Skinny_Mike

Well-known member

Hi everyone! As it turns out my one little ribbon is getting pretty lonely, so I thought I might start another campaign and try to get him a buddy! Its time for a challenge! :fencing

Its funny we all get inspired in different ways. About a year or so ago we all watched in awe as one of my modeling idols chuckw, was building the Planet Models Ju-388. If you didn’t get a chance to see that build, here’s a link to it.

chuckw's Ju-388

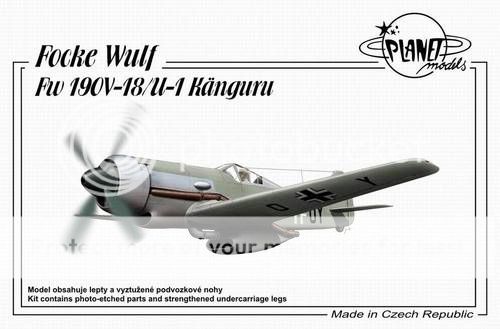

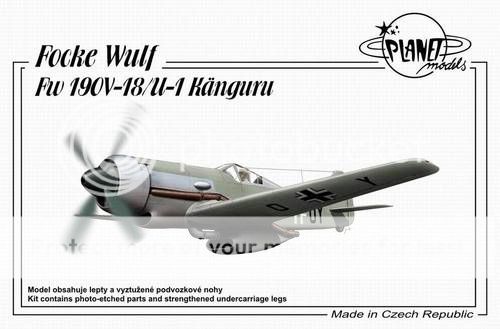

For those of you that know me, I’m a bomber guy and pretty knowledgeable in the air to ground arena. This airplane immediately appealed to me, and following along with the fantastic build, inspired me to get my own Ju-388 kit. The problem is, I’ve been terrified to build it! I mean let’s face it, it’s a pretty expensive kit and as with most short run resin kits, takes a lot of skill to get it right. How does that get me to here? Well I’ve decided to build a slightly smaller full resin kit as practice. I saw this kit at Sprue Brothers, thought it looked cool, figured the single color paint scheme would be easier to accomplish so why not give it a try! It’s a confidence builder if you will. So here is the kit…

A brief history. In 1942 the RLM determined that there was a need for a new high altitude fighter to combat the allied bombers. The FW-190, while a great aircraft had pretty poor high altitude performance. Focke Wulf designers started work on an FW190 derivative powered by a DB603A engine. This was in theory to become the FW-190C aircraft. The FW190V-18/U1 aircraft used a DB603 engine driving a 4 bladed prop. The aircraft had a turbo charger installed under the belly of the aircraft. Exhaust gases were provided through long pipes that extended over the wing roots to the assembly. This effort was eventually discontinued due to problems with the turbo charger and the pressurized canopy.

