Adam Baker

Active member

Got this kit from Saul, to do a build review, and then he posted up a pic of the truck w/ a face drawn on it and suggested building it at part of the Face It campaign, so here I am!

This is actually a combination of 2 kits.

The 2 wheel chassis is part of the M-1078 uparmored FMTV kit, w/ the soft side/unarmored cab from the 3 axle M-1083 kit.

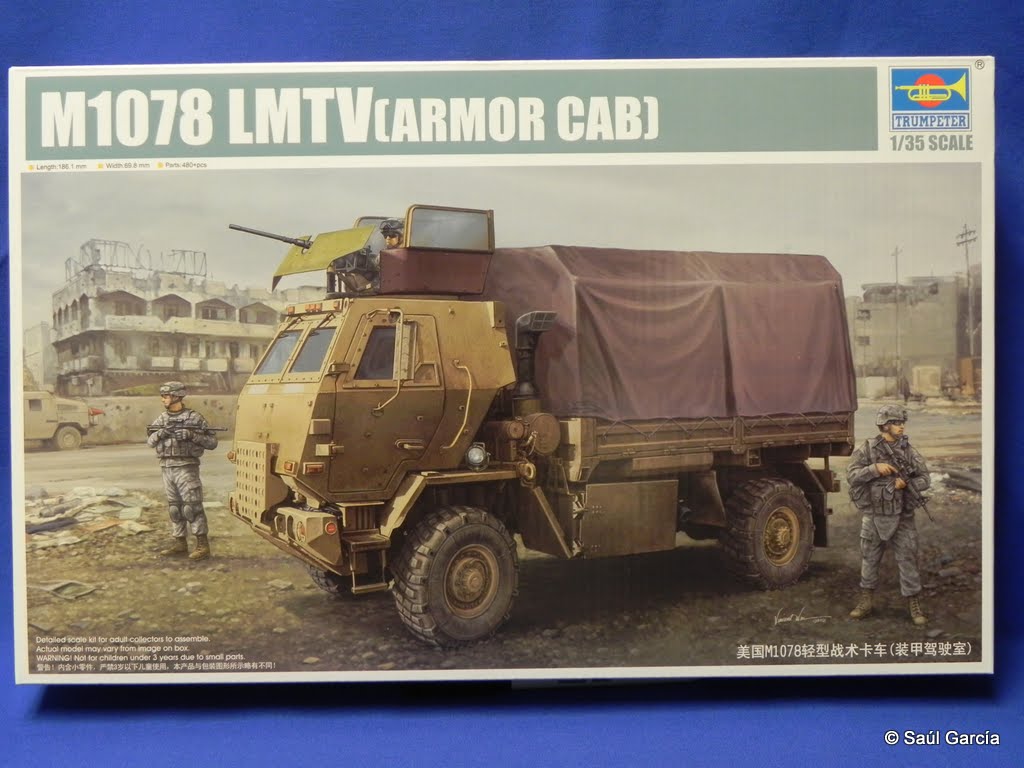

M-1078 Kit

Pic of the real thing w/ the face.

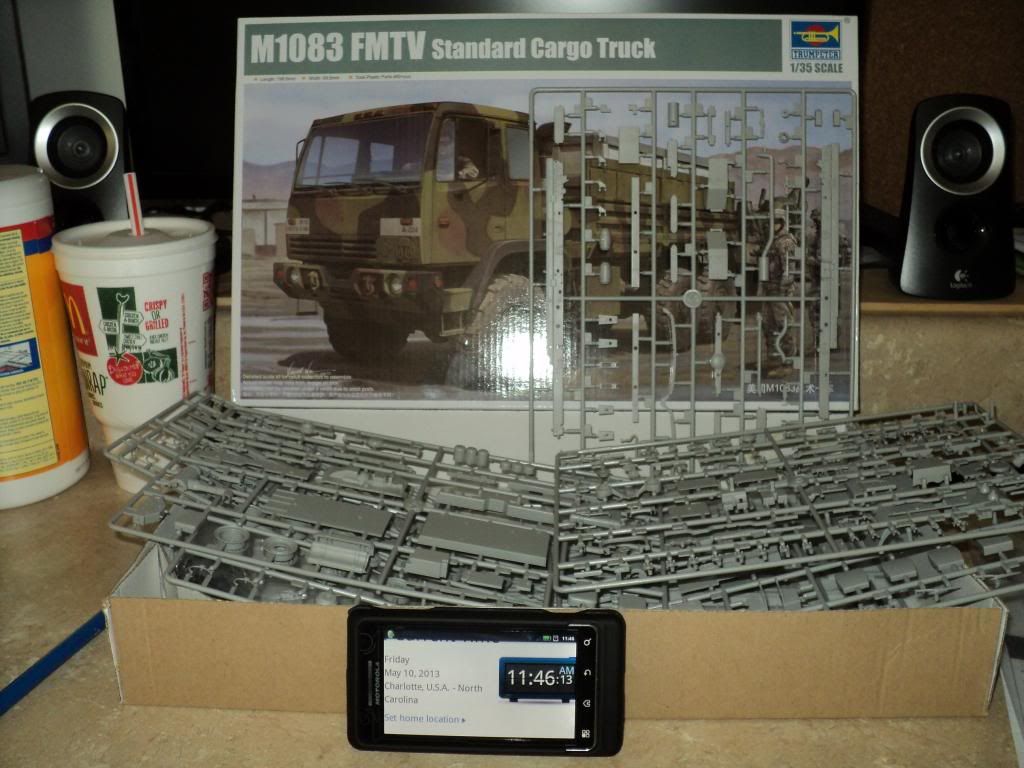

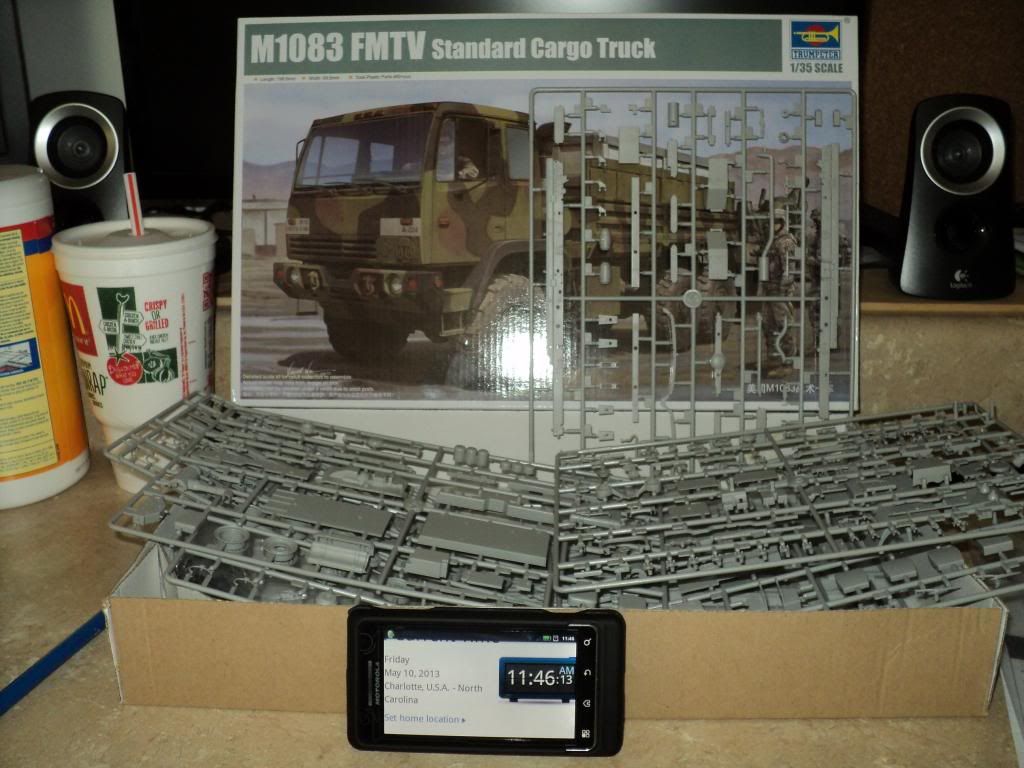

And then the requisite time stamp shots.

