-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maddog Manufacturing 2018 Production

- Thread starter Duke Maddog

- Start date

Duke Maddog

Well-known member

Thanks for the awesome replies guys!

Dave, there's only three because that was what I only got done that day. Didn't have much time to do too much more and besides, my batteries died before I could shoot pics of other progress. Stay tuned my friend, there's a lot more coming.

Frank, you're welcome for the tip. It's great stuff that helps give a good mask and is easy to deal with. Keep an eye on the thickness of course; too thick and it'll shift, too thin and it won't stick to the model. The buildings are right now just being built. I don't really have too much space for a diorama; especially one that will fit that Berlin House, but I am thinking of trying to utilize them somehow in a photo-base for my completed models. I also am considering them as possible wargame pieces for a table top war game.

Thanks Luiz! I'm glad to see you stop in again.

Thanks Razor. I'm just planning on finishing them up right now; I just hope I can make them look great.

Dave, there's only three because that was what I only got done that day. Didn't have much time to do too much more and besides, my batteries died before I could shoot pics of other progress. Stay tuned my friend, there's a lot more coming.

Frank, you're welcome for the tip. It's great stuff that helps give a good mask and is easy to deal with. Keep an eye on the thickness of course; too thick and it'll shift, too thin and it won't stick to the model. The buildings are right now just being built. I don't really have too much space for a diorama; especially one that will fit that Berlin House, but I am thinking of trying to utilize them somehow in a photo-base for my completed models. I also am considering them as possible wargame pieces for a table top war game.

Thanks Luiz! I'm glad to see you stop in again.

Thanks Razor. I'm just planning on finishing them up right now; I just hope I can make them look great.

Duke Maddog

Well-known member

Hey, I know about Federal disaster areas and you're lacking 10 bureaucrats telling 6 federal disaster assistant chiefs how the local government should be doing their job.

:yipee

LOL! Yeah, but I actually do: they are all rolled up inside one tiny little wife! :woohoo: :yipee

Duke Maddog

Well-known member

Here's another large update showing all the work I got done in my Hobby Room since Monday. This is a long one so I'll be breaking this update into two posts. My aircraft will be in the first one, then my armor/vehicles and ships will be in the second one.

Without further ado, let's start our tour of the hanger....

I started with the Japanese F-2A since it was so close to being done. I applied all the decals to this first:

After they dried, I shot a dullcoat to seal them, once I finished adding Solvaset to them to remove the silvering. I seem to have a lot of problems with silvering lately for some odd reason; despite my use of clear glosscoats....

After that, I added the landing gear and gear doors, along with the wing pylons:

Later, I painted the interior of the wheel wells white, along with the landing gear. I also painted the exterior of the doors and the pylons in Intermediate Blue to match the underside:

Finally, I added the main wheels to the landing gear and added the missiles to the wingtips. Later I might add more ordinance to the underside of this aircraft but for now, I'm happy to leave it as is:

That's one down.....

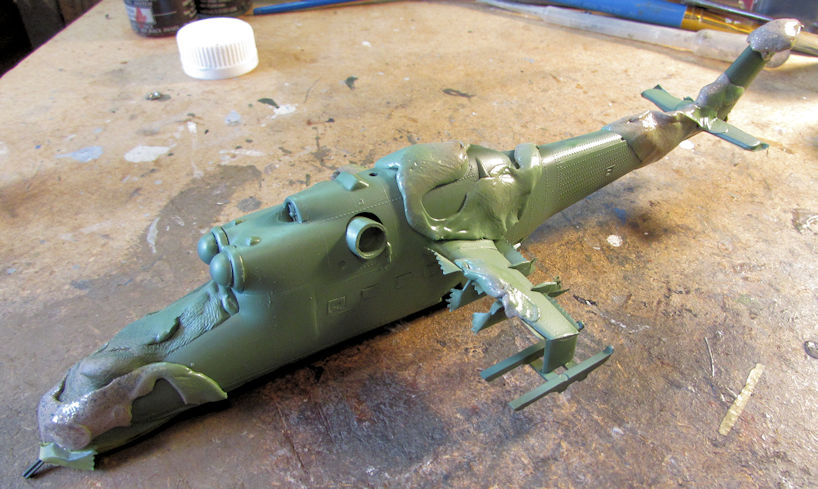

Next, I pulled out my Nigerian Mi-24 Hind that I've been attempting to pull off the shelf of shame. Previously, this helicopter was shot with grey on the underside and then the windows and underside were masked to get this ready for paint. So, out came the airbrush and the first base color was painted on:

Once that dried, I applied the first layer of Silly Putty to cover the medium green and get this ready for the second color:

After that, I shot the pale green on this:

It's kinda hard to see the difference here in this light, but I assure you it is a different color.

Next I extended the Silly Putty mask to cover the pale green:

The next color was Sand that was sprayed on:

Now all three colors were finished. after it all dried, it was time to remove all that masking...

Here's the final result:

Pretty impressive scheme if I do say so myself. I like these unique camouflage patterns.

Okay, that completes my aircraft update, now it's time to check out the motor pool and shipyards in the next post.

Part I complete, on to Part II...

Without further ado, let's start our tour of the hanger....

I started with the Japanese F-2A since it was so close to being done. I applied all the decals to this first:

After they dried, I shot a dullcoat to seal them, once I finished adding Solvaset to them to remove the silvering. I seem to have a lot of problems with silvering lately for some odd reason; despite my use of clear glosscoats....

After that, I added the landing gear and gear doors, along with the wing pylons:

Later, I painted the interior of the wheel wells white, along with the landing gear. I also painted the exterior of the doors and the pylons in Intermediate Blue to match the underside:

Finally, I added the main wheels to the landing gear and added the missiles to the wingtips. Later I might add more ordinance to the underside of this aircraft but for now, I'm happy to leave it as is:

That's one down.....

Next, I pulled out my Nigerian Mi-24 Hind that I've been attempting to pull off the shelf of shame. Previously, this helicopter was shot with grey on the underside and then the windows and underside were masked to get this ready for paint. So, out came the airbrush and the first base color was painted on:

Once that dried, I applied the first layer of Silly Putty to cover the medium green and get this ready for the second color:

After that, I shot the pale green on this:

It's kinda hard to see the difference here in this light, but I assure you it is a different color.

Next I extended the Silly Putty mask to cover the pale green:

The next color was Sand that was sprayed on:

Now all three colors were finished. after it all dried, it was time to remove all that masking...

Here's the final result:

Pretty impressive scheme if I do say so myself. I like these unique camouflage patterns.

Okay, that completes my aircraft update, now it's time to check out the motor pool and shipyards in the next post.

Part I complete, on to Part II...

Duke Maddog

Well-known member

Now for Part II.

Let's now take a tour of the motor pool to see the latest progress I got done on my vehicles I've been working on. I'll start with the little Japanese Kurogane pickup truck. The fight with this little beastie is almost over. I got the wheels all installed on it and now it is ready for touch up painting and weathering:

And that's another one down....

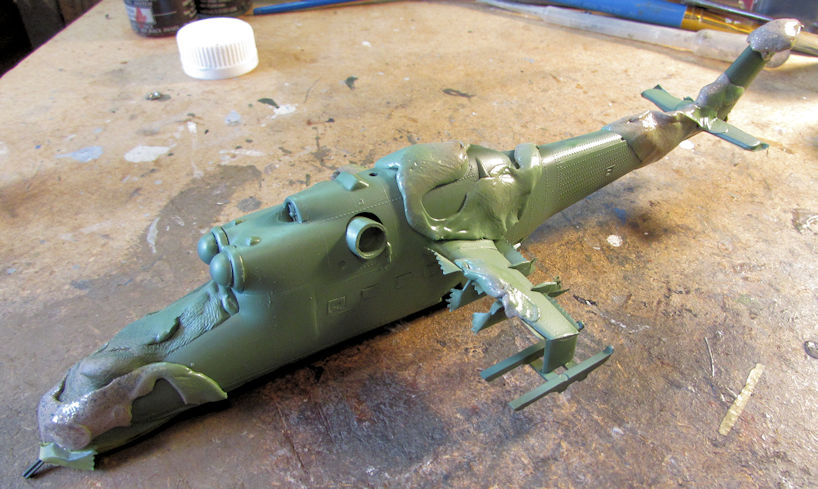

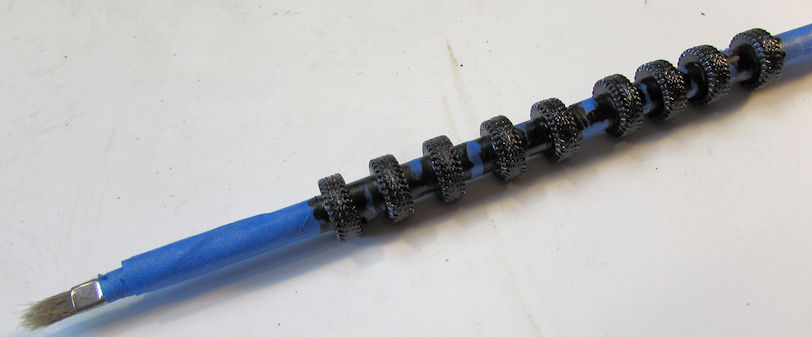

Next I started work on the two Humvees. To start with, I pulled the wheels out of the bag to paint. I wondered how I was going to do this since they were packed all loose in a baggie. Finally, I hit upon an idea: I taped a large paint brush handle to make it thick enough to hold these tires and then slipped them on:

Painting was a snap after that:

Later I wondered why I painted them in the first place but you'll see why later on...

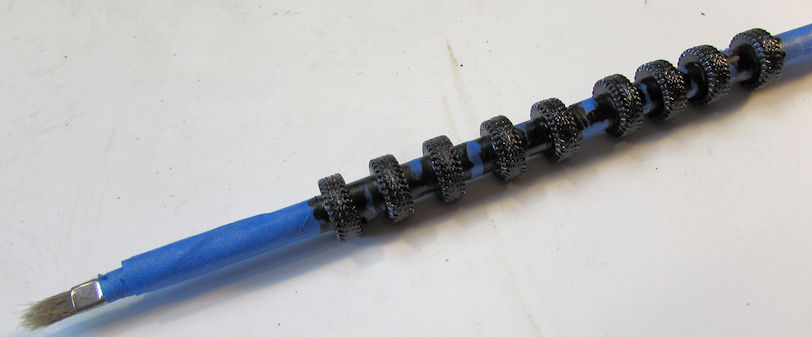

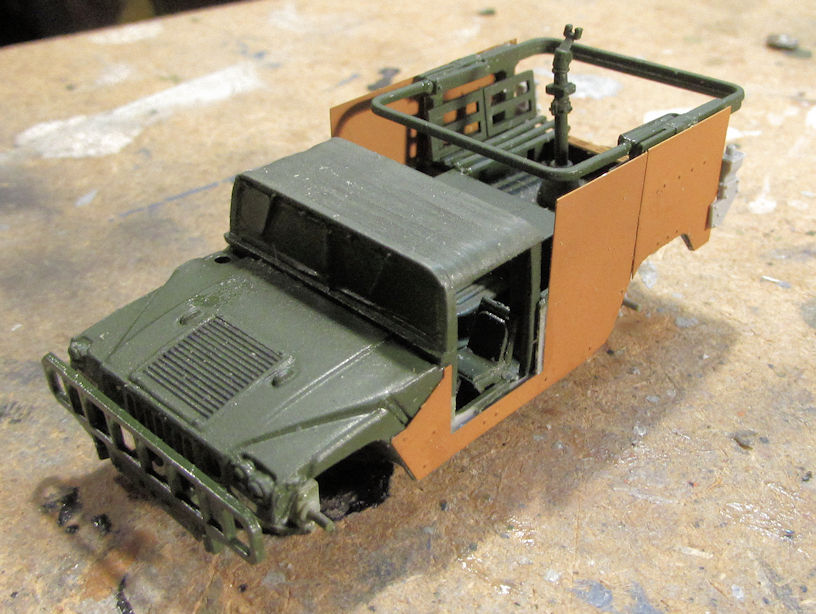

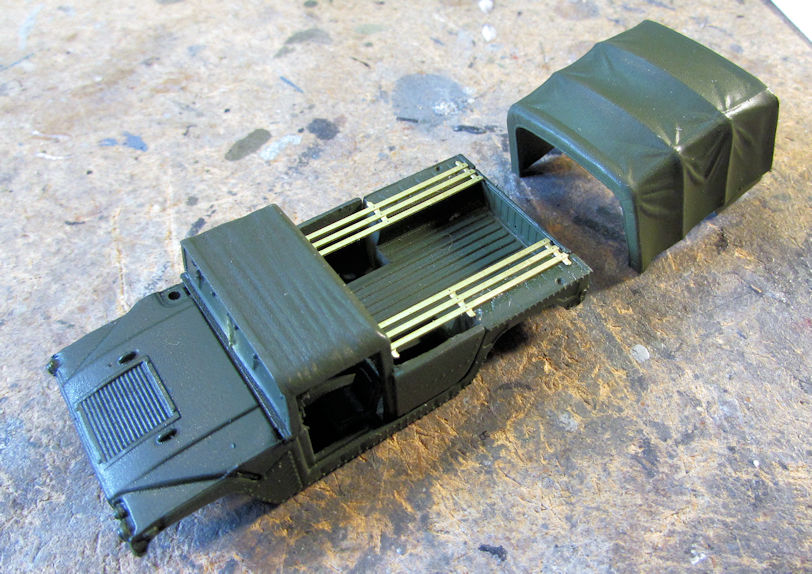

While I waited for them to dry, I added the photo-etch to the two Humvees, starting with the bench grid on the troop carrier:

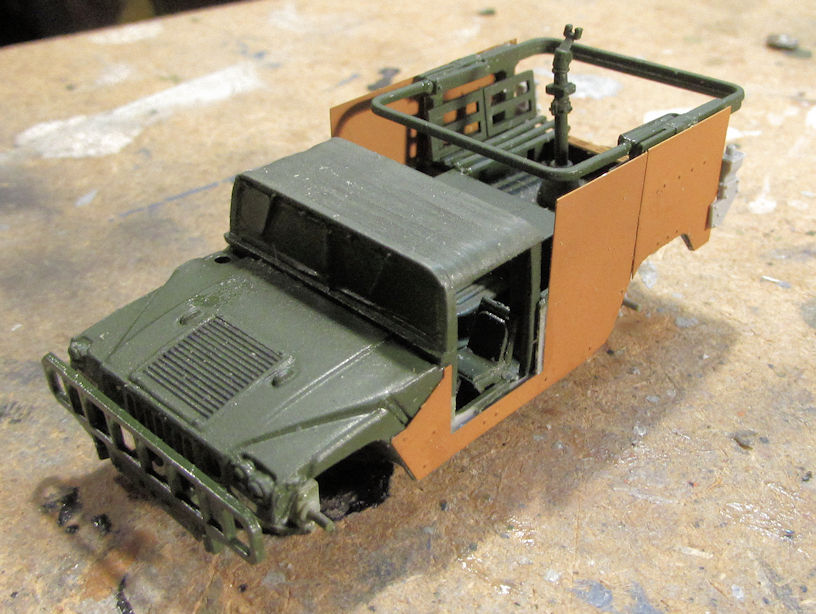

Then I added the armor plate to the gun truck:

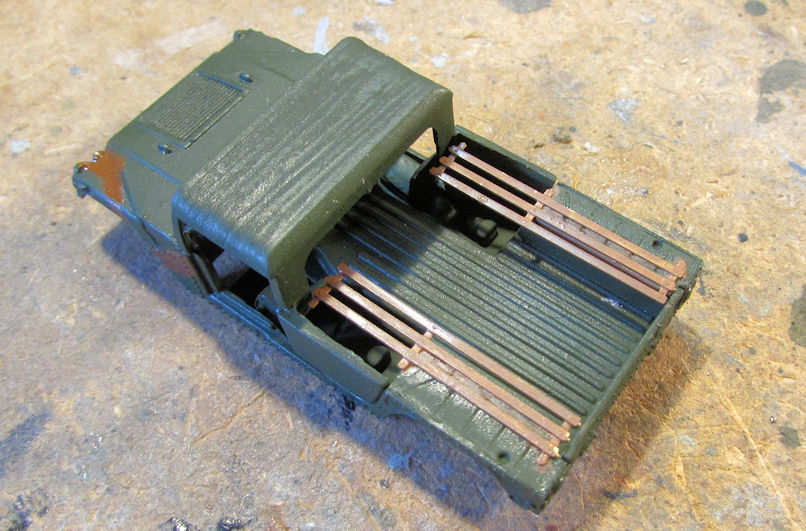

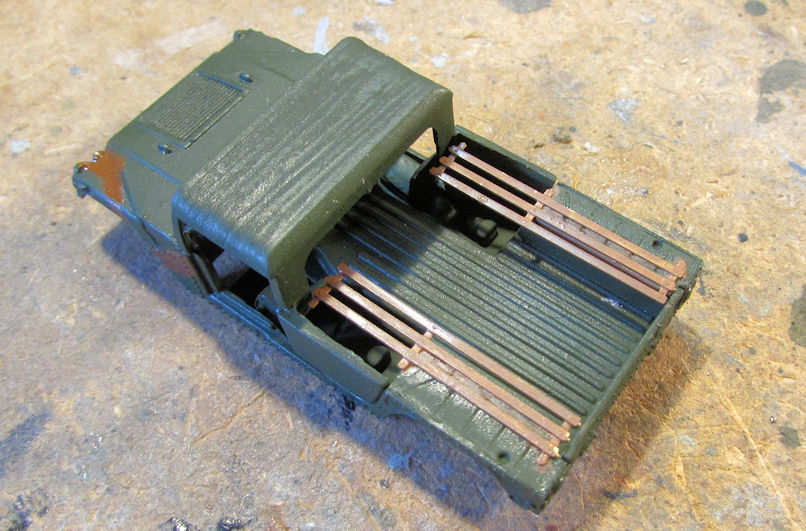

I then painted the bench grid in the troop carrier before adding the canvas tilt:

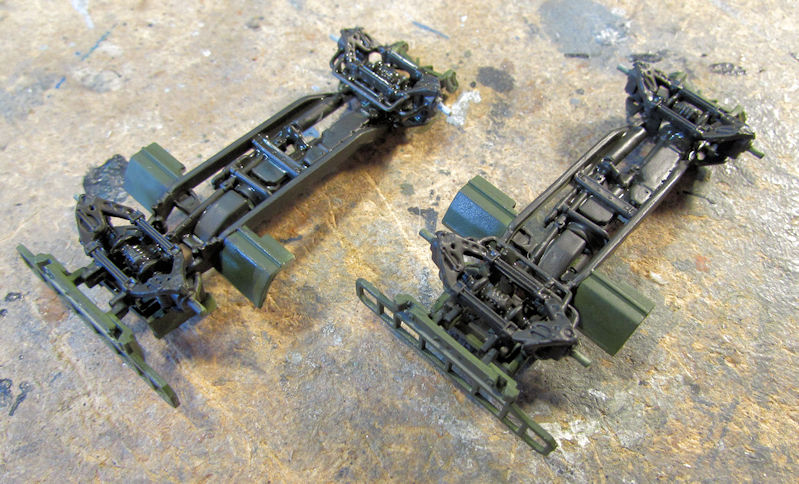

Finally, the wheels were dry enough so I could install them on the hubs. The problem was that the ridge used to hold the tires on the hubs was far too big to get the tires around them. They were too big to push on through the tires. So, I had to sand down all eight of the interior ridges to make these tires fit over them. The sanded one is to the right:

Now you can see what I was talking about.

Finally, I added all the tires to the hubs. Here is the first four that I did. You can see what I meant about painting them first; everything scraped off during the installation on the hubs:

I'm glad that was done. Man that hurt my fingers!

Moving on; I added the cabin doors to the front and then painted the camouflage pattern on the troop carrier:

Yeah, that door does look like it's protruding quite far. I tried everything to get it to flush in, but to no avail.

I then painted the undersides of the two Humvees:

...and then installed the wheels:

Finally, here they are after decals and dullcoats. Now these two are ready for final weathering:

That's two more down.....

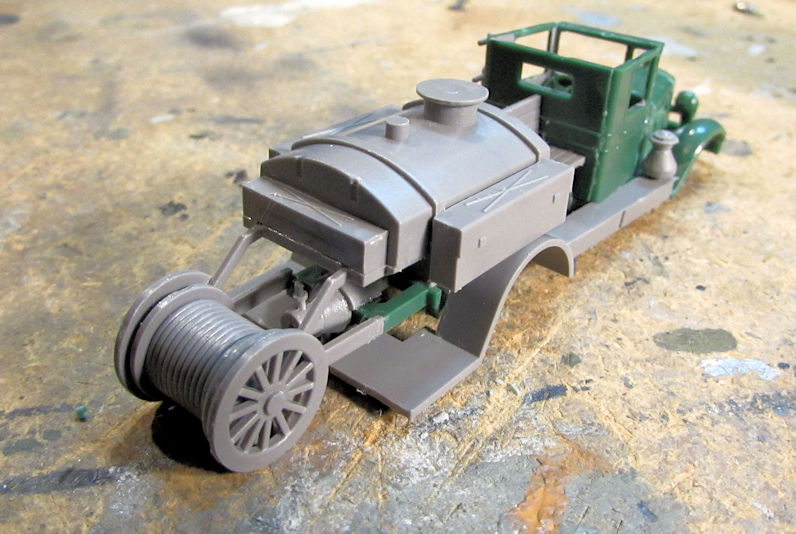

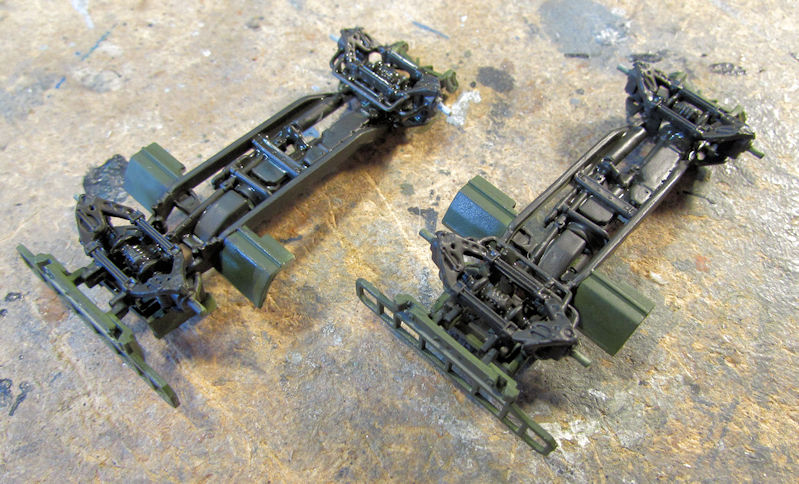

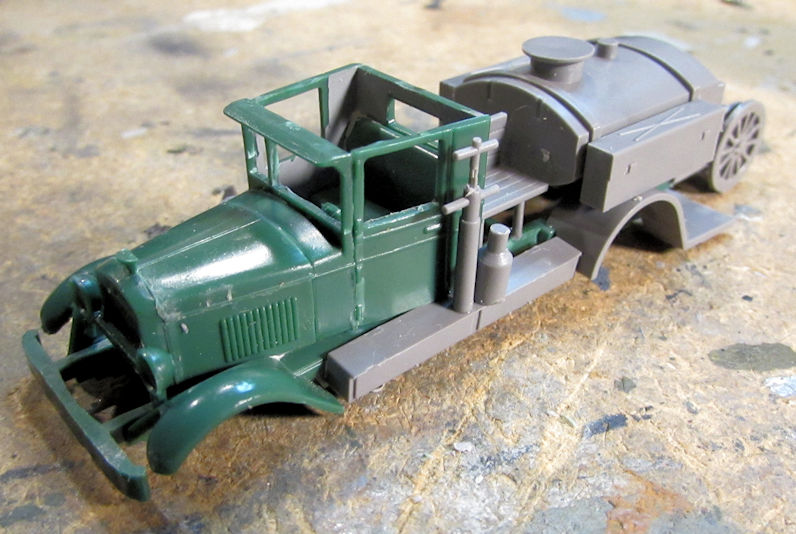

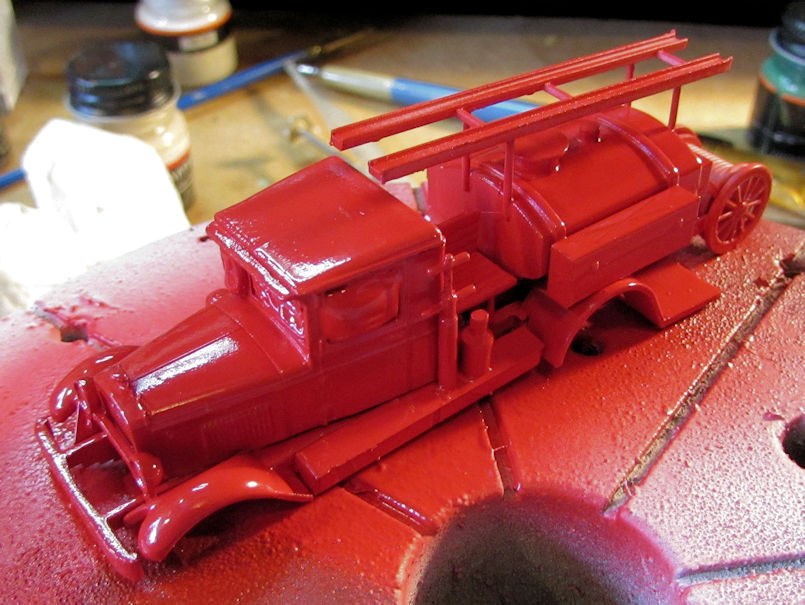

Another truck I started some time ago finally got some more assembly done. My Russian ZIS-5 Fire truck which was in sub-assemblies finally got put together... mostly:

