jeaton01

Well-known member

I finished this one yesterday. I've read a lot of harsh words about the kit but my experience was not so bad. I did reprofile the top of the fuselage from the turret forward as it should have a increasing radius of curvature from square at the turret to rounded at the gunner's canopy. All the glass fit fine. The kit is a challenge to get aligned because there are so many intersections. I glued the wings to the central pod first, judging by eye to get 2 degrees dihedral in the outer wing panels with the pod vertical. Then I attached the booms to the tailplane, making sure the fins were 90 degrees to the stab. Next I attached that assembly to the wings. One side needed some grinding on the bottom of the wing, the other fit pretty well. A misfit of the booms to the wing is I think the easiest to correct, as you end up with 90 degree intersections that are easy to fill. I used a little Tamiya filler and Perfect Plastic Putty and didn't need to do any sanding. If I build another I will build a jig to attach the pod to the boom as doing it by eye resulted in a very small error but that was enough to make the right wing tip about 3/32 higher than the left.

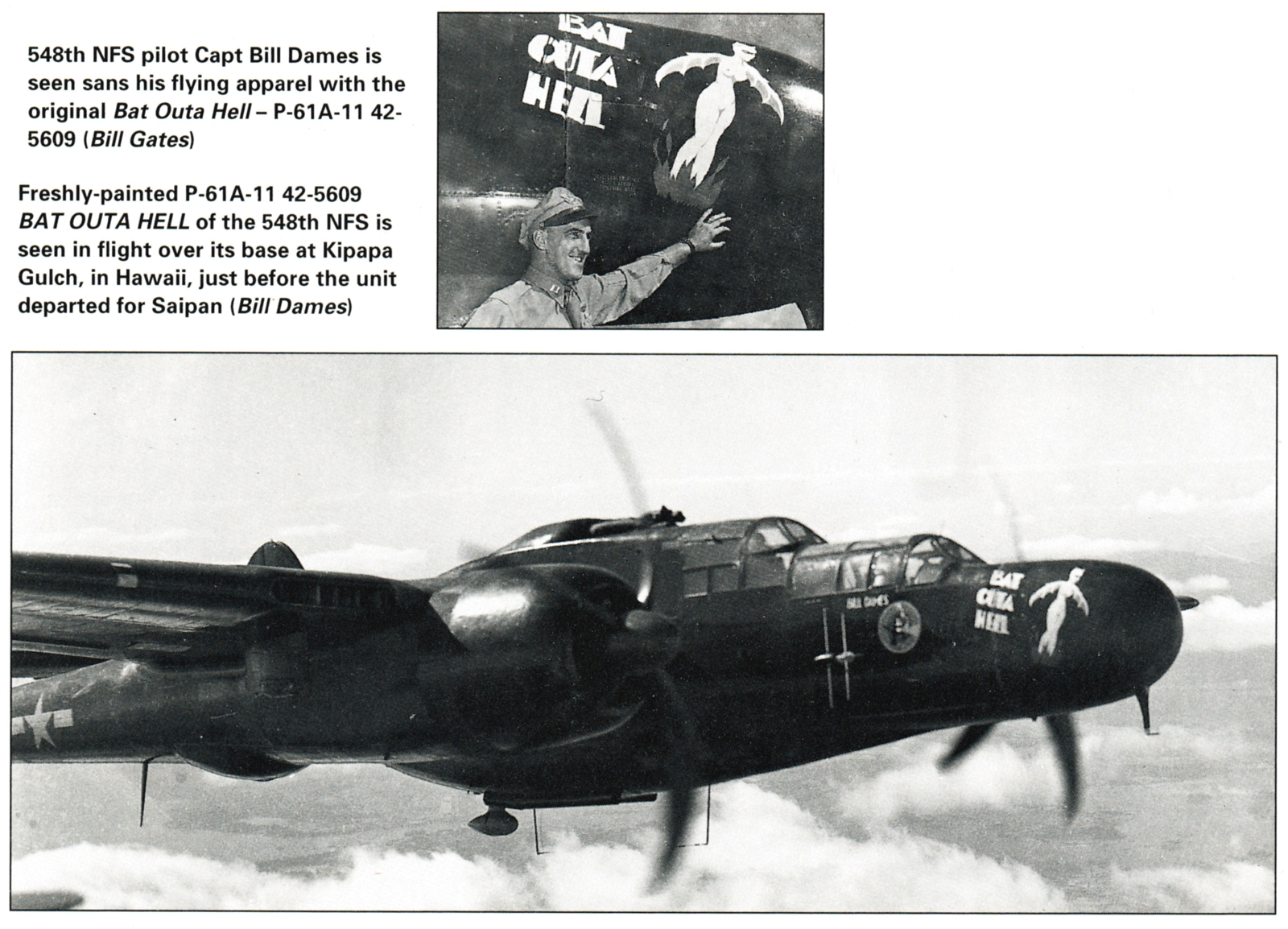

The serial numbers and wing walks were painted using stencils, and the nose art/pilot name were decals made in John's Secret Workshop somewhere in Northern California. Other markings are 45 year old kit decals. I used the first photo for my example to model.

The serial numbers and wing walks were painted using stencils, and the nose art/pilot name were decals made in John's Secret Workshop somewhere in Northern California. Other markings are 45 year old kit decals. I used the first photo for my example to model.