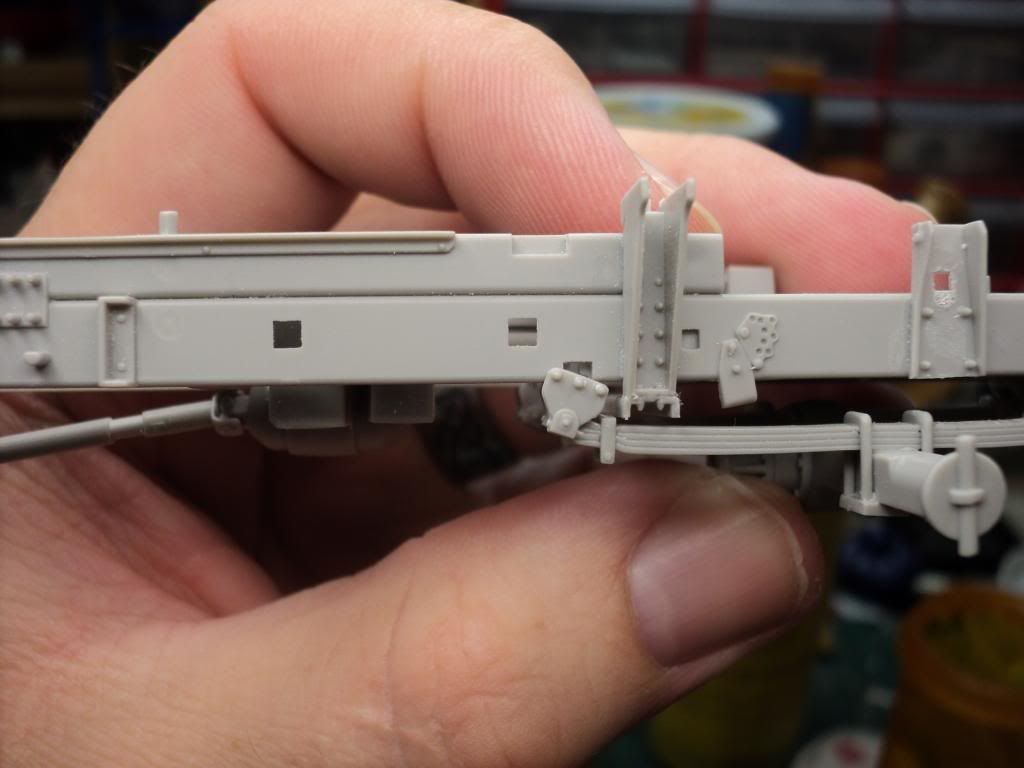

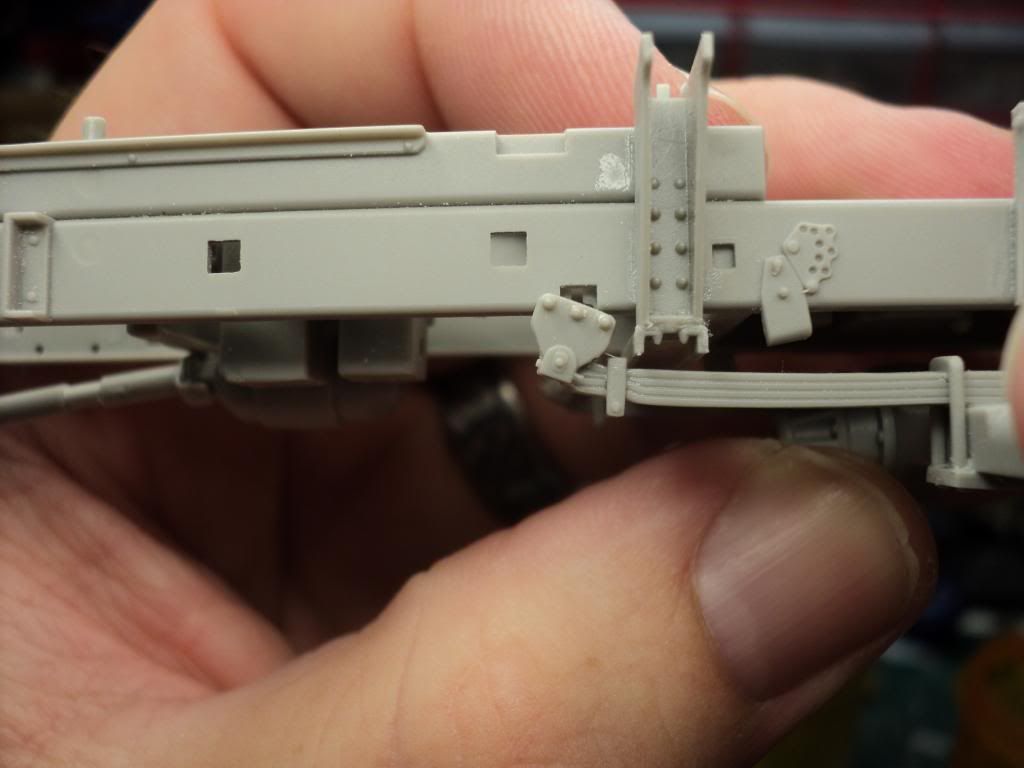

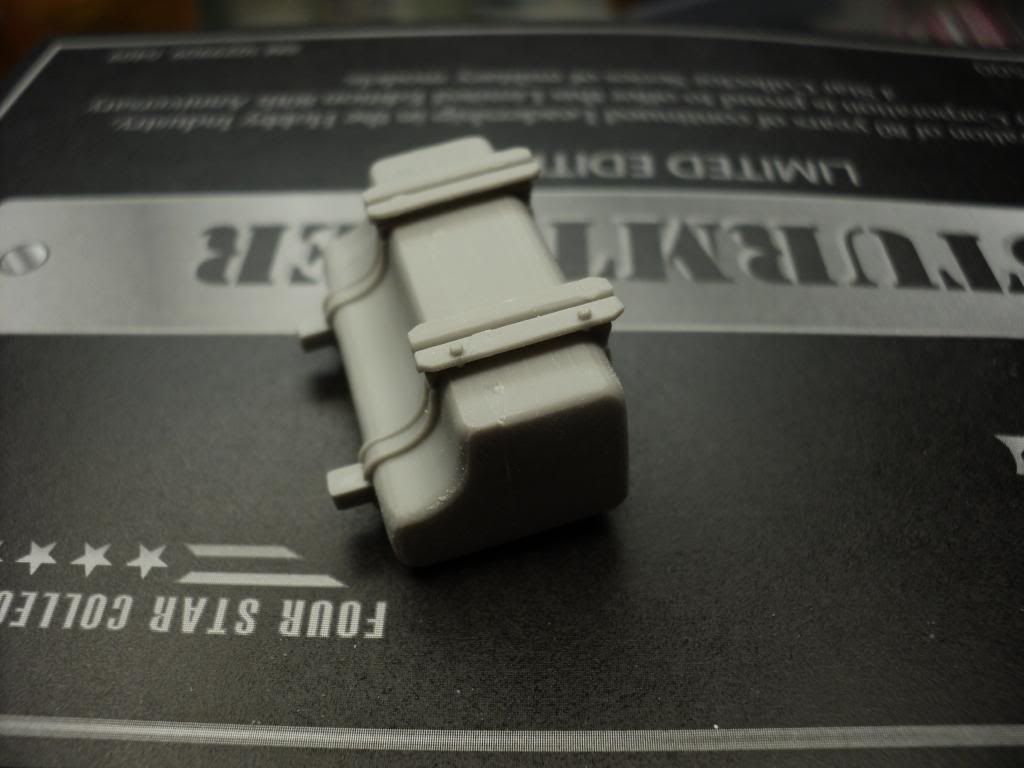

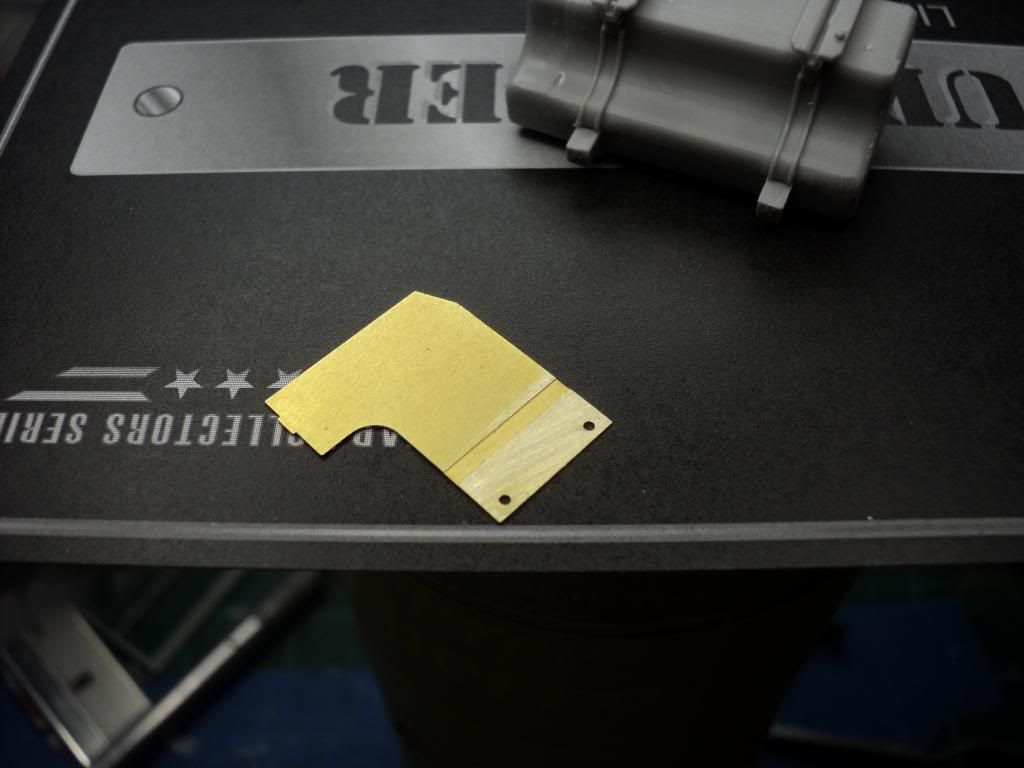

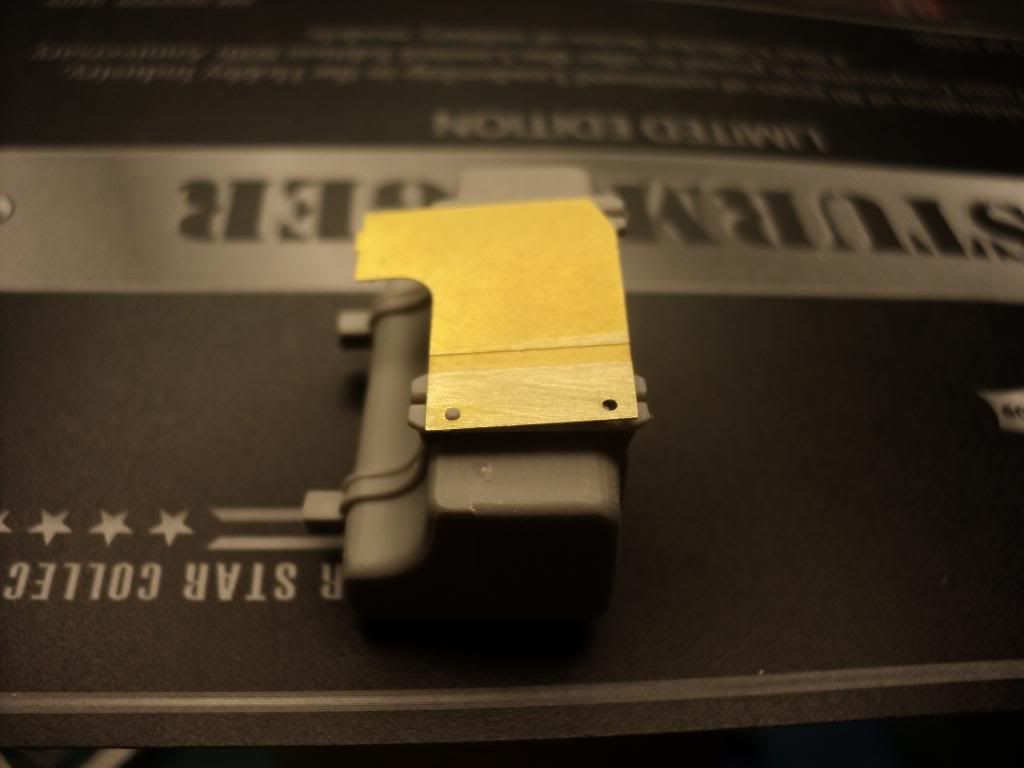

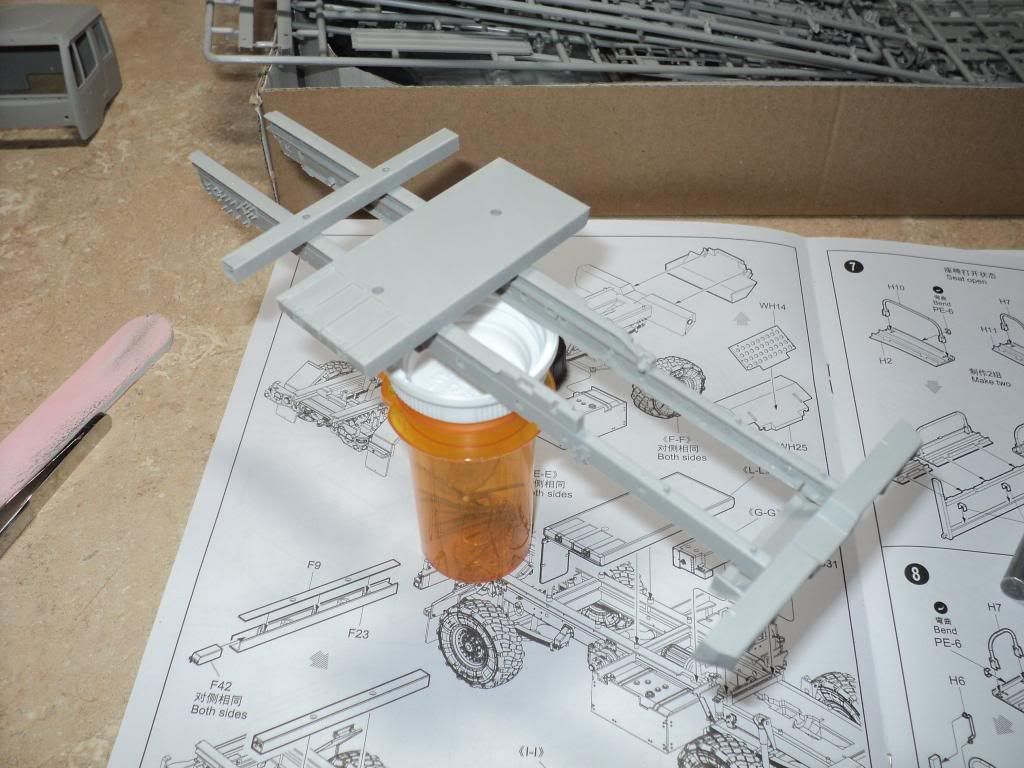

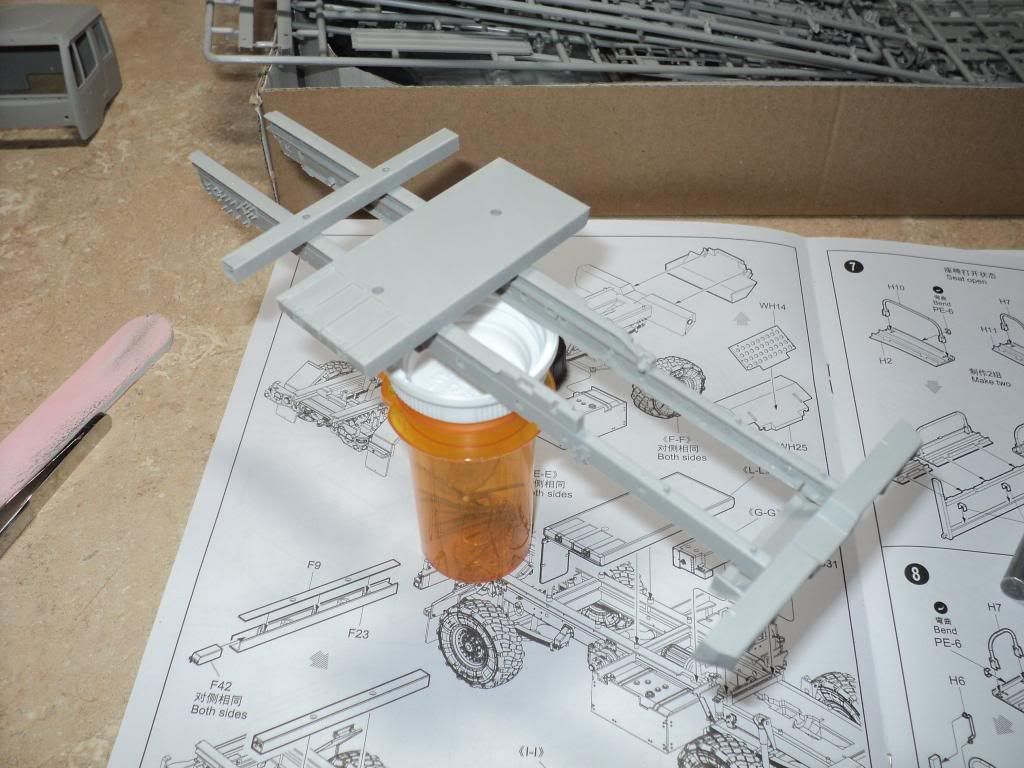