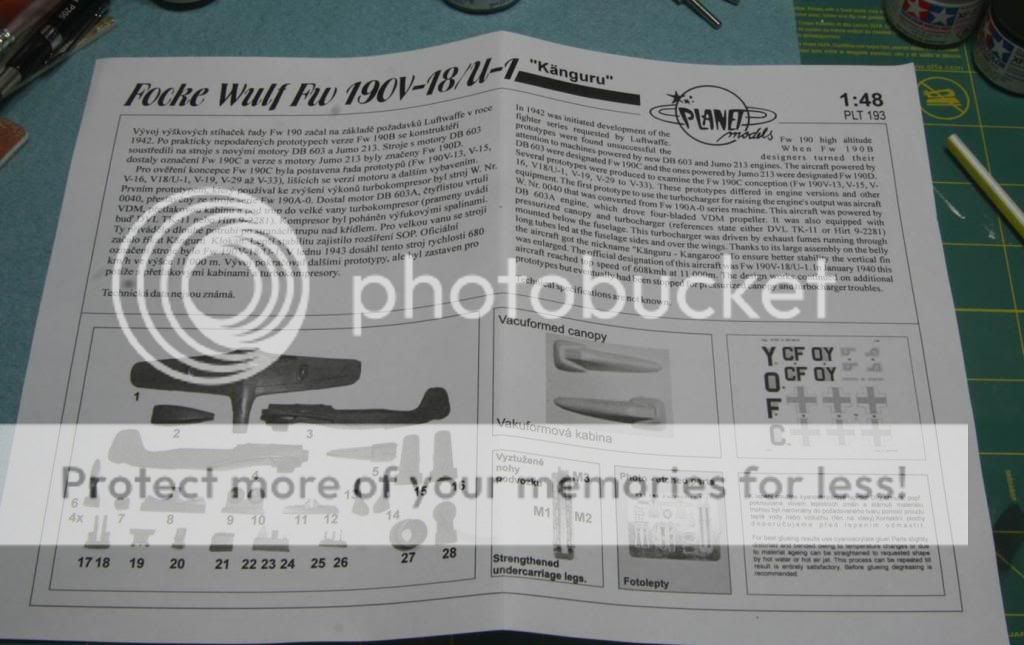

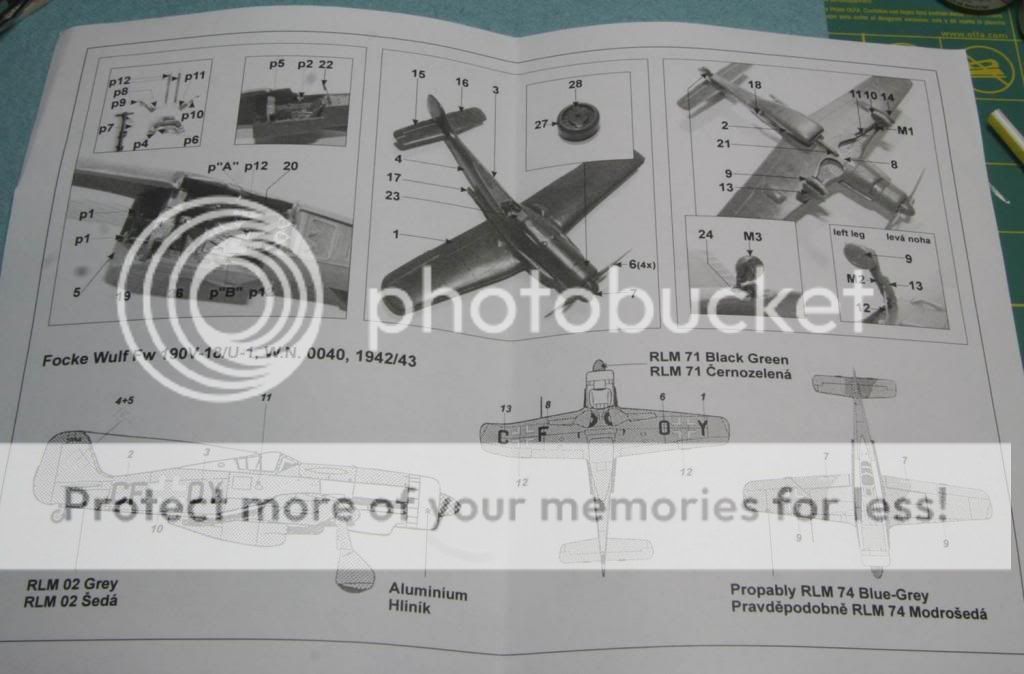

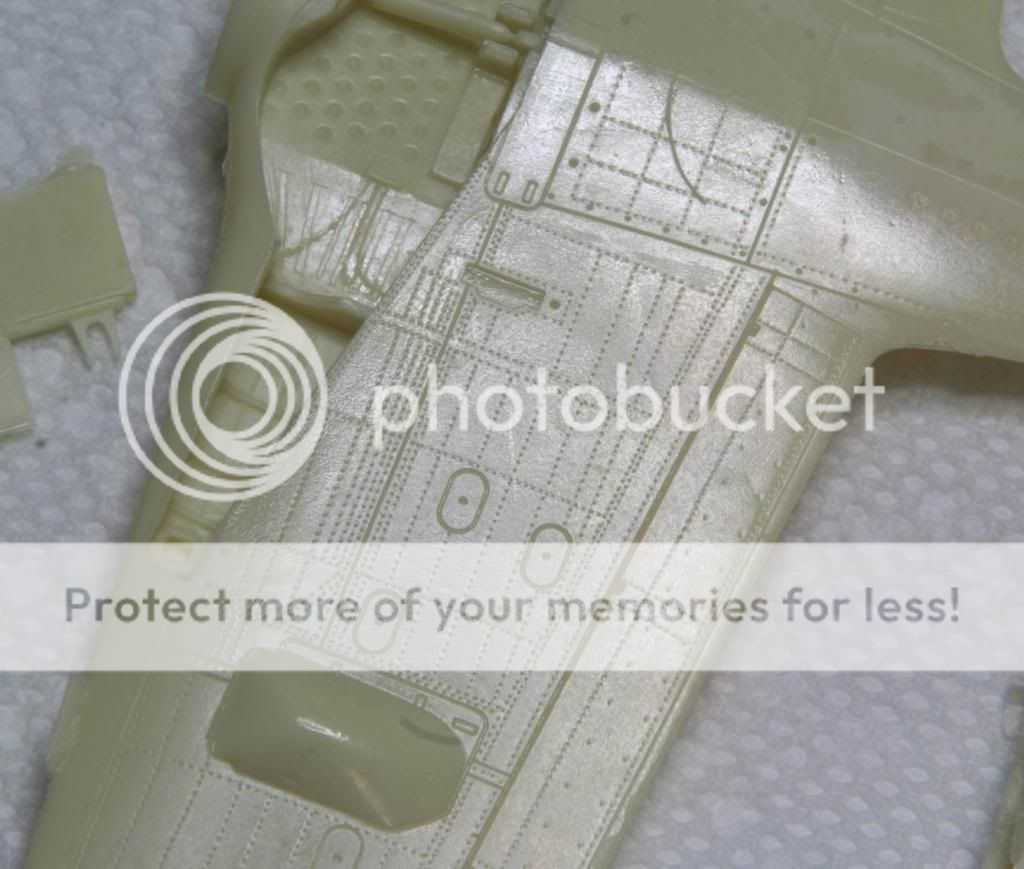

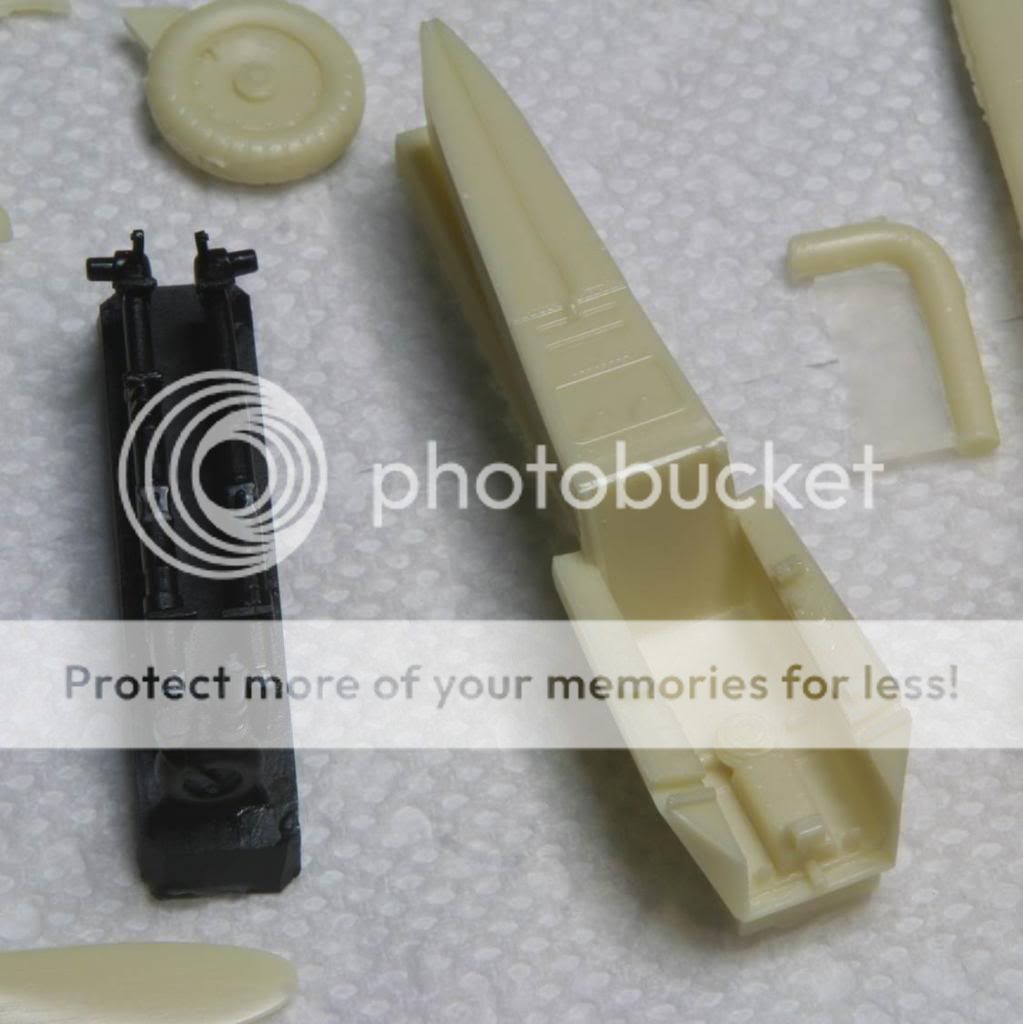

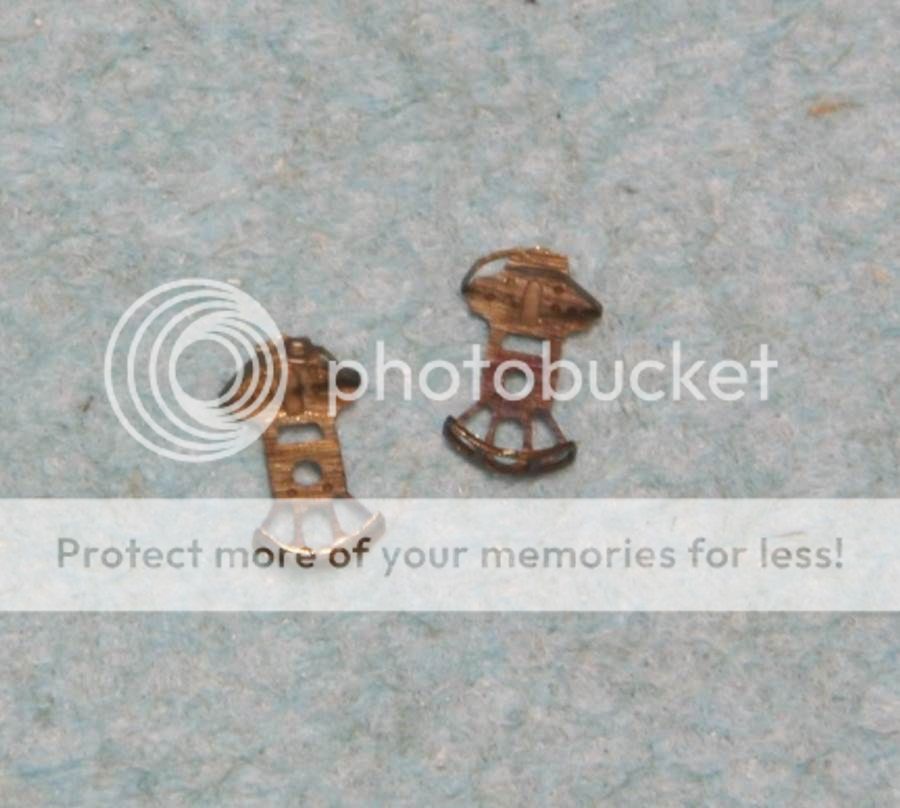

On to the kit! The box for this kit is pretty small, roughly the same size as the boxes for Hase’s egg planes. Inside we find a collection of parts is assorted bags. The fuselage halves are bagged separately and so are the wings, which are fully assembled. There are decals and two vacuformed canopies, one extra, and a small photo etch fret. We also get a one page instruction sheet.

I started by putting all the resin bits into a nice warm bath with some dish soap. I like to let my resin soak overnight and then scrub with a soft toothbrush. Then I’ll let them dry. This one will probably be a slow starter over the rest of the month while I finish up my other two kits, but it’ll pick up to my usual snail’s pace after that! :snoopy

