad that was in the Victory Day Parade in Moscow in 2010 it is going to be all clean (though not shiney) I will just have to figure out how to make the flag it had flying.

Videos on U-tube have been helpful.

I have started in working on my T-90 again. As the one I chose to do was the lead tank in the squad that was in the Victory Day Parade in Moscow in 2010 it is going to be all clean (though not shiney) I will just have to figure out how to make the flag it had flying.

Videos on U-tube have been helpful.