The instructions have you start by building the frame, but since its separate frame rails w/ cross pieces, I decided to start by building the pieces that span the frame, prior to building the frame, so that I could attempt to make sure that the frame was straight & square, so that all 4 wheels touch the ground.

I also started assembling the cab, to help keep everything square.

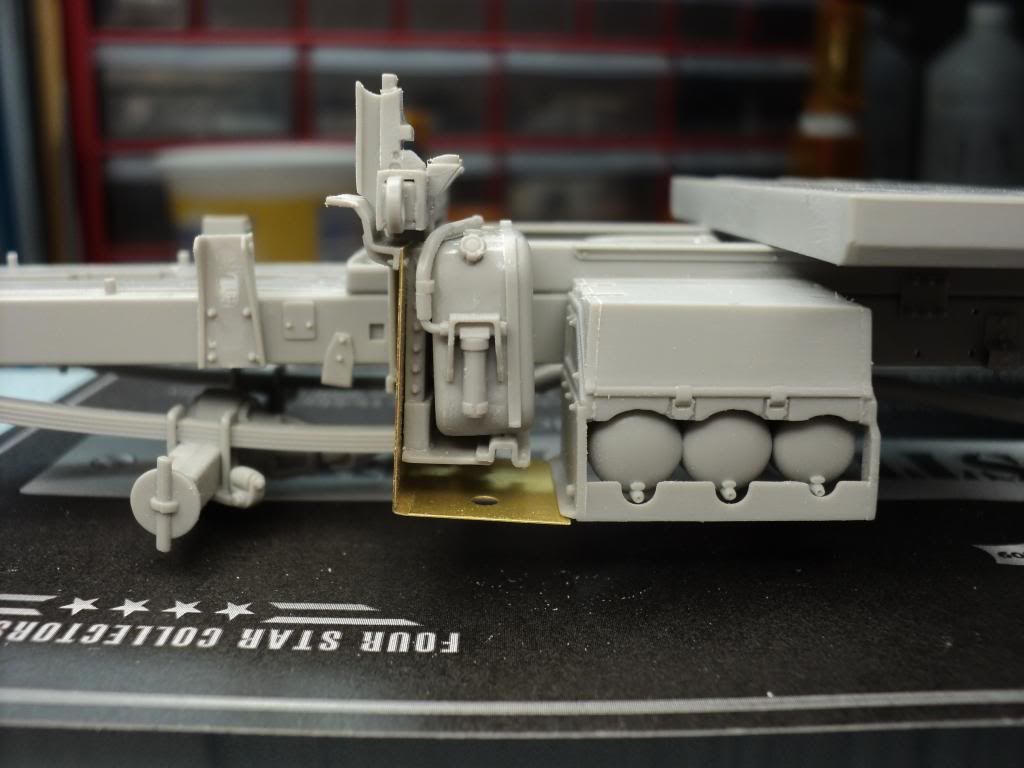

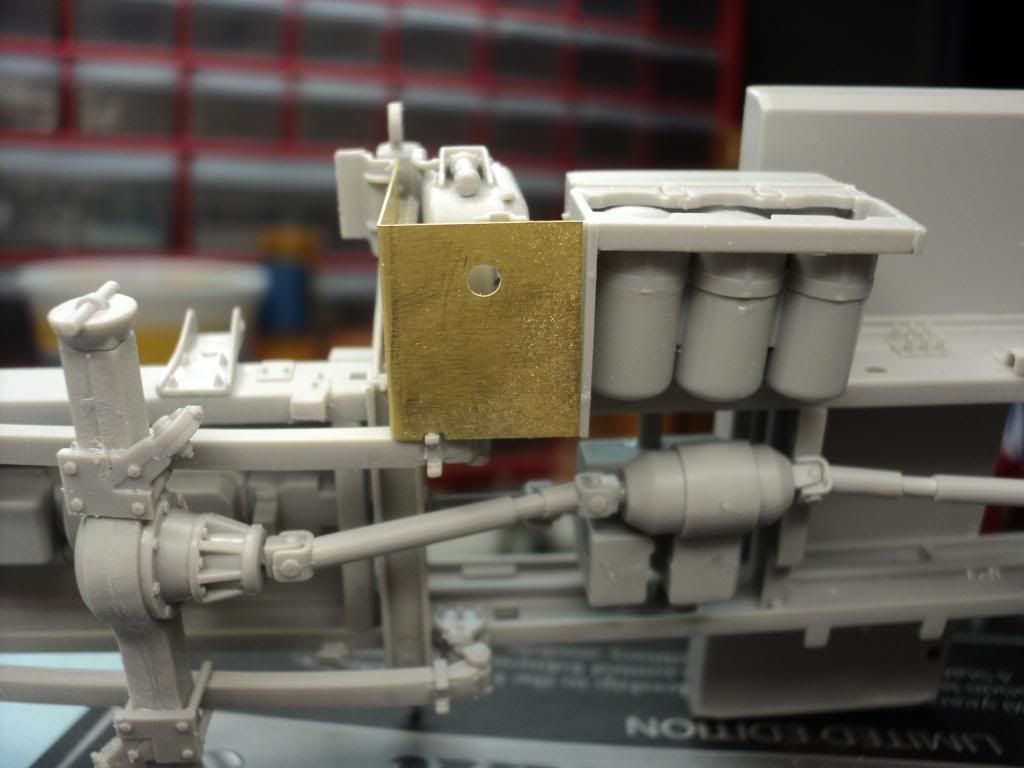

Once that was done, I started working on assembling the frame.