This is going to be a challenge for me for sure – so wish me luck!

Mike!

Oh yeah and just to show I'm legal for the campaign...

Its funny we all get inspired in different ways. About a year or so ago we all watched in awe as one of my modeling idols chuckw, was building the Planet Models Ju-388. If you didn’t get a chance to see that build, here’s a link to it.

chuckw's Ju-388

For those of you that know me, I’m a bomber guy and pretty knowledgeable in the air to ground arena. This airplane immediately appealed to me, and following along with the fantastic build, inspired me to get my own Ju-388 kit. The problem is, I’ve been terrified to build it! I mean let’s face it, it’s a pretty expensive kit and as with most short run resin kits, takes a lot of skill to get it right. How does that get me to here? Well I’ve decided to build a slightly smaller full resin kit as practice. I saw this kit at Sprue Brothers, thought it looked cool, figured the single color paint scheme would be easier to accomplish so why not give it a try! It’s a confidence builder if you will. So here is the kit…

A brief history. In 1942 the RLM determined that there was a need for a new high altitude fighter to combat the allied bombers. The FW-190, while a great aircraft had pretty poor high altitude performance. Focke Wulf designers started work on an FW190 derivative powered by a DB603A engine. This was in theory to become the FW-190C aircraft. The FW190V-18/U1 aircraft used a DB603 engine driving a 4 bladed prop. The aircraft had a turbo charger installed under the belly of the aircraft. Exhaust gases were provided through long pipes that extended over the wing roots to the assembly. This effort was eventually discontinued due to problems with the turbo charger and the pressurized canopy.

