Rhino

Super Moderator

I happened upon a Silent Service Vet at a gas station in Altoona one afternoon not long ago. Bob Kirby joined the US Navy at 17 years young. He was an electrician's mate 2nd class.

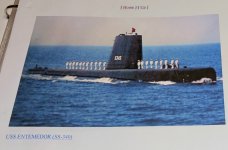

He was generous enough to share a couple of photos of his boat. The first picture is his boat in her GUPPY1b configuration. These submarines were redesigned as hunter-killer subs. (SSK for sailors.) The second is USS Entemedor after her conversion to GUPPY II and transfer to the Turkish Navy.

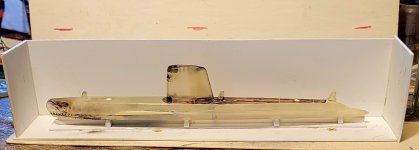

Against my better judgement I ordered a kit from the Far East. First hint: This is NOT the Balao class USS Barbel SS-316. She was lost in February of 1945 near Palawan and would not have made it into the US Navy GUPPY program. Likewise, this model is also NOT USS Barbel II SS-580, the forerunner to nuclear powered Attack boats, or any of her diesel/electric sisters. This misnamed 1/700 kit does fill an interesting gap in 1/700 US Navy submarines from WWII through the 1950's. Kinda cool!

The bright salmon-colored 3D resin is brittle and does not sand easily. The detail is interesting, and does resemble Mr. Kirby's submarine. Not too many parts and seemingly accurate, simple instructions. For removal of the kit parts Dremel grinding is recommended. Snipping this stuff will fracture/splinter it.

Frame work and supports removed. USS Banana-dor? The waterline resin hull print is severely warped. No big deal. Run it under warm water and flatten the ol' Girl out, right?

WRONG!

Here's why. Clever Chingada 3D printers made the model hollow. Everywhere there is a hull penetration or a limber hole, you can see into it or through it. Honestly, a really cool feature for a model sub in this scale, IF the friggin' hull is flat at the waterline!!

This also makes molding and resin casting near impossible because of all the air that will escape from the hull openings under pressure, ruining the RTV mold.

I ground holes in the underside of the hull and dripped Future into it. The Future ran from bow to stern inside the accursed, hollow warped hull. I hoped to seal all the holes from within. I'm considering chopping the bottom of the waterline hull out, installing brass tubing in the groove and heating/ bending this communist-made prick flat.

Option B: Use the kit Portsmouth sail to modify a Fujimi 1/700 Balao-class submarine model to make USS Entemedor, drop this $13.50 Chinese 3D turd in the burn trash and be a Happy Guy. The Fujimi kit would need the BQR-2 sonar transducer array up forward.

Option C: Fill, mold and cast the step sail. make as many GUPPY 1b conversion kits as I want.

Stay tuned for more exciting submarine model developments!

Oh, Hey. Don't buy this warped submarine model Turd from China. It's one thing to buy a cool looking 3D printed model kit. Assembling same is a VERY different proposition. I recall buying the inaccurate 3D printed 1/700 Calypso kit. Similar garbage.

He was generous enough to share a couple of photos of his boat. The first picture is his boat in her GUPPY1b configuration. These submarines were redesigned as hunter-killer subs. (SSK for sailors.) The second is USS Entemedor after her conversion to GUPPY II and transfer to the Turkish Navy.

Against my better judgement I ordered a kit from the Far East. First hint: This is NOT the Balao class USS Barbel SS-316. She was lost in February of 1945 near Palawan and would not have made it into the US Navy GUPPY program. Likewise, this model is also NOT USS Barbel II SS-580, the forerunner to nuclear powered Attack boats, or any of her diesel/electric sisters. This misnamed 1/700 kit does fill an interesting gap in 1/700 US Navy submarines from WWII through the 1950's. Kinda cool!

The bright salmon-colored 3D resin is brittle and does not sand easily. The detail is interesting, and does resemble Mr. Kirby's submarine. Not too many parts and seemingly accurate, simple instructions. For removal of the kit parts Dremel grinding is recommended. Snipping this stuff will fracture/splinter it.

Frame work and supports removed. USS Banana-dor? The waterline resin hull print is severely warped. No big deal. Run it under warm water and flatten the ol' Girl out, right?

WRONG!

Here's why. Clever Chingada 3D printers made the model hollow. Everywhere there is a hull penetration or a limber hole, you can see into it or through it. Honestly, a really cool feature for a model sub in this scale, IF the friggin' hull is flat at the waterline!!

This also makes molding and resin casting near impossible because of all the air that will escape from the hull openings under pressure, ruining the RTV mold.

I ground holes in the underside of the hull and dripped Future into it. The Future ran from bow to stern inside the accursed, hollow warped hull. I hoped to seal all the holes from within. I'm considering chopping the bottom of the waterline hull out, installing brass tubing in the groove and heating/ bending this communist-made prick flat.

Option B: Use the kit Portsmouth sail to modify a Fujimi 1/700 Balao-class submarine model to make USS Entemedor, drop this $13.50 Chinese 3D turd in the burn trash and be a Happy Guy. The Fujimi kit would need the BQR-2 sonar transducer array up forward.

Option C: Fill, mold and cast the step sail. make as many GUPPY 1b conversion kits as I want.

Stay tuned for more exciting submarine model developments!

Oh, Hey. Don't buy this warped submarine model Turd from China. It's one thing to buy a cool looking 3D printed model kit. Assembling same is a VERY different proposition. I recall buying the inaccurate 3D printed 1/700 Calypso kit. Similar garbage.