Duke Maddog

Well-known member

It's been awhile and real life has gotten in the way a bit, but now I have a chance to re-open Maddog Manufacturing to show our 2024 production. There's quiet a bit to show doe this tour, so it might have to be broken up into two posts. The trams have been maintained and updated and so they are ready for the next tour. All aboard whenever you're ready!

Our first stop as always is the Hangar. There's a lot of wonderful activity happening here. In this first bay, we still have the Russian Schtormovic waiting for the propeller replacement as well as a few other parts that need to be found:

In the next bay, we have the German Me-110 all painted with a base coat, waiting for more camouflage:

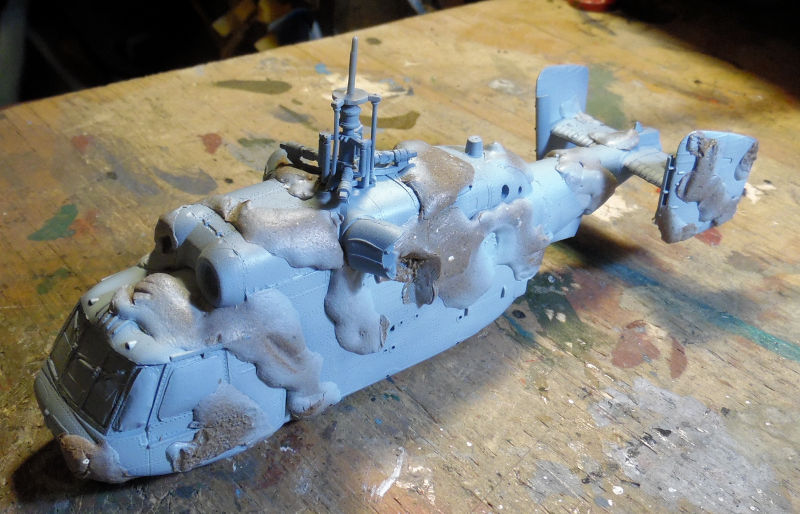

Next we have a Nigerian Mi-24 Hind that needs some modifications to fit the new canopy we got. Then additional parts can be added to finish this off:

Speaking of helicopters, we have this Russian Ka-26 Helix waiting for the rest of the camouflage before more work can be done on it:

Now we start getting into the bigger planes. In this bay we have the British Airways Concorde SST that needs more filling and sanding work before any further work can be done:

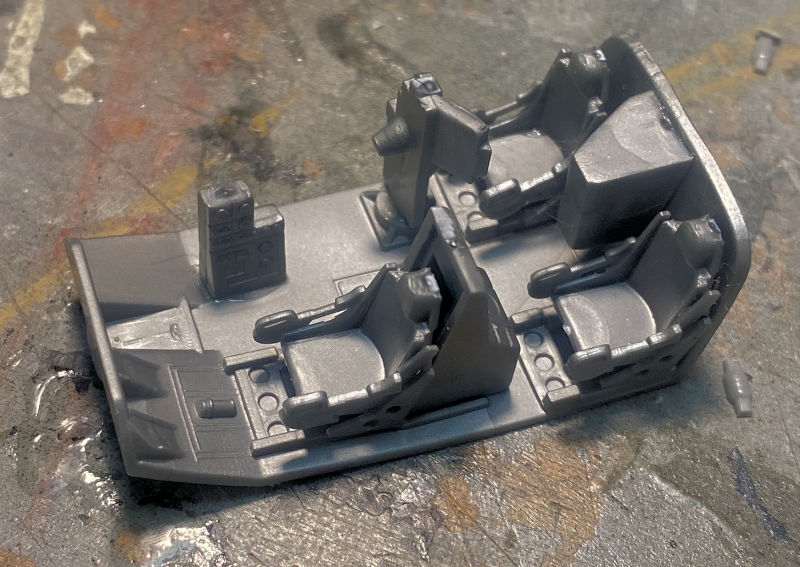

Next is a new project started this year. It;s a US Air Force B-66 Destroyer aircraft that got the cockpit assembled first:

Later the wings and engines were assembled. These went together far better than expected for such an old kit:

In this next bay we have the Russian Tu-142 Bear H bomber that has been built up to this point:

Bot sure what else needs doing before we assemble it, but we'll be revisiting this bay sometime soon. Further down we have one of two Tu-16 Badgers under construction. They have both been built to this stage, but I'm only showing the one for now since the pics are the same:

Finally in this last bay we have a simple model of the Russian As-15 Kent cruise missile. There are two in the box, one in flight and one on the transport trailer. They are both ready for paint:

That concludes the tour of the Hangar for now, lets head out to the Shipyards to see what's under construction there.

