This thread is posted so that people can add to it.

I keep one tube each of thin and gel type cyano-acrylate (super glue) cement in the freezer. This allows longer working time.

My application tools are simple wire loops, drafting pens, modified large sewing needles, and small knitting needles. I rarely use the accelerator spray (I have Zap Kicker) as it smells of bug spray. To control spreading, I use petroleum jelly (Vaseline brand is what is in my workshop but you can grab the Kentucky (use the postal acronym to get this joke) Jelly from the bedroom if you have it to spare :woohoo and cellophane tape of various thicknesses.

and cellophane tape of various thicknesses.

I use the lids from coffee cans to place the puddle of cement. Flex when the glue is dry to remove and re-use the lid.

When using the glues to fill gaps, pin holes, scratches, etc, I mark both sides of the gap or scratch (whatever needs filling), with a permanent marker. I apply the glue, the accelerator (this is done with a tool similar to the wire loop described) and then sand. When the only remaining ink marks are from within the gap or scratch (whatever needs filling), the item is filled and sanded flush.

See here:

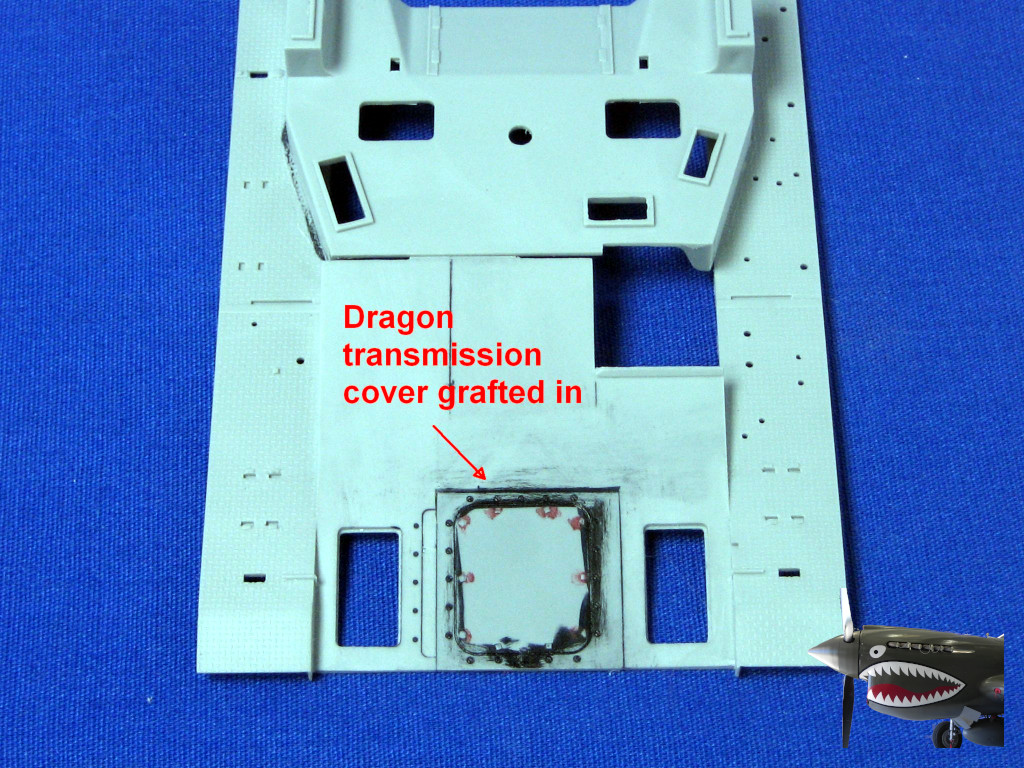

The left side has had the old transmission hatch filled and the new grafted one is in the middle of the sanding process.