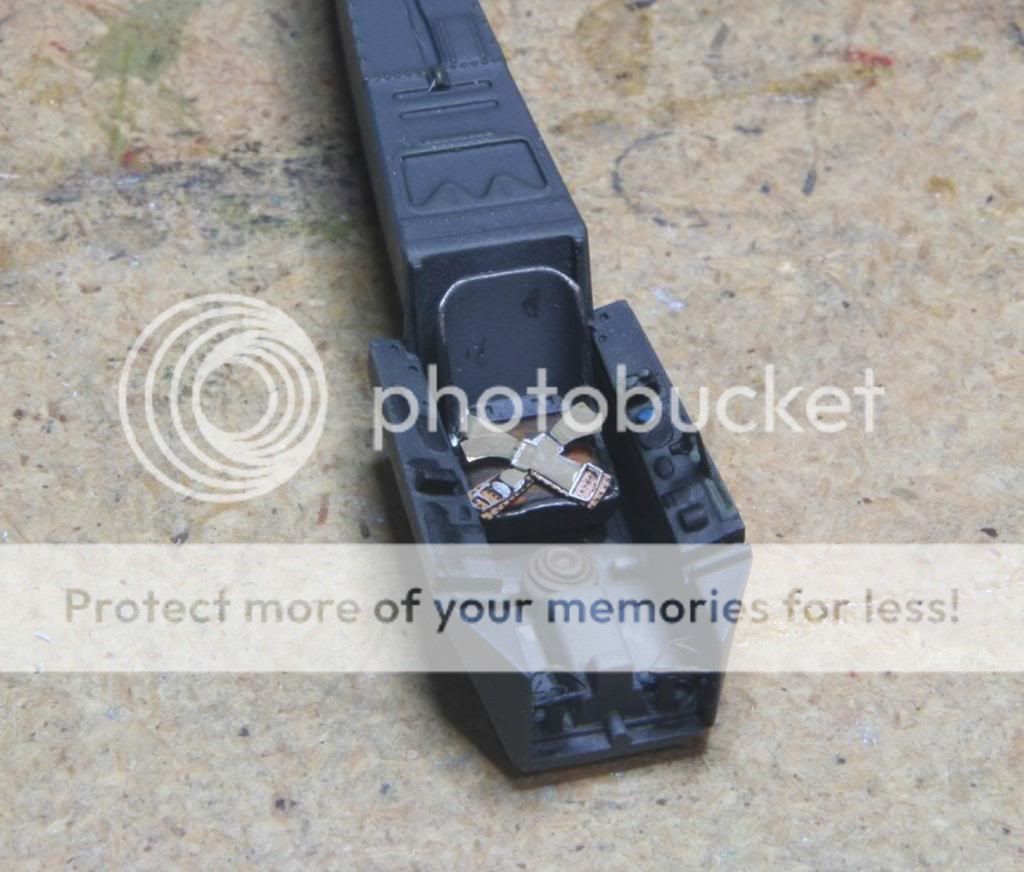

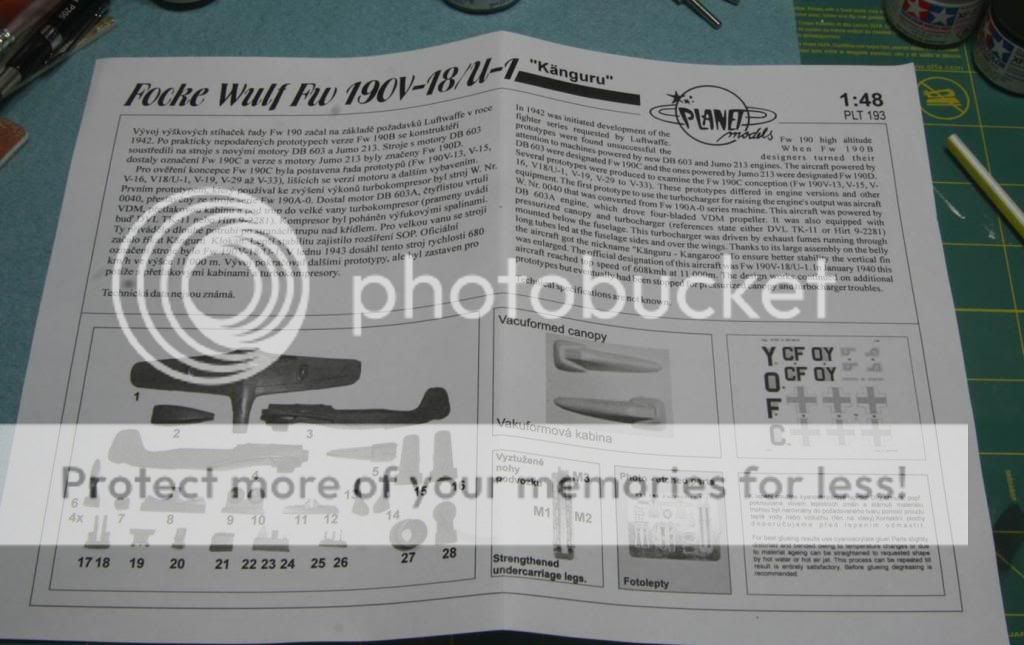

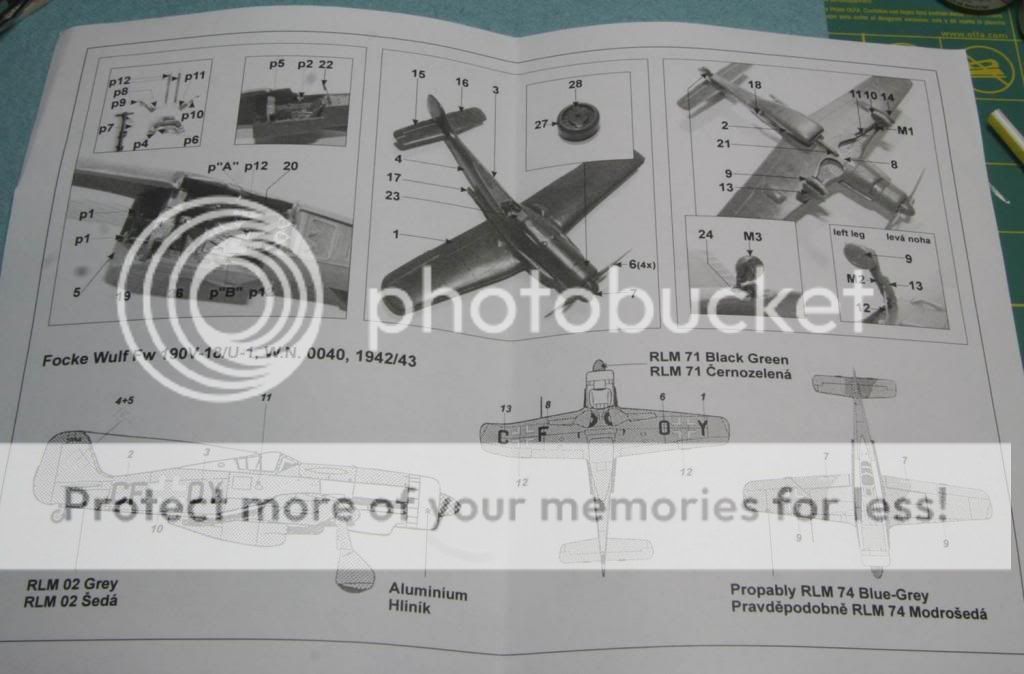

On to the kit! The box for this kit is pretty small, roughly the same size as the boxes for Hase’s egg planes. Inside we find a collection of parts is assorted bags. The fuselage halves are bagged separately and so are the wings, which are fully assembled. There are decals and two vacuformed canopies, one extra, and a small photo etch fret. We also get a one page instruction sheet.

