-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Latest Acquisitions Revisited!

- Thread starter tomwes

- Start date

Greg Kimsey

Well-known member

That's a negative ghost rider. But if they are like any other enamel such as Testors, Humbrol, or MCW, thinning and cleaning with Xylene will do the trick for airbrushing or brush brushing. For brush brushing a Sable hair (particularly Kolinski sable but 'spensive as H E double hockey sticks) will give you the best results. Use in well ventilated area!!Do any of you Men use these Ukrainian enamel paints? Teresa won these and I know squat about them, except shipping from Ukraine is PRICEY!!

helios

Well-known member

That's great to hear there are still some companies that give a rat's a** about customer service.More news about this.

Kevin at USA Airbrush Supply contacted Ken at Badger, Ken put a stop to my returning the defected airbrush and is sending me a new one instead.

Thanks to both for exceptional service!

Well the replacement hasn't shown up yet but we'll see.That's great to hear there are still some companies that give a rat's a** about customer service.

jknaus

Administrator

Got a bunch of stuff in Friday but no pics. AM for my F-15E, Me 163, CH-54, and some more kits. I got the two new ICM 1/32 HS 123s and they look sweet.

CSM new Tenders and motorcycles. These are 1/35 and 3D printed and look fantastic. Pictures eventually. Also some novelties which I think will be handy.

First is a heat transfer printer. When I saw a video clip on FB I figured it would be awesome to use it to put crib notes and diagrams on the kit instructions. I find it hard to juggle refs while building and will print out pages that get mixed up or lost during the construction or in storage. This printer prints a small 20 to 50mm sheet that sticks to whatever you decide it should stick to. So if I find a drawing or picture of an assembly I figure I can print it out and stick it to the instructions at that step for a quick ref or reminder. Got one for my wife as well for her stuff and can be used for canning etc.

Click the pic for a link.

And I also got a neat little mini Drill Press. Looks like the price has gone up some.

Again just click pic for link. Got a number of books also. Now to smarten up and stop buying stuff and start building.

James

CSM new Tenders and motorcycles. These are 1/35 and 3D printed and look fantastic. Pictures eventually. Also some novelties which I think will be handy.

First is a heat transfer printer. When I saw a video clip on FB I figured it would be awesome to use it to put crib notes and diagrams on the kit instructions. I find it hard to juggle refs while building and will print out pages that get mixed up or lost during the construction or in storage. This printer prints a small 20 to 50mm sheet that sticks to whatever you decide it should stick to. So if I find a drawing or picture of an assembly I figure I can print it out and stick it to the instructions at that step for a quick ref or reminder. Got one for my wife as well for her stuff and can be used for canning etc.

Click the pic for a link.

And I also got a neat little mini Drill Press. Looks like the price has gone up some.

Again just click pic for link. Got a number of books also. Now to smarten up and stop buying stuff and start building.

James

paddy

Well-known member

I think i metioned before there are so many think that i would love to own but when i ask myself how often i would use it and if it arrived tomorrow what do i need it for...........i cant think of anything.

