You guys are most Welcome,my pleasure.

"Storage Boxes"

"Storage Boxes"

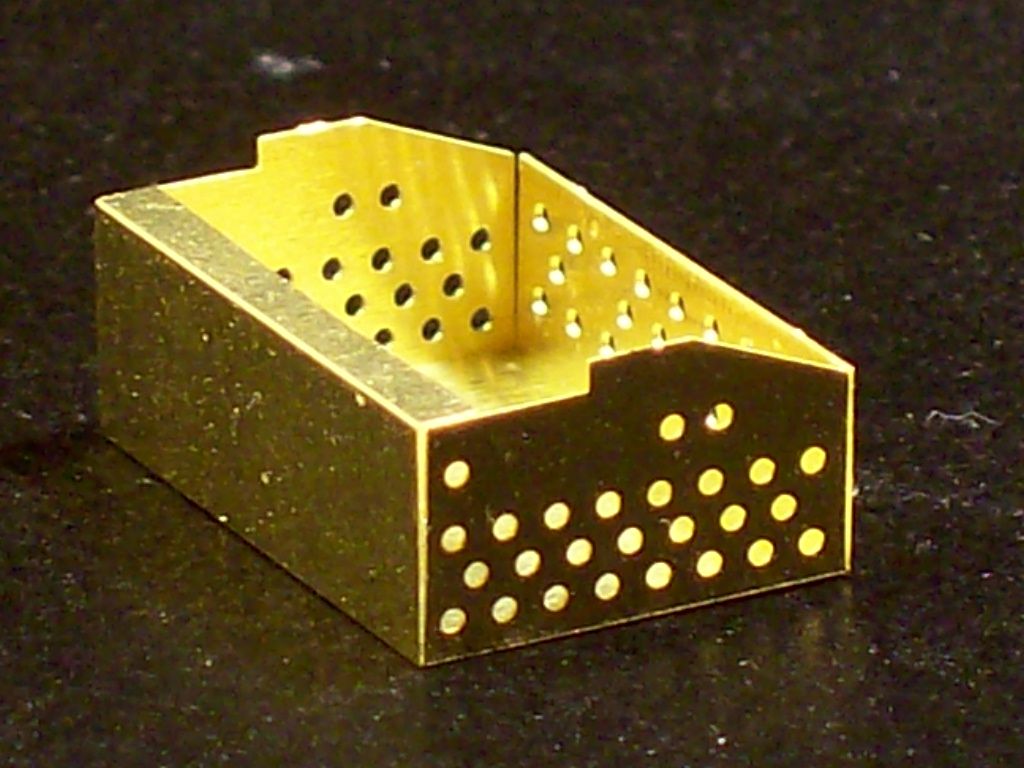

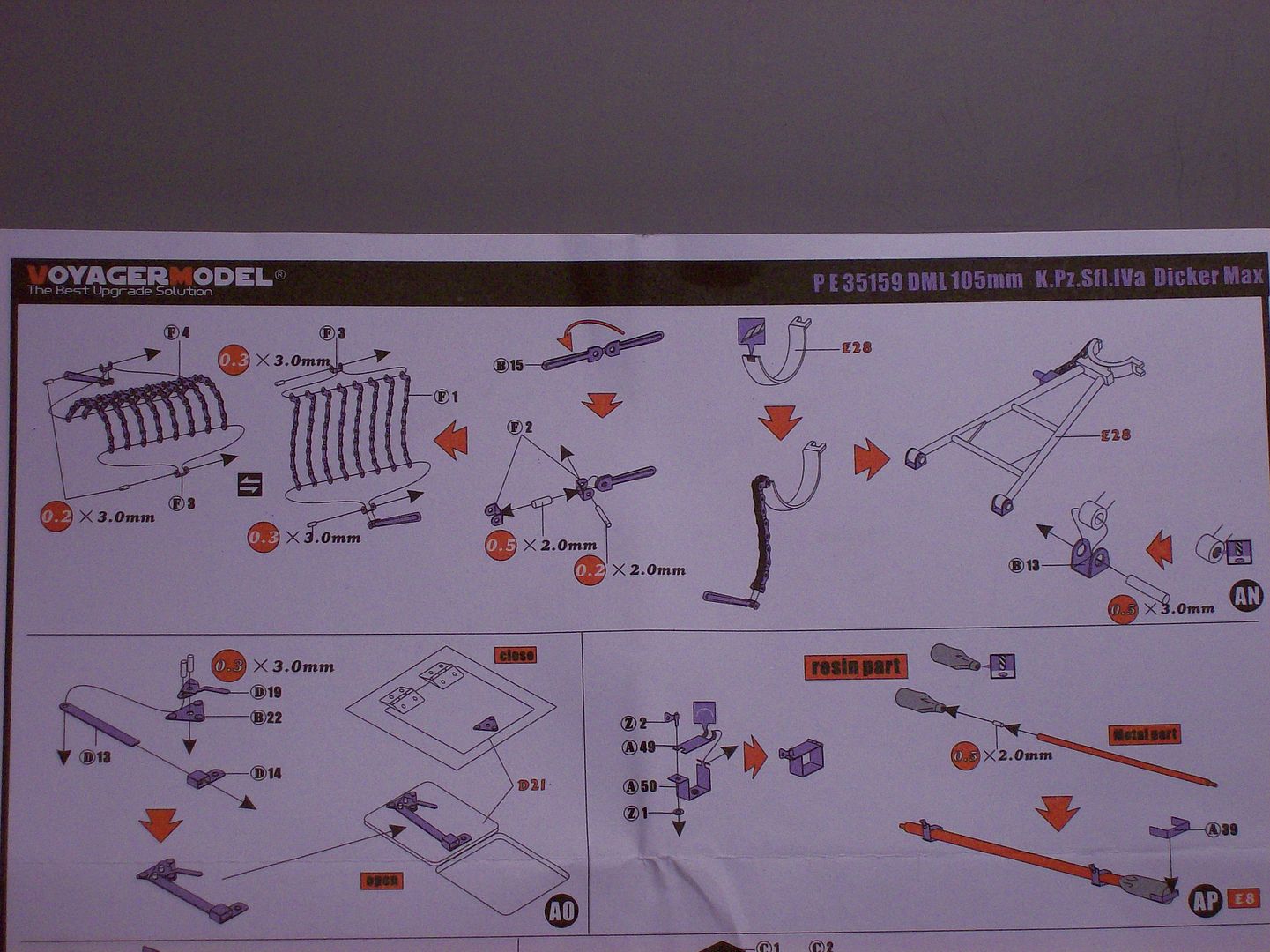

I make all my boxes just about the same way. Every now and then you'll run across what I call a wrap around side box but I still fold it almost the same way.

