jeaton01

Well-known member

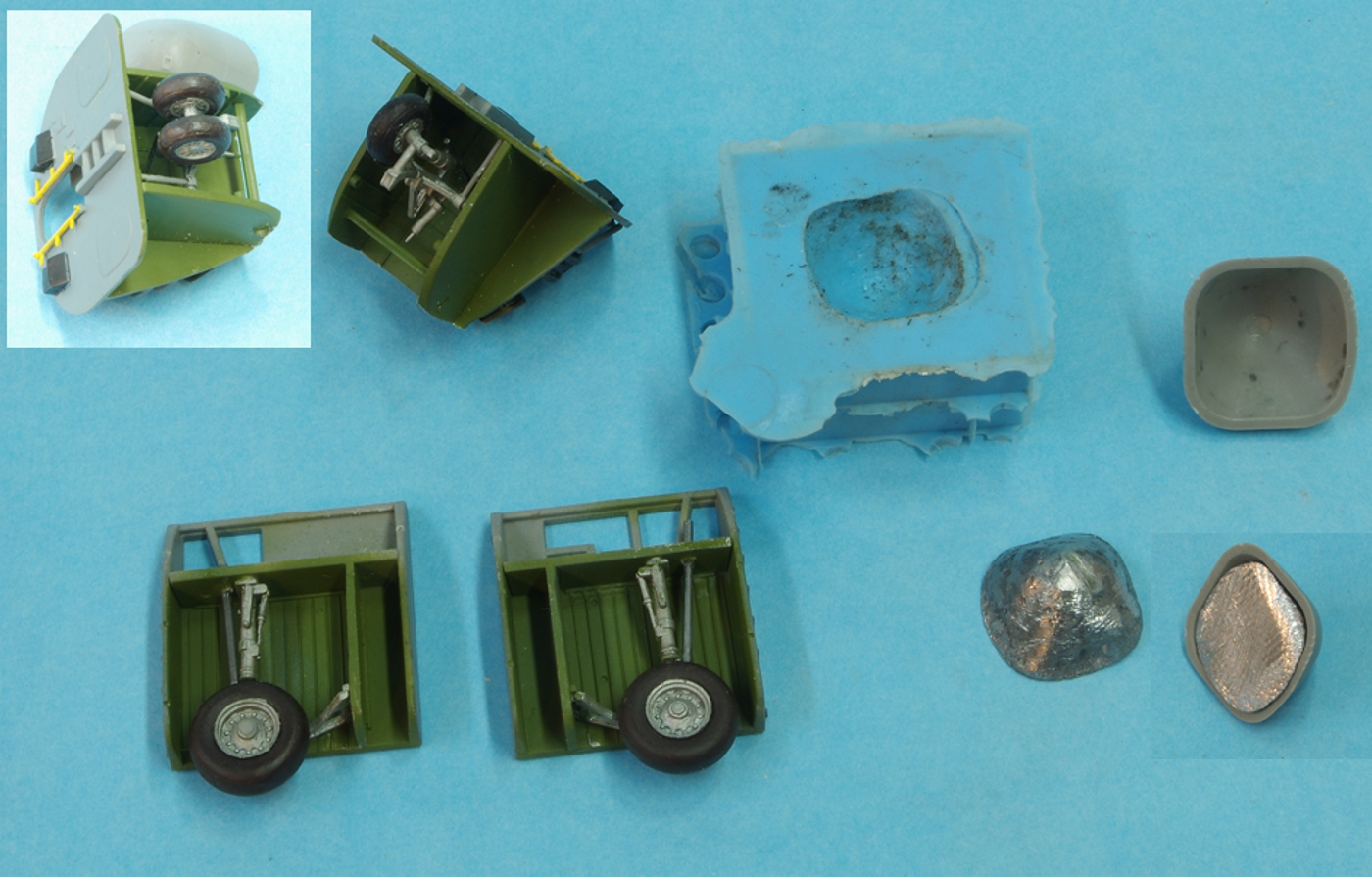

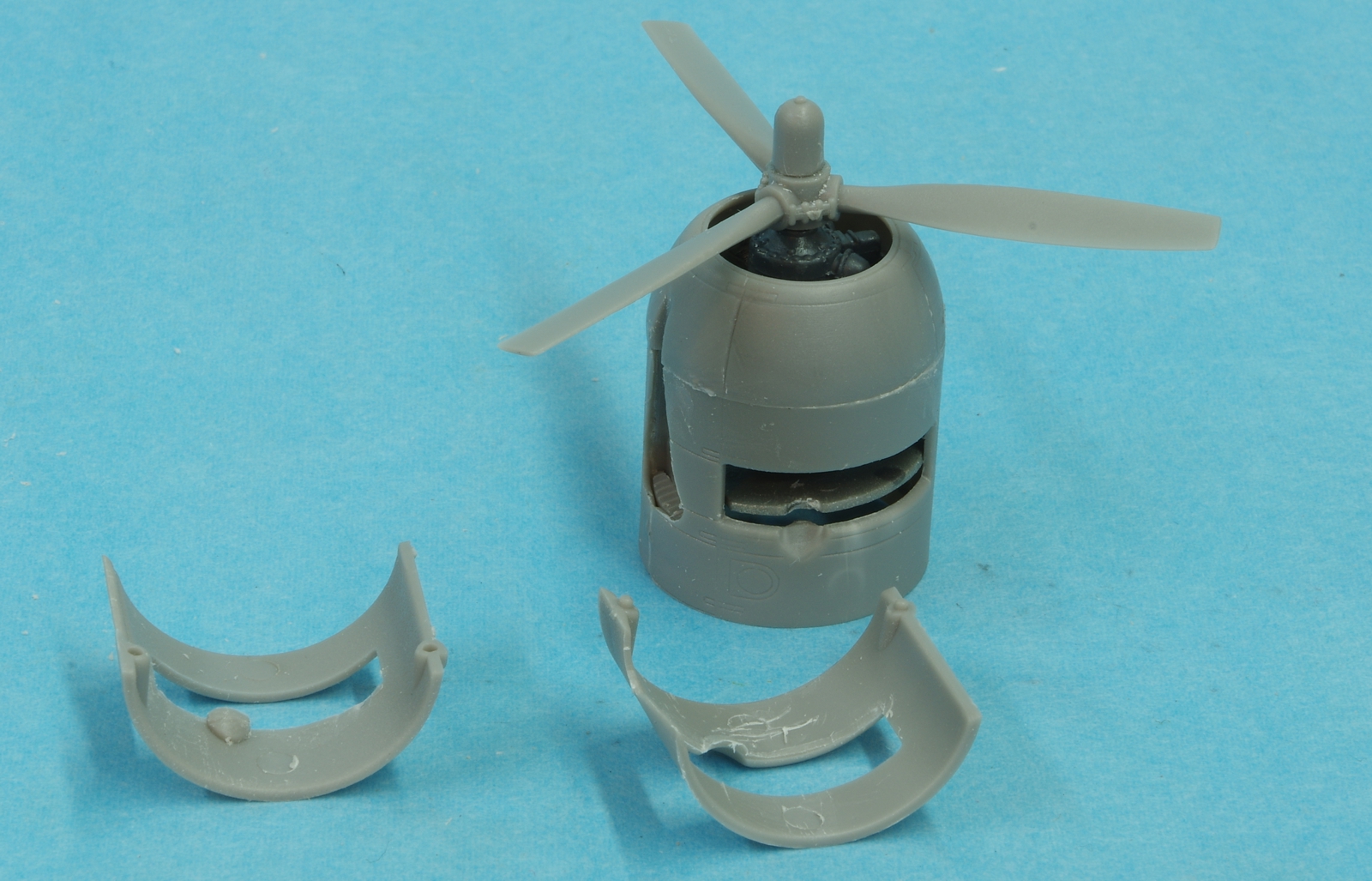

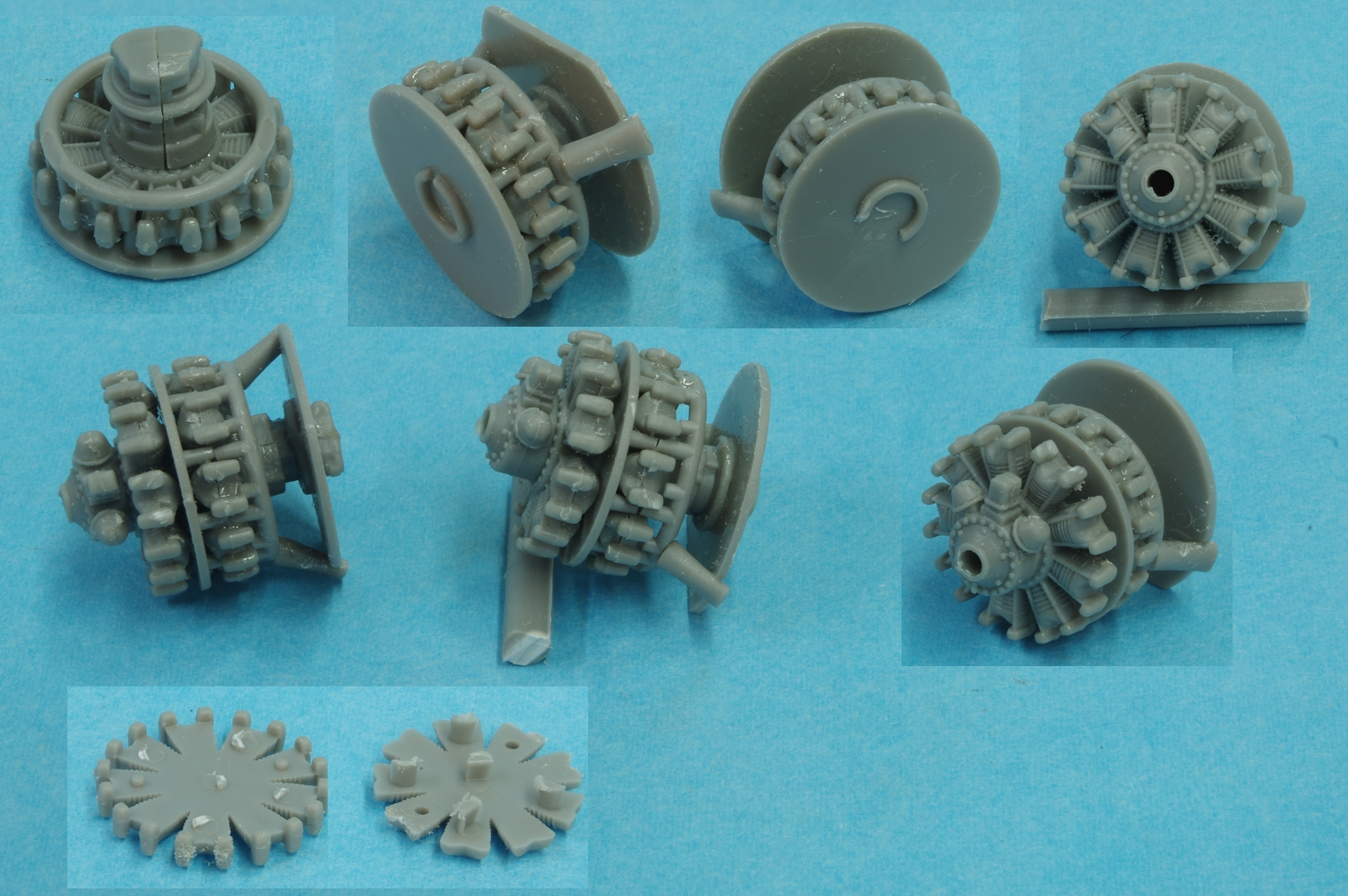

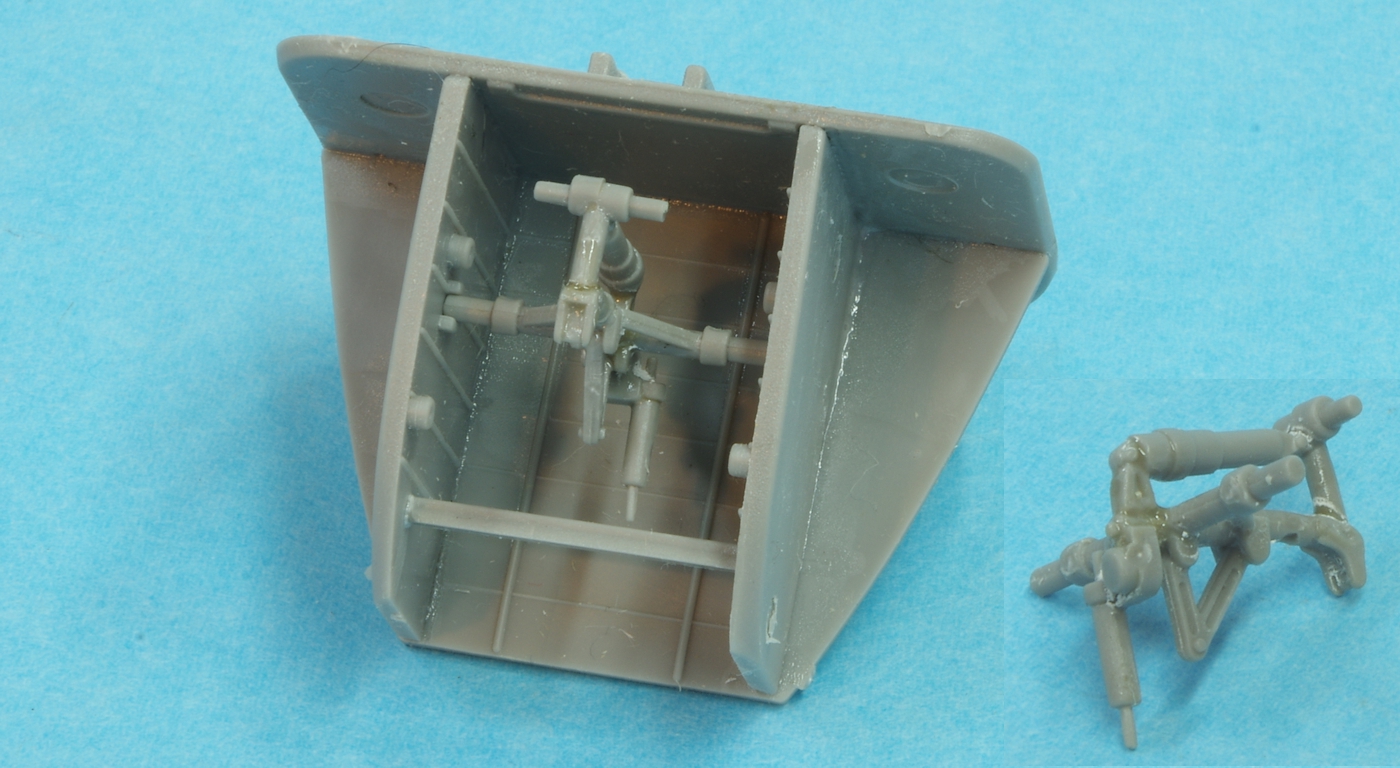

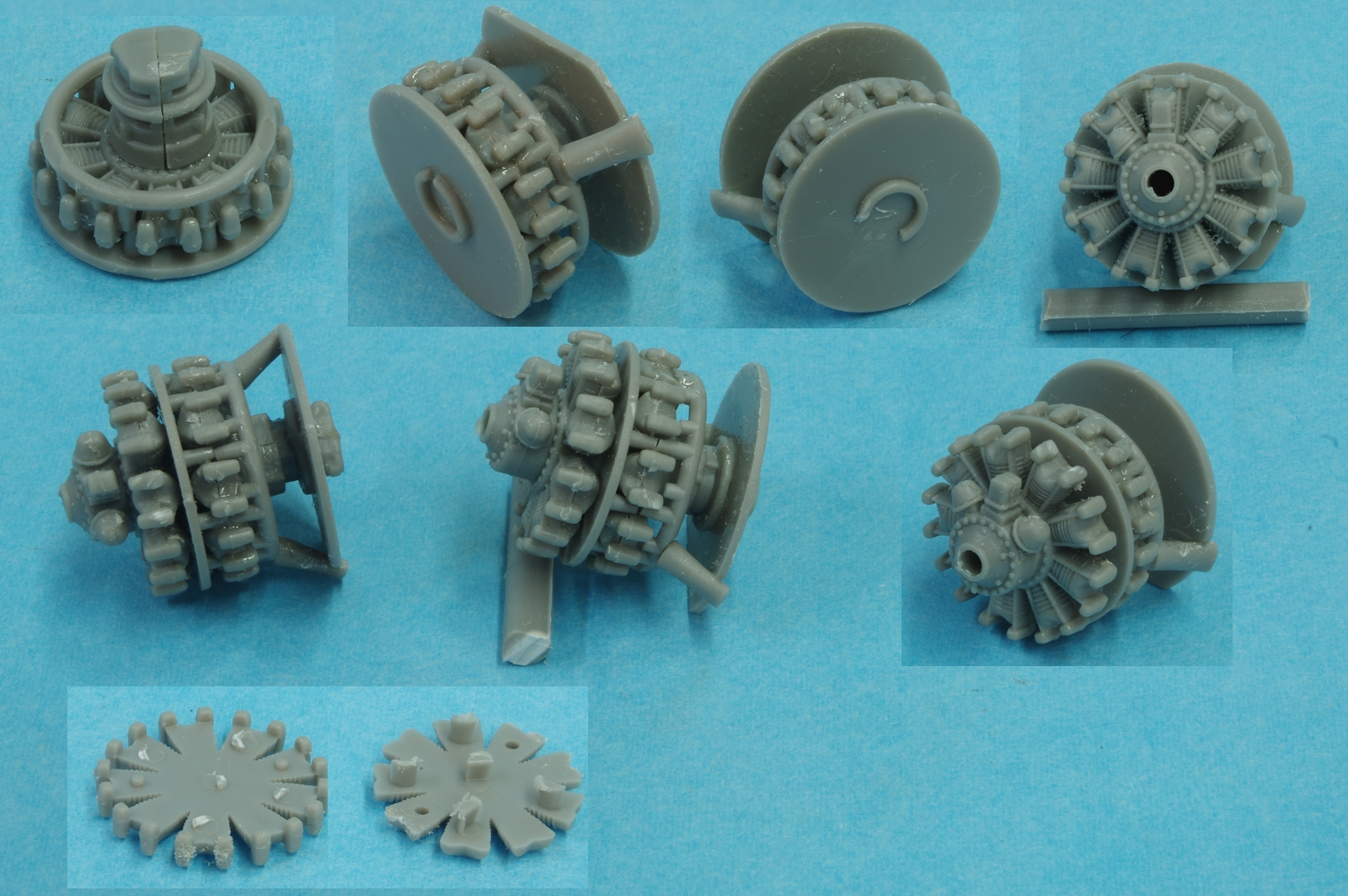

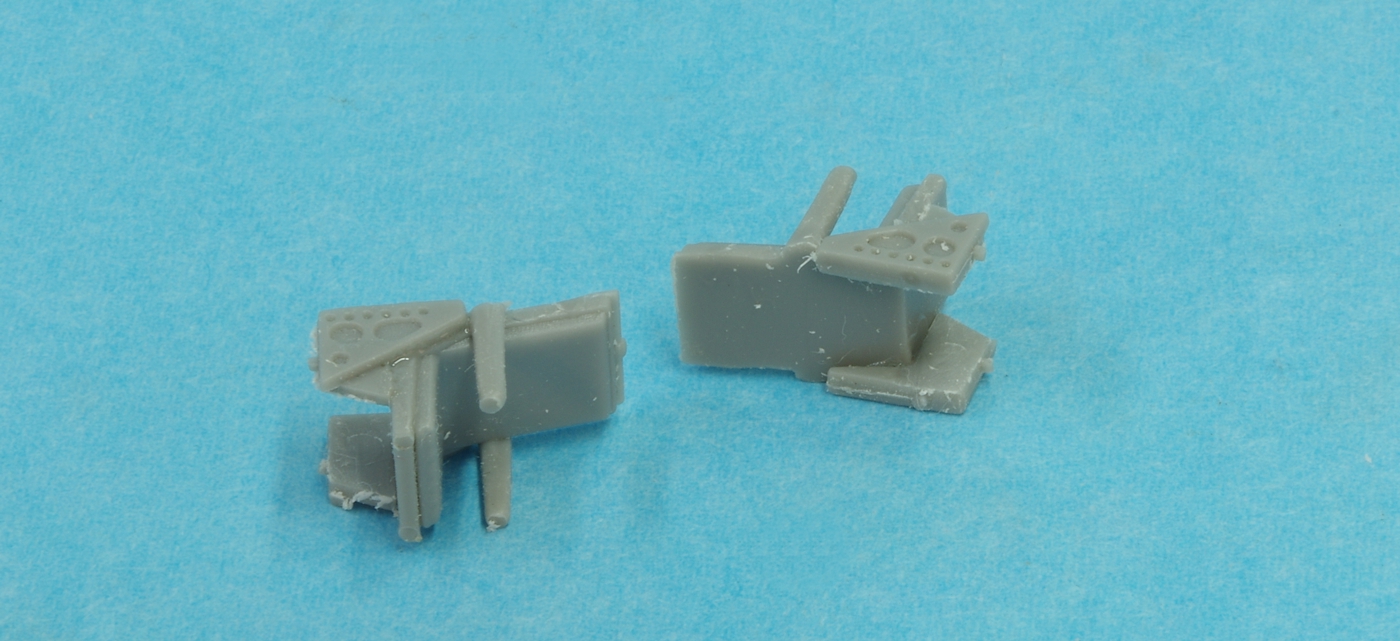

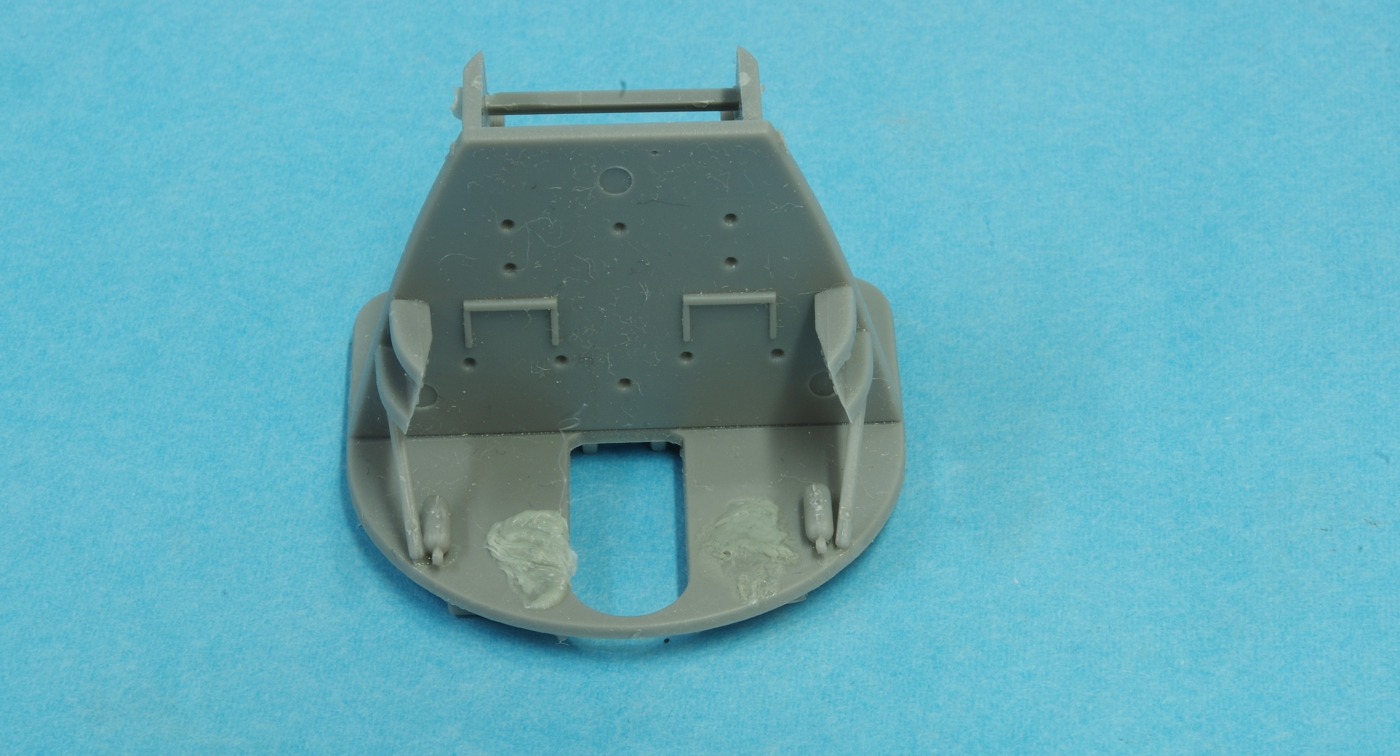

I've made a start on the Roden C-123. It's a very detailed kit, however, I don't think their mold making abilities are quite up to handling the kind of fine details designed into the parts That makes building more difficult. Also, the plastic doesn't seem to like Tamiya thin cement, or CA for that