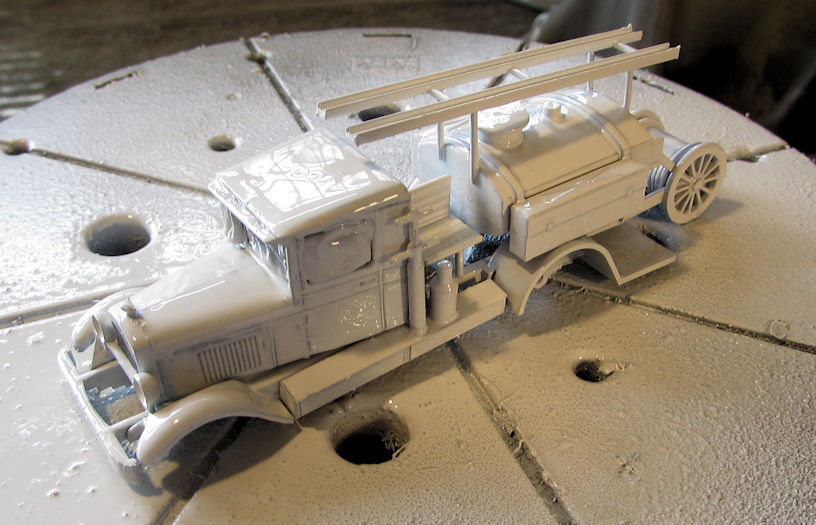

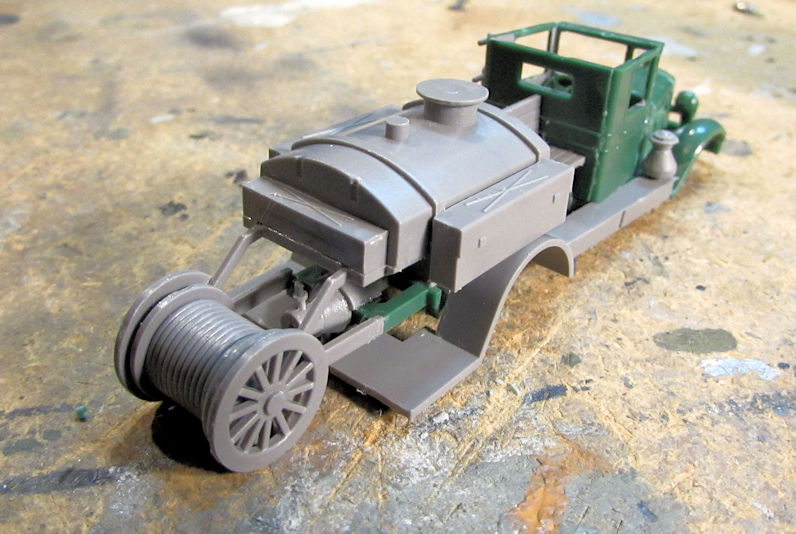

Later on I added the windows to the cab and then closed up the roof. I also added the ladder framework above the tank:

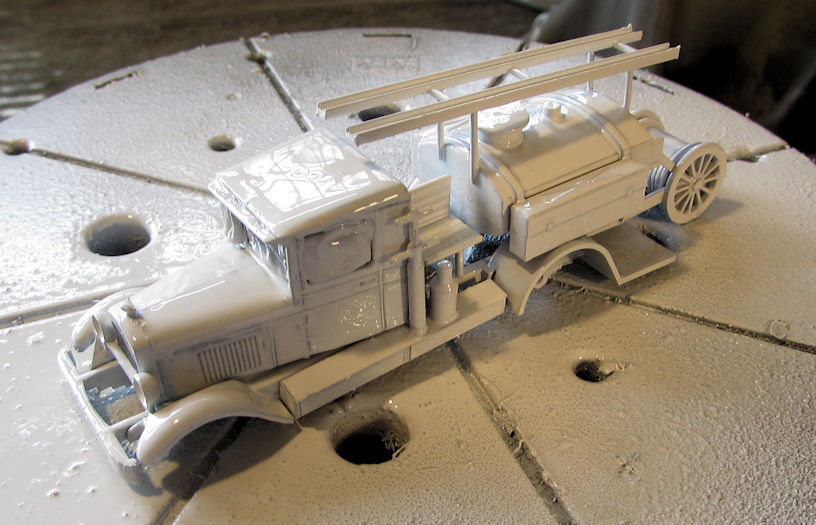

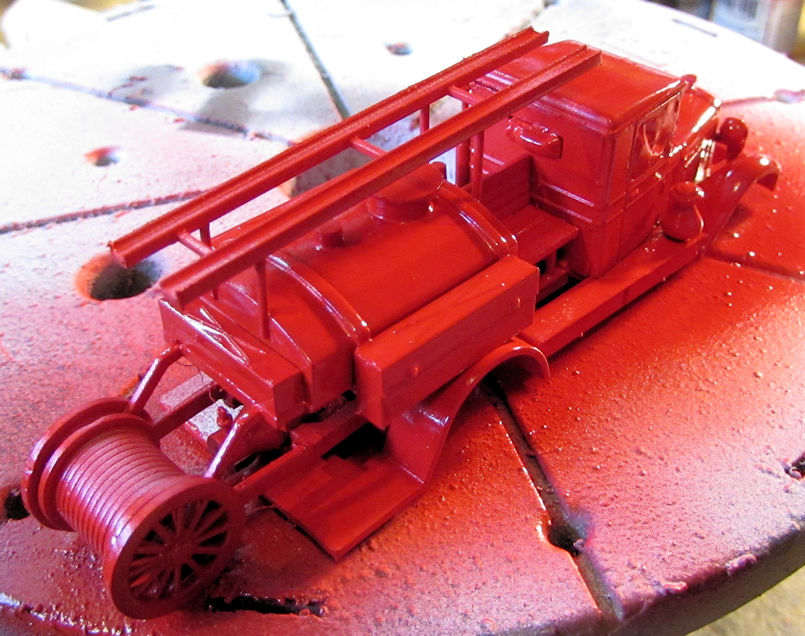

Once that was dry, I masked the windows with Silly Putty to prepare this for paint:

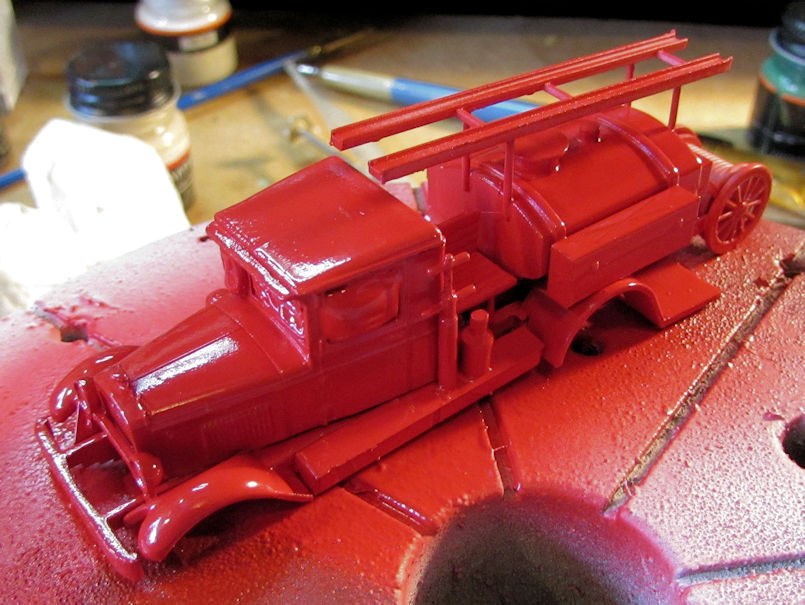

First was a white primer coat. It is still wet in this picture:

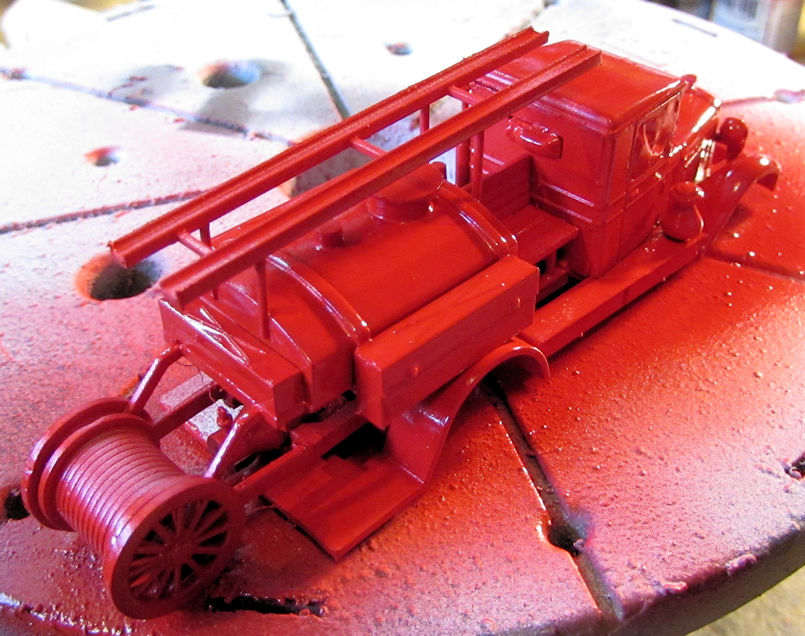

Once the primer dried though, I shot the red over it:

That's as far as I got so far on this. I have it drying now.

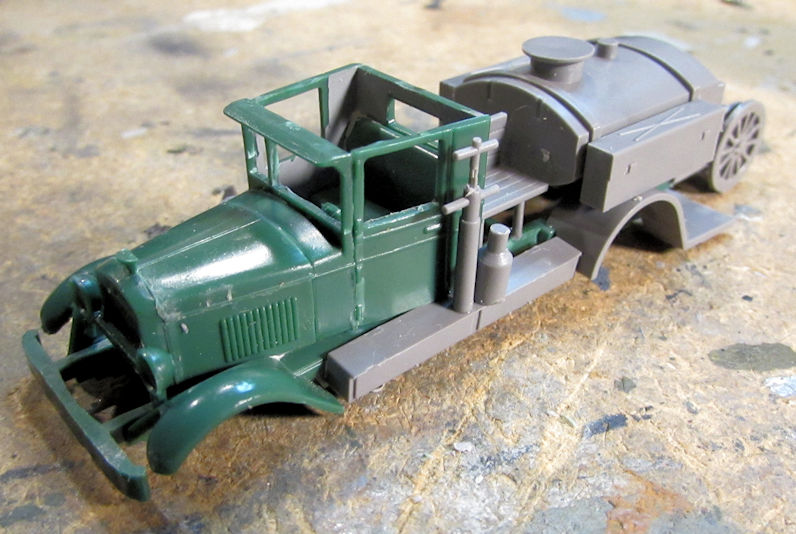

Finally, I decided to build another truck for the WWI campaign here on the Alliance. I didn't get too far yet, but I have the main cab done so far...

...and the engine all assembled:

Once I get the chassis done, this will fly.