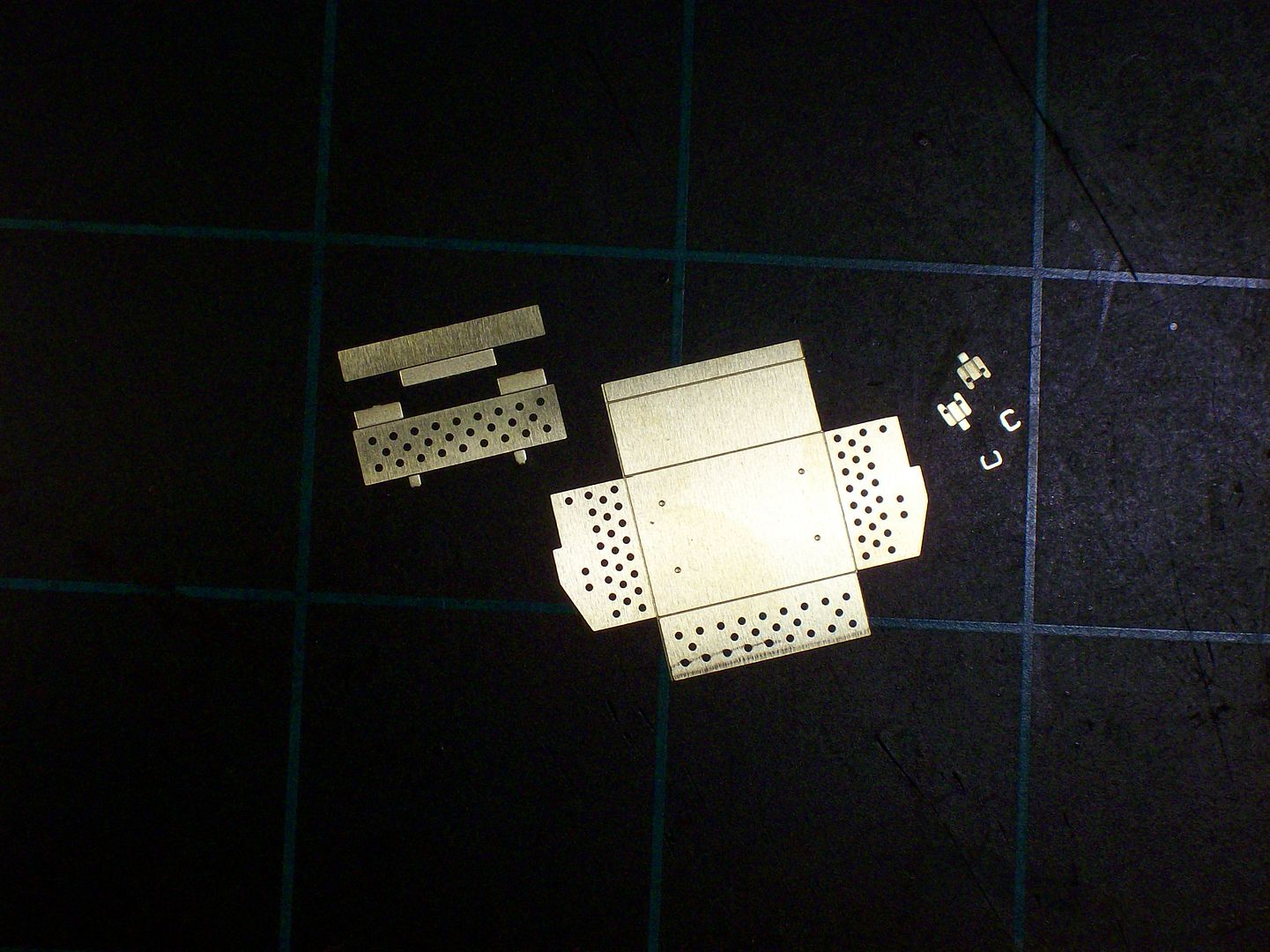

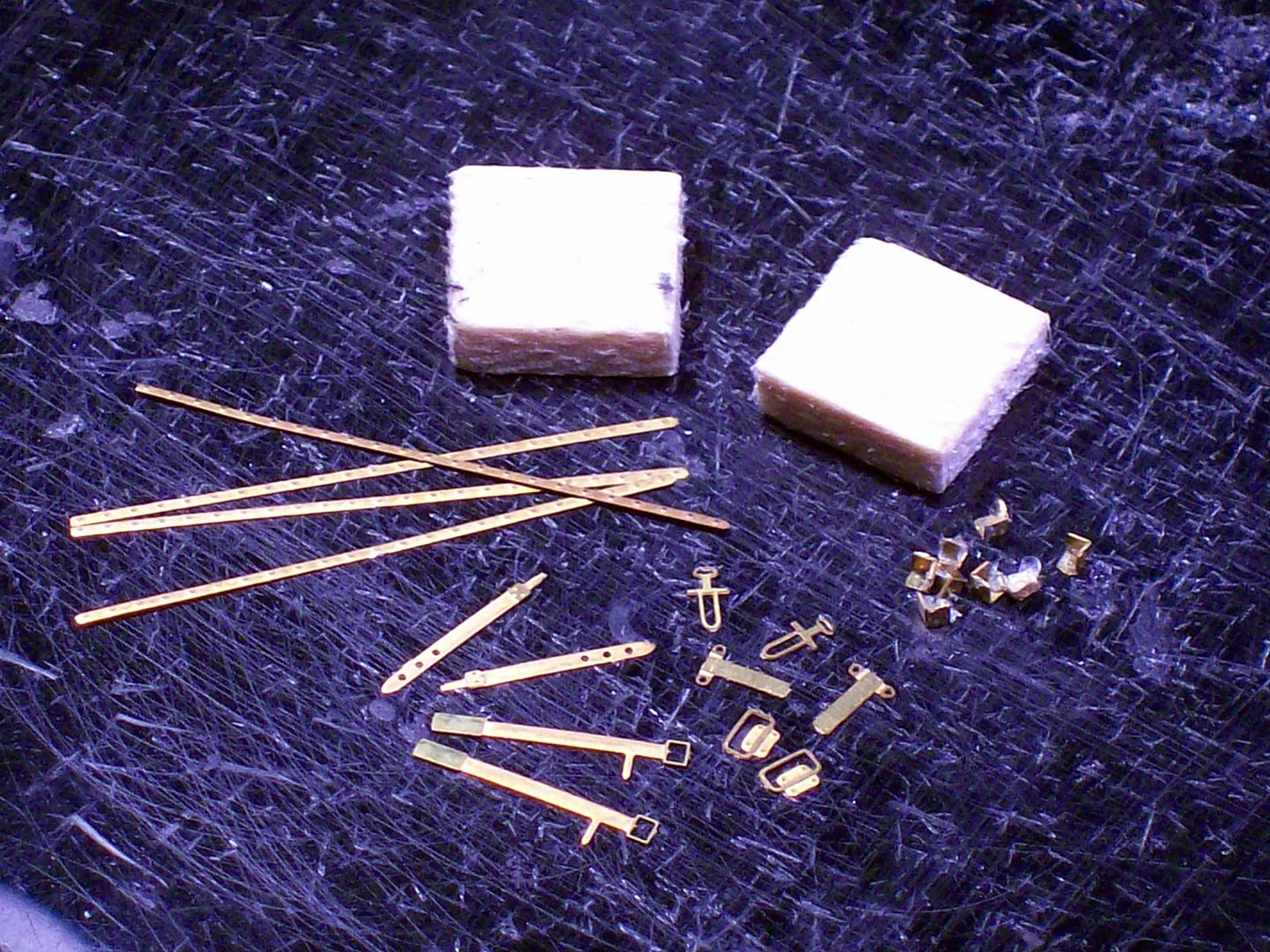

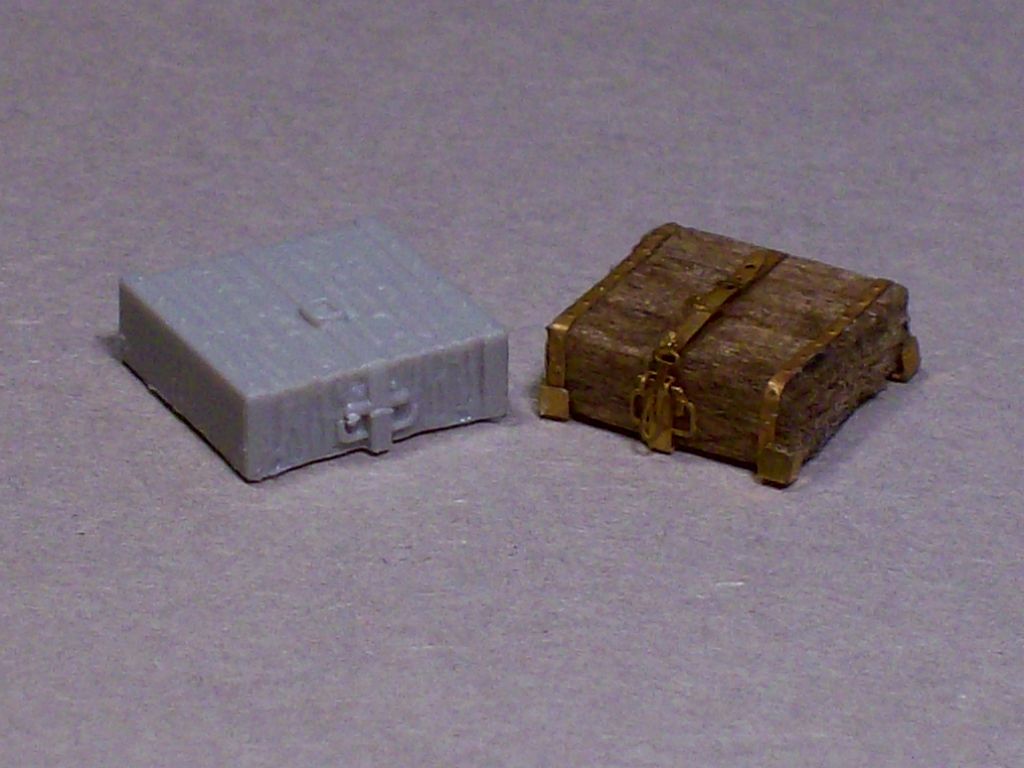

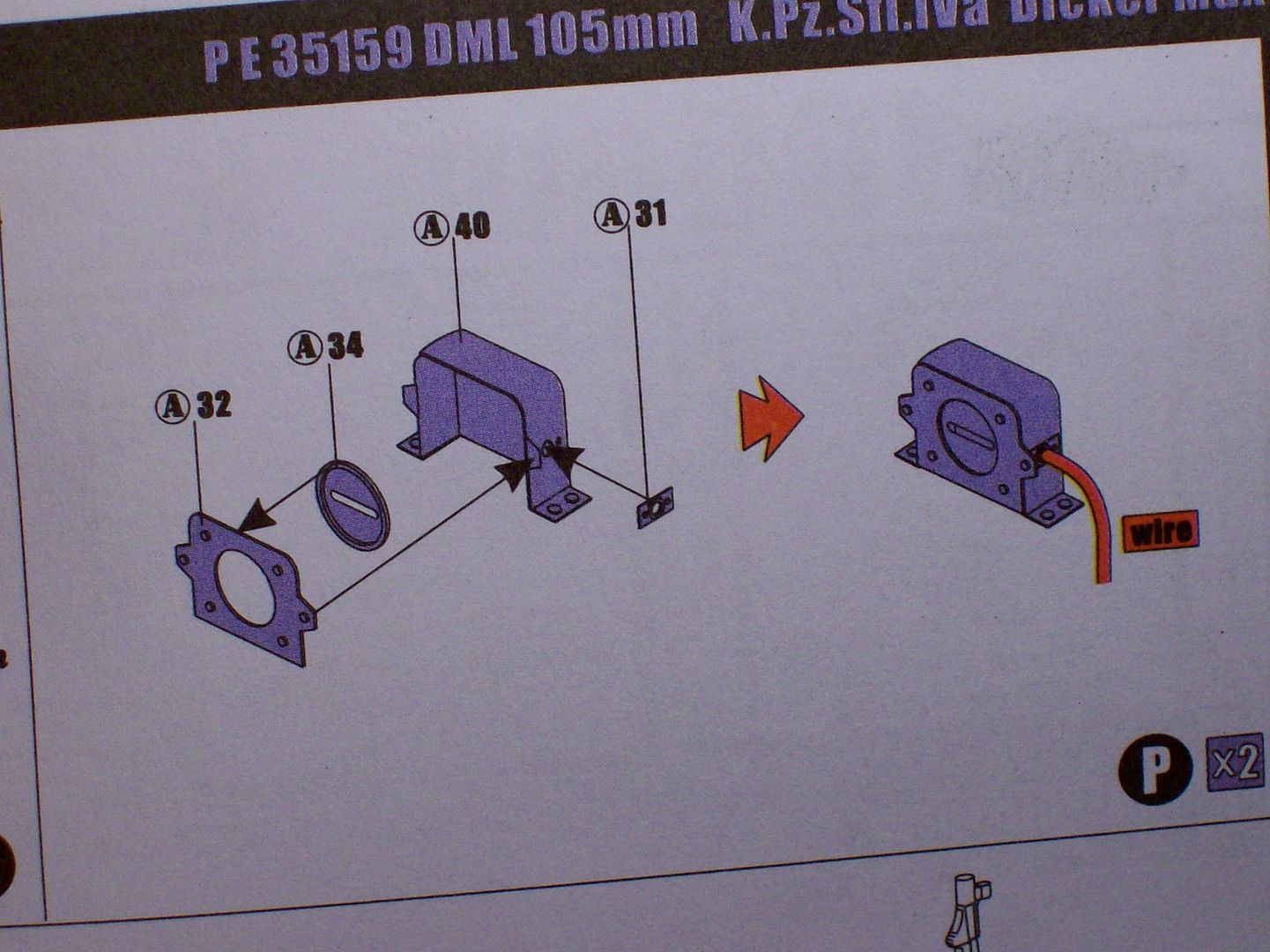

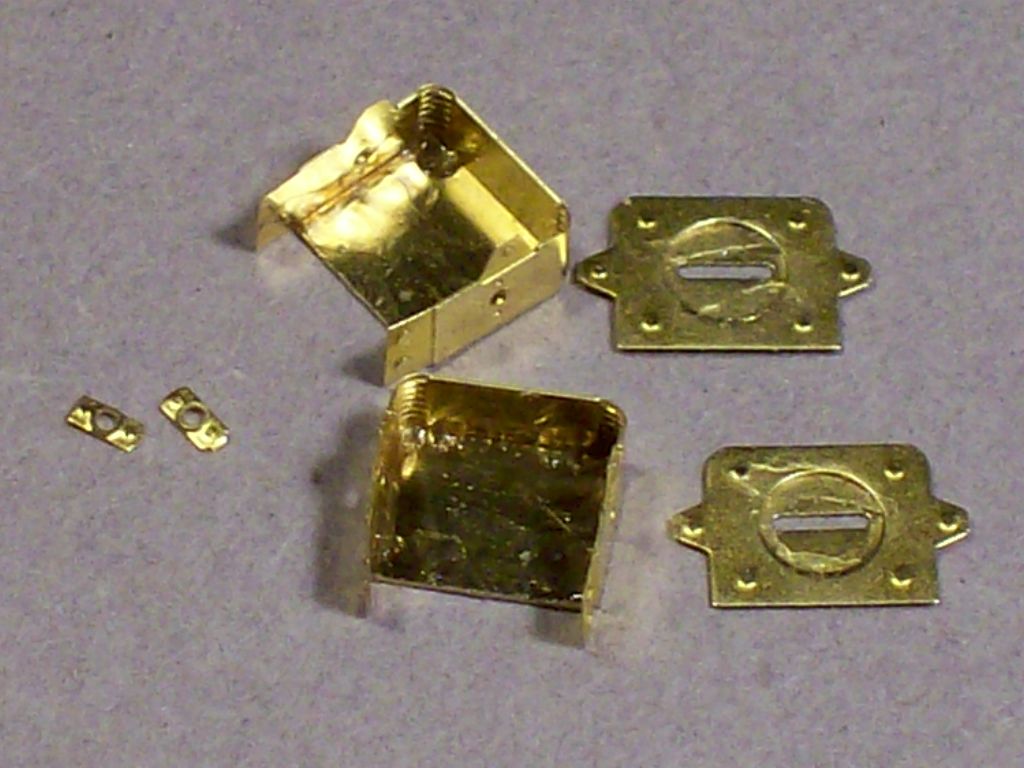

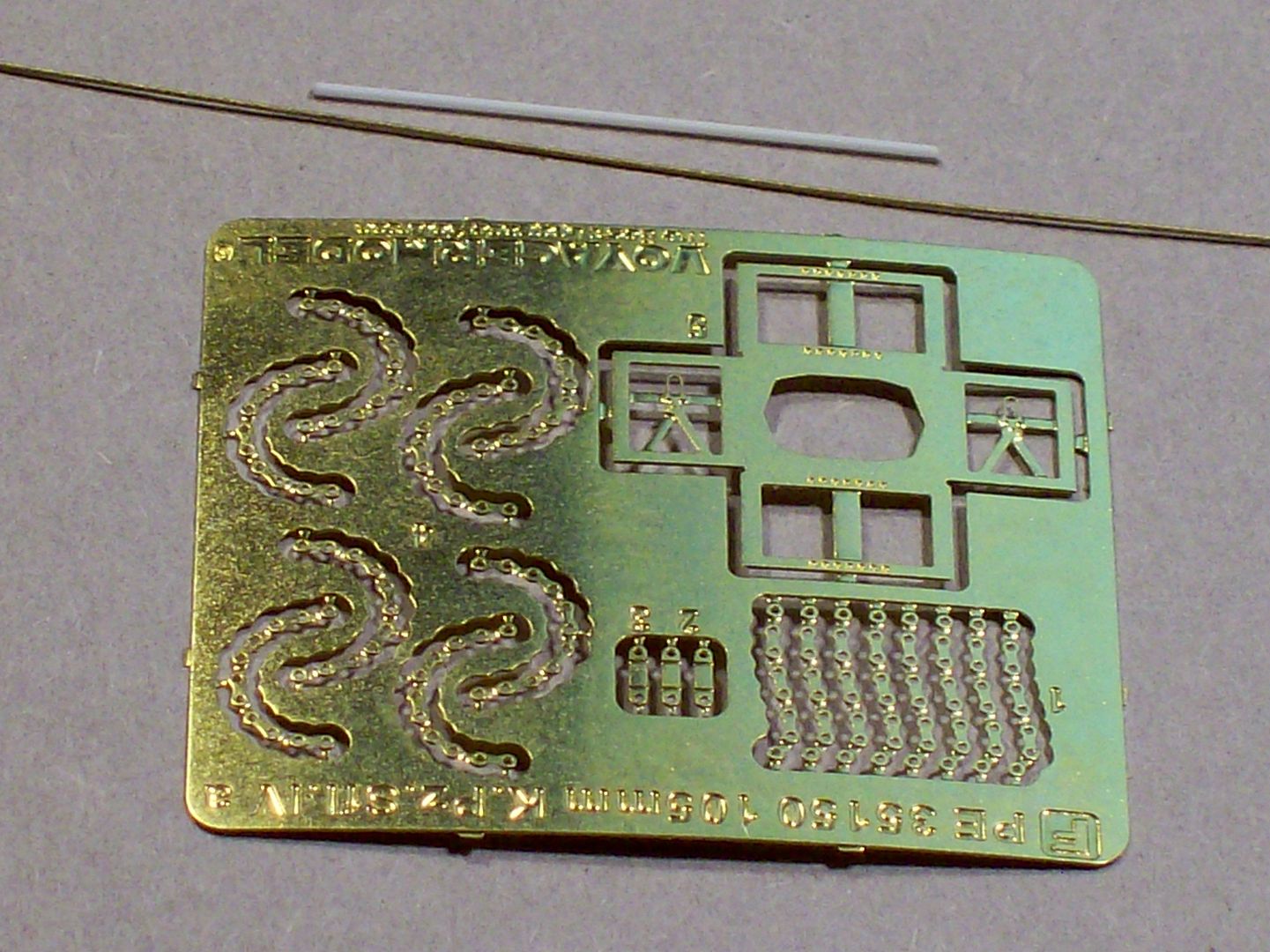