matter. I am using the Testors glue in the triangular bottle right now and it seems to be working, and will try the Touch and Flow Tenax like stuff also. The engines have a lot of detail, most of which will be hidden. I found on assembling the first one that the alignment of the cylinder banks is off, with the rear bank lined up directly behind the front bank, where the rear bank in the real world is offset so the rear cylinders are lined up with the air gap between the front cylinders. It really doesn't matter in this case but being an old engine guy I just couldn't stand it. I didn't fix the first one because I had already glued the front housing on and didn't want to mess it up trying to move it. The pictures show how I modified the second engine. I didn't like their method of attaching the props, I'll do my usual brass tube and music wire method to attach them. The nose gear will ultimately rest on a spider web of struts so a lot of time was spent figuring how that was to be done. The main gear has an odd way of attaching the wheels, they have you put the inner wheel half on the strut, then there is a plastic keeper washer that is glued on to hold the inner wheel half. Then you are to put the outer wheel half on. Clumsy to sand and paint! I assembled all of the main gear parts because I wasn't confident of how the parts fit without doing it all at once. A little misalignment on that narrow gear and the wings will surely not be level. The instructions are not clear enough for me on these assemblies.

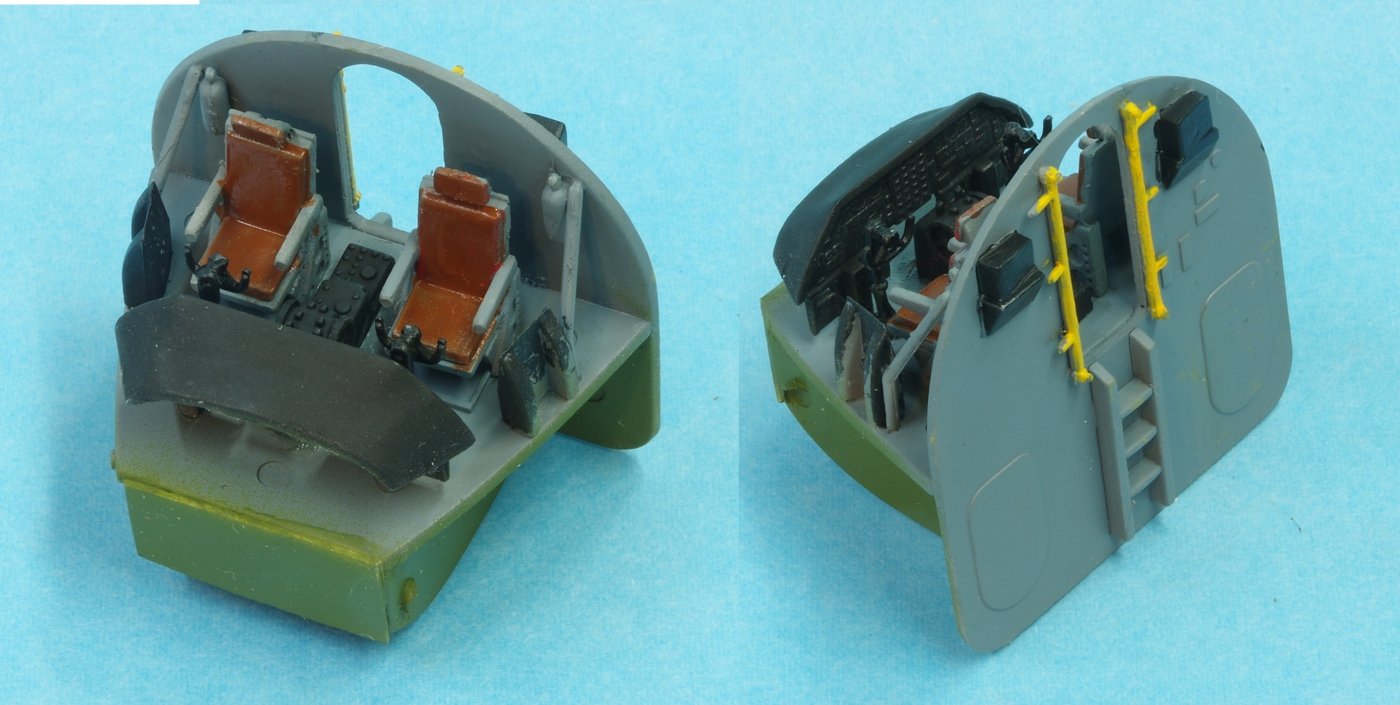

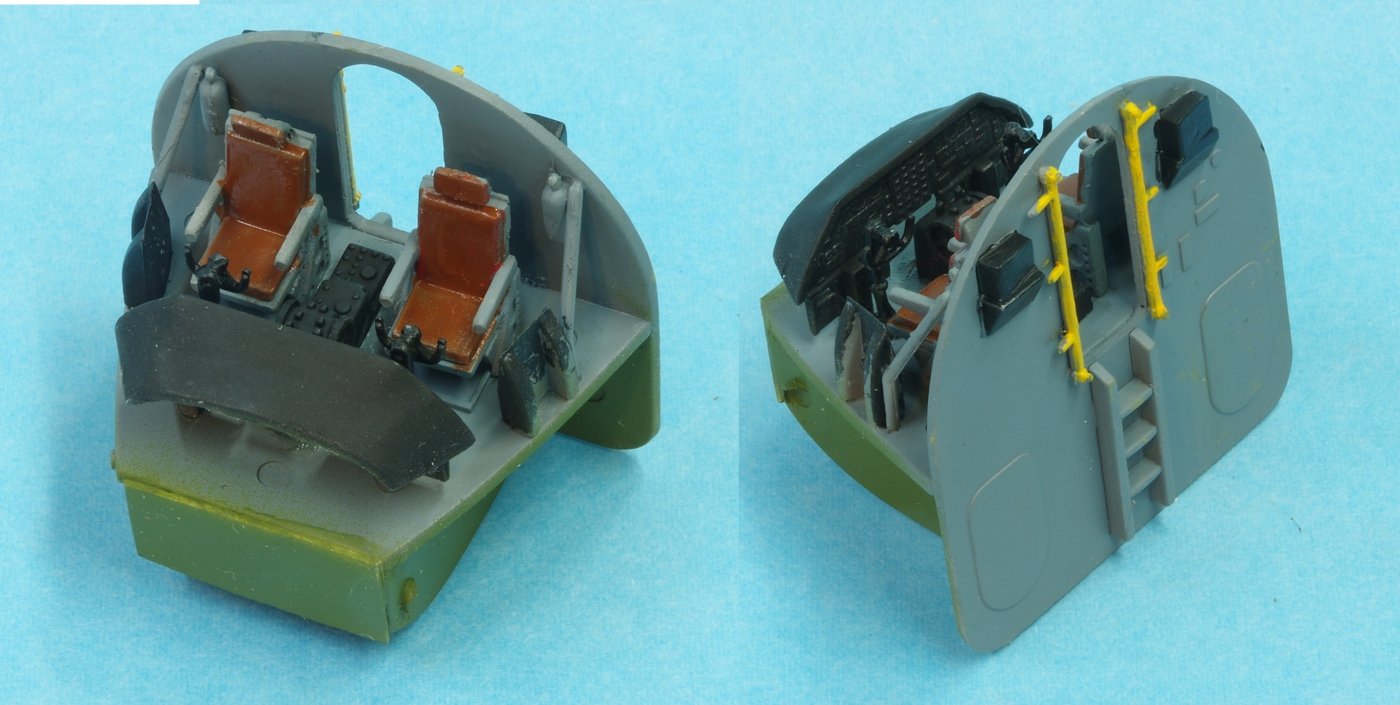

Some of the cockpit parts were assembled and two ejector pin marks on the back wall of the cockpit were fixed using melted sprue.

I made masks for the wheels and windows this afternoon using a Silhouette Cameo vinyl cutter. There will be paint soon!