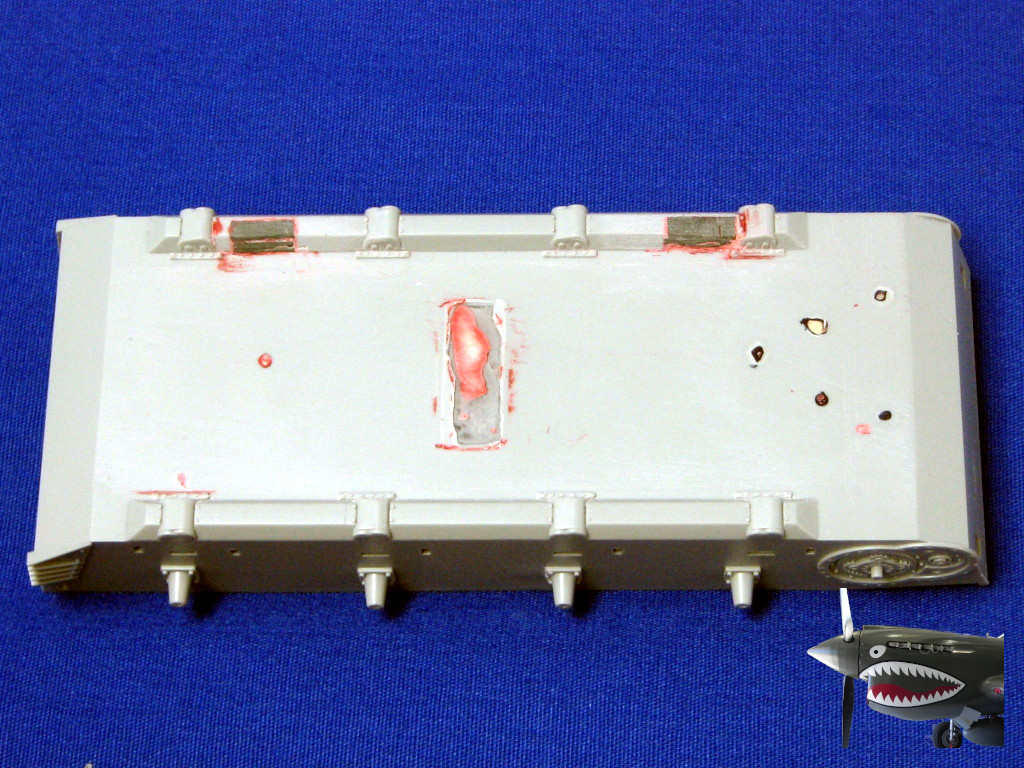

When filling larger gaps, such as those in the suspension beams and the hole on the bottom of this hull tub, I used a piece of cellophane tape pulled taut across the gap.

Cyano-Acrylate glues do not stick to the adhesive side of the cellophane tape (I used packing tape in this instance but office cellophane tape works as well). I placed glue along the edges of the cellophane to plastic joints and placed the rough-cut plastic plug in the large gaps. Allow to dry thoroughly (overnight in this case). Do NOT use an accelerator as I have found these to cause pitting and uneven drying.

Smaller gaps, like those seen towards the front of the hull above caused when I removed some molded-on access plates, can be filled with just CA on the tautly placed cellophane tape. No plastic slugs were used here.

Remove the cellophane and be amazed that the tape's adhesive has not stuck to the glue. The dried Cyano-Acrylate (CA) is shiny and does need some sanding to remove the gloss and ensure it is all flush but this is far easier than with putty and no fear of shrinkage.

I have used both cellophane strips and petroleum jelly to control spreading. When making a fillet on aircraft models (yes, I build those) I have used cellophane stacked to the desired thickness and applied the CA in very thin layers until I achieved the thickness I was after.

A little sanding to even things out, remove the cellophane and VOILA! A fillet that is proud of the surface.

I have been unsuccessful in using CA to make round head rivets on flat disks punched with my trusty Waldron sets. They never dry to the same size and it is obvious.

I hope these tips help.

Let's see what you do...

Regards,

I keep one tube each of thin and gel type cyano-acrylate (super glue) cement in the freezer. This allows longer working time.

My application tools are simple wire loops, drafting pens, modified large sewing needles, and small knitting needles. I rarely use the accelerator spray (I have Zap Kicker) as it smells of bug spray. To control spreading, I use petroleum jelly (Vaseline brand is what is in my workshop but you can grab the Kentucky (use the postal acronym to get this joke) Jelly from the bedroom if you have it to spare :woohoo

I use the lids from coffee cans to place the puddle of cement. Flex when the glue is dry to remove and re-use the lid.

When using the glues to fill gaps, pin holes, scratches, etc, I mark both sides of the gap or scratch (whatever needs filling), with a permanent marker. I apply the glue, the accelerator (this is done with a tool similar to the wire loop described) and then sand. When the only remaining ink marks are from within the gap or scratch (whatever needs filling), the item is filled and sanded flush.

See here:

The left side has had the old transmission hatch filled and the new grafted one is in the middle of the sanding process.

When filling larger gaps, such as those in the suspension beams and the hole on the bottom of this hull tub, I used a piece of cellophane tape pulled taut across the gap.

Cyano-Acrylate glues do not stick to the adhesive side of the cellophane tape (I used packing tape in this instance but office cellophane tape works as well). I placed glue along the edges of the cellophane to plastic joints and placed the rough-cut plastic plug in the large gaps. Allow to dry thoroughly (overnight in this case). Do NOT use an accelerator as I have found these to cause pitting and uneven drying.

Smaller gaps, like those seen towards the front of the hull above caused when I removed some molded-on access plates, can be filled with just CA on the tautly placed cellophane tape. No plastic slugs were used here.

Remove the cellophane and be amazed that the tape's adhesive has not stuck to the glue. The dried Cyano-Acrylate (CA) is shiny and does need some sanding to remove the gloss and ensure it is all flush but this is far easier than with putty and no fear of shrinkage.

I have used both cellophane strips and petroleum jelly to control spreading. When making a fillet on aircraft models (yes, I build those) I have used cellophane stacked to the desired thickness and applied the CA in very thin layers until I achieved the thickness I was after.

A little sanding to even things out, remove the cellophane and VOILA! A fillet that is proud of the surface.

I have been unsuccessful in using CA to make round head rivets on flat disks punched with my trusty Waldron sets. They never dry to the same size and it is obvious.

I hope these tips help.

Let's see what you do...

Regards,