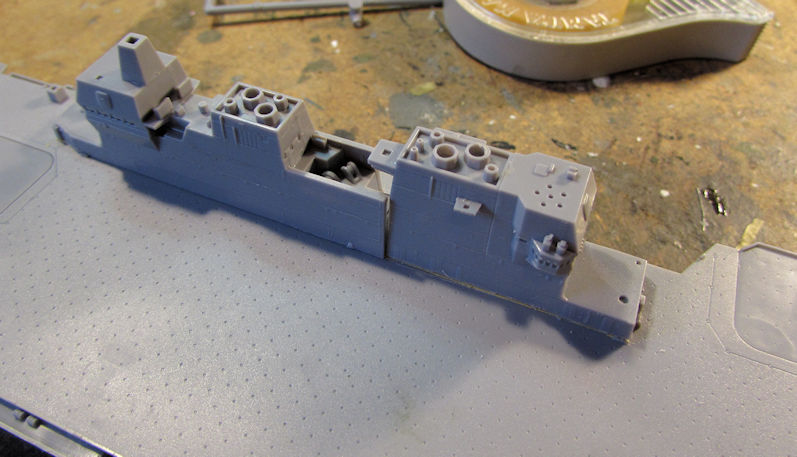

Let's move on to my shipyards now....

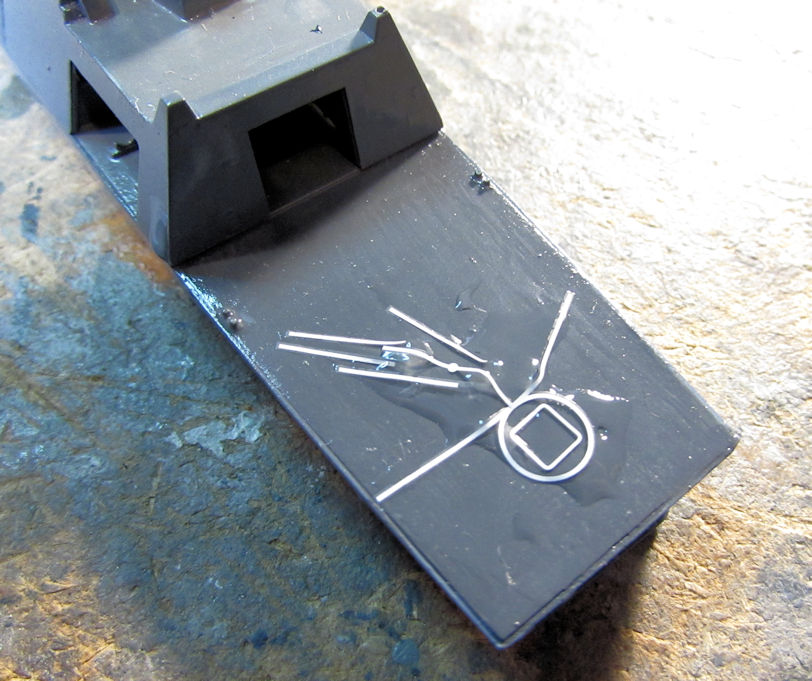

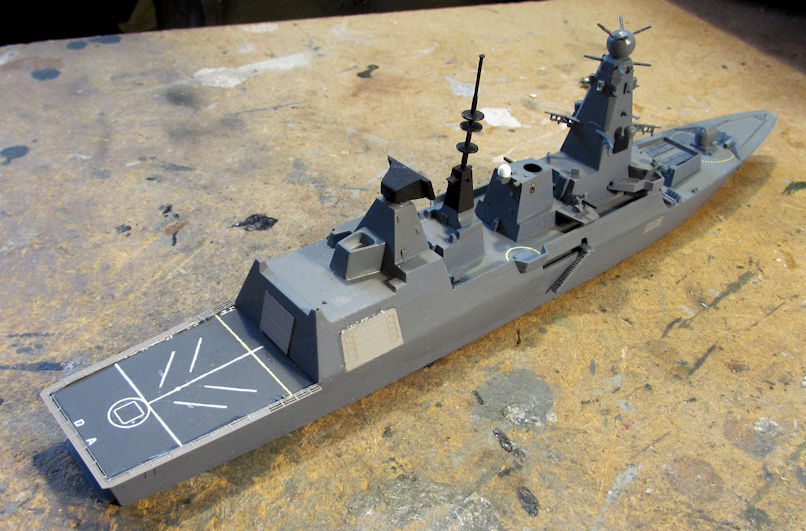

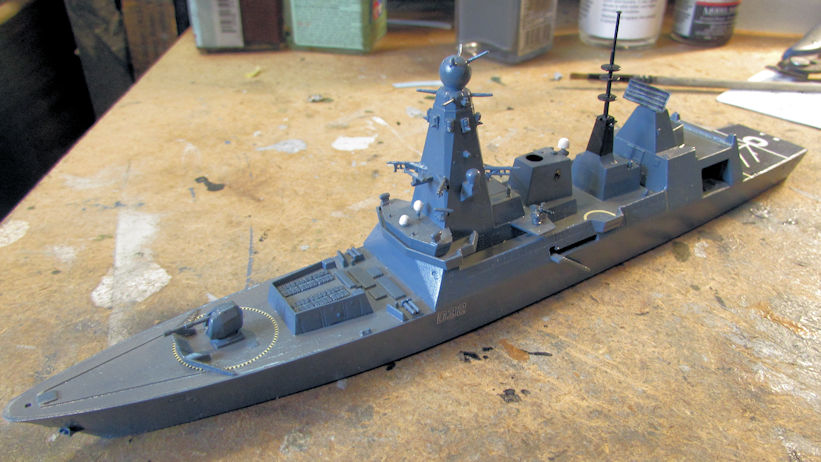

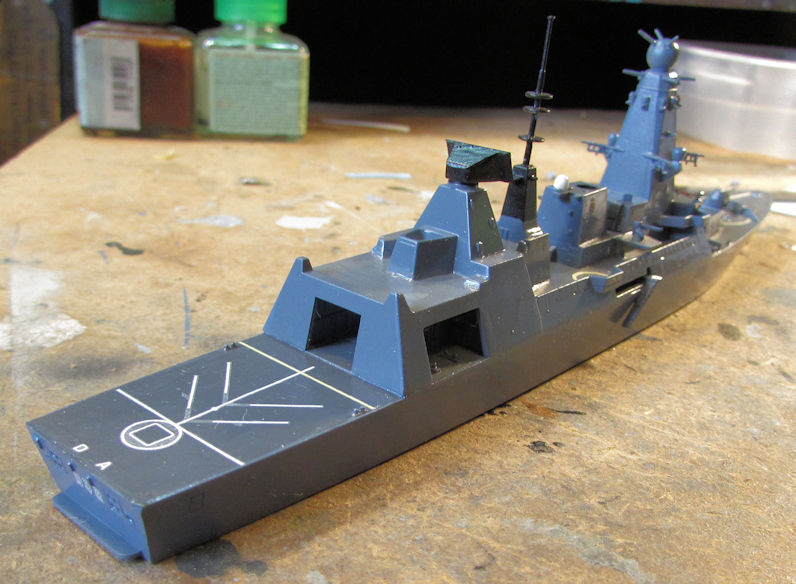

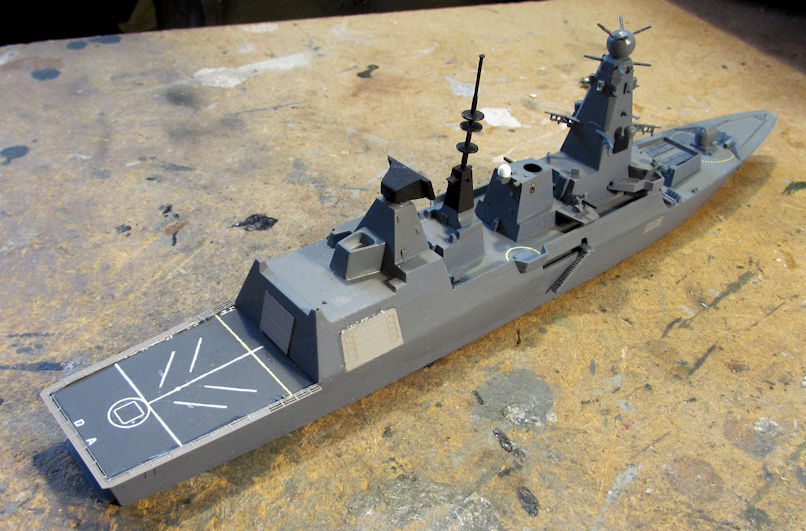

The HMS Daring destroyer was almost complete. It was time to do the decals on this model. The way Dragon did the helicopter deck decal was totally screwed up! I had to cut all around every strip on this decal. Putting it on the deck was almost impossible, as you can see here:

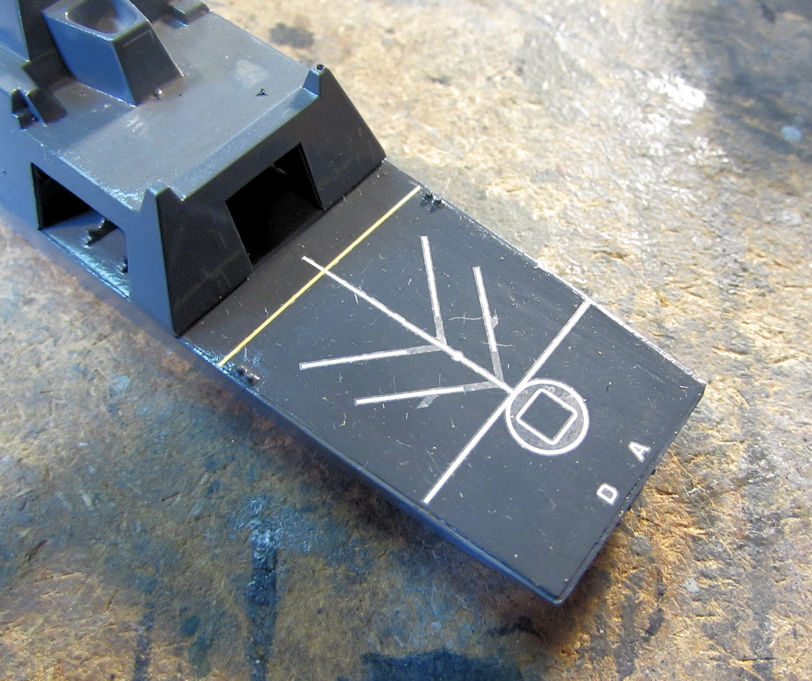

Finally, I managed to get this all laid flat the way it is supposed to look. It wasn't easy but surprisingly, I didn't even break this:

I later doused this with Solvaset to eliminate that silvering. I'm still having so much trouble with silvering....

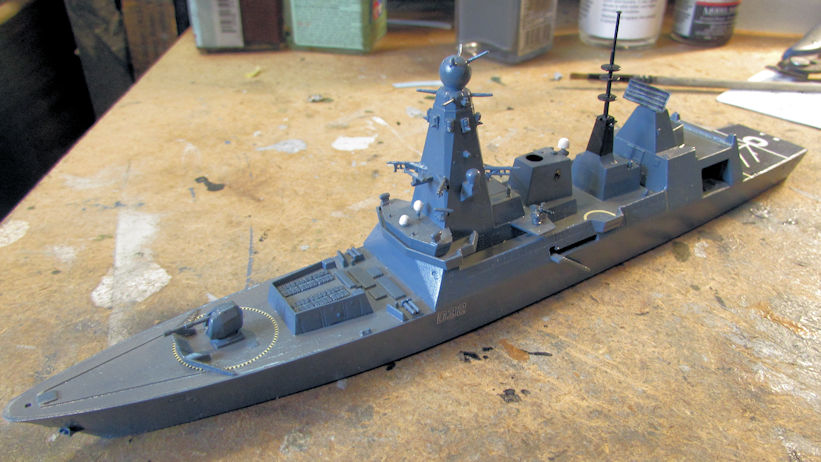

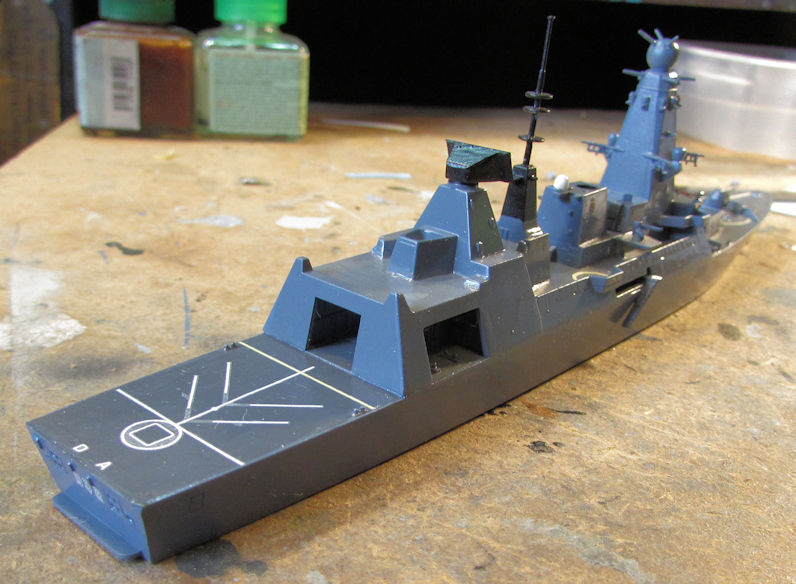

All the rest of the decals went on fine, especially after more Solvaset:

Finally, I added the last of the photo-etch parts; the hanger door, boat deck doors and the safety net around the helicopter deck:

And another one down.......