For this demo we'll use a box you see on a lot of the German 38(t)models. It's used for tools and jack storage. These parts are from a Griffon PE set and there's the main body of the box,the lib with hinge and the two latches.

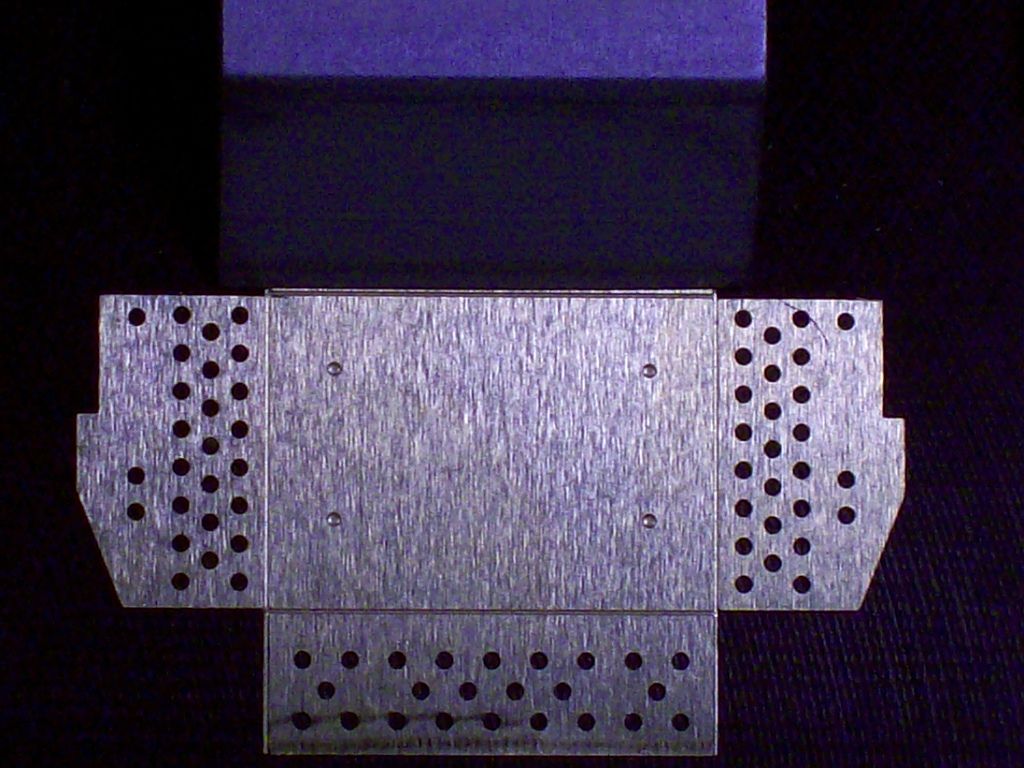

I'll start with the rear wall,using my Hold-N-Fold,where you can see the two scored lines. One marks where to fold for the base of the wall the other is for a lip that folds to the inside. I'll fold the base line first and then move it out and fold the lip.

Yeah the picture is black but you can see how close I place the edge of the folding shoe to the line. I found that leaving a little of the line showing beyond the shoe makes for a better fold then being right on top of it.