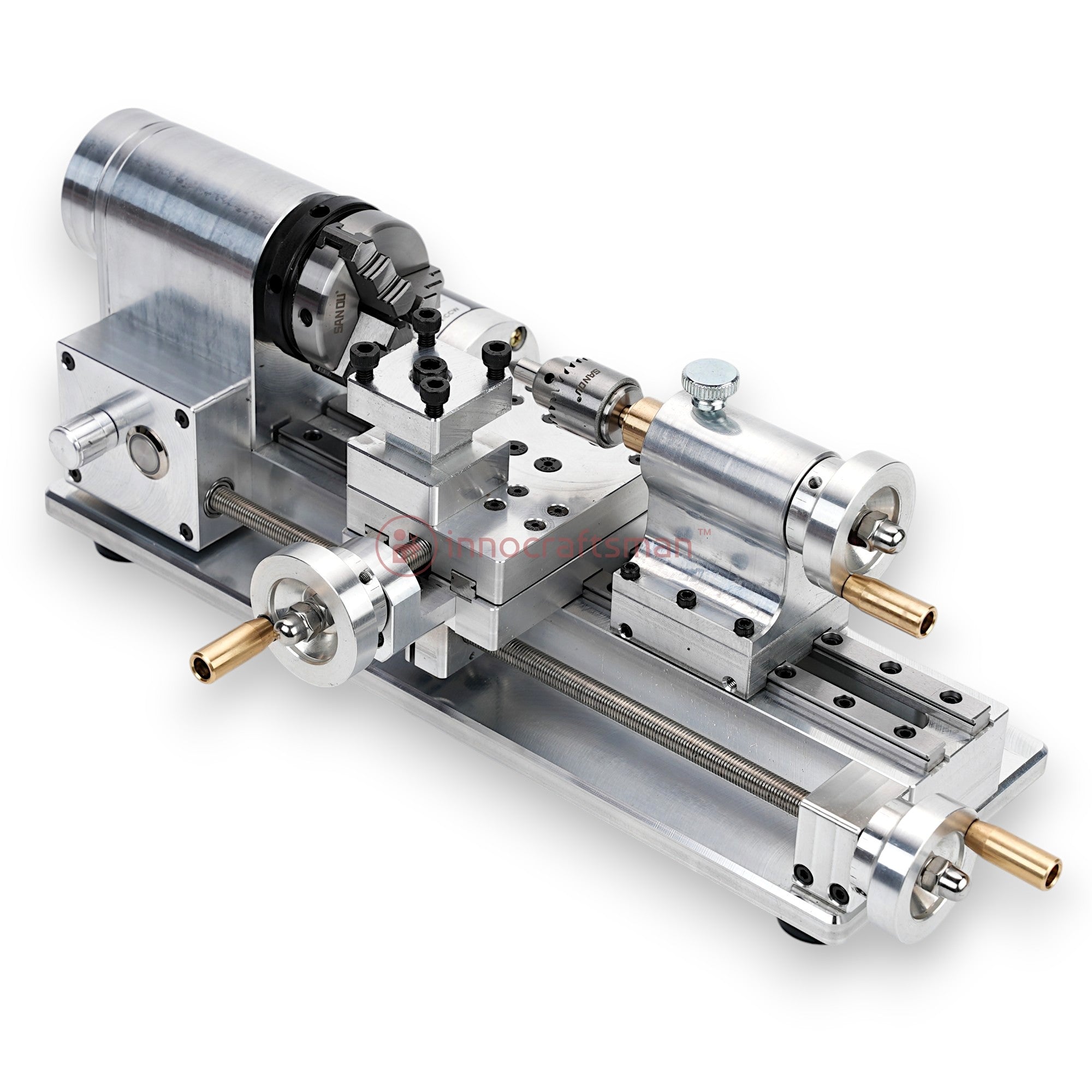

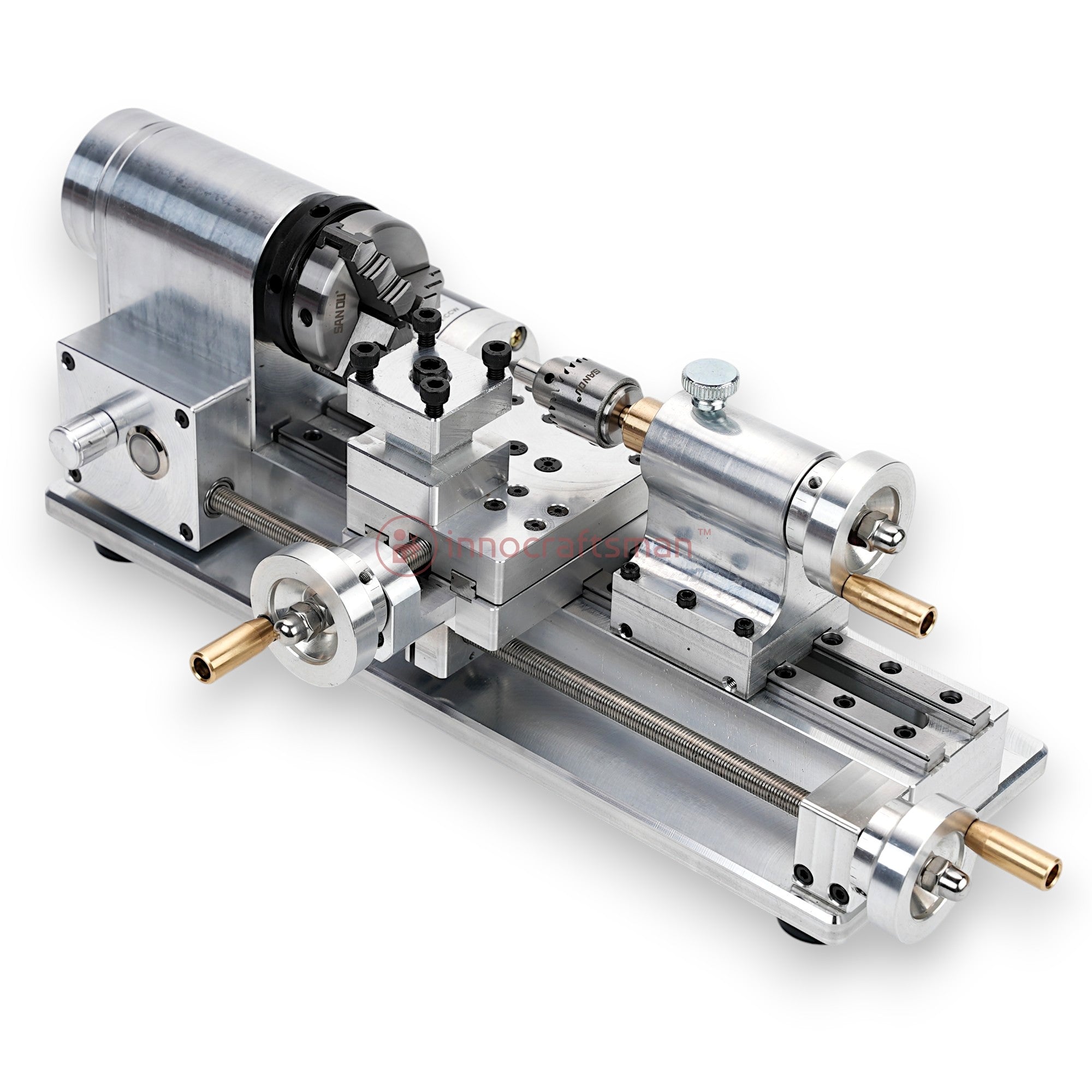

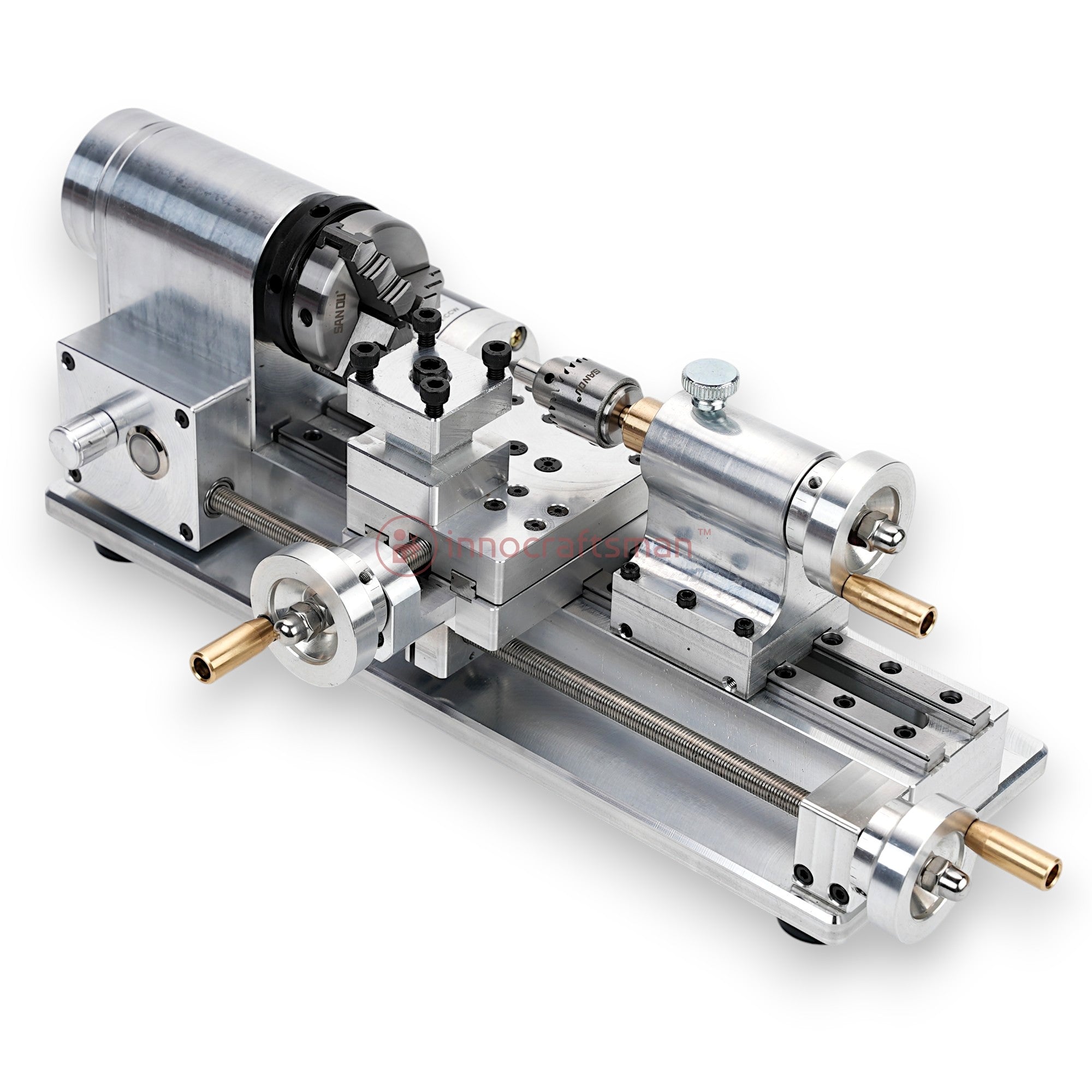

I dont want to be like people who build a stash of models that they will never build by having a stash of tools i will never use but i do love this.

innocraftsman.com

innocraftsman.com

the whole thing is just 13" long and with a power feed !!!

and with a power feed !!!

The problem is if you have the space there are better lathes but larger, 3x the size, 3x the usefulness, and only 2x the price.

However with any machine tool weight is paramount with size, any old lathe will most likely be cast iron and there is a very good reason for than. If you want to turn to .001" and the lathe bed has a flex of .003" forget it That little lathe above would probably need to be bolted down to an ally or cast iron slab that would not flex but even then the lathe itself might flex between its rigid mounting points.