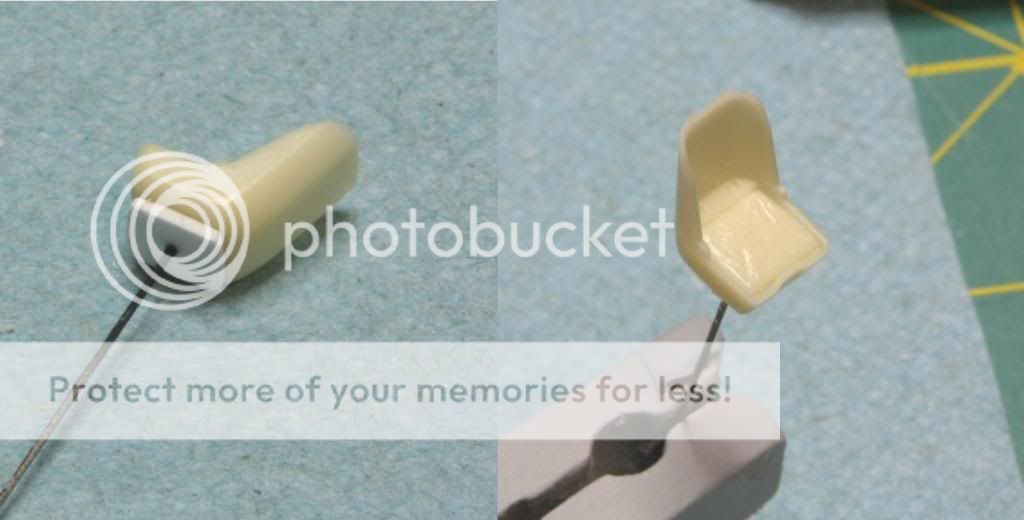

I started by putting all the resin bits into a nice warm bath with some dish soap. I like to let my resin soak overnight and then scrub with a soft toothbrush. Then I’ll let them dry. This one will probably be a slow starter over the rest of the month while I finish up my other two kits, but it’ll pick up to my usual snail’s pace after that! :snoopy

This is going to be a challenge for me for sure – so wish me luck!

Mike!

Oh yeah and just to show I'm legal for the campaign...