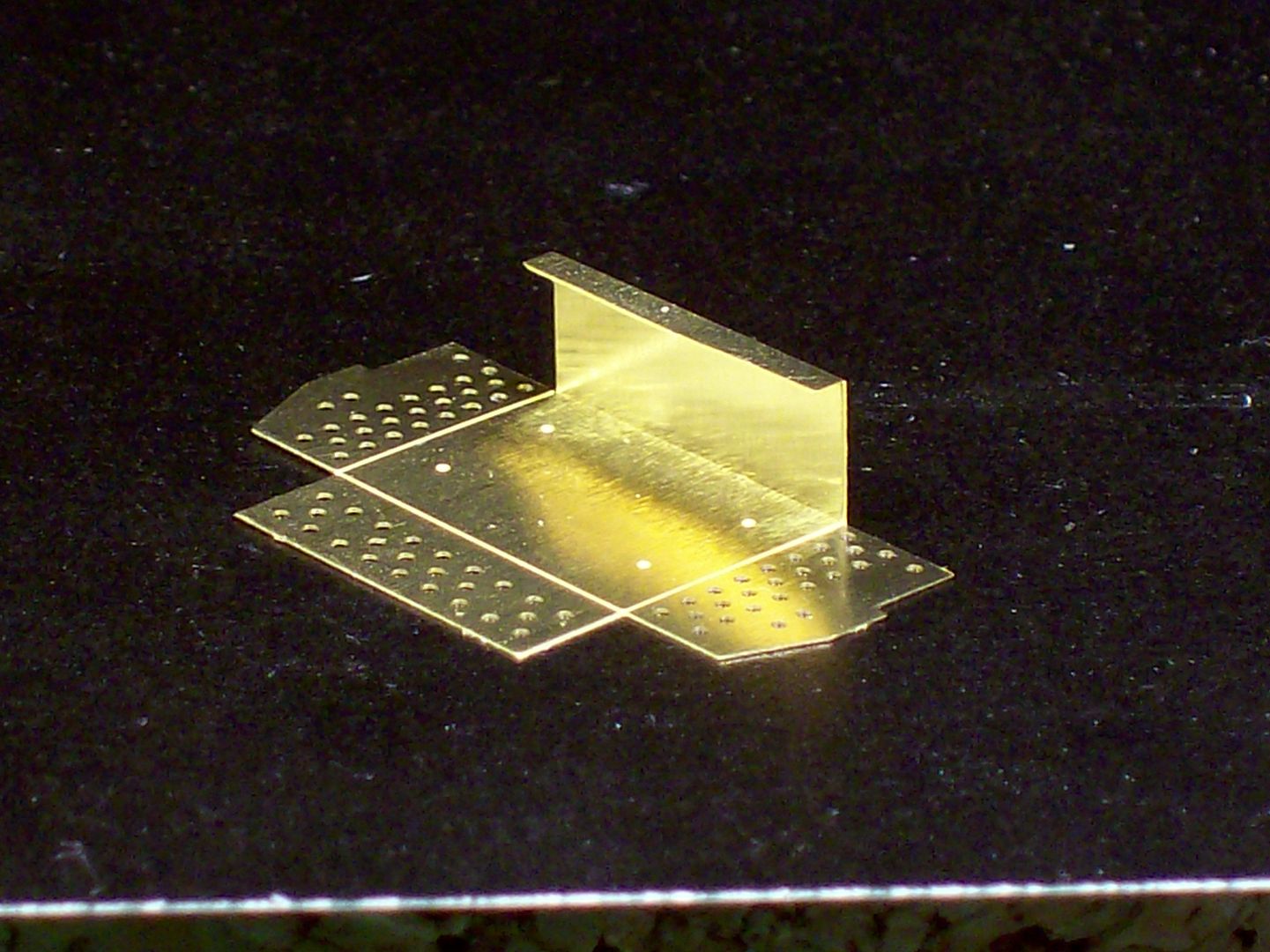

I've made the first two folds here.The little lip is square with the back wall but i've folded the wall itself just a tiny bit more inward than vertical.

In this case the next fold will be the front wall.Once again just a little more than vertical. Next both side walls. I can't fold the sides as much because they bottom out on the base plate of the bender.

Using my "L" shaped tweezers and finger tips i'll adjust the sides in or out to get the tightest square corners I can. By folding the front and back walls pass the vertical I can take advantage of the small amount of spring action aiding me to get those corner cracks tighter.

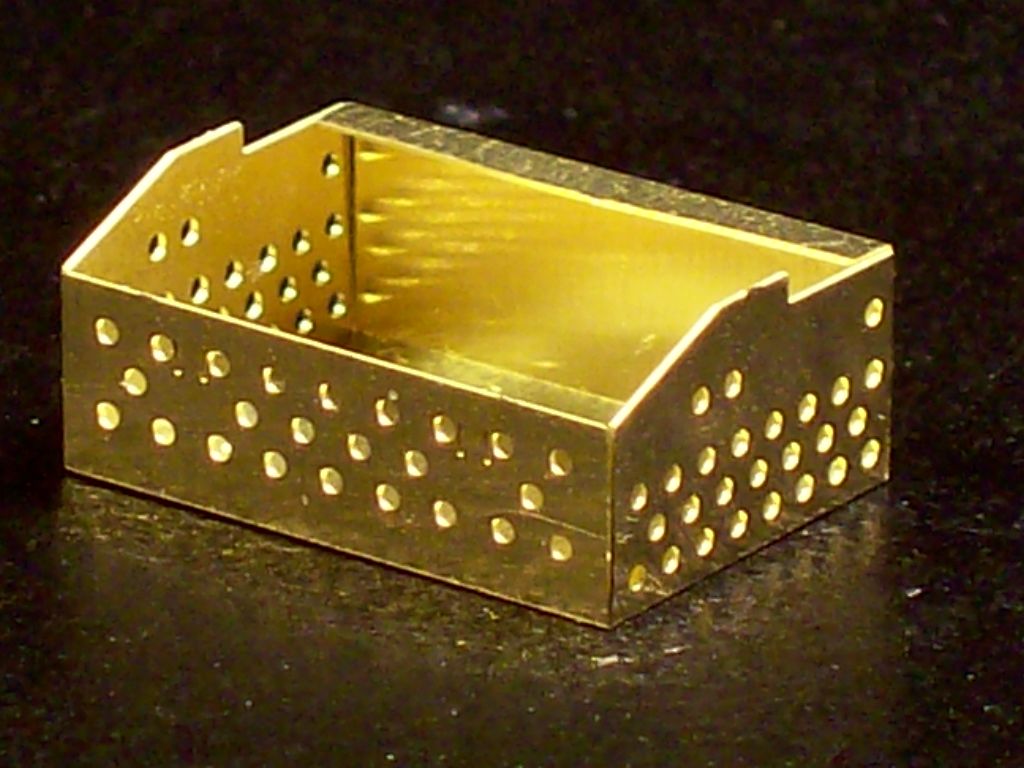

The reflection on the edges makes the corner junctions look huge but they're tight.