After that, I wanted something simple....

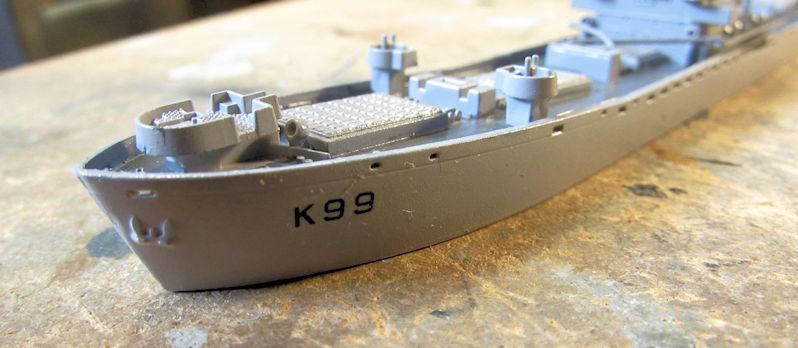

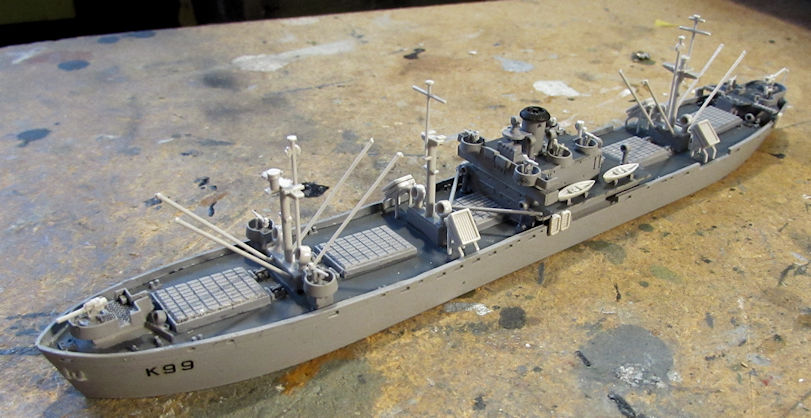

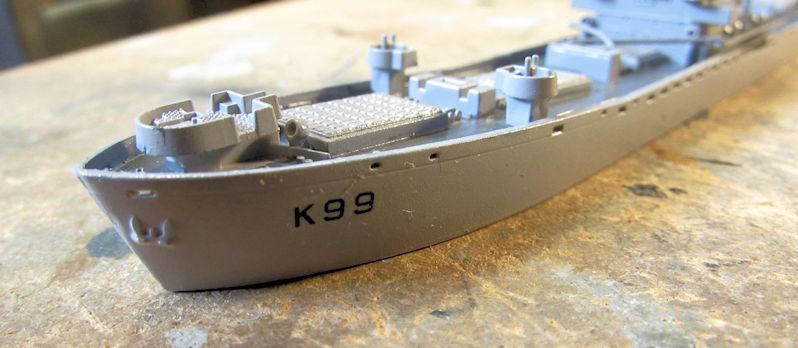

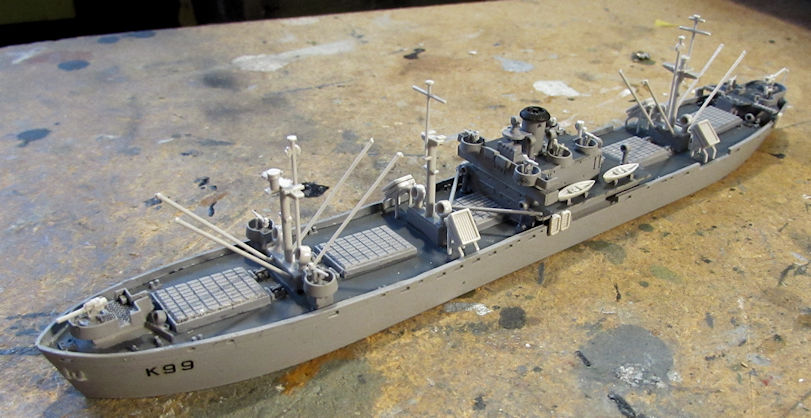

I pulled out my USS Bootes Liberty Ship and added the decals to the bow; all two of them:

After that was dry, I dullcoated this and then installed all the final greeblies and masts on this ship to finish it off:

All that was left was to finish detail painting that and it was done.

Another one down....

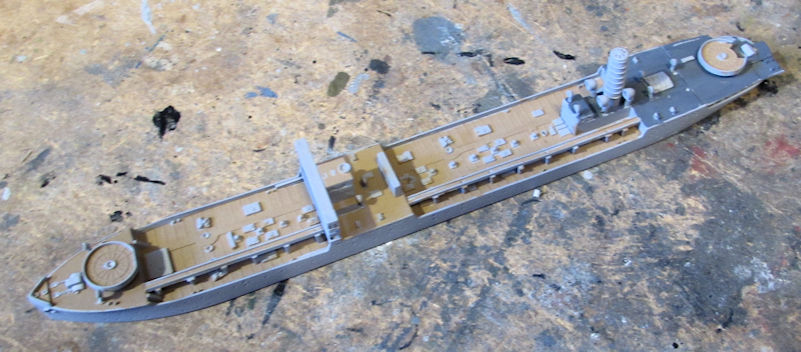

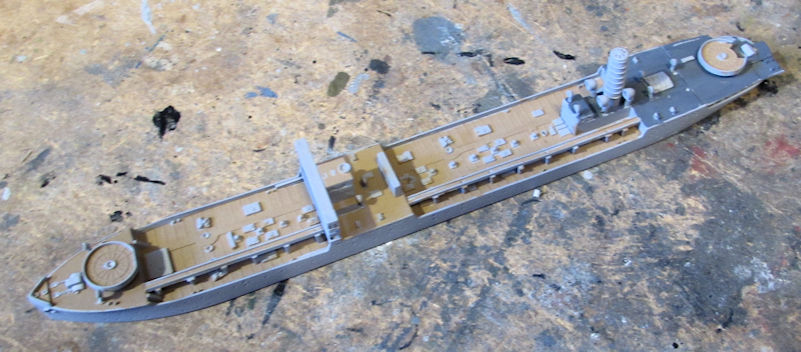

Since I was able to finish the Bootes so quickly, I also pulled out the Japanese Fleet Oiler and got the decks all painted up:

After that was dry, added all the last greeblies and masts as well. I was going to apply decals, but the decal sheet they included in the kit was for a Japanese destroyer. So, no markings on this beastie:

All that's left here is detail painting also.

....and a final one down......

Okay, that completes this long and tedious update. My apologies for the length; I'll try to slow down if it helps.

Thanks all for looking in, comments are welcome. Feel free to check out the armor, aircraft and ships Forums to see the finished models.

Let's now take a tour of the motor pool to see the latest progress I got done on my vehicles I've been working on. I'll start with the little Japanese Kurogane pickup truck. The fight with this little beastie is almost over. I got the wheels all installed on it and now it is ready for touch up painting and weathering:

And that's another one down....

Next I started work on the two Humvees. To start with, I pulled the wheels out of the bag to paint. I wondered how I was going to do this since they were packed all loose in a baggie. Finally, I hit upon an idea: I taped a large paint brush handle to make it thick enough to hold these tires and then slipped them on:

Painting was a snap after that:

Later I wondered why I painted them in the first place but you'll see why later on...

While I waited for them to dry, I added the photo-etch to the two Humvees, starting with the bench grid on the troop carrier:

Then I added the armor plate to the gun truck:

I then painted the bench grid in the troop carrier before adding the canvas tilt:

Finally, the wheels were dry enough so I could install them on the hubs. The problem was that the ridge used to hold the tires on the hubs was far too big to get the tires around them. They were too big to push on through the tires. So, I had to sand down all eight of the interior ridges to make these tires fit over them. The sanded one is to the right:

Now you can see what I was talking about.

Finally, I added all the tires to the hubs. Here is the first four that I did. You can see what I meant about painting them first; everything scraped off during the installation on the hubs:

I'm glad that was done. Man that hurt my fingers!

Moving on; I added the cabin doors to the front and then painted the camouflage pattern on the troop carrier:

Yeah, that door does look like it's protruding quite far. I tried everything to get it to flush in, but to no avail.

I then painted the undersides of the two Humvees:

...and then installed the wheels:

Finally, here they are after decals and dullcoats. Now these two are ready for final weathering:

That's two more down.....

Another truck I started some time ago finally got some more assembly done. My Russian ZIS-5 Fire truck which was in sub-assemblies finally got put together... mostly:

Later on I added the windows to the cab and then closed up the roof. I also added the ladder framework above the tank:

Once that was dry, I masked the windows with Silly Putty to prepare this for paint:

First was a white primer coat. It is still wet in this picture:

Once the primer dried though, I shot the red over it:

That's as far as I got so far on this. I have it drying now.

Finally, I decided to build another truck for the WWI campaign here on the Alliance. I didn't get too far yet, but I have the main cab done so far...

...and the engine all assembled:

Once I get the chassis done, this will fly.

Let's move on to my shipyards now....

The HMS Daring destroyer was almost complete. It was time to do the decals on this model. The way Dragon did the helicopter deck decal was totally screwed up! I had to cut all around every strip on this decal. Putting it on the deck was almost impossible, as you can see here:

Finally, I managed to get this all laid flat the way it is supposed to look. It wasn't easy but surprisingly, I didn't even break this:

I later doused this with Solvaset to eliminate that silvering. I'm still having so much trouble with silvering....

All the rest of the decals went on fine, especially after more Solvaset:

Finally, I added the last of the photo-etch parts; the hanger door, boat deck doors and the safety net around the helicopter deck:

And another one down.......

After that, I wanted something simple....

I pulled out my USS Bootes Liberty Ship and added the decals to the bow; all two of them:

After that was dry, I dullcoated this and then installed all the final greeblies and masts on this ship to finish it off:

All that was left was to finish detail painting that and it was done.

Another one down....

Since I was able to finish the Bootes so quickly, I also pulled out the Japanese Fleet Oiler and got the decks all painted up:

After that was dry, added all the last greeblies and masts as well. I was going to apply decals, but the decal sheet they included in the kit was for a Japanese destroyer. So, no markings on this beastie:

All that's left here is detail painting also.

....and a final one down......

Okay, that completes this long and tedious update. My apologies for the length; I'll try to slow down if it helps.

Thanks all for looking in, comments are welcome. Feel free to check out the armor, aircraft and ships Forums to see the finished models.

Duke Maddog

Well-known member

Mark,

The red is going to be a little bright in the woods, maybe??????

All are looking great.

May we have more, PLEASE SIR?

Frank

:yipee

LOL! Thanks Frank! Yeah, but it won't be heading to the woods... unless it needs to fight a forest fire!

Thanks again for the compliments. Yes, You may have more! Stay tuned, more to come.

MM2CVS9

Active member

Thanks everyone for the awesome replies!

EJ, the Sacramento is the Trumpeter 1/700 scale kit. I would love to see your work on the Mattaponi AO41.

Thanks for the info. Got a log going for the Mattaponi going here -

https://modelersalliance.org/forum/in-the-navy/152602-ej-s-1960-s-fleet-oiler-build-ao41

Will have an update soon. Kinda got hung up on the scratchbuilt fueling hoses. Thanks for your interest.

EJ

Duke Maddog

Well-known member

Thanks EJ for the link. I'll go check it out now.

Duke Maddog

Well-known member

Thanks Kenny! I didn't see you slip in there.

Duke Maddog

Well-known member

Well, after a very rough couple weeks, I have finally managed to get something done worth posting here. I didn't feel like painting or decaling, so almost all of this is construction.

I'll start with my one aircraft.

At my recent SoCal AMPS meeting, we had our annual "Four-Hour Build Challenge" where we were to choose an unbuilt, unstarted kit and build it over the course of the next four hours to see how far along we could get in that time. This was the second time we had done this challenge. The first time, most guys over-estimated how quickly they could finish something so almost nobody completed anything; except for three of us. I finished three models myself that time; all the way to the weathering stage.

