Old Dog

Well-known member

I wasn't sure where to put these but since they are civilian and not military this seemed like the spot. All the structures show are built to 1/24 scale which makes some of them quite large. I also like to build structures that actually existed but do some freelance as well.

First up is this station based on one that once existed in Linnville, NC.

I don't generally put interiors in buildings as one would need to get down on their hands an knees to look through the windows and small exterior details are usually limited as I find they tend to disappear over time. The scale does allow for some detail, this was the first time I ever tried modeling flowers

Next up is a firehouse from Orbisonia, PA. It sat abandoned for a number of years but was refurbished as a residence retaining much the look of the original. I don't have a current photo but here are a couple taken during construction and before painting

Next up is a 20s era gas station (my layout is placed in the 20s). It is free lanced but based on photos of ones from the era. The name is from a friend and fellow model railroader who is an auto mechanic, his screen name is Rooster and hence the chickens and eggs for sale sign

Next up is a grist mill, totally free lance again but using features from photos of a number of structures

Next up is an engine house modeled after one located in Mt. Union, PA, for reference this structure is 17" wide and 33" long making it a handful to work on and move

As I noted earlier I don't usually do interiors but due to the large windows I did put some basic stuff inside

Not all structures are large, these passenger waiting shelters add bit of sometimes overlooked detail

Another small structure is this water tank made from an old tank car, such things were common on branch and short line railroads

This trestle with a wooden truss bridge was built to replace a 20+ year old structure that has seen its better day

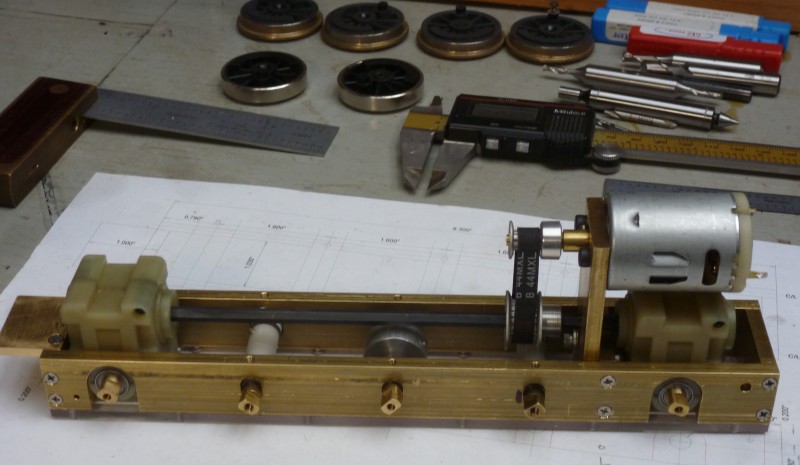

The next item wasn't a total scratch build, the boiler,cab and superstructure were from another locomotive with some details changed and others added, the frame and drive were scratch built. The goal was to create a locomotive type not commercially available. The frame was machined from brass and the motor, gearboxes and other drive parts were commercially available parts. I have a small lathe and bench top milling machine and I love designing and building drive trains. Brass is my favorite material to machine,it's easy on tooling and for the most part doesn't require lubrication making clean up easy. The completed locomotive

And a photo of the frame and drive under construction

OK, I won't bore you with any more, any questions feel free to ask and as always thanks for looking

First up is this station based on one that once existed in Linnville, NC.

I don't generally put interiors in buildings as one would need to get down on their hands an knees to look through the windows and small exterior details are usually limited as I find they tend to disappear over time. The scale does allow for some detail, this was the first time I ever tried modeling flowers

Next up is a firehouse from Orbisonia, PA. It sat abandoned for a number of years but was refurbished as a residence retaining much the look of the original. I don't have a current photo but here are a couple taken during construction and before painting

Next up is a 20s era gas station (my layout is placed in the 20s). It is free lanced but based on photos of ones from the era. The name is from a friend and fellow model railroader who is an auto mechanic, his screen name is Rooster and hence the chickens and eggs for sale sign

Next up is a grist mill, totally free lance again but using features from photos of a number of structures

Next up is an engine house modeled after one located in Mt. Union, PA, for reference this structure is 17" wide and 33" long making it a handful to work on and move

As I noted earlier I don't usually do interiors but due to the large windows I did put some basic stuff inside

Not all structures are large, these passenger waiting shelters add bit of sometimes overlooked detail

Another small structure is this water tank made from an old tank car, such things were common on branch and short line railroads

This trestle with a wooden truss bridge was built to replace a 20+ year old structure that has seen its better day

The next item wasn't a total scratch build, the boiler,cab and superstructure were from another locomotive with some details changed and others added, the frame and drive were scratch built. The goal was to create a locomotive type not commercially available. The frame was machined from brass and the motor, gearboxes and other drive parts were commercially available parts. I have a small lathe and bench top milling machine and I love designing and building drive trains. Brass is my favorite material to machine,it's easy on tooling and for the most part doesn't require lubrication making clean up easy. The completed locomotive

And a photo of the frame and drive under construction

OK, I won't bore you with any more, any questions feel free to ask and as always thanks for looking