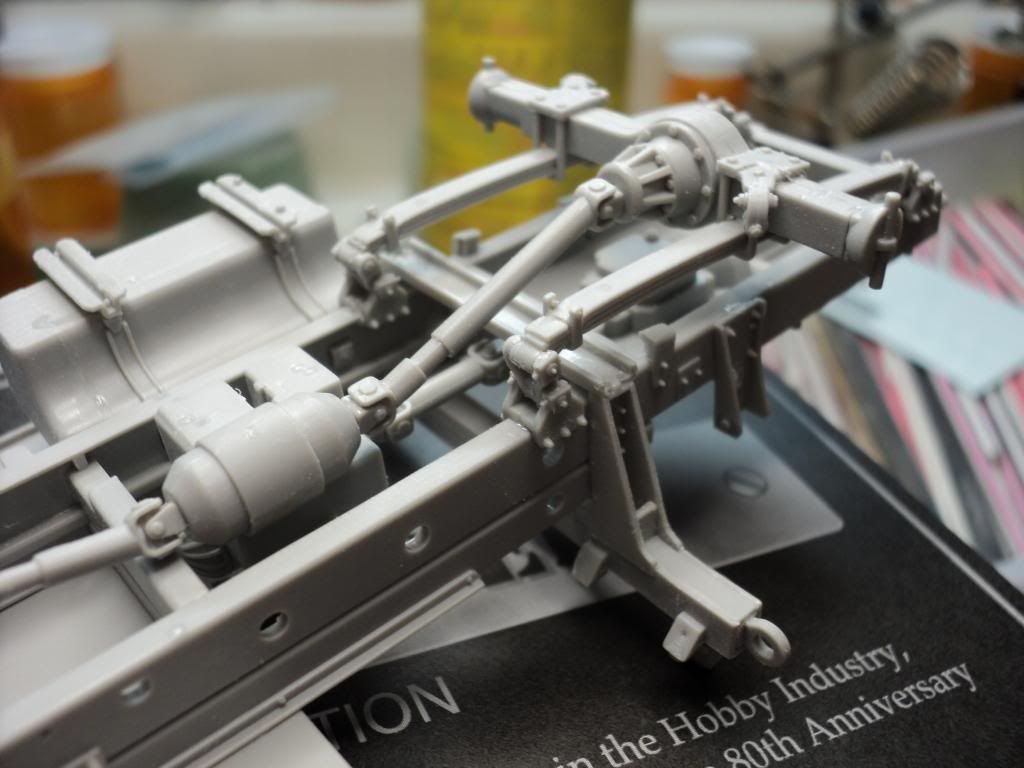

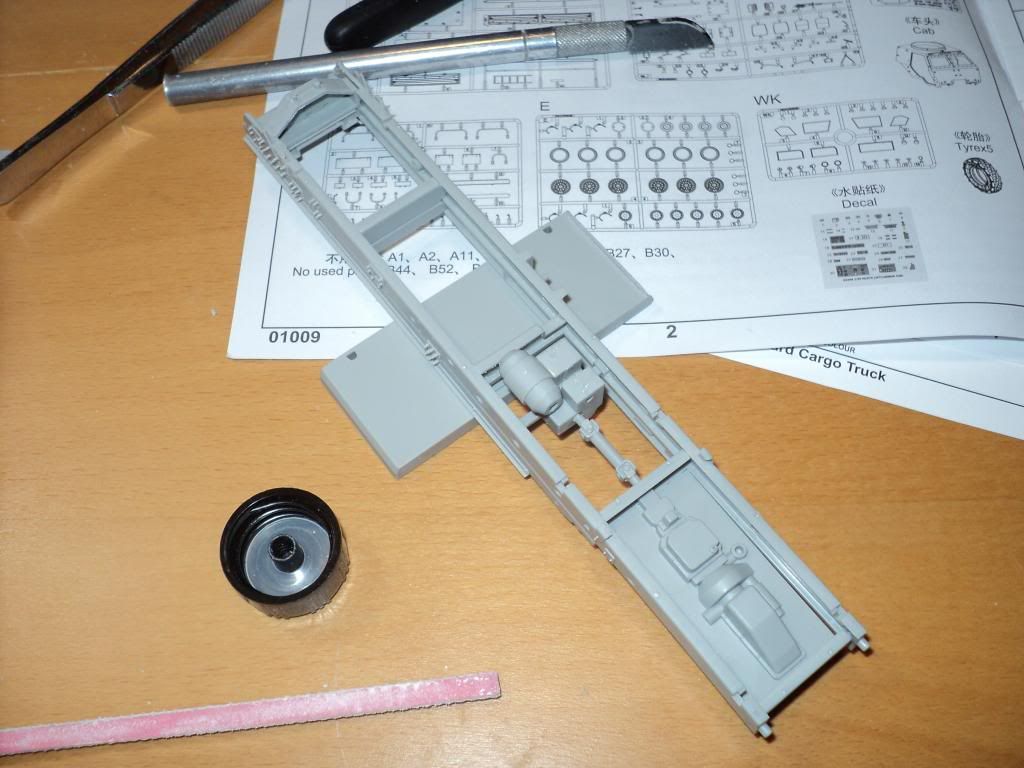

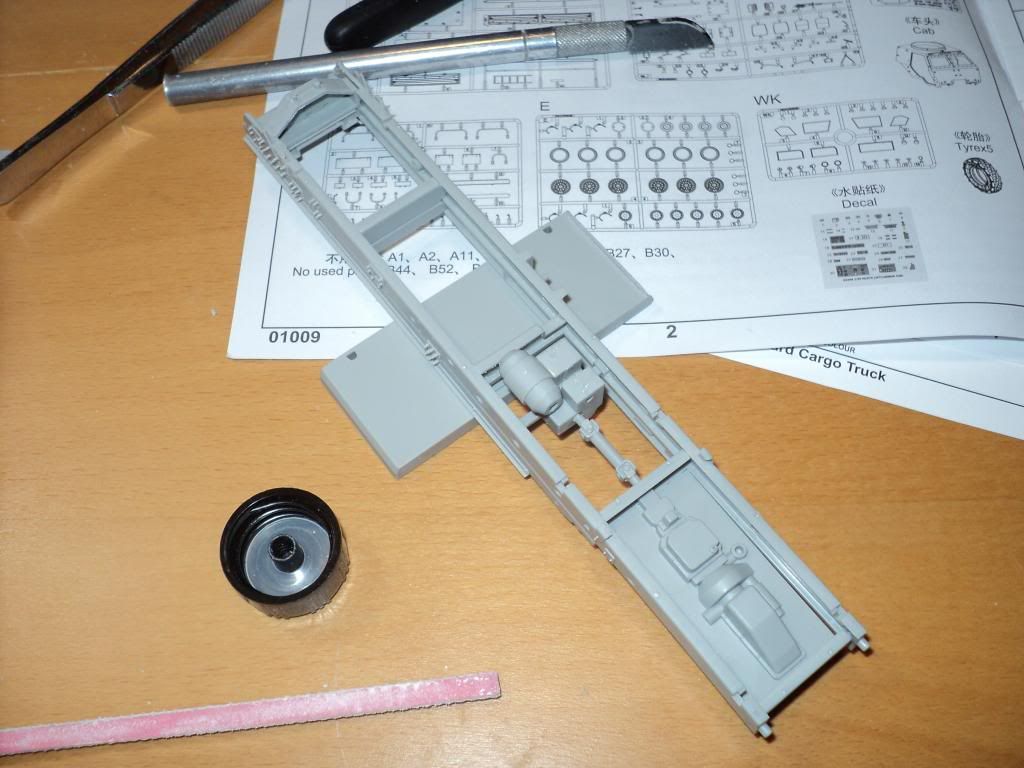

And here the frame is completely assembled.

I've started working on the suspension components so that I can assemble the whole suspension in a single go, to ensure as much as possible that all 4 wheels will touch the ground.

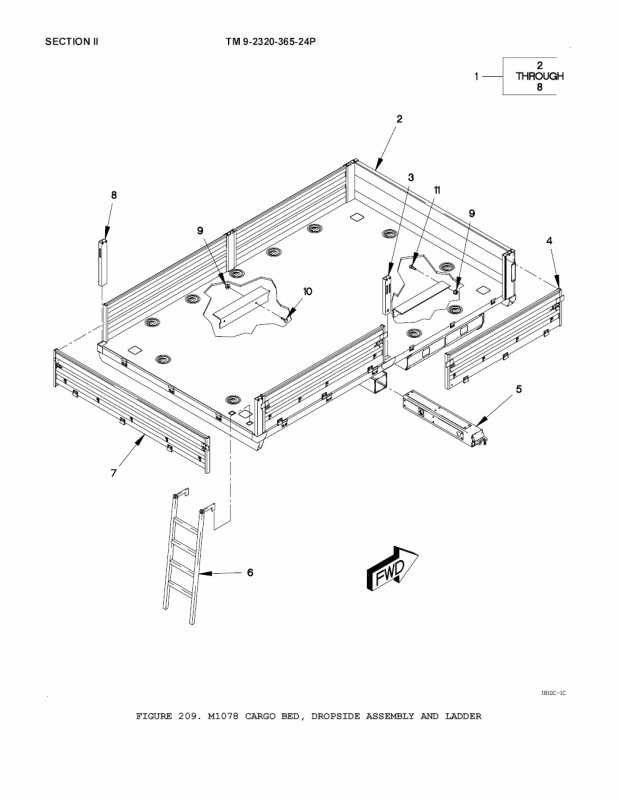

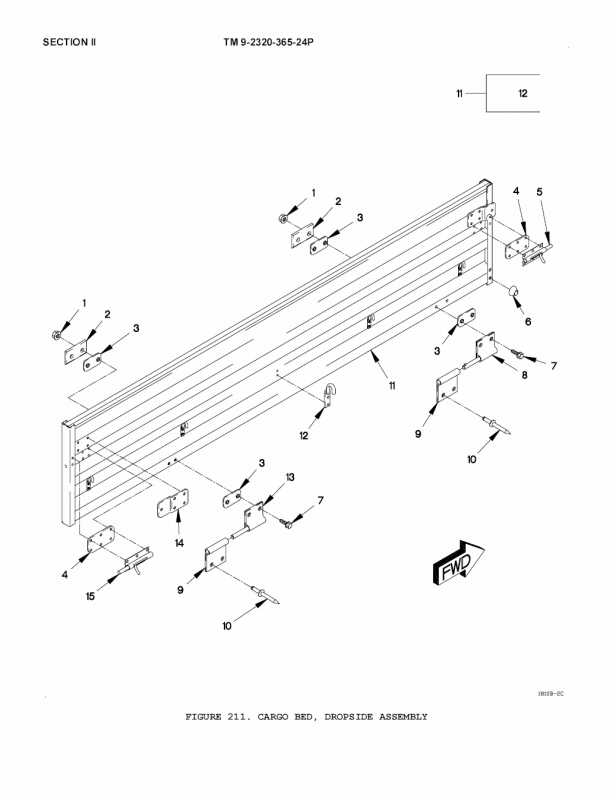

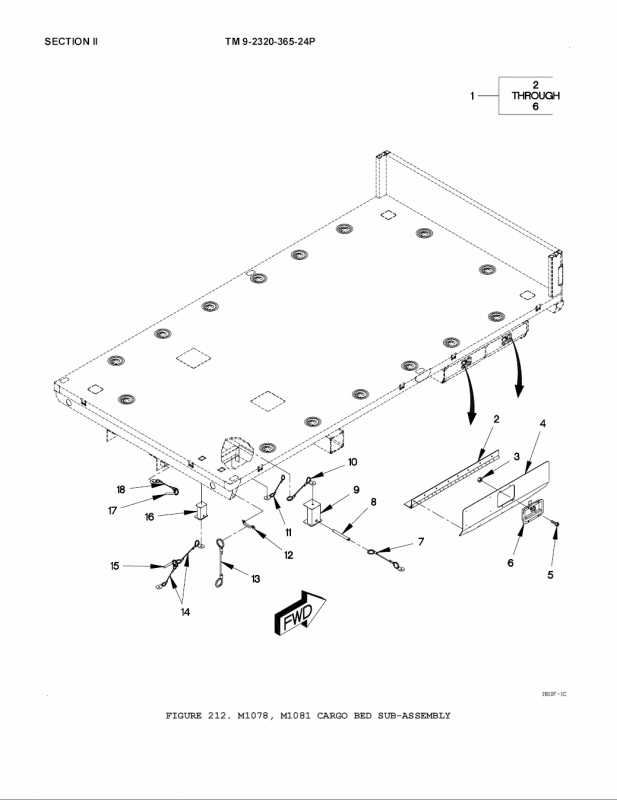

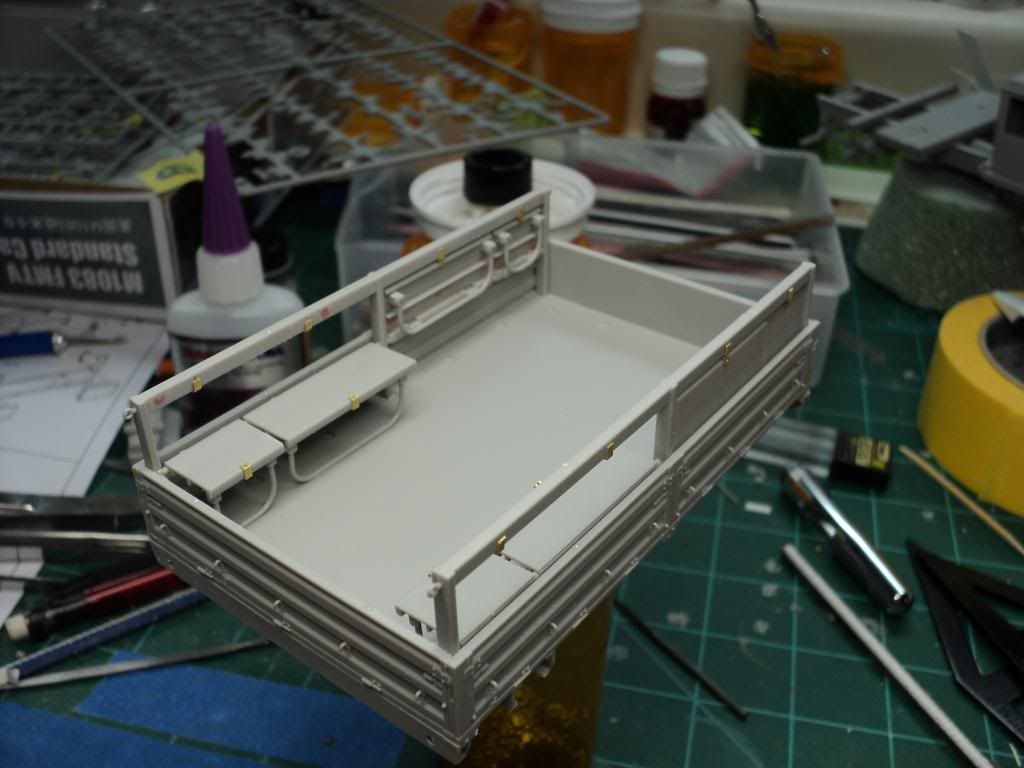

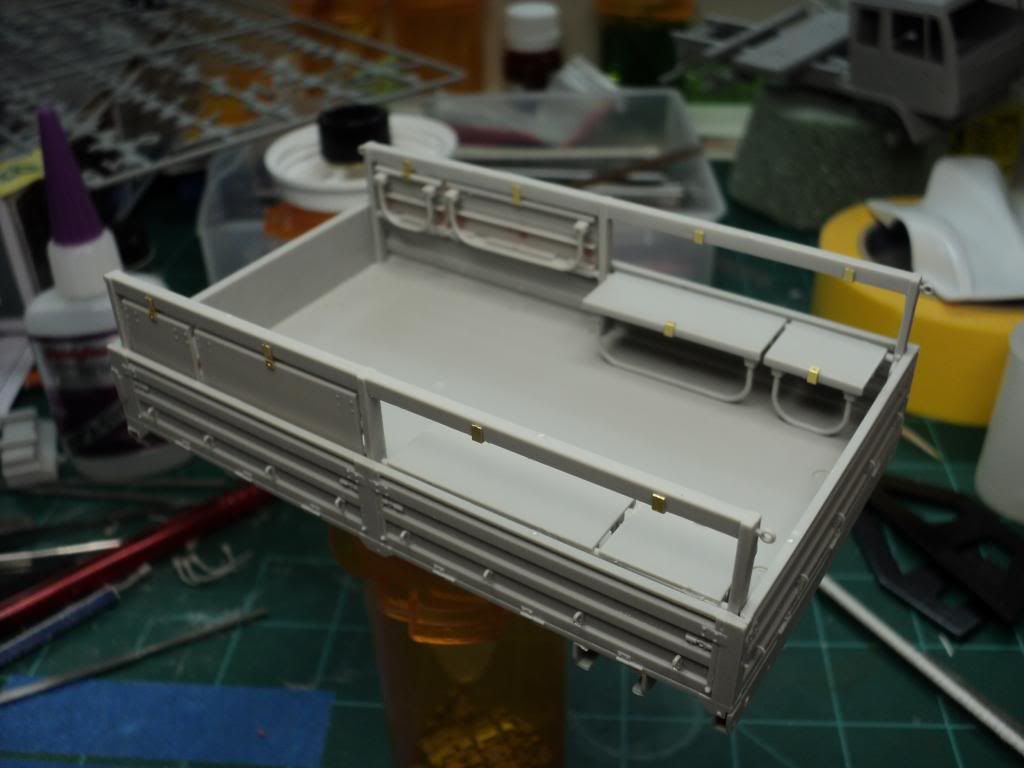

I've also started looking at the cargo bed. The kit doesnt come w/ provisions for the canopy over the bed, but I dont think it would be too incredibly difficult to fashion the frames & the canopy. The kit also comes w/ an option