Tail-dragon

Member

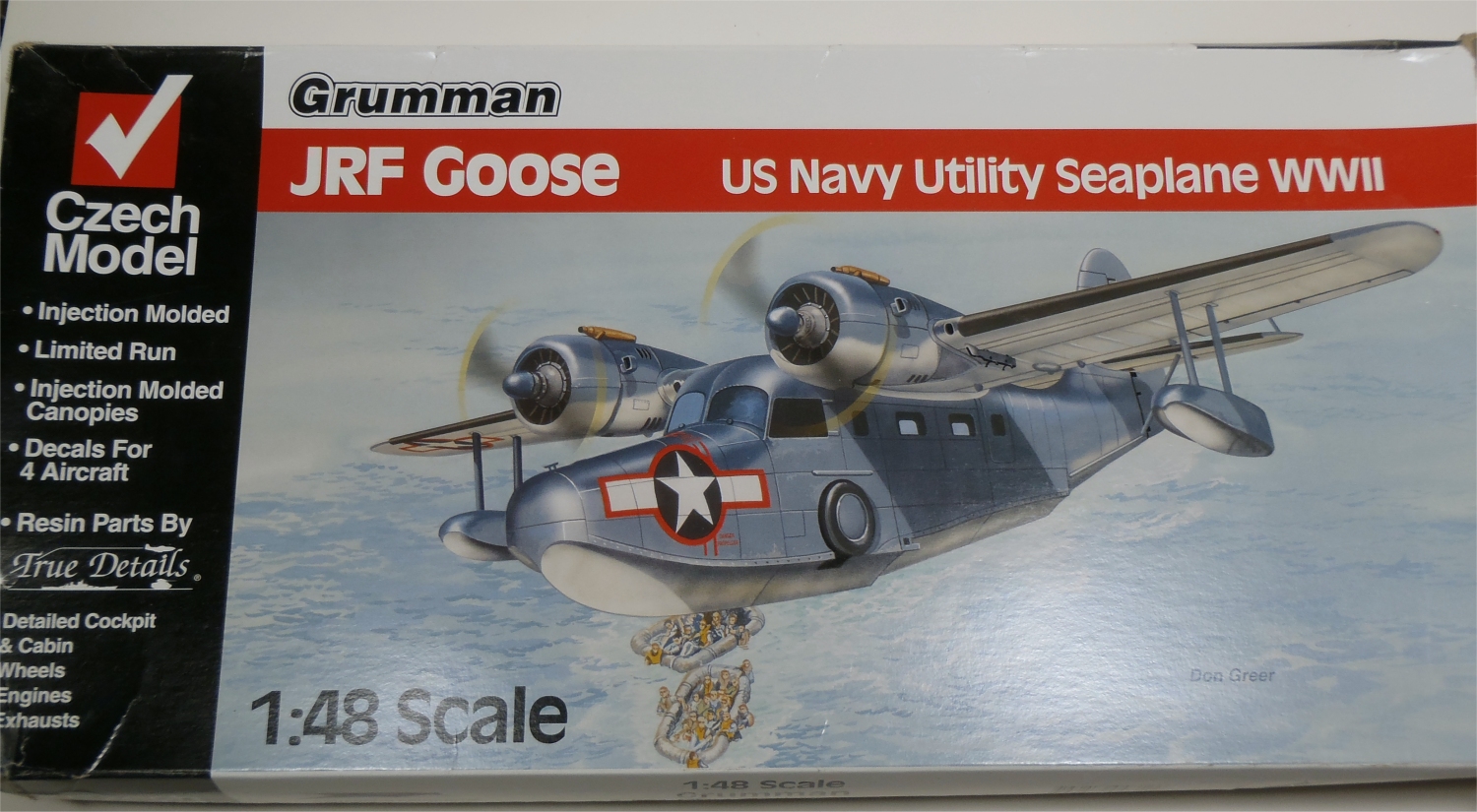

I thought I would share a recent build, the 1/48 Czech Models Grumman Goose. I have read that this kit was under development for Classic Airframes, but with the demise of CA, was released by Czech Models. It certainly has the look and feel of a CA short run kit. As a short run kit it, is a nice challenge, no locating pins, heavy trailing edges, many missing finer details, clubs for propellers, but an interesting aircraft none the less.

My first step was to decide what to do with the engines and props (very rough kit parts, and rough, incorrect resin engines) Eleven brass, aluminum and plastic parts went into one prop, which was then used as a master to resin cast replacements. I tried to correct the engines, but in the end replaced them with Vector R-985's with pushrods and wiring added.

From the engines, I went on to the wings and tail feathers. Trail edges had to be thinned considerably, and missing details such as cowl vents, leading edge cooling vents, panel hinges, aileron actuators added, incorrect trim tabs filled, and missing panel lines rescribed.

and the tail feathers had the controls separated, hinges fabricated, trim tab actuators added.

more later ...

My first step was to decide what to do with the engines and props (very rough kit parts, and rough, incorrect resin engines) Eleven brass, aluminum and plastic parts went into one prop, which was then used as a master to resin cast replacements. I tried to correct the engines, but in the end replaced them with Vector R-985's with pushrods and wiring added.

From the engines, I went on to the wings and tail feathers. Trail edges had to be thinned considerably, and missing details such as cowl vents, leading edge cooling vents, panel hinges, aileron actuators added, incorrect trim tabs filled, and missing panel lines rescribed.

and the tail feathers had the controls separated, hinges fabricated, trim tab actuators added.

more later ...

Last edited: