paddy

Well-known member

So whats it all about then ?

Model Factory Hiro is a Japanese company that makes white metal kits, very much the same as a plastic kit but, you guessed it, in white metal.

They mostly make cars and motorcycles but i think there has been the odd Tank and ship.

https://www.modelfactoryhiro.com/SHOP/322676/list.html

I thought i would post some info as i dont think everyone has seen these kits before and they are quite expensive.

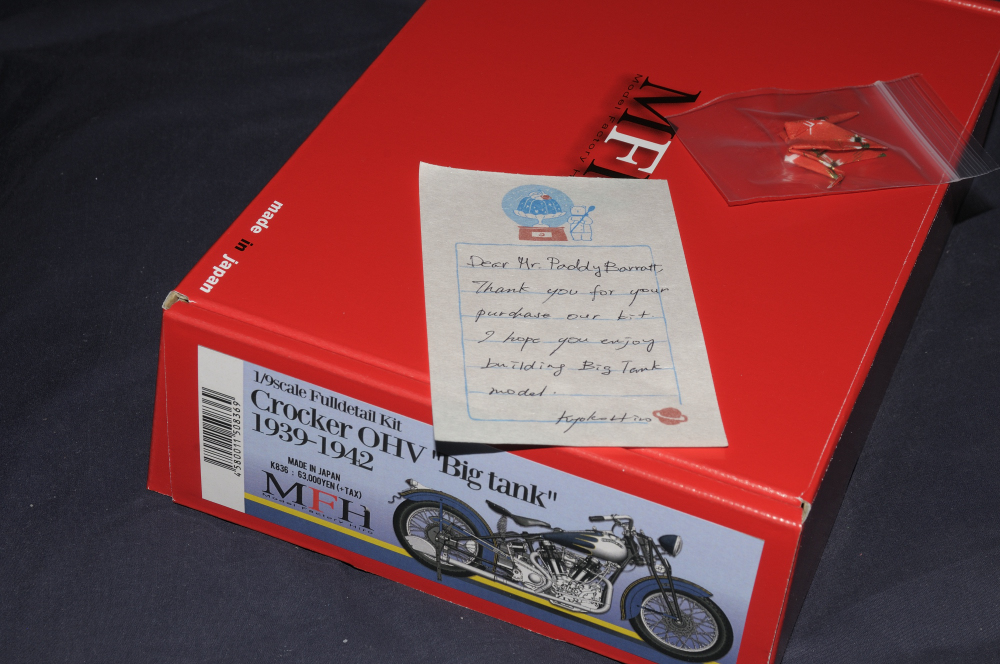

Basically it works like this, you send Mr Hiro approx £360 or $425 and he sends you a nice thank you note

And a bit of origami

Oh and he includes the kit you ordered as well.....

Parts are mostly loose in bags all are white metal with the exception of the seat cover, tires and a few other parts of wire and clear , Decals and a sheet of PE

Wheel rims and mudguards

Frame and handlebars

And assorted engine and cycleparts

Wheel spokes bottom left and Spoke nipples middle right

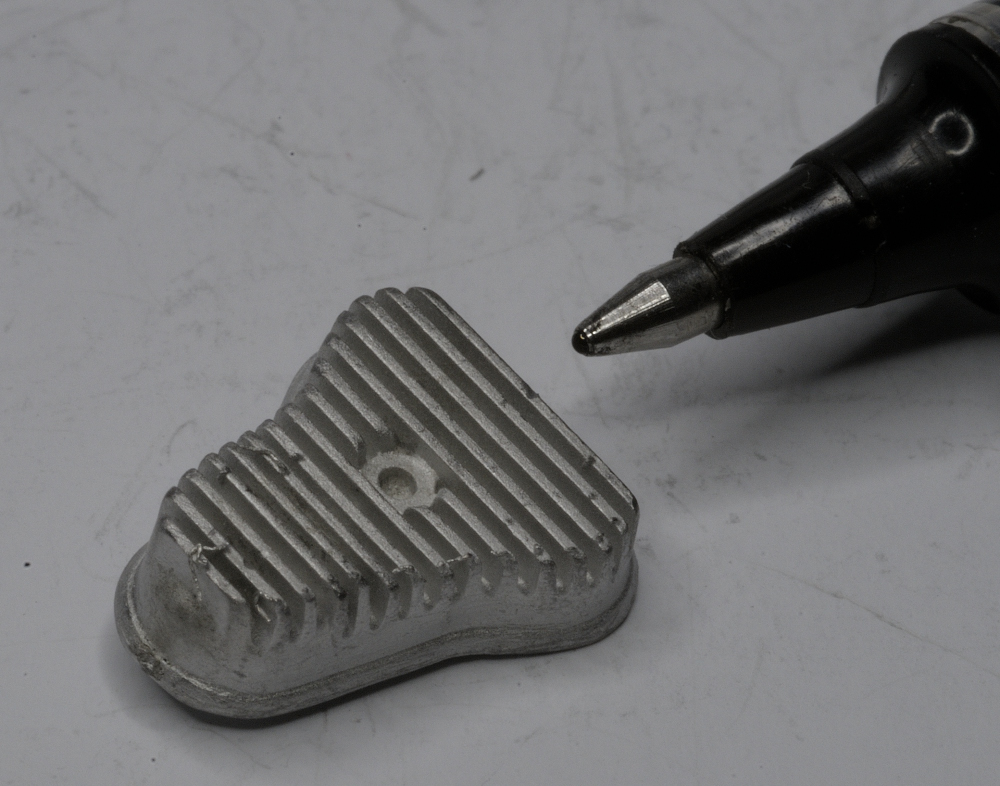

a few close up pics to show quality of castings, very little flash or cleaning up to do but i am not sure about surface finish at the stage re: getting a smooth paint finish

Carb body, note this is 8mm long

Crank case casting

Name plates for fuel tank

Exhaust silencer end

Ball point pen has 0.8mm ball for scale/size.

So thats it, what could be simpler ? should have it done by lunch time.

truth is i dont know where to start and i am a bit intimidated by it

Model Factory Hiro is a Japanese company that makes white metal kits, very much the same as a plastic kit but, you guessed it, in white metal.

They mostly make cars and motorcycles but i think there has been the odd Tank and ship.

https://www.modelfactoryhiro.com/SHOP/322676/list.html

I thought i would post some info as i dont think everyone has seen these kits before and they are quite expensive.

Basically it works like this, you send Mr Hiro approx £360 or $425 and he sends you a nice thank you note

And a bit of origami

Oh and he includes the kit you ordered as well.....

Parts are mostly loose in bags all are white metal with the exception of the seat cover, tires and a few other parts of wire and clear , Decals and a sheet of PE

Wheel rims and mudguards

Frame and handlebars

And assorted engine and cycleparts

Wheel spokes bottom left and Spoke nipples middle right

a few close up pics to show quality of castings, very little flash or cleaning up to do but i am not sure about surface finish at the stage re: getting a smooth paint finish

Carb body, note this is 8mm long

Crank case casting

Name plates for fuel tank

Exhaust silencer end

Ball point pen has 0.8mm ball for scale/size.

So thats it, what could be simpler ? should have it done by lunch time.

truth is i dont know where to start and i am a bit intimidated by it