for the troop seats in the bed, either in the up or down position, so I'm thinking about maybe doing it half & half. One side willl have the seats up, and the other side will have the seats down. Thinking about maybe putting some cargo in the bed w/ a couple soldiers sitting on the seats.

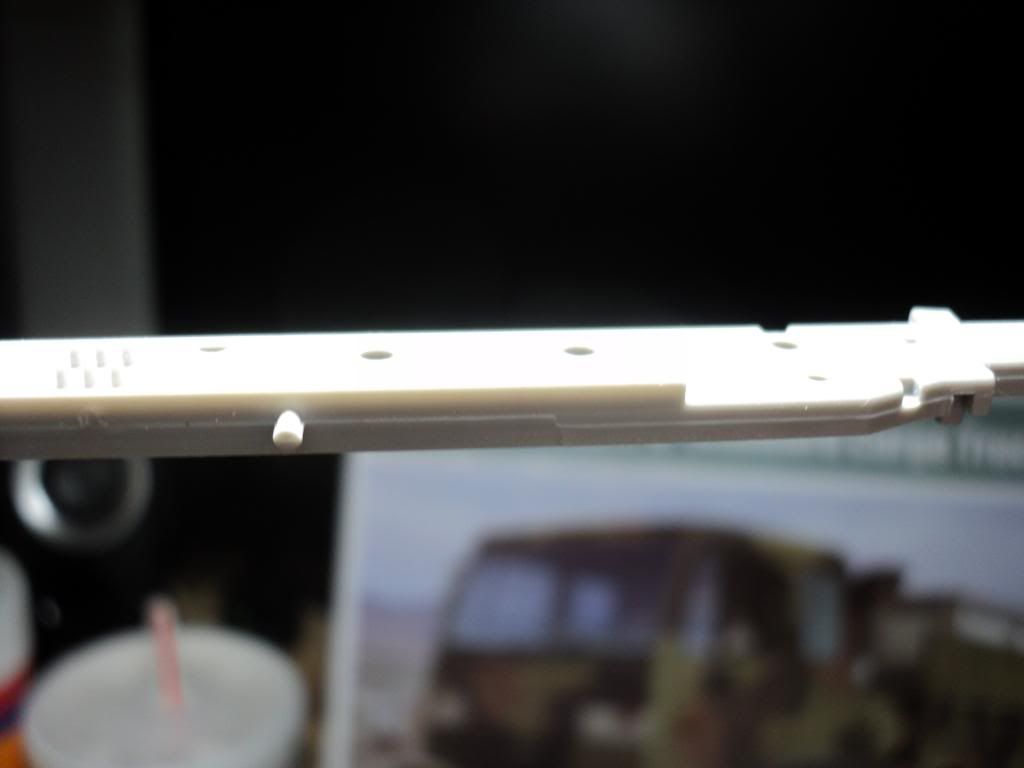

So far I'm impressed w/ the kit. Its the first Trumpeter kit I've worked on. Fit so far has been very nice, w/ no real issues as far as fit is concerned. I have noticed that the mold seams are a bit heavy in places, w/ the frame rails so far having the heaviest seams I've had to deal w/.

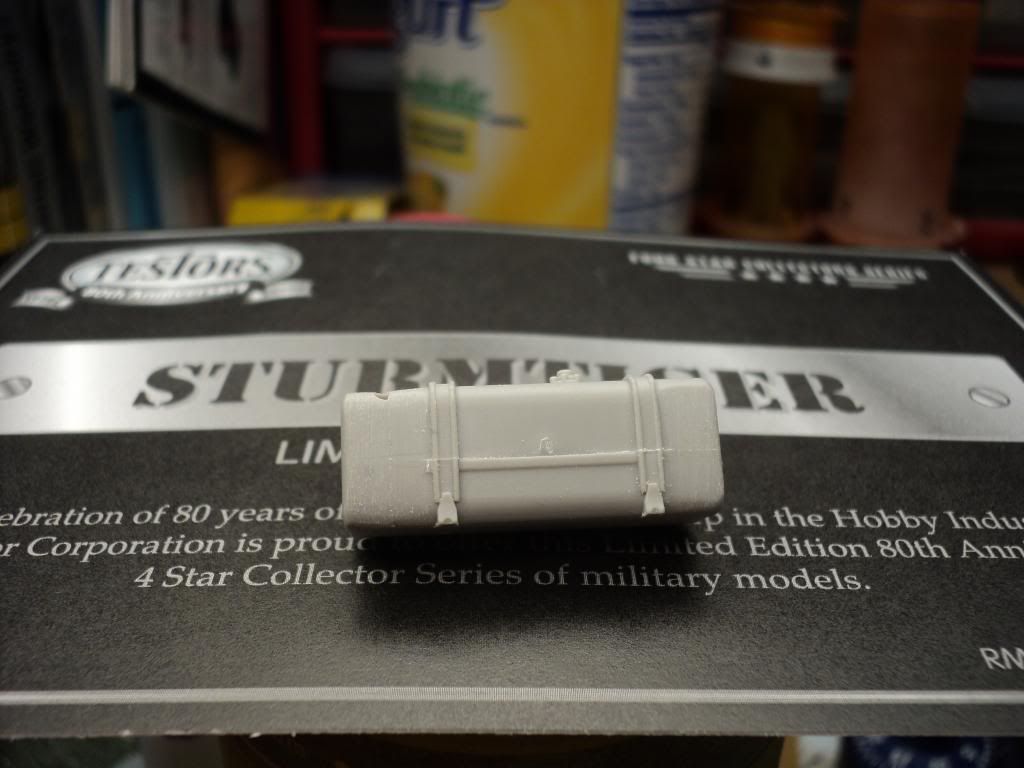

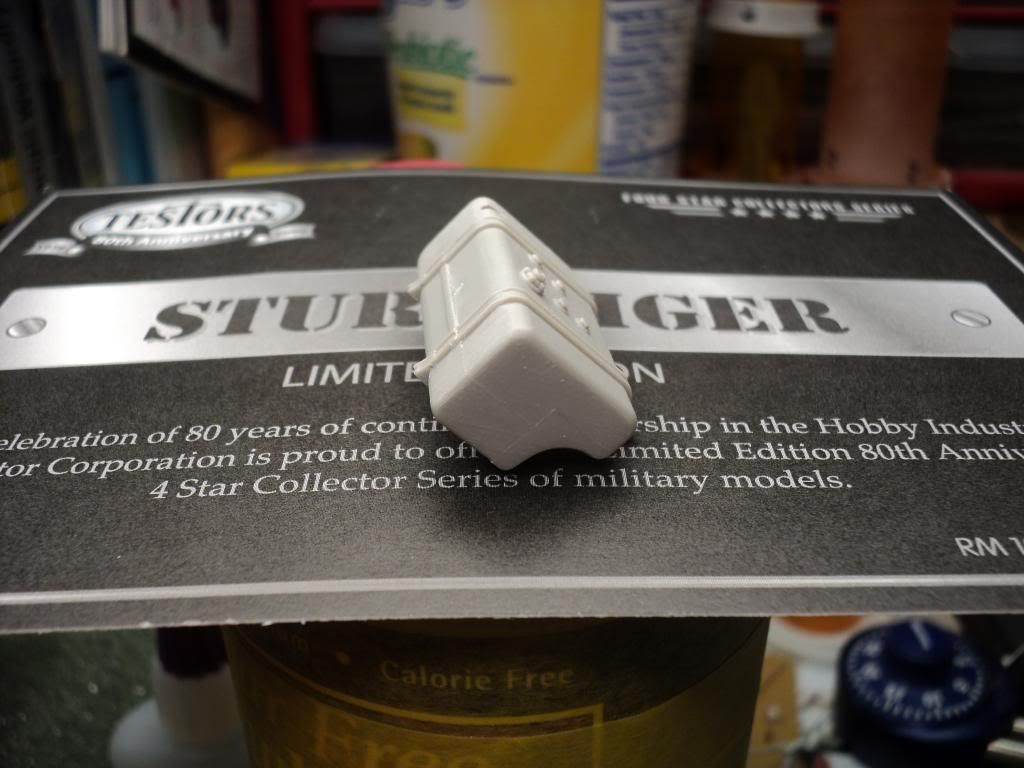

Here's a picture, but its not the best. I was at my mom's place this weekend, so didnt have my photobooth or anything w/ me to help get better pictures.

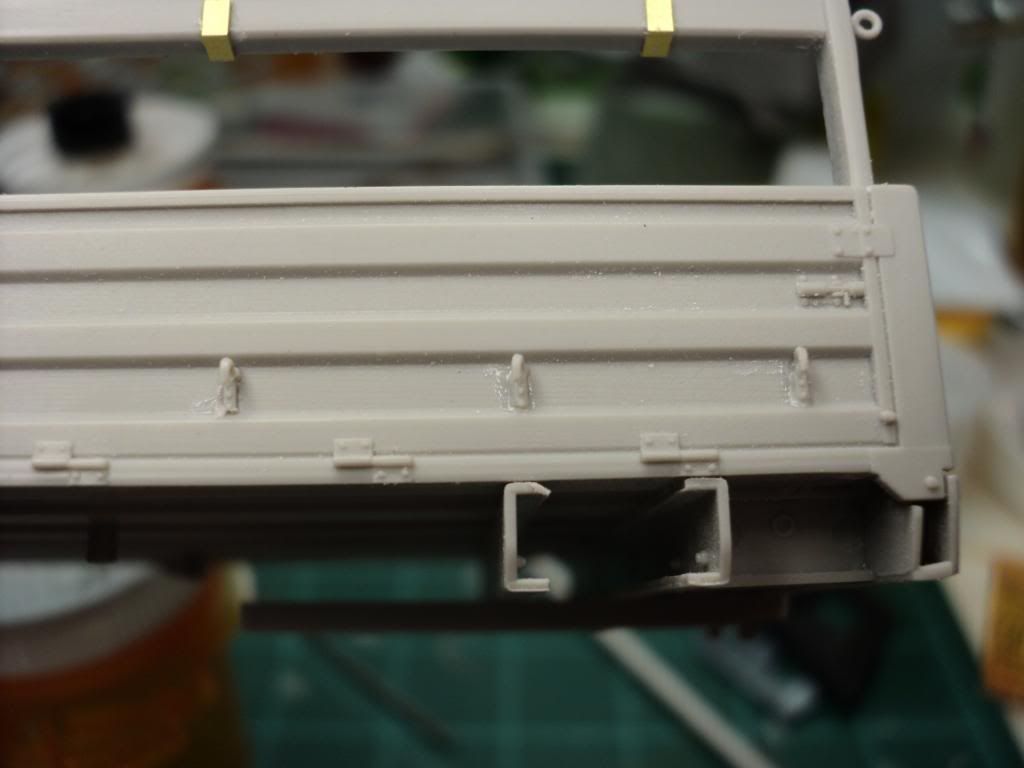

There is an abundance of punch marks, but the vast majority seem to be placed in areas that either wont be seen at all, or are in places that are difficult to see. The most visible punch marks are on the insides of the cargo bed sides, but thankfully they're fairly small and should be easily dealt w/ by using punched .010" styrene disks that I can sand flush.

This is actually a combination of 2 kits.

The 2 wheel chassis is part of the M-1078 uparmored FMTV kit, w/ the soft side/unarmored cab from the 3 axle M-1083 kit.

M-1078 Kit

Pic of the real thing w/ the face.

And then the requisite time stamp shots.

The instructions have you start by building the frame, but since its separate frame rails w/ cross pieces, I decided to start by building the pieces that span the frame, prior to building the frame, so that I could attempt to make sure that the frame was straight & square, so that all 4 wheels touch the ground.

I also started assembling the cab, to help keep everything square.

Once that was done, I started working on assembling the frame.

And here the frame is completely assembled.

I've started working on the suspension components so that I can assemble the whole suspension in a single go, to ensure as much as possible that all 4 wheels will touch the ground.

I've also started looking at the cargo bed. The kit doesnt come w/ provisions for the canopy over the bed, but I dont think it would be too incredibly difficult to fashion the frames & the canopy. The kit also comes w/ an option for the troop seats in the bed, either in the up or down position, so I'm thinking about maybe doing it half & half. One side willl have the seats up, and the other side will have the seats down. Thinking about maybe putting some cargo in the bed w/ a couple soldiers sitting on the seats.

So far I'm impressed w/ the kit. Its the first Trumpeter kit I've worked on. Fit so far has been very nice, w/ no real issues as far as fit is concerned. I have noticed that the mold seams are a bit heavy in places, w/ the frame rails so far having the heaviest seams I've had to deal w/.

Here's a picture, but its not the best. I was at my mom's place this weekend, so didnt have my photobooth or anything w/ me to help get better pictures.

There is an abundance of punch marks, but the vast majority seem to be placed in areas that either wont be seen at all, or are in places that are difficult to see. The most visible punch marks are on the insides of the cargo bed sides, but thankfully they're fairly small and should be easily dealt w/ by using punched .010" styrene disks that I can sand flush.