I walked down to the garage today as part of my exercise and get back at it plan. I looked at a couple of projects that are on the bench, don't think I'm ready for that yet.

I looked at my Epic Failed Mighty Messerschmidt and wondered why all the coats failed except for the decal?

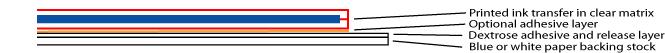

You can see where the lacquer thinner ate at the clear coat over the top of the decal but it didn't burn through all the layers and primer like it did in surrounding areas.

Now...what is it about the decal that seals against lacquer and could we take advantage if it?? :hmmm

I looked at my Epic Failed Mighty Messerschmidt and wondered why all the coats failed except for the decal?

You can see where the lacquer thinner ate at the clear coat over the top of the decal but it didn't burn through all the layers and primer like it did in surrounding areas.

Now...what is it about the decal that seals against lacquer and could we take advantage if it?? :hmmm

). Instead of paint, I went over that with a few coats of Future. I set the loz decal with MicroSol and let me tell you, that was the most tenacious bond I've ever dealt with. When I decided to pull the loz off the tailplane, I soaked it overnight in water, another night in straight vinegar, but the only way to get them off was physically scraping. And that was straight decal, not sealing with anything.

). Instead of paint, I went over that with a few coats of Future. I set the loz decal with MicroSol and let me tell you, that was the most tenacious bond I've ever dealt with. When I decided to pull the loz off the tailplane, I soaked it overnight in water, another night in straight vinegar, but the only way to get them off was physically scraping. And that was straight decal, not sealing with anything.