Here in the Shipyards there's a good bit of activity. First, let's head to the small slipways where a couple of my motor torpedo boats are under construction.

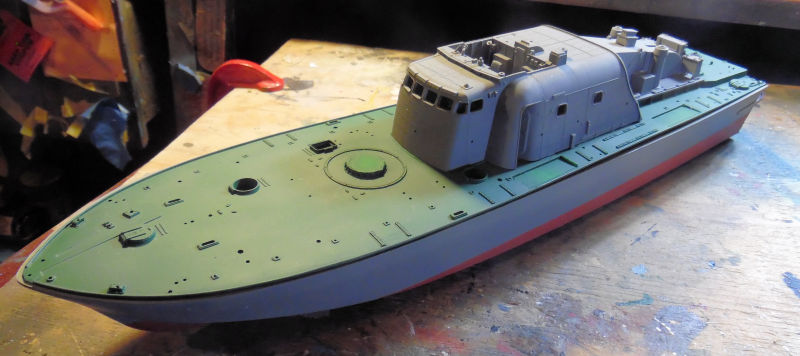

First up is this Japanese PT-15 torpedo boat that has been halfway assembled. Painting will be easy as it's all one color once all the greeblies go on:

In the next slipway is the British Vospers Perkasa boat that is a little further along. We just have to start adding some of the detail parts:

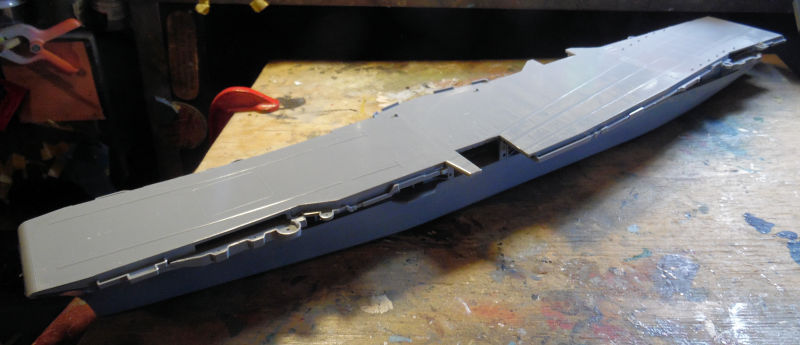

Now we can move onto the bigger drydocks where some new carriers and a steamboat are under construction. This first drydock has the German Aircraft Carrier Peter Strasser which is mostly complete and ready for deck paint:

The next drydock has the USS Shangri-La which finally got the hull completed. The deck is just dry fit on this right now:

In the next drydock over is the USS Enterprise 1980's fit that needs the deck painted with the lines:

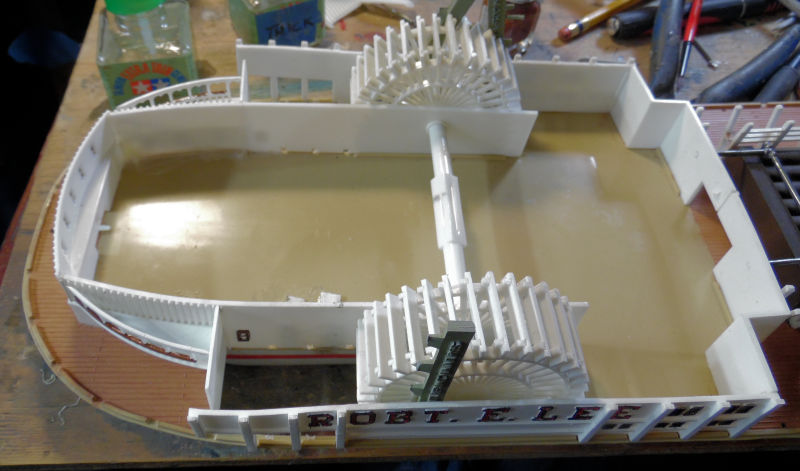

In this final drydock, the Robert E Lee is slowly taking shape. This first pic shows it mostly mocked up to this point to give an idea of what will be done next:

What is actually happening here is this.... the side pieces with the lettering were quite warped so part of them was glued into place with spacers to make sure they glued into the proper and correct position:

Then once they were dry in front, the back ends were glued and clamped into place:

Additional work will slowly commence. It;s like every part is warped out of true so they all have to be warmed and re-positioned not the proper shape, or slowly glued down on one end and slowly worked into place with glue and clamps.

That concludes the Shipyards part of this tour, next is our catch all workshop that currently has two cars under construction.

This first one is the 1929 Coca Cola delivery van built up to this point. The red coat has been giving me a lot of difficulty laying down smooth:

This second car is the Packard roadster that has been fighting me for quite some time. Hopefully it gets finished this year:

Now that we are through all these sections of Maddog Manufacturing, we will continue the tour of the Motor Pool in the next post.

Our first stop as always is the Hangar. There's a lot of wonderful activity happening here. In this first bay, we still have the Russian Schtormovic waiting for the propeller replacement as well as a few other parts that need to be found:

In the next bay, we have the German Me-110 all painted with a base coat, waiting for more camouflage:

Next we have a Nigerian Mi-24 Hind that needs some modifications to fit the new canopy we got. Then additional parts can be added to finish this off:

Speaking of helicopters, we have this Russian Ka-26 Helix waiting for the rest of the camouflage before more work can be done on it:

Now we start getting into the bigger planes. In this bay we have the British Airways Concorde SST that needs more filling and sanding work before any further work can be done:

Next is a new project started this year. It;s a US Air Force B-66 Destroyer aircraft that got the cockpit assembled first:

Later the wings and engines were assembled. These went together far better than expected for such an old kit:

In this next bay we have the Russian Tu-142 Bear H bomber that has been built up to this point:

Bot sure what else needs doing before we assemble it, but we'll be revisiting this bay sometime soon. Further down we have one of two Tu-16 Badgers under construction. They have both been built to this stage, but I'm only showing the one for now since the pics are the same:

Finally in this last bay we have a simple model of the Russian As-15 Kent cruise missile. There are two in the box, one in flight and one on the transport trailer. They are both ready for paint:

That concludes the tour of the Hangar for now, lets head out to the Shipyards to see what's under construction there.

Here in the Shipyards there's a good bit of activity. First, let's head to the small slipways where a couple of my motor torpedo boats are under construction.

First up is this Japanese PT-15 torpedo boat that has been halfway assembled. Painting will be easy as it's all one color once all the greeblies go on:

In the next slipway is the British Vospers Perkasa boat that is a little further along. We just have to start adding some of the detail parts:

Now we can move onto the bigger drydocks where some new carriers and a steamboat are under construction. This first drydock has the German Aircraft Carrier Peter Strasser which is mostly complete and ready for deck paint:

The next drydock has the USS Shangri-La which finally got the hull completed. The deck is just dry fit on this right now:

In the next drydock over is the USS Enterprise 1980's fit that needs the deck painted with the lines:

In this final drydock, the Robert E Lee is slowly taking shape. This first pic shows it mostly mocked up to this point to give an idea of what will be done next:

What is actually happening here is this.... the side pieces with the lettering were quite warped so part of them was glued into place with spacers to make sure they glued into the proper and correct position:

Then once they were dry in front, the back ends were glued and clamped into place:

Additional work will slowly commence. It;s like every part is warped out of true so they all have to be warmed and re-positioned not the proper shape, or slowly glued down on one end and slowly worked into place with glue and clamps.

That concludes the Shipyards part of this tour, next is our catch all workshop that currently has two cars under construction.

This first one is the 1929 Coca Cola delivery van built up to this point. The red coat has been giving me a lot of difficulty laying down smooth:

This second car is the Packard roadster that has been fighting me for quite some time. Hopefully it gets finished this year:

Now that we are through all these sections of Maddog Manufacturing, we will continue the tour of the Motor Pool in the next post.