This time I was far from that successful. I started with a simple bagged Airfix kit of a Saunders Roe experimental jet that had about 14 parts to it. I got the fuselage assembled first, then painted the pilot inside along with what could be seen of the cockpit:

No, you can't see the cockpit in that pic but I did it. Next I finished off all the wings and tail, then masked off the cockpit for painting. I shot it with a white paint; after fixing the damage that occurred after I dropped it on the way outside:

Then I dropped it again after painting so I had to wait till it dried and tried to sand out the damage to the paint. Some of it was apparently still wet since I found fingerprints on it afterward. After that dried, I tried again, only to damage the paint again. Okay, enough of that, I moved on to something else....

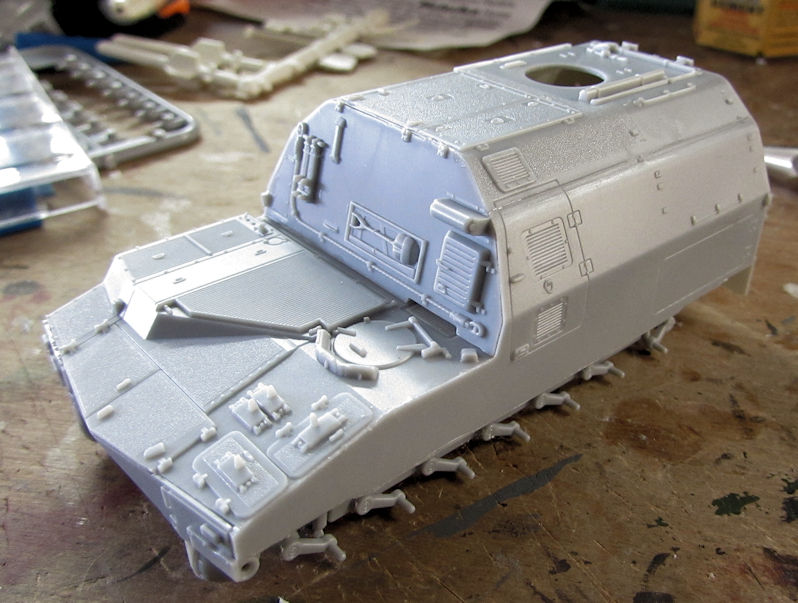

I pulled out an armor model and tried that. This was the Riich Models M-992 ammunition carrier for the M-109 Paladin. It should have been a simple build and started that way when I first assembled the main hull and superstructure. This was the result after 15 minutes:

I then tried to install the wheels and tracks. What a disaster! After fighting this for another 2.5 hours, I had this result; which doesn't show well all the gaps from poorly placed or missing indy links:

Part of the reason I had such difficulty with that was because I somehow managed to reverse some of the links near the end of the attempt to install them. That meant trying to find the reversed ones; pulling everything back off and trying to re-glue them all on again. I think I repeated that mistake at least three times before I finally got those tracks right. Finally, after all that and dinner break, I was too far gone to even try painting this so I gave up for the remaining 20 minutes of the time.

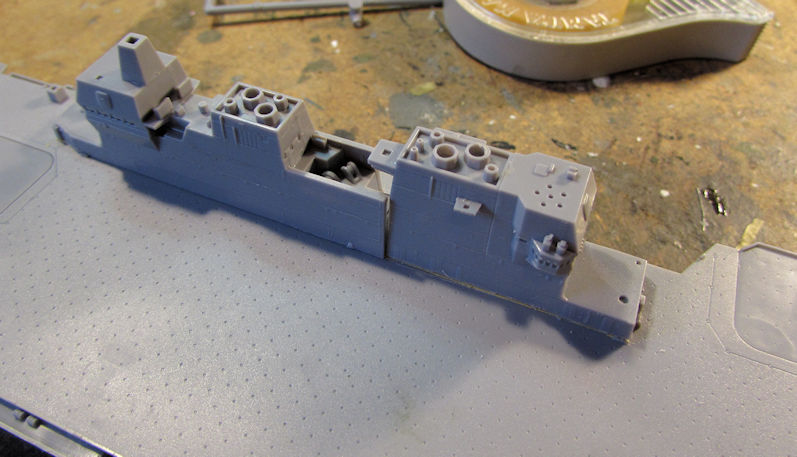

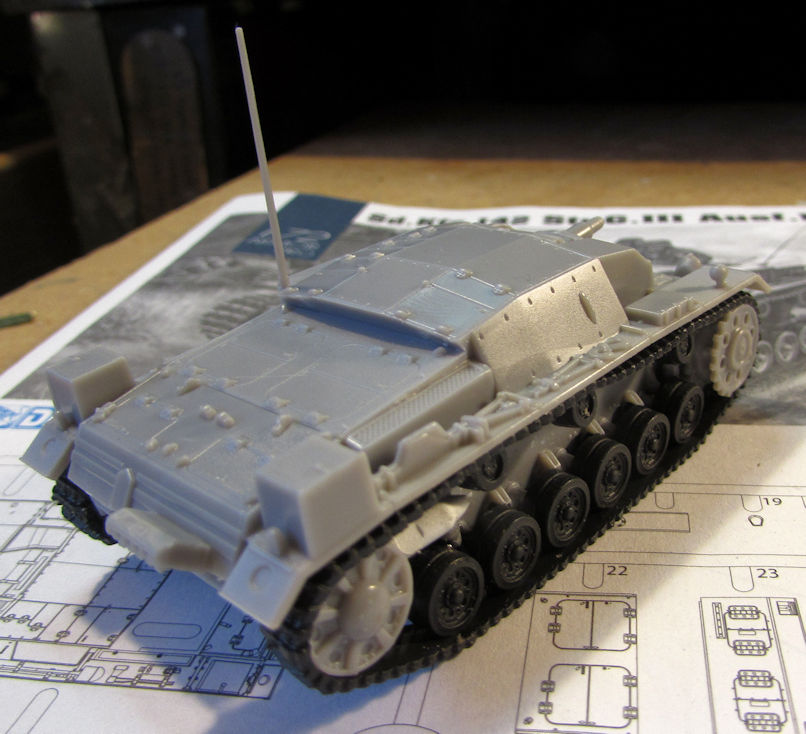

After the meeting, another friend and fellow AMPS member came up and offered me his 1/72 scale Dragon StuG he'd started for the build challenge. He had broken the rear idler since the tracks were too tight so he gave up on it. Since he had only done it for the challenge he didn't want to finish it since he doesn't normally do 1/72 scale armor. I accepted. Later when I got home I managed to get the rear idler glued on and then added the tracks. The other idler had been skewed as well so I adjusted it, and then added more glue to strengthen the bond more. Here it is after the repair:

The white pieces in front of the idlers are sprue scraps that I'd positioned in there to hold the wheels straight while the glue dried. Of course, that tall antenna has already become 'shortened' when this got knocked over; breaking the upper third off. Oh well....

Later on at home, I had a tough time getting the mojo up to work on anything. It seemed every time I tried to do something, I screwed it up so I was constantly walking out of my hobby room in disgust. It's a miracle I got anything done at all. After all that crap, I just simply pulled out some short-run models and went to work on them. After all I figured, if I'm gonna screw something up, it wouldn't be as noticeable as if it were done on a well-molded kit. Besides, there was something rather therapeutic about cleaning all the parts; sanding and test fitting over and over to figure out how best to make the parts fit.

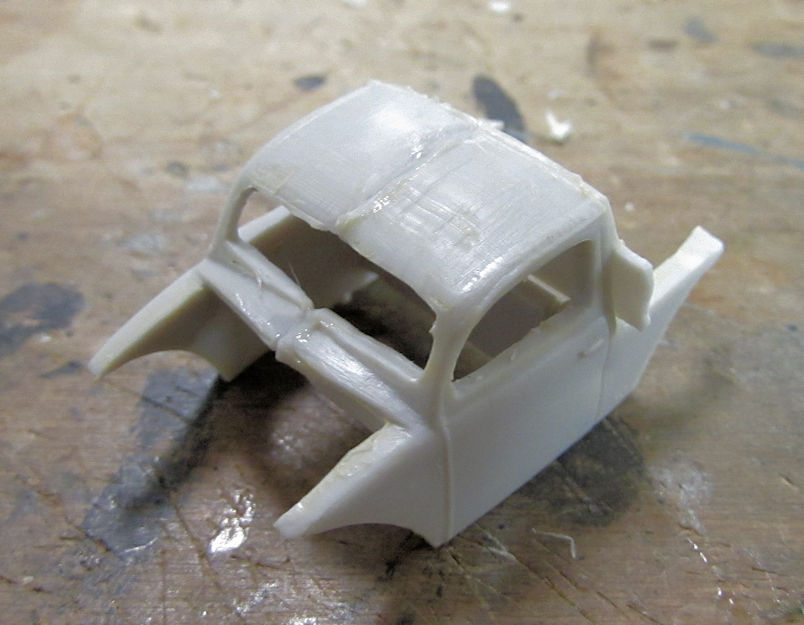

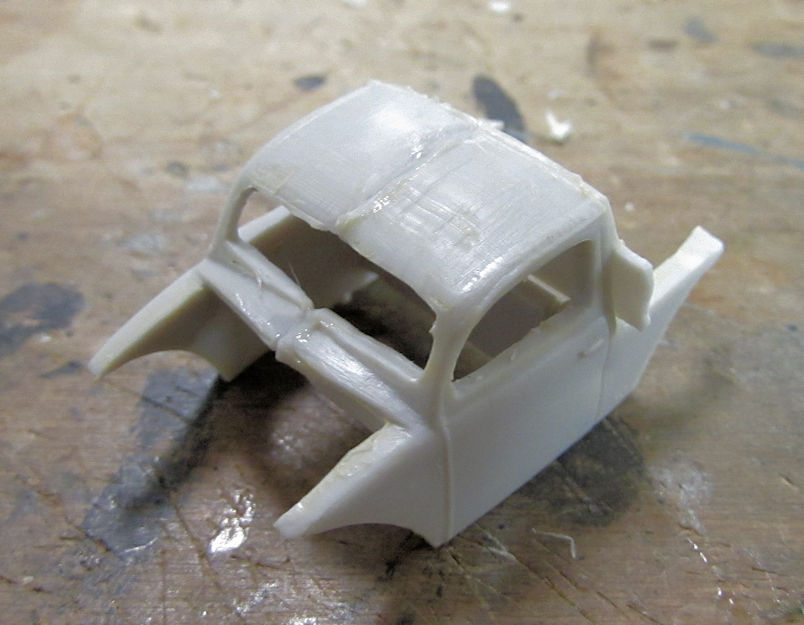

The first little short run model I worked on was this little Military Wheels 1/72 scale Volkswagen 'pickup'. I started with the lower chassis and interior which I did not shoot pics of. I then went and assembled the main cab:

After building the rear cargo bed, I test fit that, the lower chassis and the front hood all together to see how this little beastie would look:

This also allowed me to see where the issues were. I worked on them and added the windows. I then got the body cemented down to the chassis; and added the roof rack; the fender and some other little fiddly bits. I also added some acrylic filler to the seams which needs to be re-done to fill the tiny holes there:

Moving on, I also started another Military Wheels Volkswagen; this one has a larger nose to increase the cargo space in the front. Again, I assembled the interior and the lower chassis but didn't shoot pics of it yet. The upper body was started though; and it was a bear to build due to being in five pieces with no attachment points. I got most of it assembled, leaving the nose off till later:

You can see how rough this was to assemble, given the crude glue joins from difficult, poorly molded parts. Still, I felt good doing this.

Later I test fit this and the nose to the chassis and interior:

What a schnozz on that little beetle! Here it is sitting next to the 'pickup' beetle:

Later I sanded it all as smooth as possible, and then used Mr. Surface on the remaining crevices that were left:

That's as far as I got on that one.

