I found these old photos from the VLS years. I thought they might be of interest. The photos are in stages. The first ones are from 1983, when I started up the business until 1985, when I had to retire from the St. Louis police department and run it full time. We moved to our first industrial location at number #14 and number # 17 Cross Keys Center. I will begin with this post and continue in subsequent posts as I scan the photos. Of course, there will be some photos duplicated from my other posts of stories from the past.

From 1983 to 1988

This is the first of a series of VLS nostalgia, beginning way back in December, 1983. The first volume is from 1983 to around 1988. As I find and process the photos, I will be adding to all the volumes taking a pictorial journey from 1983 when it was started in my basement, to January, 2007, when it was sold to MMD/Squadron in Dallas,Texas. During my last visit to that company in July, 2015, I was surprised to see so much of VLS office furniture as well as shelving and production/warehouse equipment. Even the CEO's office was furnished with the same items from my old office ar VLS. It was very nostalgic for me. MMD/Squadron ceased to exist several months ago. A pity, both companies had long histories in the model industry. The original Squadron/MMD was created by Jerry Campbell. Jerry Campbell had a brilliant mind for business. He was from the beginning, my most dreaded competitor. He sold MMD to the same financial institution that a short time later would buy VLS.

Both Jerry and I were lifetime modelers. That certainly doesn't mean just because we were that all modelers can be good managers of model businesses. I do believe that good managers MUST have a knowledge of the model business in order to succeed. It is a truly unique business. Both subsequent managers appointed by the corporation in Florida were savvy, talented managers. Neither had a clue about the model business. Most good business managers are capable of running most types of businesses, but, the model business is so unique, it requires both good management skills as well as a serious knowledge of models and the model market. I always kept some modelers on staff at VLS, but I quickly learned to know which were advising me out of knowledge rather than emotions. One of my first was a guy that loved US Army jeeps. After he left, I had an overstock of Jeep kits for years. You must separate yourself from the modeler and the businessman and allow each to do his job independently. The modeler is not a good businessman and the businessman if not a good modeler.

Looking back, the story began almost 40 years ago. At that time, modeling, and especially diorama building was in it’s infancy. The vast array of products available today were only a dream. I remember that as if it was yesterday. I had been competing in shows throughout Europe and North America and, in Europe, I discovered so many product lines that had no International distribution. That led to my imagining a distributing/Importing company that would import all those exciting models and accessories to the American market.

This is one of the two fronts of the original VLS facility in St. Louis after moving the company out of my basement. I remember beaming with pride!

#14 was where we did production.

.

#17 was the sales office and a meager warehouse, two of the original employees were Wes Bradley and Don Wardlaw!

Back in those days, practically the only aftermarket products were vacu-form kits. Airmodel from Germany was the top seller! But, we carried 18 different vac-form lines, some were Formaplane, (From England), Schmidt, (From Germany), So many years ago, I can't remember most of the names. You had to be an advanced modeler with a ton of patience to build those very crude kits!

In those early days, Don Wardlaw was the sole member of our art dept. That is a young Bob Letterman beside him! (1985) and a young Don beside Bob! Don was a very tall and talented guy!

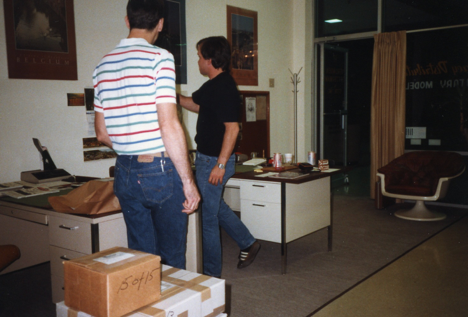

After a few months we added on another room and then, in 1986 we moved into a much larger area, number 25 cross keys center. It was about 7,000 square feet in size, about triple the space we had previously. In these photos, we were planning the remodeling! We had so many big dreams in those days! Here we are planning the layout of the sales floor. Back then, we had the sales floor and the products in close proximity as the sales people would take an order, then pull the products and take them to shipping at the rear of the facility.

Designing the production facilities.We produced a line of products originally named Parts Depot, later Techstar. They were some of the very first aftermarket accessory lines in the military miniature field. Later, after the merger with Verlinden productions, we also manufactured the plaster buildings as they were too fragile to ship from Europe.

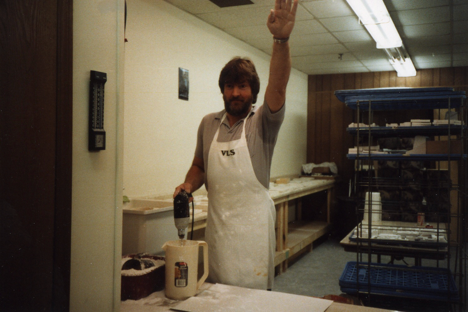

I had met Lewis Pruneau at conventions and we became close friends and are still good friends to this day. He was in charge of production and VLS Creative Services back then as well as Verlinden Productions USA. This was Lewis being Lewis! Probably the single most creative guy I ever knew! An incredible diorama builder!

Then, there was the entire crew in 1984. From left to right. Lewis Pruneau, Bob Letterman, Wes Bradley, Tom Gerringer, Judy Baggett, Don Wardlaw and Jerry Schulte! Standing in front of a newly remodeled #25 Cross Keys Center we had just moved into. It was more than double the square footage of the two inconveniently separate locations prior. All of us are still around except Judy Baggett. She passed away in 2013. We had a reunion at our home in 2008 of the early employees. (Photos will be posted later).

In 1988, we moved VLS to an Office/warehoiuse complex in Westport Industrial park in Maryland Heights, Mo.

From 1988 to 1991

The first 5 + years VLS was operational. First, from our house, (1983-1985), Then we rented space in Cross Keys Center from 1985 through 1988. Then in August, 1988, We had been talking to our leasing agent, (A real estate company), about our lease payments and if they would rise when the lease was up September 1st. He assured us that wouldn’t happen, then around August 20th, We received a notice that our lease payments, upon renewal, would almost double. When I confronted my agent, he just smiled and said he had no control over that and besides, there is no way we now had time to move before the lease was up. In that last three years, we had grown within the center from our original 700 square feet to over 11,000 square feet. It was a huge task, he knew it, and thought there was no way we could accomplish such a massive move in that length of time. He was wrong! That entire facility was destroyed a few years later to build a strip mall.

We started immediately and within 24 hours, we had a new office/warehouse leased in western St. Louis county of 12,000 square feet for the same price as we had paid the previous three years at the original location. The next day, we shut down operations on a Friday, rented three large moving vans, and every employee began helping with the moving. We used the three trucks in rotation, we had two crews, one at each location. By Monday morning, we were totally moved and were operational. The agent met us at the old location and was amazed. It was immaculate and much nicer than when we moved in. He even had to return several thousands of dollars of security deposits.

Our new location was at 804 Fee Fee road in Westport industrial park. The name of the street was the only downside! This aerial shot was taken by an old police helicopter pilot buddy of mine. Then and even now, I still have a few friends in the department, most are retired and/or passed away today. The first building in the photo below was occupied by VLS except for one end unit as well as half the building immediately behind that served as our production unit! By then, we were being noticed by the business community in St. Louis as well as the press and several articles were produced in local newspapers and in TV interviews.

This aerial shot was taken by an old police helicopter pilot buddy of mine. Then and even now, I still have a few friends in the department, most are retired and/or passed away today. The first building in the photo below was occupied by VLS except for one end unit as well as half the building immediately behind that served as our production unit! By then, we were being noticed by the business community in St. Louis as well as the press and several articles were produced in local newspapers and in TV interviews.

This was our new main entrance.

The Summer of 1988. At that time, a photo of our crew.

Back row. Left to right, Tony Eads, Steve Miller, Chuck Stuckenberg, Jeff Raines, Herb Rigg, John Vaughn, Wes Bradley and Wim Verlinden.

2nd row, Tom Gerringer, Bob and Susan Letterman, Francois Verlinden.

1st row, Sharon Miller, Rene Sullivan and Khamini Bhatt.

These shots of the warehouse were used for promotional advertising. About that time was the transition from when color was more expensive to when black & white became more expensive. At that time, most model magazines published in black and white.

To be continued in VLS, The Middle Years.

From 1983 to 1988

This is the first of a series of VLS nostalgia, beginning way back in December, 1983. The first volume is from 1983 to around 1988. As I find and process the photos, I will be adding to all the volumes taking a pictorial journey from 1983 when it was started in my basement, to January, 2007, when it was sold to MMD/Squadron in Dallas,Texas. During my last visit to that company in July, 2015, I was surprised to see so much of VLS office furniture as well as shelving and production/warehouse equipment. Even the CEO's office was furnished with the same items from my old office ar VLS. It was very nostalgic for me. MMD/Squadron ceased to exist several months ago. A pity, both companies had long histories in the model industry. The original Squadron/MMD was created by Jerry Campbell. Jerry Campbell had a brilliant mind for business. He was from the beginning, my most dreaded competitor. He sold MMD to the same financial institution that a short time later would buy VLS.