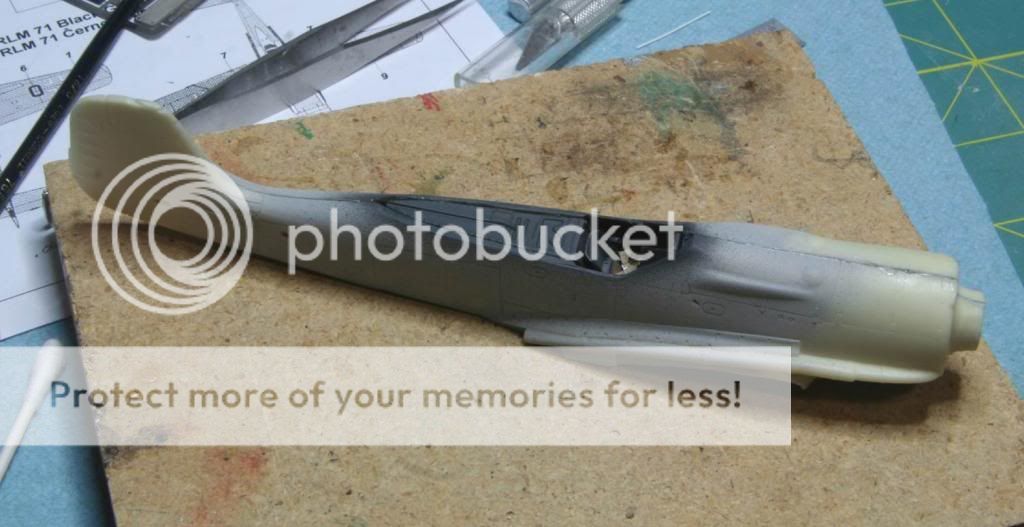

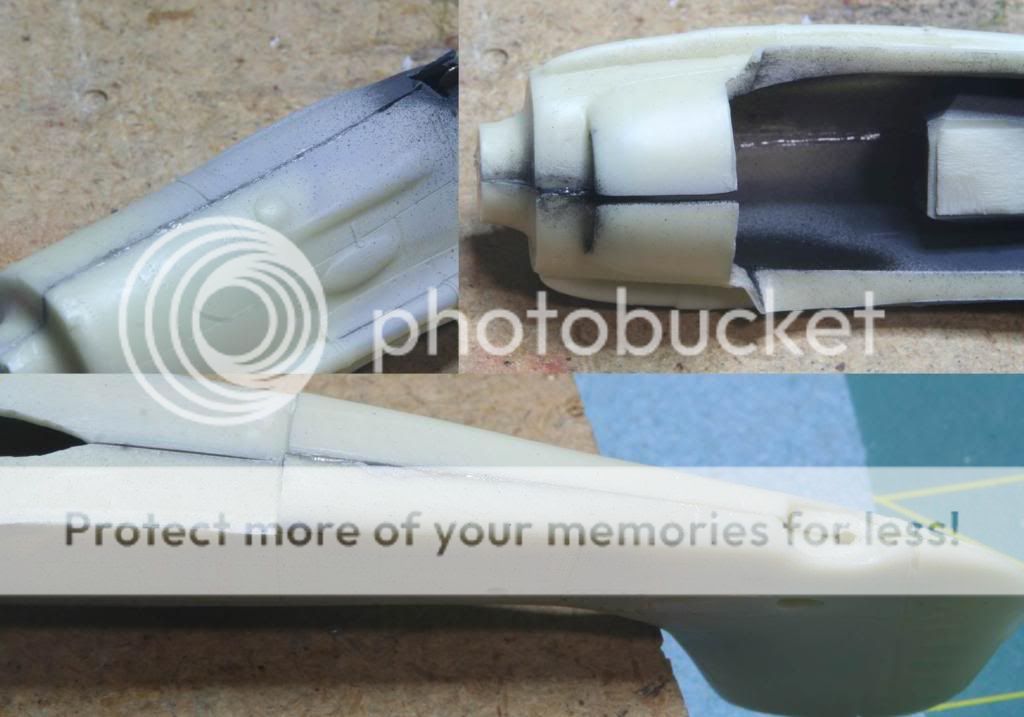

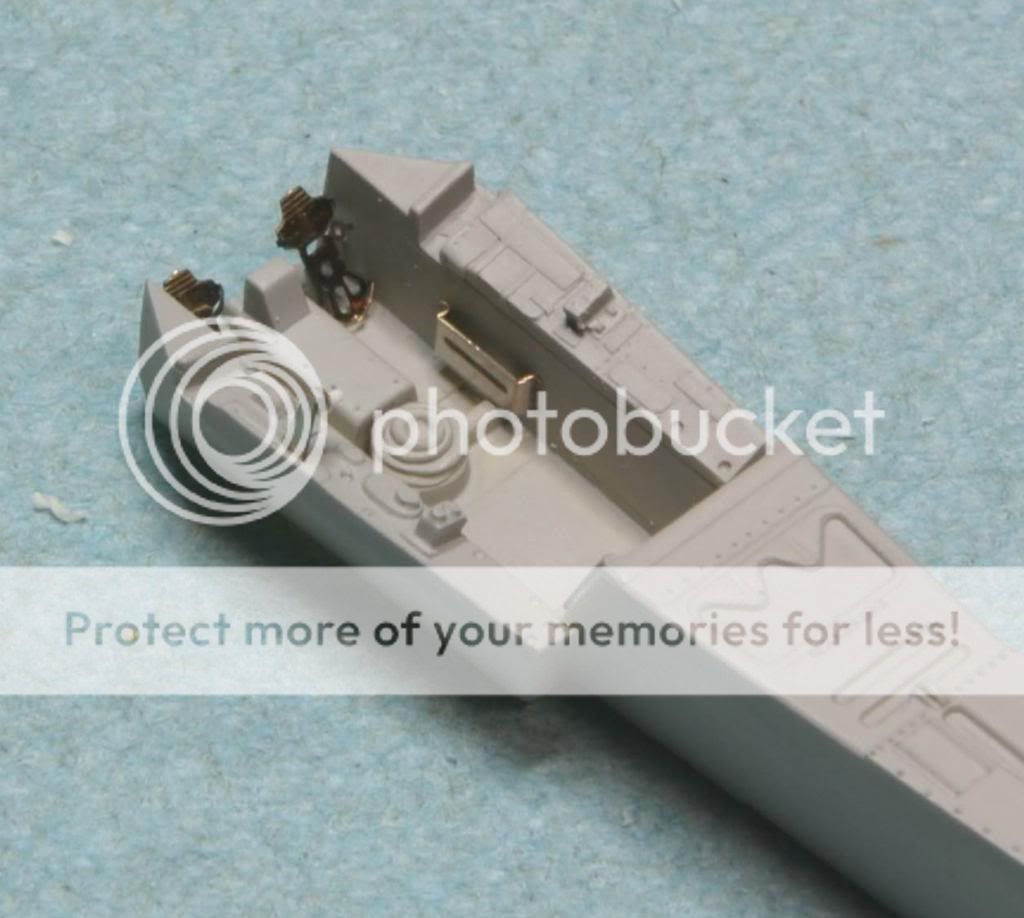

I’m going to need some putty later on! And I’ve started using finer grit sanding sticks!

I’m going to need some putty later on! And I’ve started using finer grit sanding sticks!