That little lathe above would probably need to be bolted down to an ally or cast iron slab that would not flex but even then the lathe itself might flex between its rigid mounting points.

One of the tools i used to make, i had to grind a gap in it of 5 microns so about .0002" The machine i used only had a capacity for a 6" grinding wheel so was not large but the machine weighed nearly half a ton

I dont know what this has to do with latest acquisitions but While you dont need to turn to those tolerances the rule still applies that weight equals rigidity and that means accuracy and less chatter.

I dont want to be like people who build a stash of models that they will never build by having a stash of tools i will never use but i do love this.

Mini Metal Lathe 80W

Introducing a compact yet functional DIY mini lathe, where every component is crafted from premium materials using CNC machinery for maximum precision. This lathe is perfect for crafting detailed models and intricate parts, making it ideal for creating watch parts, jewelry, and other fine...

the whole thing is just 13" long

The problem is if you have the space there are better lathes but larger, 3x the size, 3x the usefulness, and only 2x the price.

However with any machine tool weight is paramount with size, any old lathe will most likely be cast iron and there is a very good reason for than. If you want to turn to .001" and the lathe bed has a flex of .003" forget it

One of the tools i used to make, i had to grind a gap in it of 5 microns so about .0002" The machine i used only had a capacity for a 6" grinding wheel so was not large but the machine weighed nearly half a ton

I dont know what this has to do with latest acquisitions but While you dont need to turn to those tolerances the rule still applies that weight equals rigidity and that means accuracy and less chatter.

Those look pretty sure nuff. I'd rather see a machinist do a review on them to see how they stand up. I'm glad I FINALLY got some use out of the Unimat I picked up years ago.

