What tool would you like to see on the market?

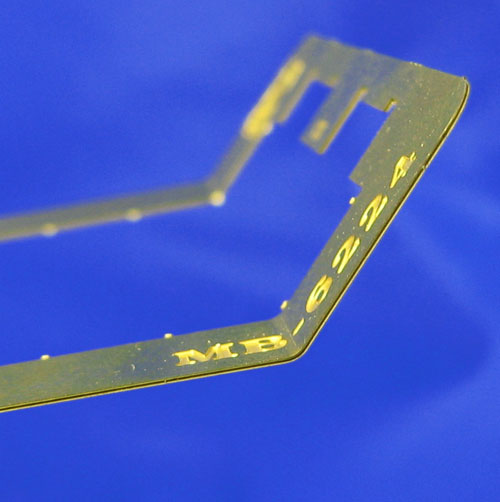

I bought the Elbow Bender from UMM-USA the other week.

http://umm-usa.com/onlinestore/product_info.php?cPath=21_100&products_id=28

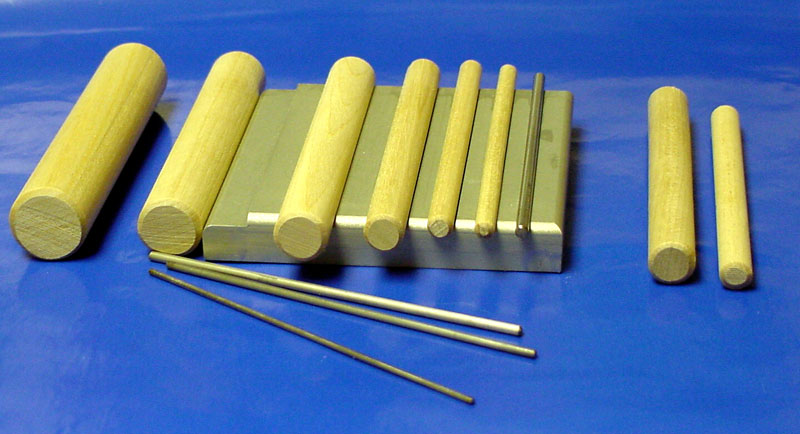

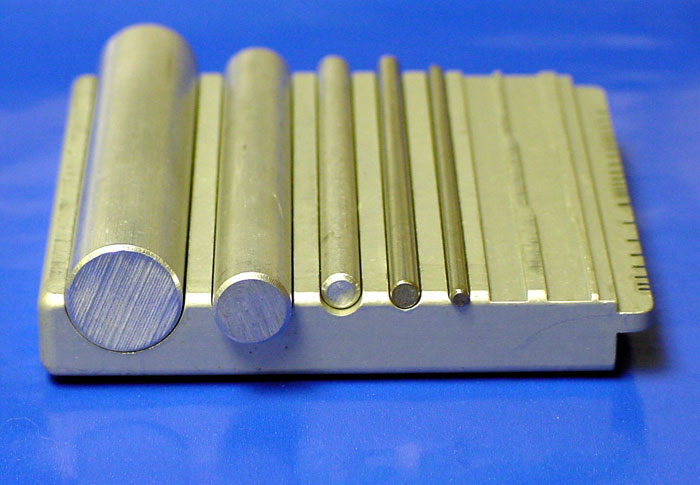

Along with the punch and die set.

http://umm-usa.com/onlinestore/product_info.php?cPath=21_145&products_id=3660

I played around with the Elbow bender some last night and found some of it's shortcomings. For one thing, it has recessed hex head screws to secure your work. Well that's kinda cumbersome when you are trying to line up your work and keep everything square. Should be thumb screws IMHO.

The Small Shop makes a great line of PE Folders. I have the 8 inch one.

http://thesmallshop.com/index.php?main_page=product_info&cPath=2&products_id=8

Has thumbscrews to secure the work and the hold down plate is spring loaded so when you loosen the screws the hold down plate lifts up and gets out of the way.

I want to see someone combine the two! Put a break/Elbow bender on a PE hold and fold. I know it would cost a good bit but if it's the quality of The Small Shop products it would be worth it.

That's all..

OH and Brass Bazookas! :dude

I bought the Elbow Bender from UMM-USA the other week.

http://umm-usa.com/onlinestore/product_info.php?cPath=21_100&products_id=28

Along with the punch and die set.

http://umm-usa.com/onlinestore/product_info.php?cPath=21_145&products_id=3660

I played around with the Elbow bender some last night and found some of it's shortcomings. For one thing, it has recessed hex head screws to secure your work. Well that's kinda cumbersome when you are trying to line up your work and keep everything square. Should be thumb screws IMHO.

The Small Shop makes a great line of PE Folders. I have the 8 inch one.

http://thesmallshop.com/index.php?main_page=product_info&cPath=2&products_id=8

Has thumbscrews to secure the work and the hold down plate is spring loaded so when you loosen the screws the hold down plate lifts up and gets out of the way.

I want to see someone combine the two! Put a break/Elbow bender on a PE hold and fold. I know it would cost a good bit but if it's the quality of The Small Shop products it would be worth it.

That's all..

OH and Brass Bazookas! :dude