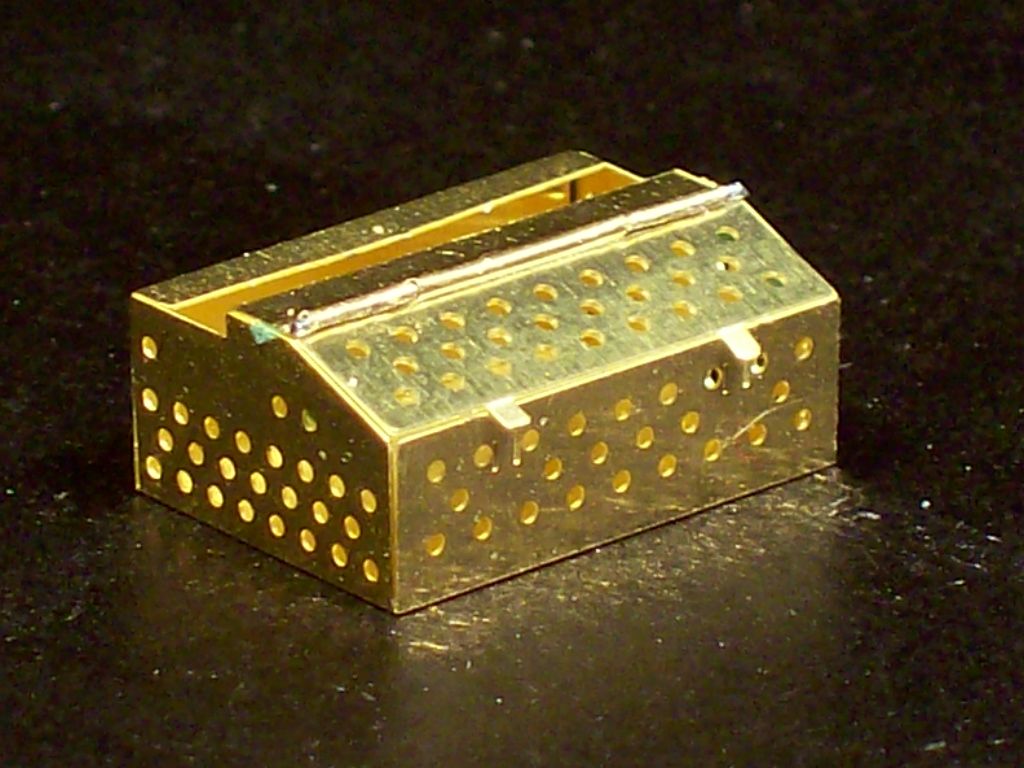

The lid is next and the hinge was formed using the same technique as in the

"HINGE" section above.

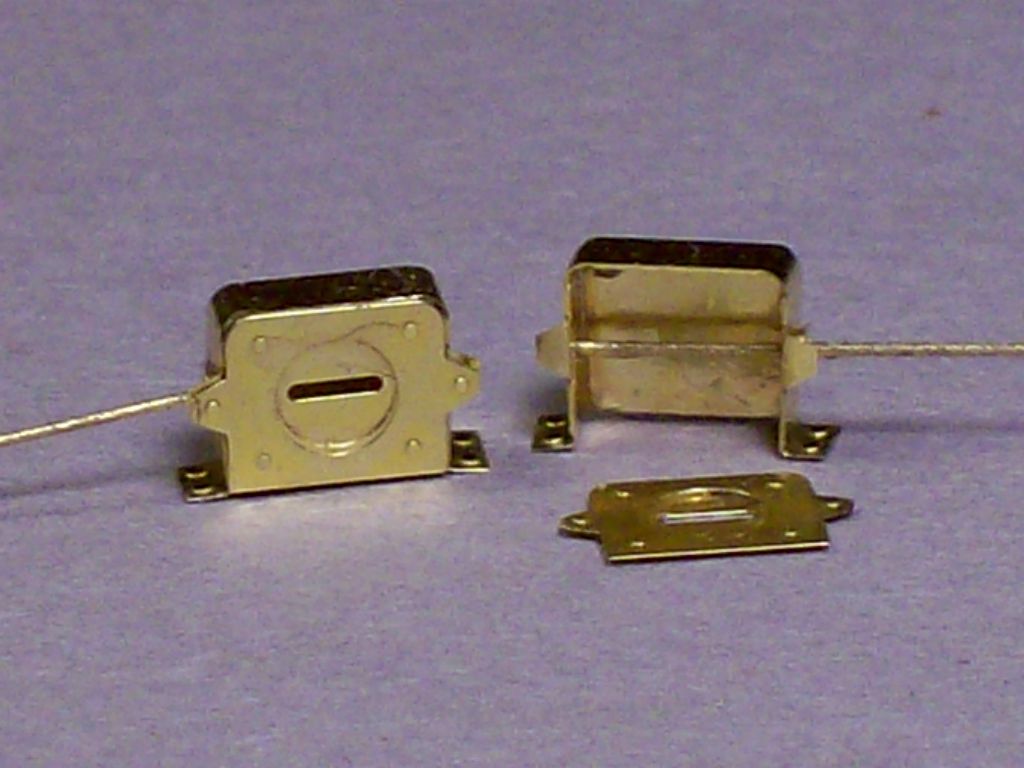

Next came the latches and man are they small.

hmy: Optivisor #10 to the rescue.

Since I want to open and close the lid I didn't latch the lid down.

With everything assembled I applied a thin line of Gator Grip glue on each inside corners of the box and on each side top edge where the hinge plate sits and let it cure for awhile.

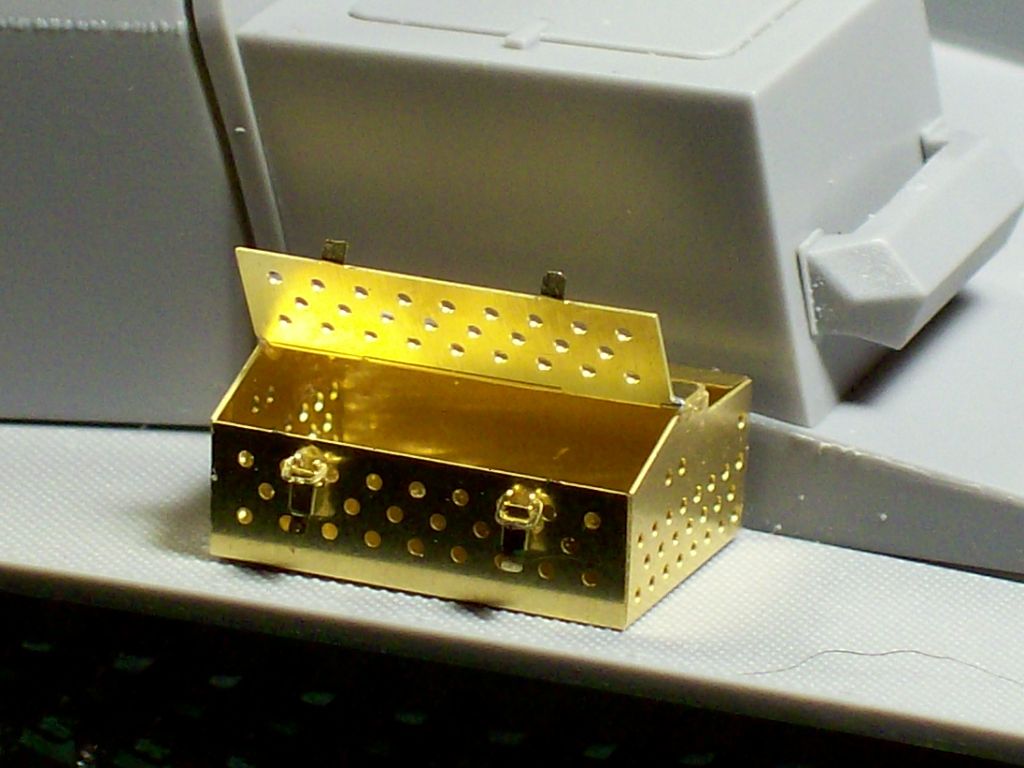

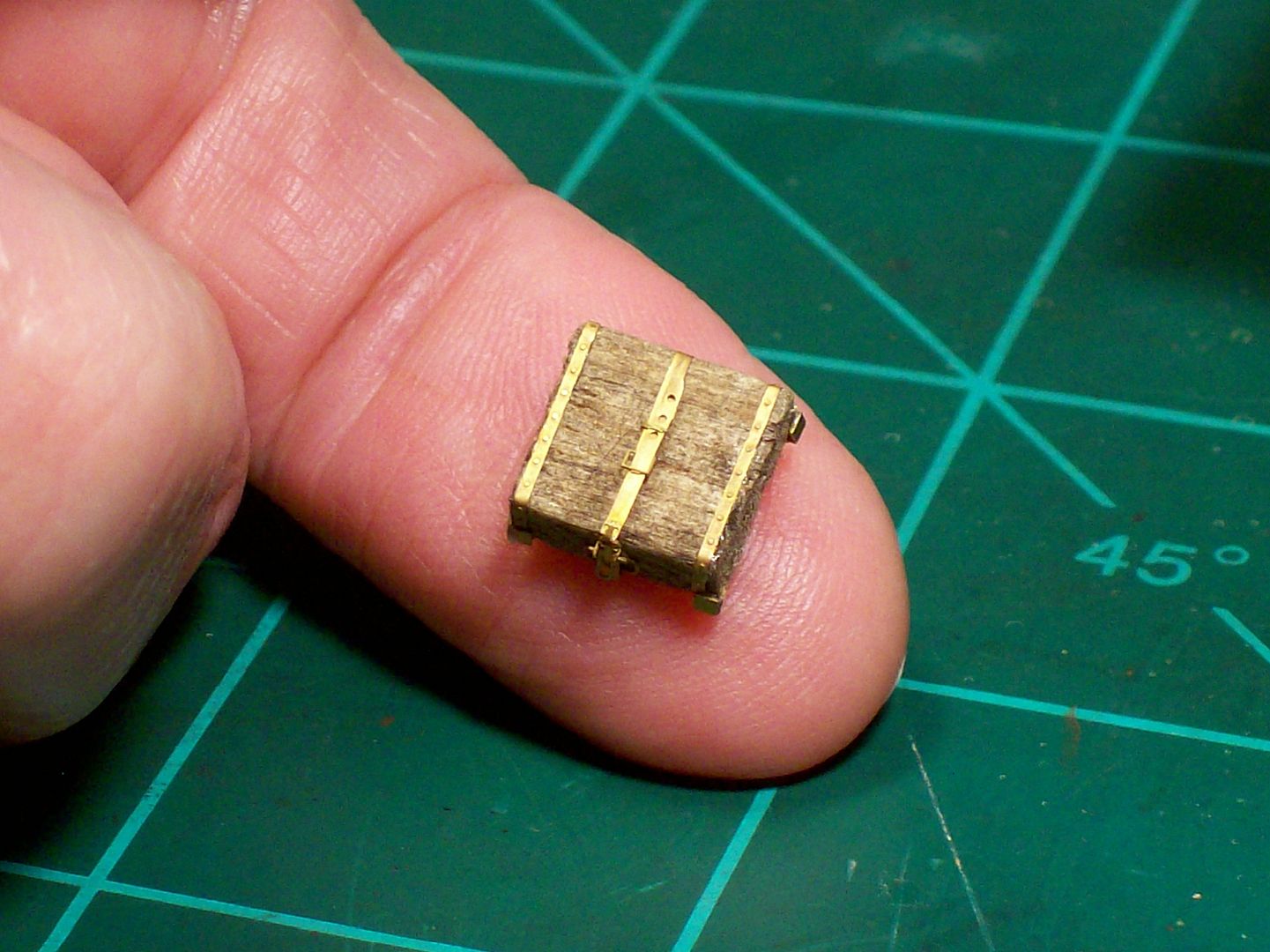

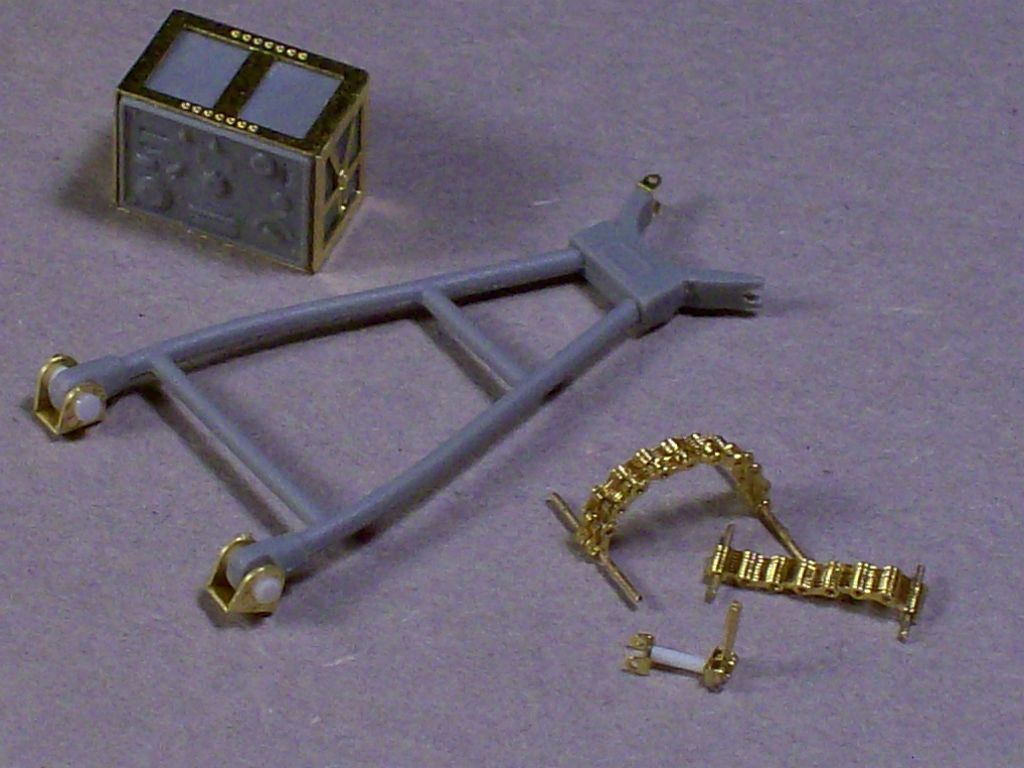

For scale I placed it on the fender of my Max to take the finished pictures.

Pretty good lookin box if I do say so myself.

I'm having fun,aren't you too?:woohoo:

Tony Lee:Hiay