Heavens Eagle

Well-known member

I get it Paddy, but years ago I kept running into the wall of "If I had ____ I could do ____" When I was given the chance to obtain all the tooling I have to repair watches, that tooling has ended up being for mostly models though enough work has been done on watches with my mini mill and watchmaker lathe to have paid for them. The Jig I use for solidity in building models came from another "If I had ____" moment and I was able to build the starting part of it. It has then grown and has a ton of attachments that I also built .. with the mini mill.I think i metioned before there are so many think that i would love to own but when i ask myself how often i would use it and if it arrived tomorrow what do i need it for...........i cant think of anything.

I dont want to be like people who build a stash of models that they will never build by having a stash of tools i will never use but i do love this.

Mini Metal Lathe 80W

Introducing a compact yet functional DIY mini lathe, where every component is crafted from premium materials using CNC machinery for maximum precision. This lathe is perfect for crafting detailed models and intricate parts, making it ideal for creating watch parts, jewelry, and other fine...innocraftsman.com

the whole thing is just 13" longand with a power feed !!!

The problem is if you have the space there are better lathes but larger, 3x the size, 3x the usefulness, and only 2x the price.

However with any machine tool weight is paramount with size, any old lathe will most likely be cast iron and there is a very good reason for than. If you want to turn to .001" and the lathe bed has a flex of .003" forget itThat little lathe above would probably need to be bolted down to an ally or cast iron slab that would not flex but even then the lathe itself might flex between its rigid mounting points.

One of the tools i used to make, i had to grind a gap in it of 5 microns so about .0002" The machine i used only had a capacity for a 6" grinding wheel so was not large but the machine weighed nearly half a ton

I dont know what this has to do with latest acquisitions but While you dont need to turn to those tolerances the rule still applies that weight equals rigidity and that means accuracy and less chatter.

I'm not saying that anyone HAS to get a lathe or mill or any other tool, but for me having the tools opened up worlds of things I could do. At some point I wouldn't mind having a little larger mill, but what I have works well enough for what I use it for.

Last night a part on my SdKfz 251/1 kit fell on the floor and vanished. I looked for it for quite a while. Basically a 1/4 inch diameter grey dot that holds the front wheel on. I have no doubt it will show up eventually, but I grabbed some acrylic measured the other part and made a replacement with the lathe. Once paint is applied there will be no difference between the two sides. Without the lathe I couldn't have made the part.

Someone asked me one time what I was going to use the lathe and especially the mill for and it came to me: "It's not what I am planning to use them for, it is what they allow me to plan" If you have it you WILL use it and it does let you go OH, I can do this on the lathe or mill. There have been a couple of times it turned into a BIG project, but I am glad I have them and they have been worth the effort and expense.

paddy

Well-known member

I am sure you are 100% right Paul and if i had this stuff i would find lots of uses for itI get it Paddy, but years ago I kept running into the wall of "If I had ____ I could do ____" When I was given the chance to obtain all the tooling I have to repair watches, that tooling has ended up being for mostly models though enough work has been done on watches with my mini mill and watchmaker lathe to have paid for them. The Jig I use for solidity in building models came from another "If I had ____" moment and I was able to build the starting part of it. It has then grown and has a ton of attachments that I also built .. with the mini mill.

I'm not saying that anyone HAS to get a lathe or mill or any other tool, but for me having the tools opened up worlds of things I could do. At some point I wouldn't mind having a little larger mill, but what I have works well enough for what I use it for.

Last night a part on my SdKfz 251/1 kit fell on the floor and vanished. I looked for it for quite a while. Basically a 1/4 inch diameter grey dot that holds the front wheel on. I have no doubt it will show up eventually, but I grabbed some acrylic measured the other part and made a replacement with the lathe. Once paint is applied there will be no difference between the two sides. Without the lathe I couldn't have made the part.

Someone asked me one time what I was going to use the lathe and especially the mill for and it came to me: "It's not what I am planning to use them for, it is what they allow me to plan" If you have it you WILL use it and it does let you go OH, I can do this on the lathe or mill. There have been a couple of times it turned into a BIG project, but I am glad I have them and they have been worth the effort and expense.

I do however think that whatever you buy, for the sake of a few more $ you could have got the upgrade or something better. This is a pyramid you never get to the top of because your Fiat 500 soon becomes a Bugatti Chiron ....