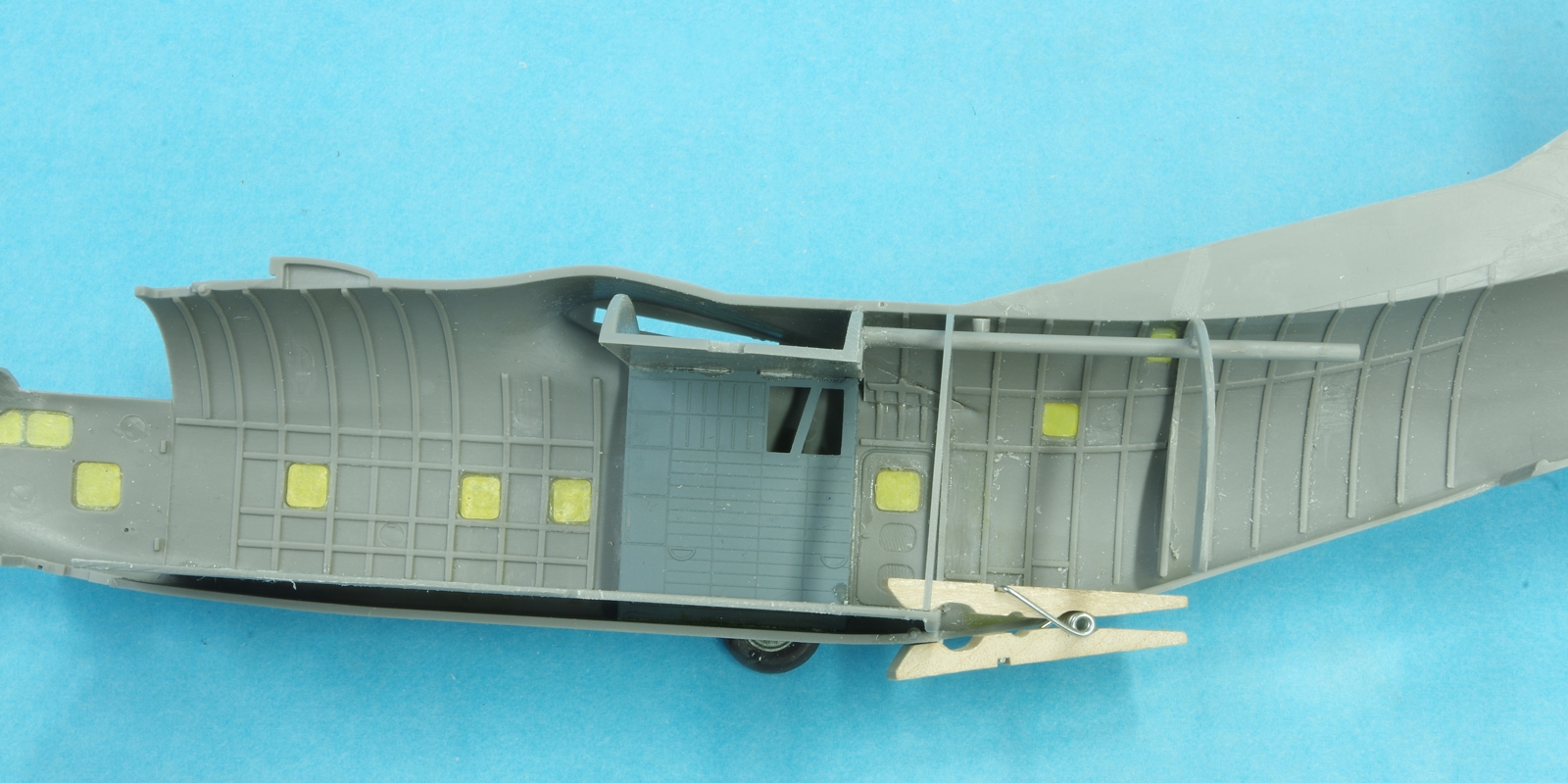

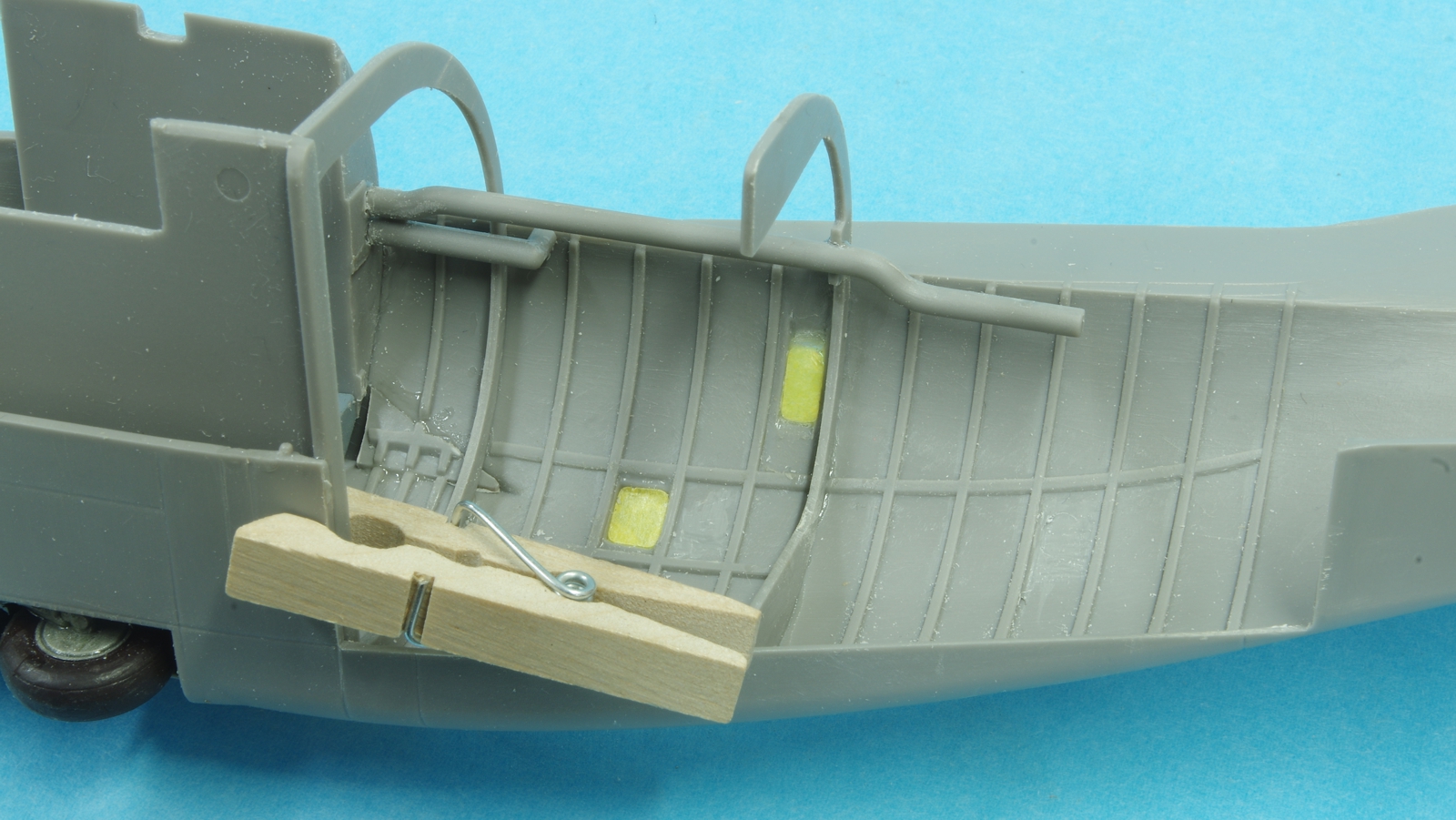

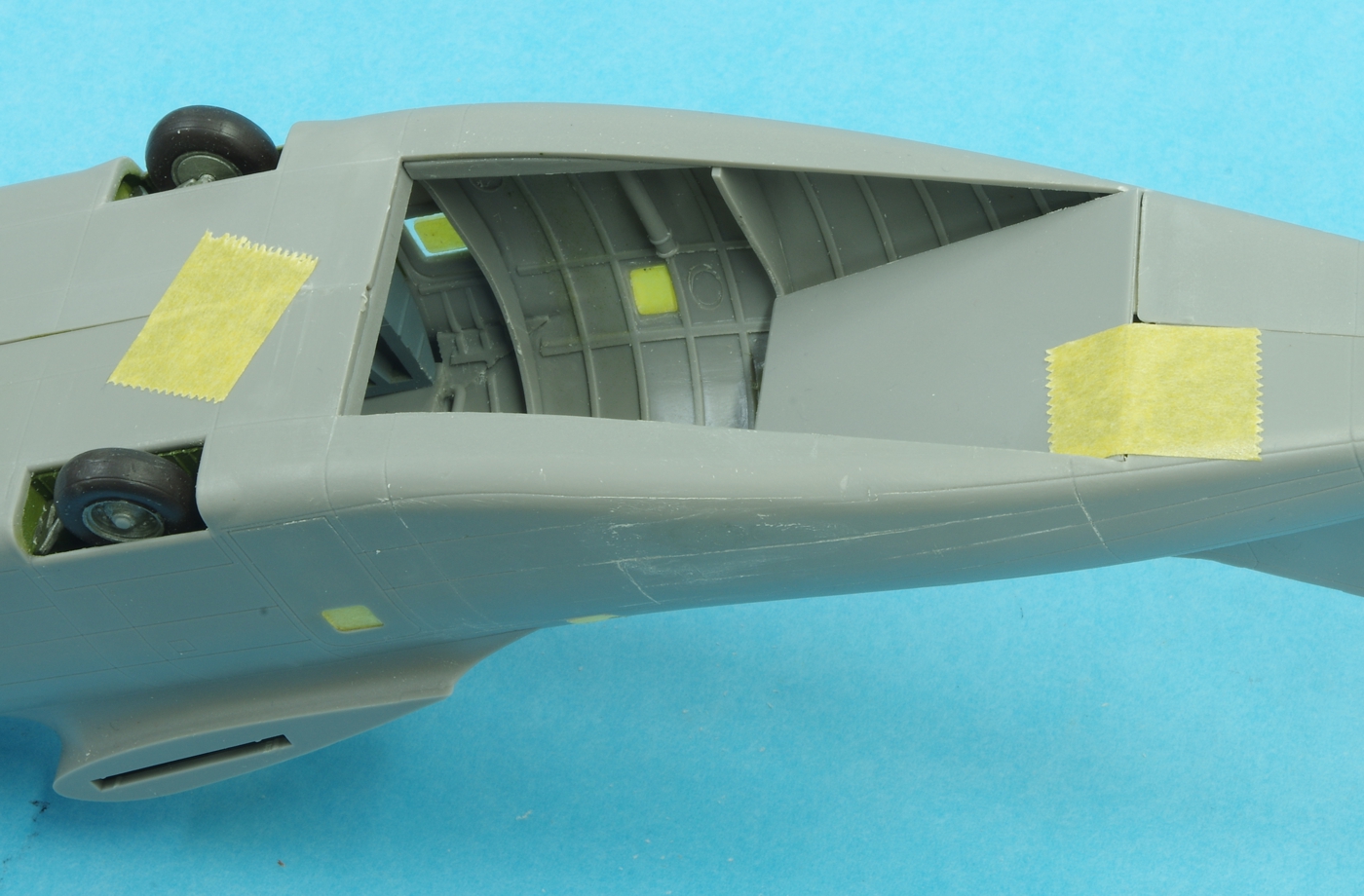

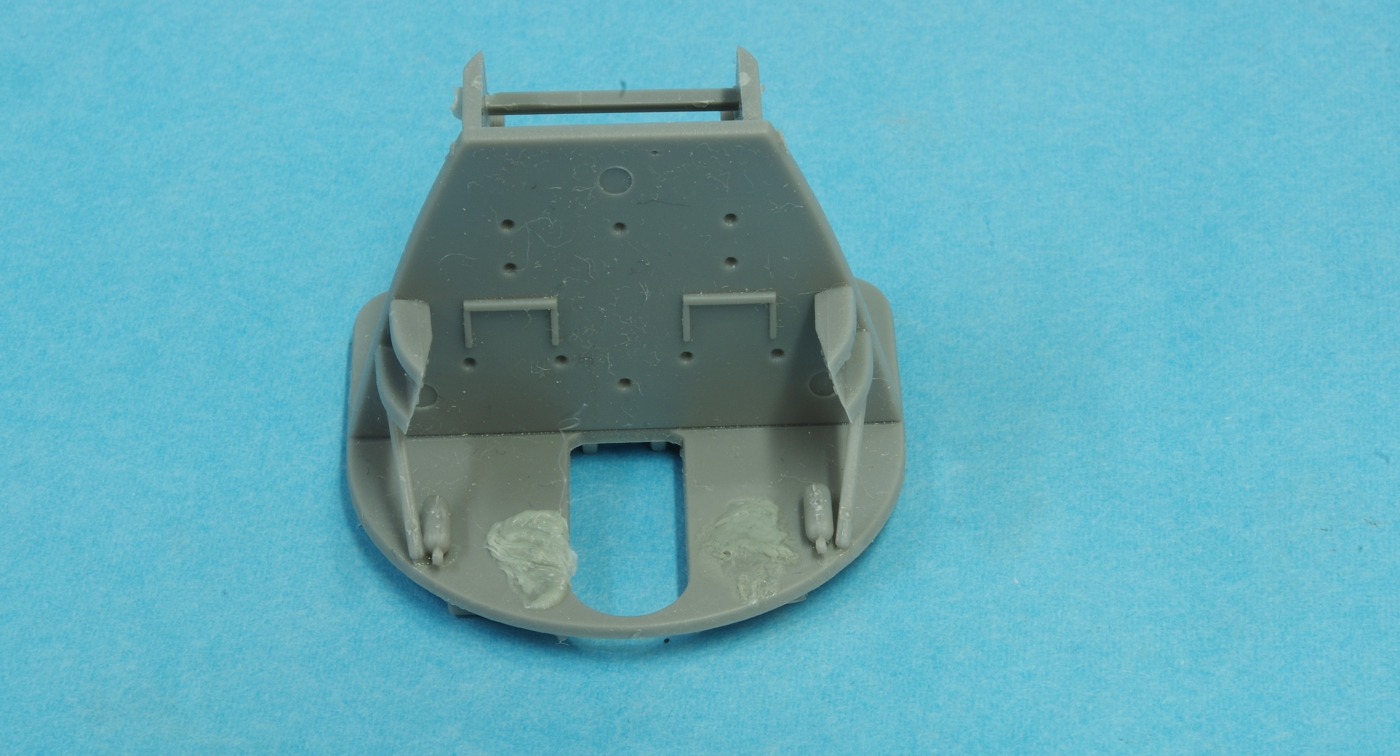

