Tankbuilder

Active member

It's a nice kit for its age. remember that this kit came out about 1975 which is 35+ years ago. Also remember that most of the early Tamiya kits were designed to be used with 2 motors and remote control box. If you think these kit tracks are bad you should see whatthe original rubber band ones were like.

There are after market styrene tracks available at a pretty low price.

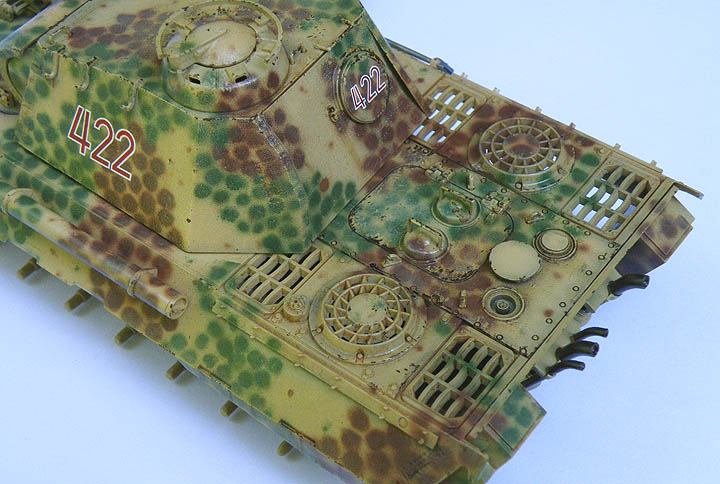

Considering the age of this kit I think it's a great build and paint scheme.

Cheers

There are after market styrene tracks available at a pretty low price.

Considering the age of this kit I think it's a great build and paint scheme.

Cheers