Both Jerry and I were lifetime modelers. That certainly doesn't mean just because we were that all modelers can be good managers of model businesses. I do believe that good managers MUST have a knowledge of the model business in order to succeed. It is a truly unique business. Both subsequent managers appointed by the corporation in Florida were savvy, talented managers. Neither had a clue about the model business. Most good business managers are capable of running most types of businesses, but, the model business is so unique, it requires both good management skills as well as a serious knowledge of models and the model market. I always kept some modelers on staff at VLS, but I quickly learned to know which were advising me out of knowledge rather than emotions. One of my first was a guy that loved US Army jeeps. After he left, I had an overstock of Jeep kits for years. You must separate yourself from the modeler and the businessman and allow each to do his job independently. The modeler is not a good businessman and the businessman if not a good modeler.

Looking back, the story began almost 40 years ago. At that time, modeling, and especially diorama building was in it’s infancy. The vast array of products available today were only a dream. I remember that as if it was yesterday. I had been competing in shows throughout Europe and North America and, in Europe, I discovered so many product lines that had no International distribution. That led to my imagining a distributing/Importing company that would import all those exciting models and accessories to the American market.

This is one of the two fronts of the original VLS facility in St. Louis after moving the company out of my basement. I remember beaming with pride!

#14 was where we did production.

.

#17 was the sales office and a meager warehouse, two of the original employees were Wes Bradley and Don Wardlaw!

Back in those days, practically the only aftermarket products were vacu-form kits. Airmodel from Germany was the top seller! But, we carried 18 different vac-form lines, some were Formaplane, (From England), Schmidt, (From Germany), So many years ago, I can't remember most of the names. You had to be an advanced modeler with a ton of patience to build those very crude kits!

In those early days, Don Wardlaw was the sole member of our art dept. That is a young Bob Letterman beside him! (1985) and a young Don beside Bob! Don was a very tall and talented guy!

After a few months we added on another room and then, in 1986 we moved into a much larger area, number 25 cross keys center. It was about 7,000 square feet in size, about triple the space we had previously. In these photos, we were planning the remodeling! We had so many big dreams in those days! Here we are planning the layout of the sales floor. Back then, we had the sales floor and the products in close proximity as the sales people would take an order, then pull the products and take them to shipping at the rear of the facility.

Designing the production facilities.We produced a line of products originally named Parts Depot, later Techstar. They were some of the very first aftermarket accessory lines in the military miniature field. Later, after the merger with Verlinden productions, we also manufactured the plaster buildings as they were too fragile to ship from Europe.

I had met Lewis Pruneau at conventions and we became close friends and are still good friends to this day. He was in charge of production and VLS Creative Services back then as well as Verlinden Productions USA. This was Lewis being Lewis! Probably the single most creative guy I ever knew! An incredible diorama builder!

Then, there was the entire crew in 1984. From left to right. Lewis Pruneau, Bob Letterman, Wes Bradley, Tom Gerringer, Judy Baggett, Don Wardlaw and Jerry Schulte! Standing in front of a newly remodeled #25 Cross Keys Center we had just moved into. It was more than double the square footage of the two inconveniently separate locations prior. All of us are still around except Judy Baggett. She passed away in 2013. We had a reunion at our home in 2008 of the early employees. (Photos will be posted later).

In 1988, we moved VLS to an Office/warehoiuse complex in Westport Industrial park in Maryland Heights, Mo.

From 1988 to 1991

The first 5 + years VLS was operational. First, from our house, (1983-1985), Then we rented space in Cross Keys Center from 1985 through 1988. Then in August, 1988, We had been talking to our leasing agent, (A real estate company), about our lease payments and if they would rise when the lease was up September 1st. He assured us that wouldn’t happen, then around August 20th, We received a notice that our lease payments, upon renewal, would almost double. When I confronted my agent, he just smiled and said he had no control over that and besides, there is no way we now had time to move before the lease was up. In that last three years, we had grown within the center from our original 700 square feet to over 11,000 square feet. It was a huge task, he knew it, and thought there was no way we could accomplish such a massive move in that length of time. He was wrong! That entire facility was destroyed a few years later to build a strip mall.

We started immediately and within 24 hours, we had a new office/warehouse leased in western St. Louis county of 12,000 square feet for the same price as we had paid the previous three years at the original location. The next day, we shut down operations on a Friday, rented three large moving vans, and every employee began helping with the moving. We used the three trucks in rotation, we had two crews, one at each location. By Monday morning, we were totally moved and were operational. The agent met us at the old location and was amazed. It was immaculate and much nicer than when we moved in. He even had to return several thousands of dollars of security deposits.

Our new location was at 804 Fee Fee road in Westport industrial park. The name of the street was the only downside!

This aerial shot was taken by an old police helicopter pilot buddy of mine. Then and even now, I still have a few friends in the department, most are retired and/or passed away today. The first building in the photo below was occupied by VLS except for one end unit as well as half the building immediately behind that served as our production unit! By then, we were being noticed by the business community in St. Louis as well as the press and several articles were produced in local newspapers and in TV interviews.

This aerial shot was taken by an old police helicopter pilot buddy of mine. Then and even now, I still have a few friends in the department, most are retired and/or passed away today. The first building in the photo below was occupied by VLS except for one end unit as well as half the building immediately behind that served as our production unit! By then, we were being noticed by the business community in St. Louis as well as the press and several articles were produced in local newspapers and in TV interviews.This was our new main entrance.

The Summer of 1988. At that time, a photo of our crew.

Back row. Left to right, Tony Eads, Steve Miller, Chuck Stuckenberg, Jeff Raines, Herb Rigg, John Vaughn, Wes Bradley and Wim Verlinden.

2nd row, Tom Gerringer, Bob and Susan Letterman, Francois Verlinden.

1st row, Sharon Miller, Rene Sullivan and Khamini Bhatt.

These shots of the warehouse were used for promotional advertising. About that time was the transition from when color was more expensive to when black & white became more expensive. At that time, most model magazines published in black and white.

To be continued in VLS, The Middle Years.

Attachments

-

1615823760537.png319 KB · Views: 59

1615823760537.png319 KB · Views: 59 -

1615823760451.png352.7 KB · Views: 59

1615823760451.png352.7 KB · Views: 59 -

1615823888879.png164.7 KB · Views: 60

1615823888879.png164.7 KB · Views: 60 -

1615823889081.png146.5 KB · Views: 60

1615823889081.png146.5 KB · Views: 60 -

1615823889187.png128.9 KB · Views: 17

1615823889187.png128.9 KB · Views: 17 -

1615823889016.png232.8 KB · Views: 58

1615823889016.png232.8 KB · Views: 58 -

1615823889238.png206.8 KB · Views: 14

1615823889238.png206.8 KB · Views: 14 -

1615823889137.png259.7 KB · Views: 14

1615823889137.png259.7 KB · Views: 14 -

1615823888950.png225.3 KB · Views: 59

1615823888950.png225.3 KB · Views: 59 -

1615823889284.png294.2 KB · Views: 13

1615823889284.png294.2 KB · Views: 13 -

1615824551089.png259.3 KB · Views: 13

1615824551089.png259.3 KB · Views: 13 -

1615824551441.png205.1 KB · Views: 11

1615824551441.png205.1 KB · Views: 11 -

1615824551165.png238.9 KB · Views: 13

1615824551165.png238.9 KB · Views: 13 -

1615824551315.png325.9 KB · Views: 13

1615824551315.png325.9 KB · Views: 13 -

1615824551378.png397.4 KB · Views: 16

1615824551378.png397.4 KB · Views: 16 -

1615824551239.png365.2 KB · Views: 11

1615824551239.png365.2 KB · Views: 11 -

1615824878001.png245.8 KB · Views: 13

1615824878001.png245.8 KB · Views: 13 -

1615824877844.png308.8 KB · Views: 12

1615824877844.png308.8 KB · Views: 12 -

1615824877930.png299 KB · Views: 14

1615824877930.png299 KB · Views: 14 -

1615825123328.png205.6 KB · Views: 13

1615825123328.png205.6 KB · Views: 13 -

1615825123475.png286.3 KB · Views: 13

1615825123475.png286.3 KB · Views: 13 -

1615825123400.png260.3 KB · Views: 12

1615825123400.png260.3 KB · Views: 12 -

1615825123239.png436.1 KB · Views: 13

1615825123239.png436.1 KB · Views: 13 -

1615825296000.png283.2 KB · Views: 14

1615825296000.png283.2 KB · Views: 14

Last edited:

After that, I got so used to them, I hardly ever notice eastern accents since.

After that, I got so used to them, I hardly ever notice eastern accents since.

.

.