Maybe now i am retired it will dawn on me i am going to die very well off with no immediate dependants and as someone said to me the other day, this is it, there is no rehearsal ....lol

By the way, that lathe above comes with a mill as well here

Innocraftsman™ Mini Lathe-Milling Machine

Lathe Functionality: Features a 350W (or 680W) high-torque motor with adjustable speed and 80mm manual three-jaw chuck, allowing for a maximum processing diameter of 60mm and length of 160mm. Ideal for working with copper, iron, aluminum, stainless steel (304), and 45 steel. Milling...

I gust lover that this thing is just 1ft long.... I do wonder about aluminium slides on an aluminium, bed.

Heavens Eagle

Well-known member

Looks to me that the slides, beds and parts that move are steel with aluminum plates holding it together. I would call it a lightweight unit. Work fine for plastic, wood, and maybe aluminum or brass.I am sure you are 100% right Paul and if i had this stuff i would find lots of uses for itThere are so many things in life i could have but i dont and that is entirely my own fault in fact i think its an illness/condition. Reading through what i wrote i can see i am publicly trying to justify things and i do this with everything which is why i dont have a new car or furniture or even a house. I could afford it all but i cant justify it to myself. No one else is involved so it just me that stops me

I do however think that whatever you buy, for the sake of a few more $ you could have got the upgrade or something better. This is a pyramid you never get to the top of because your Fiat 500 soon becomes a Bugatti Chiron ....

Maybe now i am retired it will dawn on me i am going to die very well off with no immediate dependants and as someone said to me the other day, this is it, there is no rehearsal ....lol

By the way, that lathe above comes with a mill as well here

Innocraftsman™ Mini Lathe-Milling Machine

Lathe Functionality: Features a 350W (or 680W) high-torque motor with adjustable speed and 80mm manual three-jaw chuck, allowing for a maximum processing diameter of 60mm and length of 160mm. Ideal for working with copper, iron, aluminum, stainless steel (304), and 45 steel. Milling...innocraftsman.com

I gust lover that this thing is just 1ft long.... I do wonder about aluminium slides on an aluminium, bed.

I have 3 cars, two which I drive, a Toyota Corolla that is 19 years old and a Sienna van that is 13 years old. The 3rd car is a project VW beetle (1977) that I have had since about 1985 or 6. I also have a house and that is actually cheaper than rent on a 2 bedroom apt. Yeah I have too much stuff also and have been realizing that it is ALL just stuff. We can have it for a while and at some point either the stuff goes away or we do. We can't take it with us, and IF we do come back we will not ever get out OLD stuff back let alone be aware of it.

So, I enjoy what I have here wile I am here. Hopefully for quite a while yet so I can spend a few years with my daughter and her hubby doing the things I enjoy.

Barney

Well-known member

I think I have mentioned that I grew-up in a machine shop. This was long before computers and everything was set up by hand. Milling machines and lathes were part of my life. I absolutely think that such devices are fantastic for y'all that might use them. However, they remind me of my father and THAT is not a good thing.

I certainly admire the work that many of you do with these things. Meanwhile, I stick with what comes in the box.

And yes, I have more kits than I will ever build.

I certainly admire the work that many of you do with these things. Meanwhile, I stick with what comes in the box.

And yes, I have more kits than I will ever build.

Replacement came in yesterday. Yeah for Badger and USAirbrush for standing behind their products.Well the replacement hasn't shown up yet but we'll see.

Brokeneagle

Master at Arms

I have plenty of photos after usage... plenty of weathering when in its natural state in Ukraine...

It has been a while for me, hasn't it!

Saved my rewards and treated myself a month early to birthday gifts!

So.... Doc, what's the difference? Simply a slot on aft body of the later one.

Knobs on the right column seem perfect for the 32nd scale Cobra pedal adjustment knobs!

They're not really legible and the scale is not what I normally build aircraft in but they are useful for 1/35th scale as well!

Making my own Big Sin!

Do I really need to explain why on this one?

Look how much 'mirror' material is left over for other projects!

So.... Doc, what's the difference? Simply a slot on aft body of the later one.

Knobs on the right column seem perfect for the 32nd scale Cobra pedal adjustment knobs!

They're not really legible and the scale is not what I normally build aircraft in but they are useful for 1/35th scale as well!

Making my own Big Sin!

Do I really need to explain why on this one?

Look how much 'mirror' material is left over for other projects!

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 62

- Views

- 14K