nsmekanik

Member

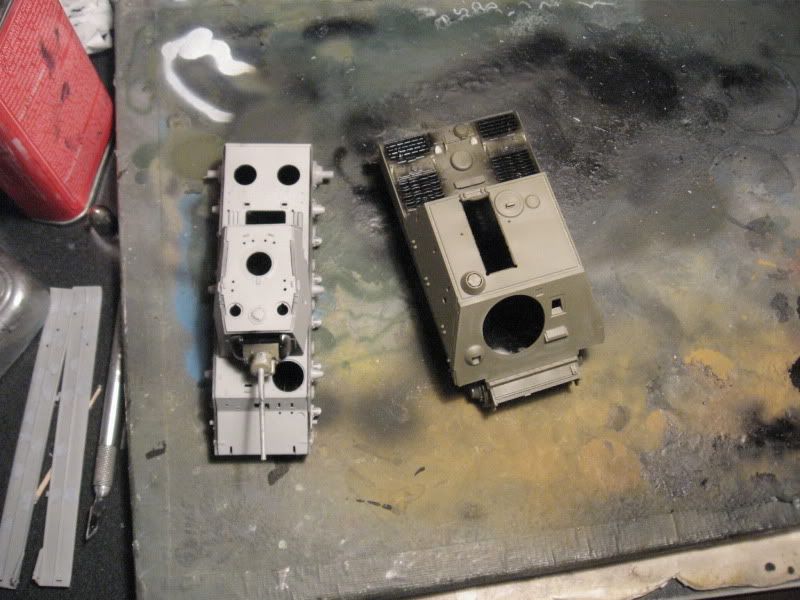

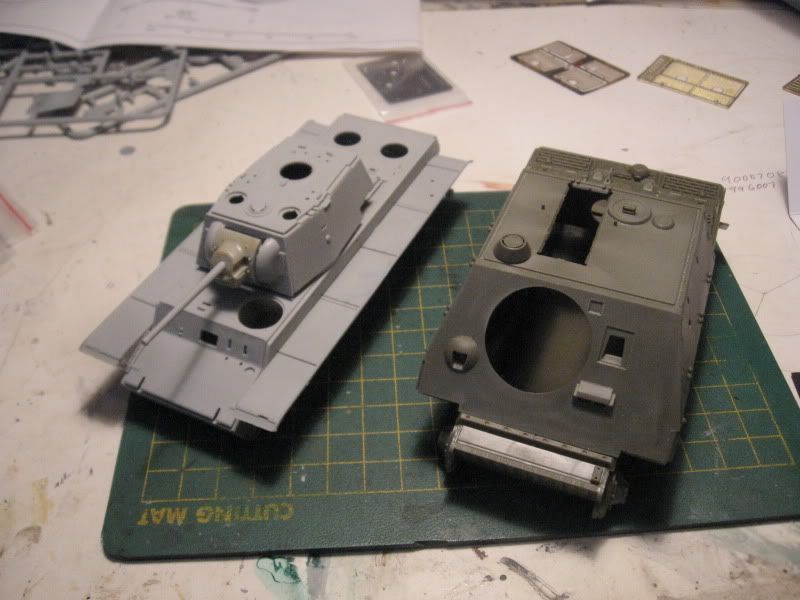

I've got 2 kits I'm playing around with at the moment, this being one of them. It is one kit that is really crying out for an interior, and well there is such a thing for the 1/35 scale version, unfortunately there is only an engine set for the Tiger, which this is based on. As it is in this scale the openings in the cooling vents are large enough to see right in there and it would appear to be almost worth getting that for the radiators.

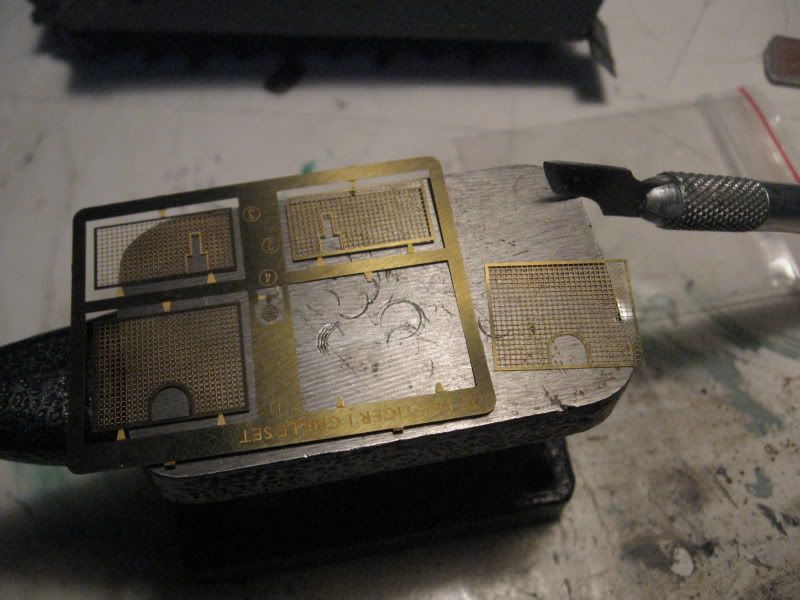

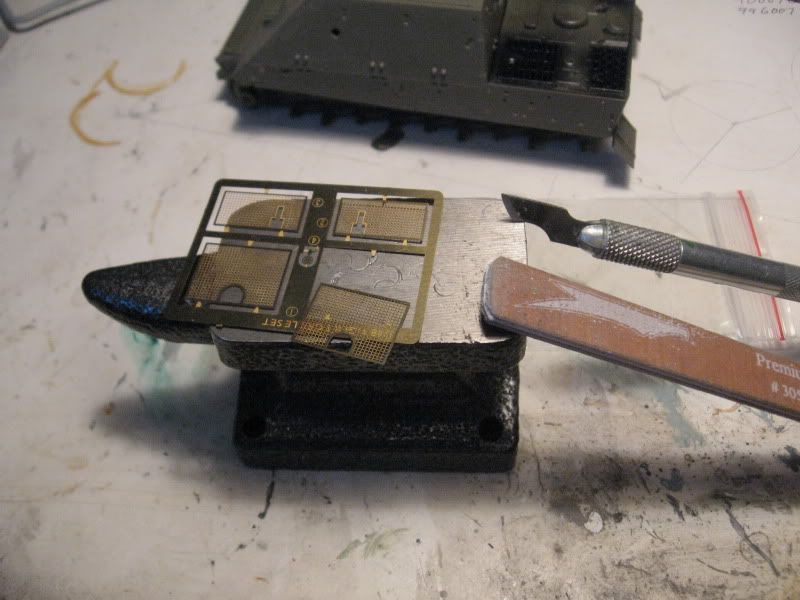

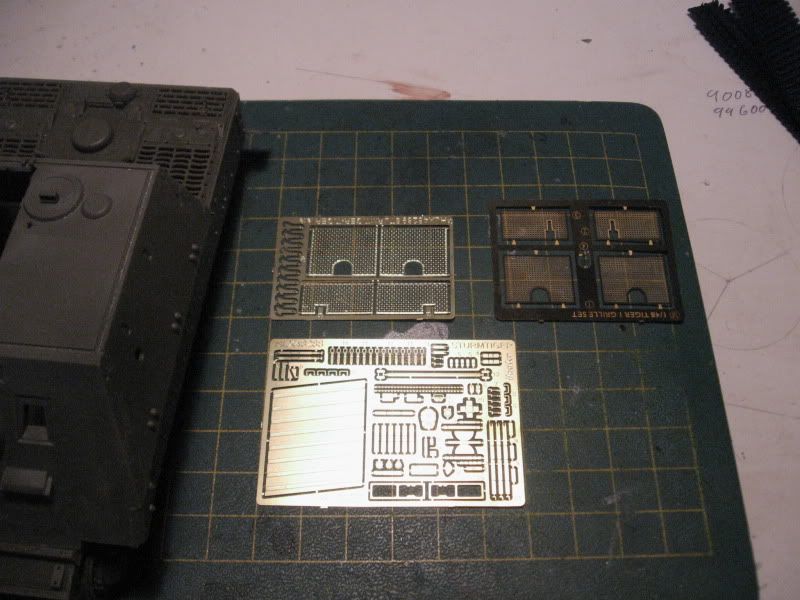

But then agian with the screen covers in place the view might be restricted enough that it won't be a big deal, have to wait and see. The kit comes with these as an etch set which are very nice and look the part with the weaving being well defined.

I also have the Hauler etch for it which also has good definition of the weave as well as the hinges for the covers, but I think the hinges are quit adequate in the moulding and the AFV screens do have a better appearance to my eye so I think I'll use those ones.

Because so much of the crew area is exposed with the open hatch that it is such a shame there is nothing out there to put in there, and as much as I'd like to do one, even though there is a Tiger interior available I think for the Tamiya kit, I'm just not up to the challenge of creating one, so the lid will have to be closed.

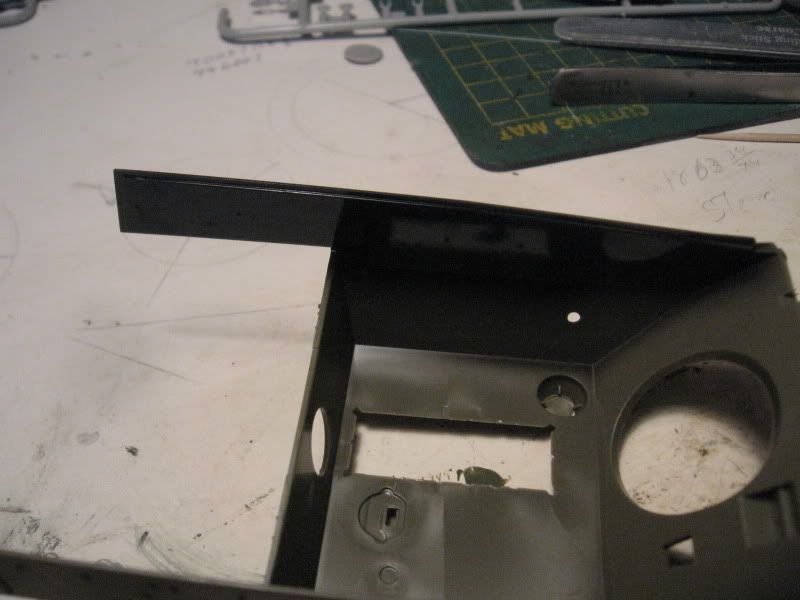

The fit is pretty good, I have glued the back piece on, even though the Zimmeritt is moulded on both the back and lower hull I did manage to get a seamless joint with very little effort. but for some reason there is nothing there to butt the rear decking up to the fighting compartment so I'll have to add a strip of plastic to get a secure joint with when the time comes.

I'm not going to be moving on this one very fast, but I thought I'd start this so I can add to it as I go.