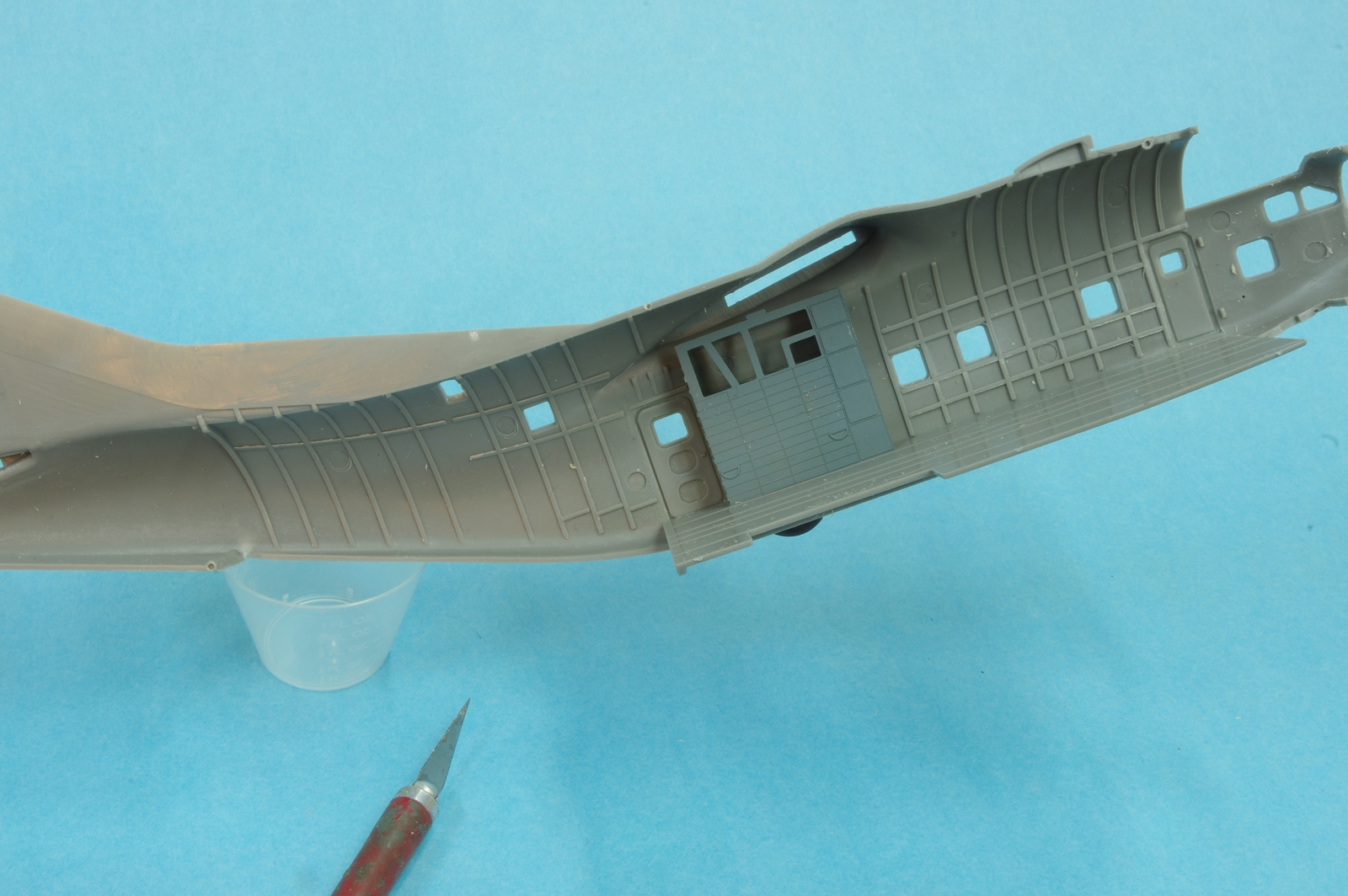

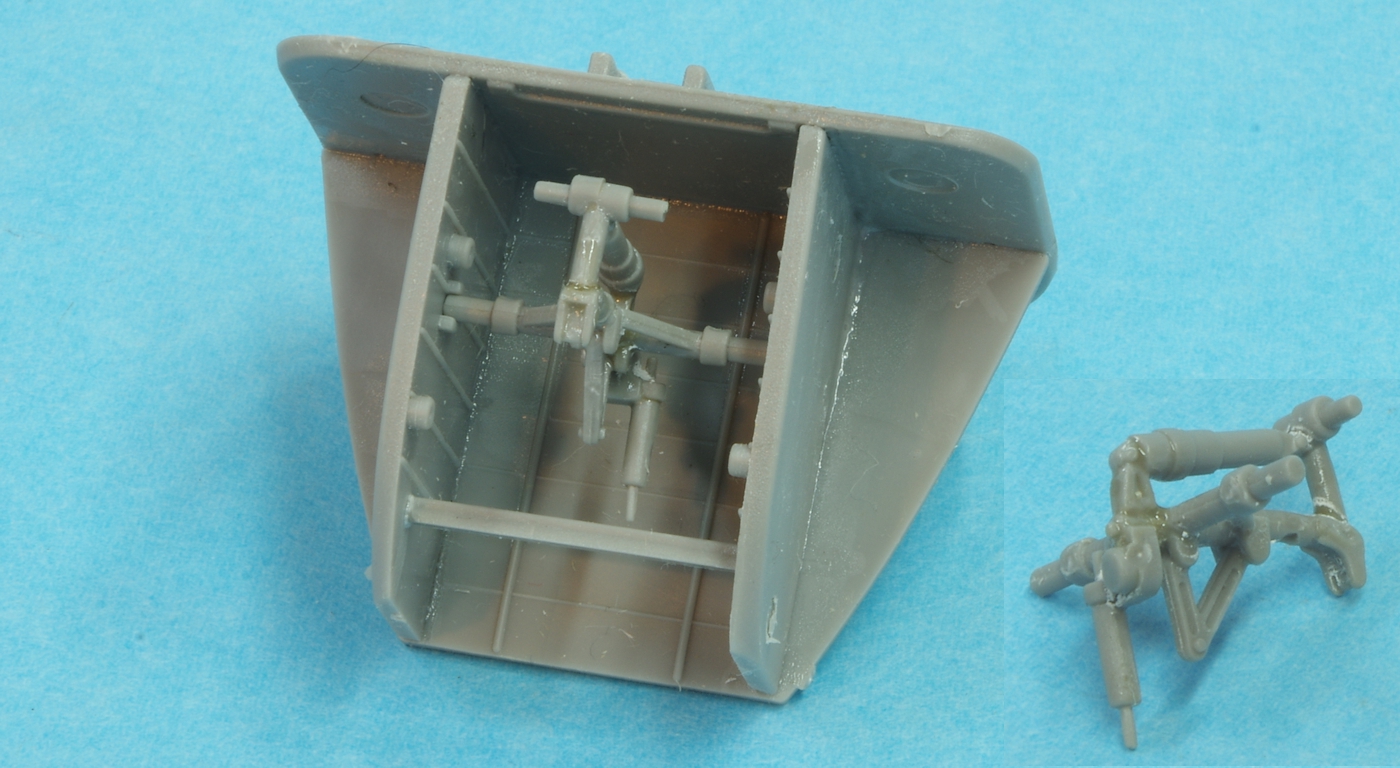

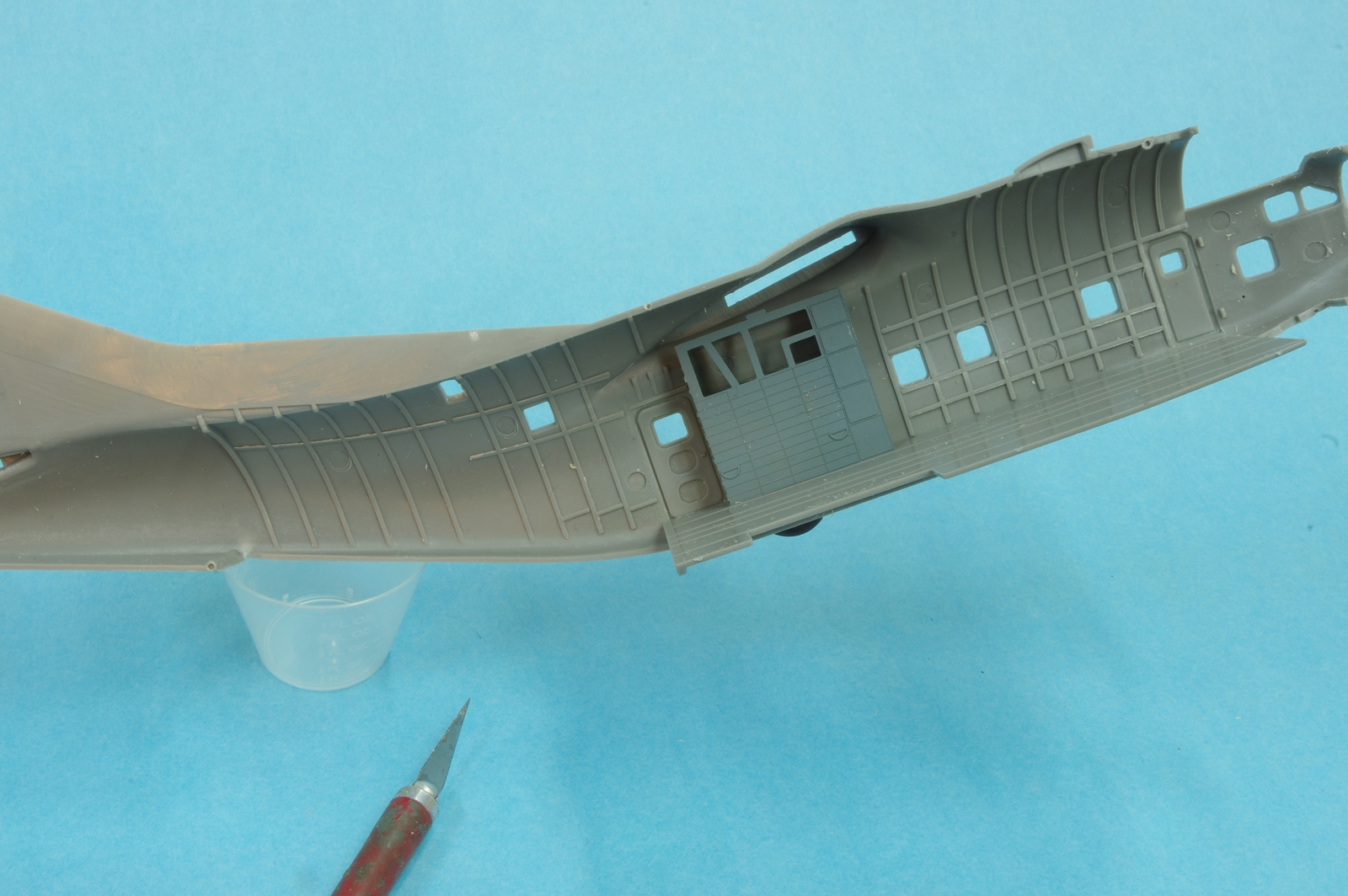

There was no positive locating method for the wheel well assembly so the floor was used to locate it and then lines were scribed on both sides of the well assembly.

Interior green was applied to the fuselage area enclosed by the wheel well. The well is not yet permanently installed.

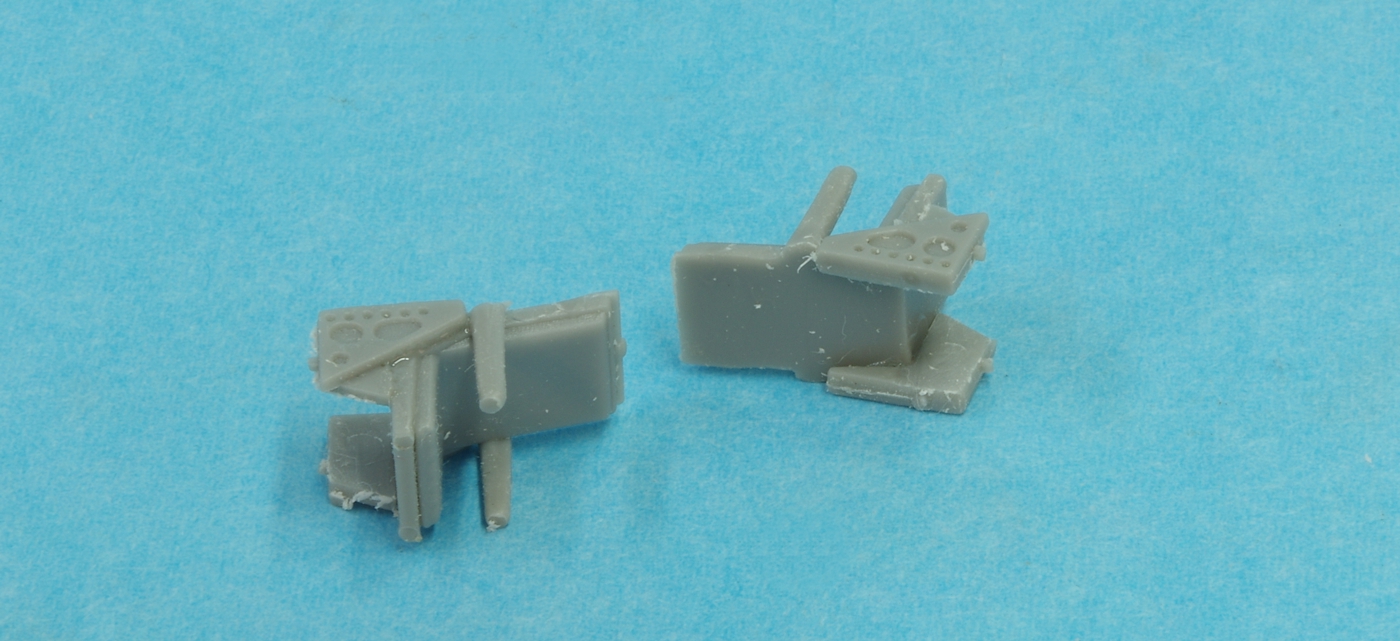

The landing gear assemblies complete and painted. There are some actuator arms for the nose gear doors that the instructions call for at this point but they are going to be left off until the very last.

Still a flat coat to go but the cockpit is together and painted. The lower parts below the cockpit floor were painted interior green because there is a window in the fuselage in that area.

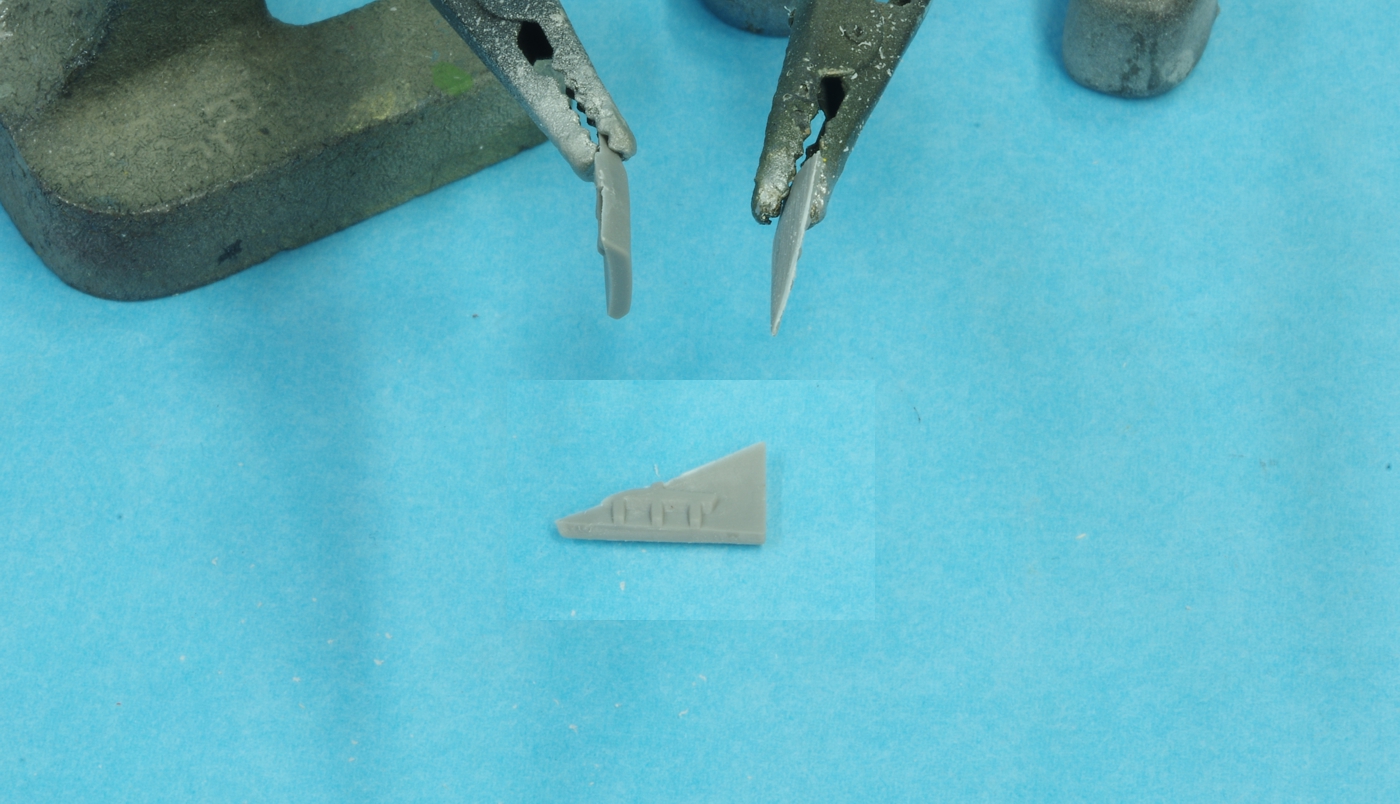

20 grams of weight are called for in the nose. A silicone mold is curing and tomorrow a weight will be cast in it. Clay was pressed into the nose cone to develop the shape.

Some of the cockpit parts were assembled and two ejector pin marks on the back wall of the cockpit were fixed using melted sprue.

I made masks for the wheels and windows this afternoon using a Silhouette Cameo vinyl cutter. There will be paint soon!

There was no positive locating method for the wheel well assembly so the floor was used to locate it and then lines were scribed on both sides of the well assembly.

Interior green was applied to the fuselage area enclosed by the wheel well. The well is not yet permanently installed.

The landing gear assemblies complete and painted. There are some actuator arms for the nose gear doors that the instructions call for at this point but they are going to be left off until the very last.

Still a flat coat to go but the cockpit is together and painted. The lower parts below the cockpit floor were painted interior green because there is a window in the fuselage in that area.

20 grams of weight are called for in the nose. A silicone mold is curing and tomorrow a weight will be cast in it. Clay was pressed into the nose cone to develop the shape.