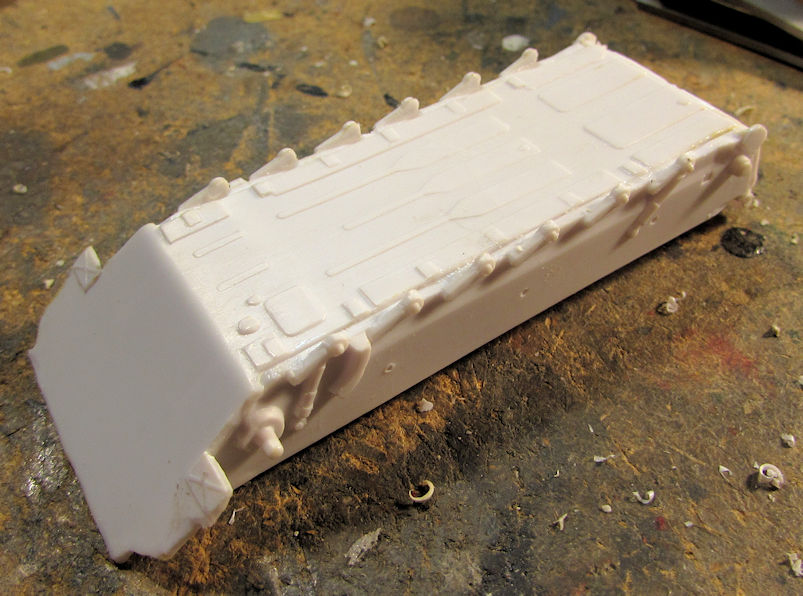

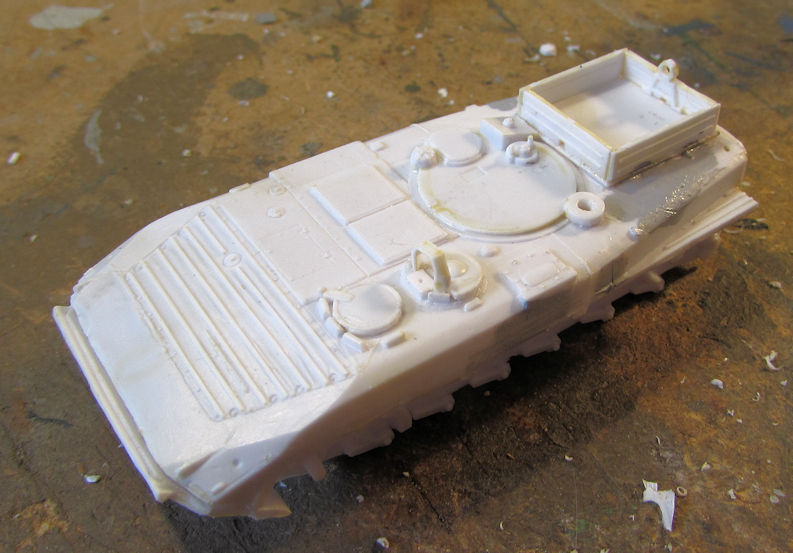

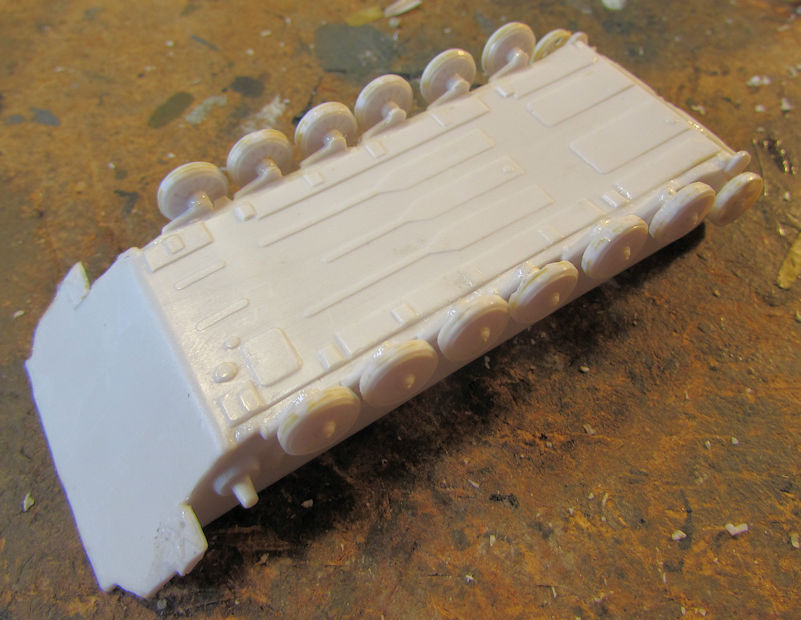

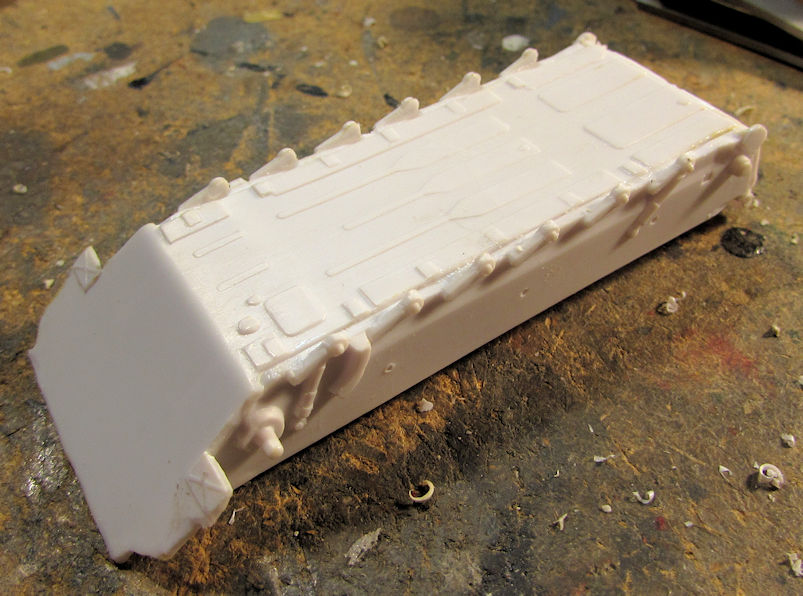

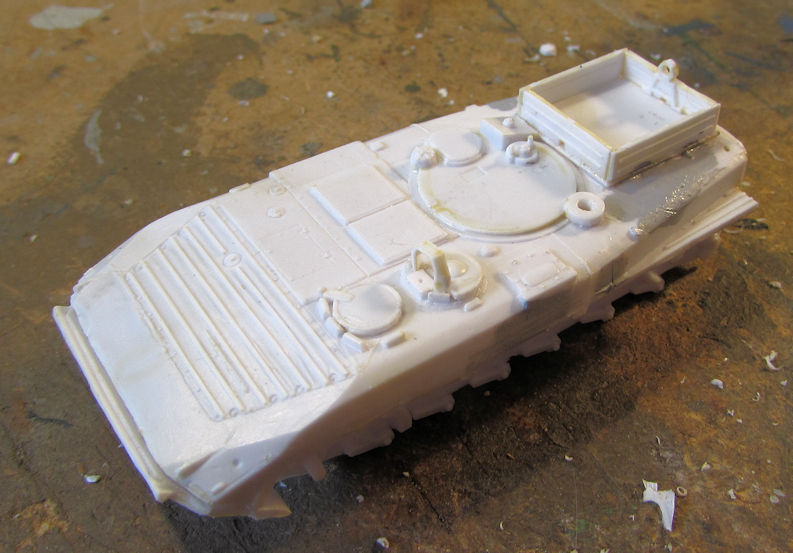

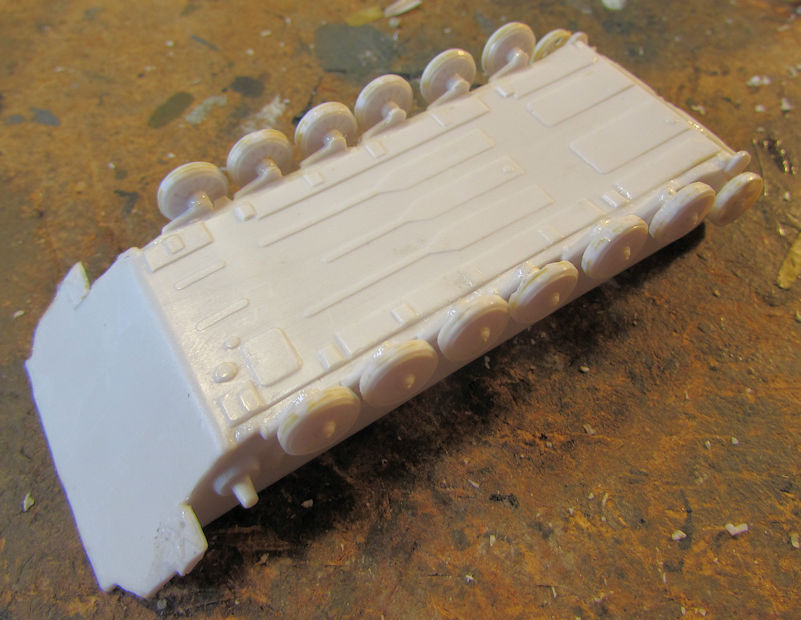

Moving on, I started another short-run kit; this time an ACE Russian BREM recovery vehicle based on the BMP I. I love doing ACE kits; it can be so relaxing doing the mind-numbing cleanup on all the parts. I started on the lower hull first:

I then test-fit the upper hull to it to see how well the lower hull was assembled:

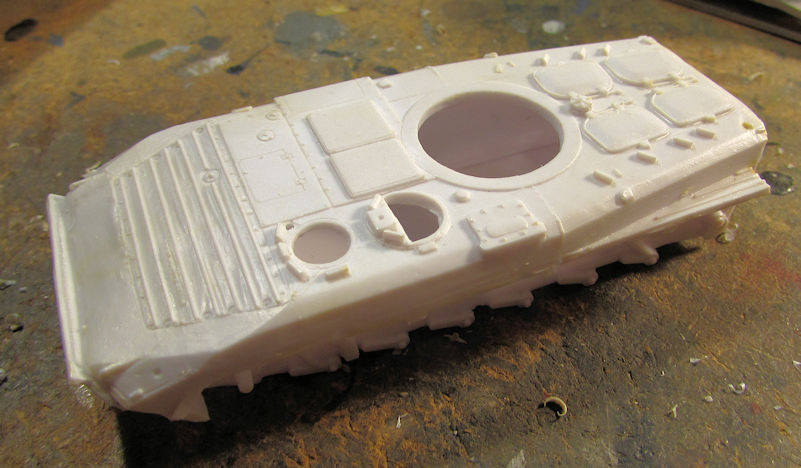

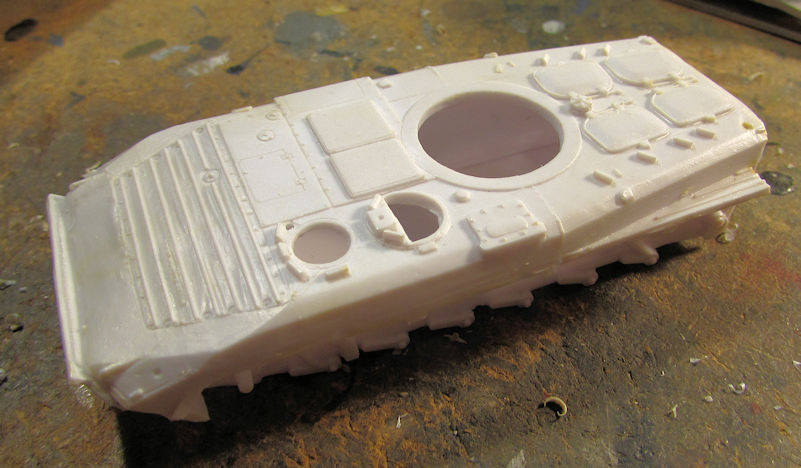

I then found out that everything behind the turret had to be removed so I carved everything off and added the floor of the back work box on top of the bare area and clamped it down. I also added the armor plate over the turret ring:

I then found out I'd put in on sideways so I had to carve it off and turn it 90 degrees and re-cement it. Afterwards, I added the sides of that box and the hatches for the driver and TC:

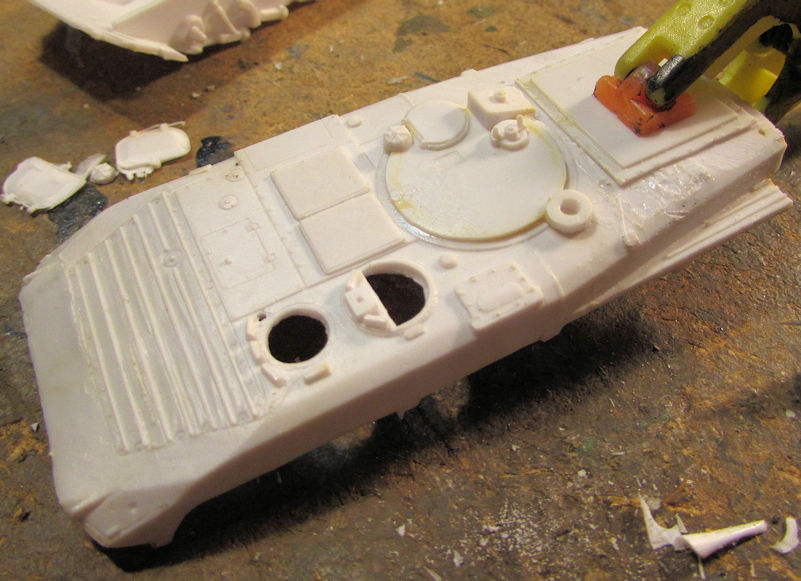

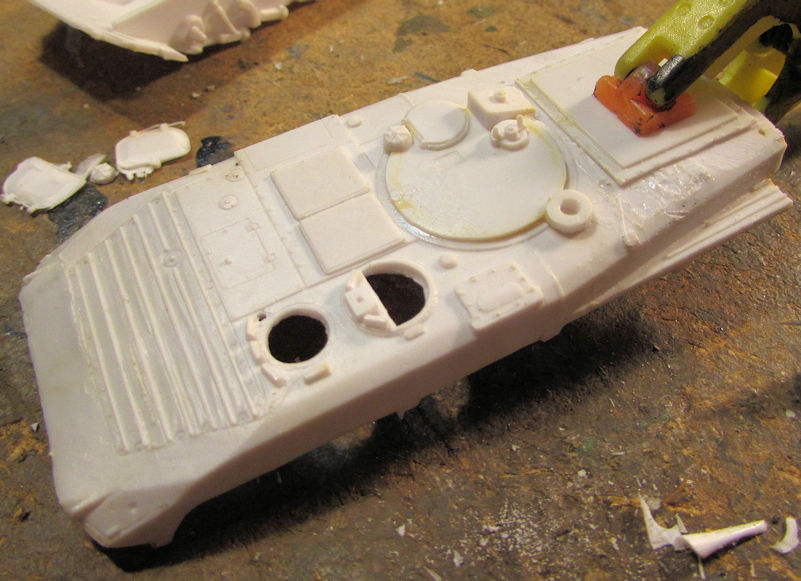

While that was drying, I added the wheels and idlers to the lower hull:

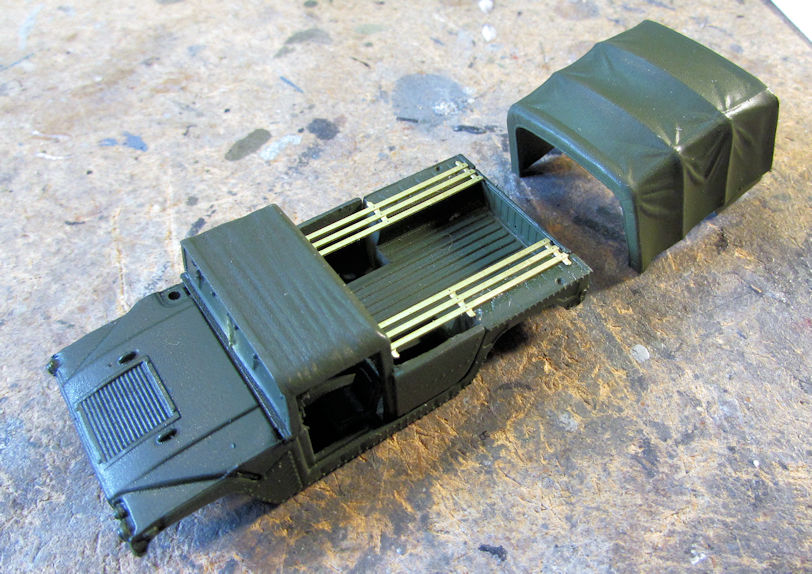

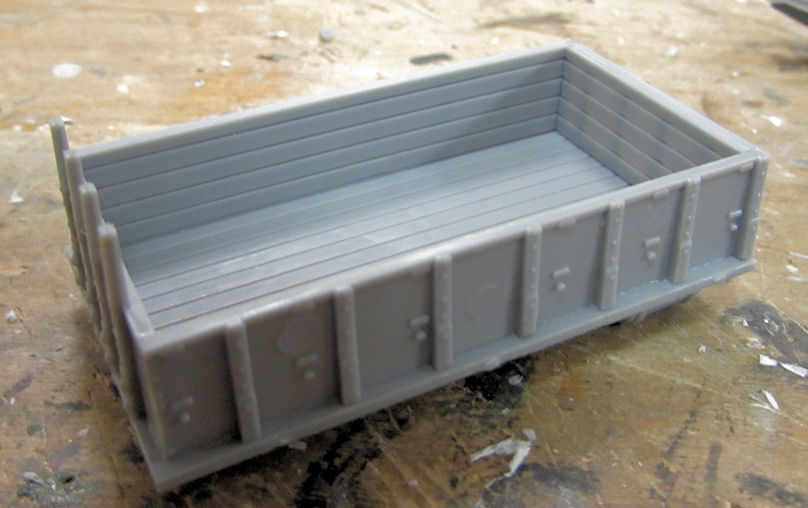

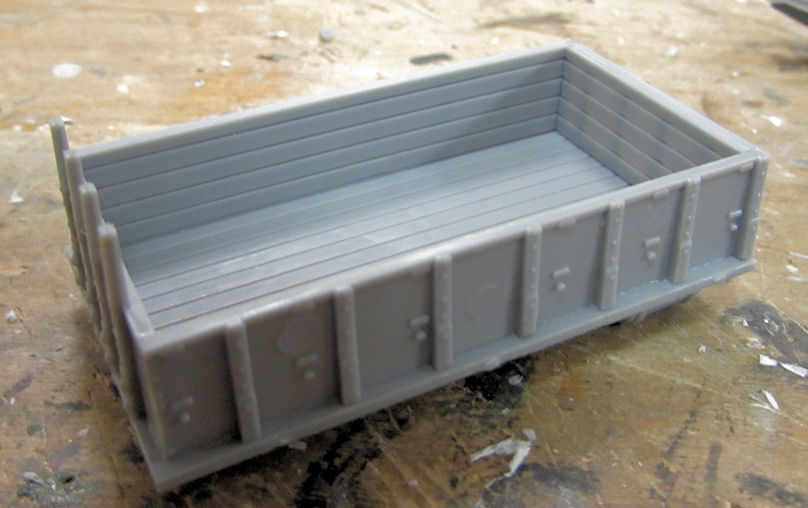

That's as far as I got with that. I then pulled out the MACK Truck and decided to build the rear cargo bed for that. I couldn't go wrong there; after all it's just a box. Fortunately I was right:

I then decided to do more with this. I assembled the chassis:

Once that was dry, I installed the cab and the dry-fit the cargo bed:

This one will be getting the tilt. I assembled the tilt and added it to the bed to see how it fit:

Not bad. This is gonna look good. I am now ready to paint this.

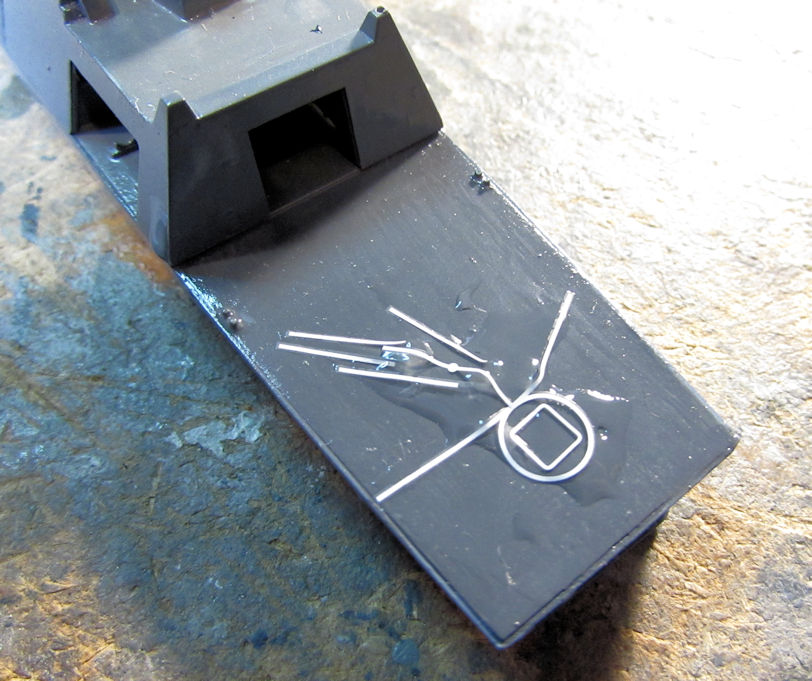

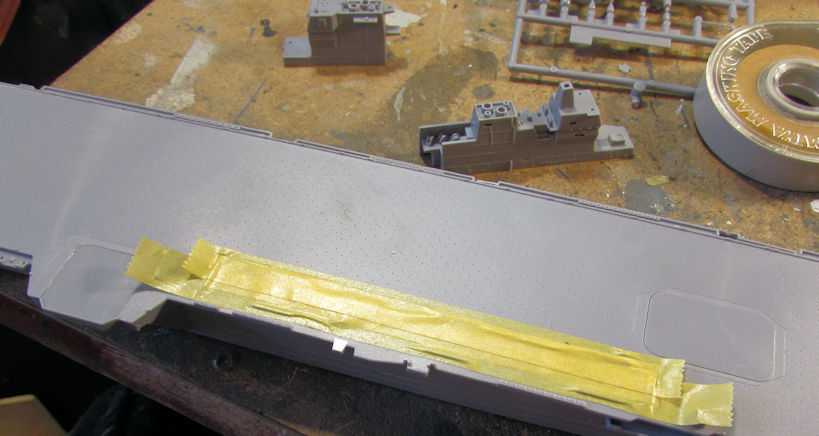

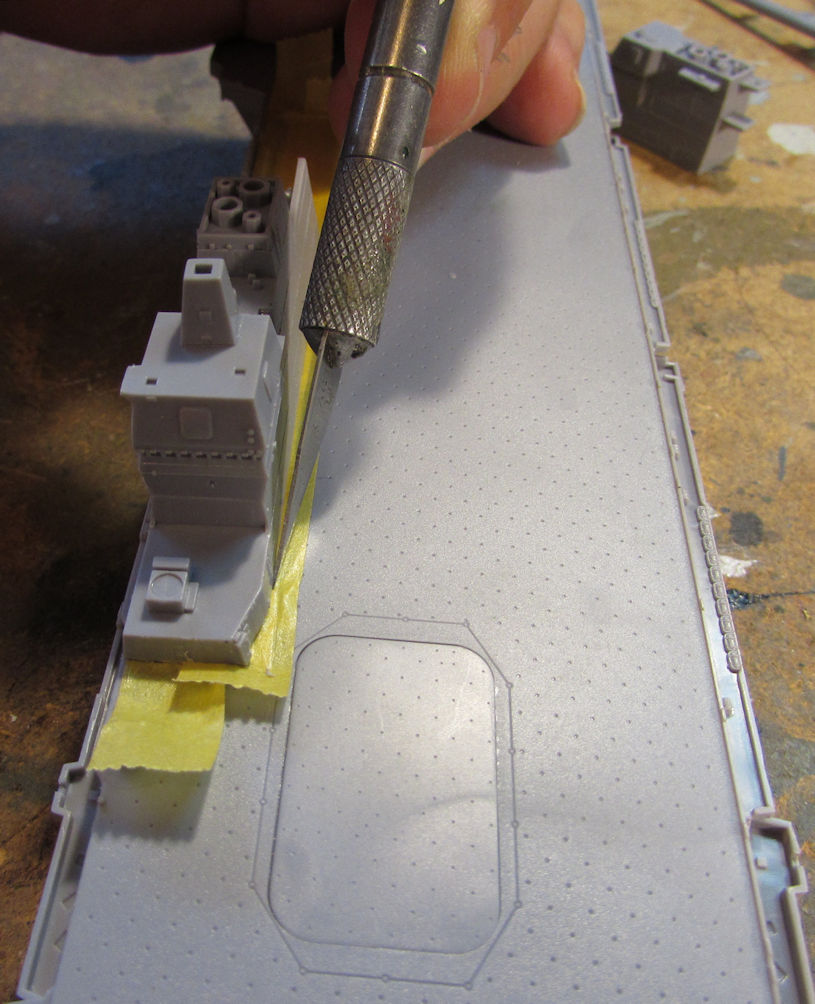

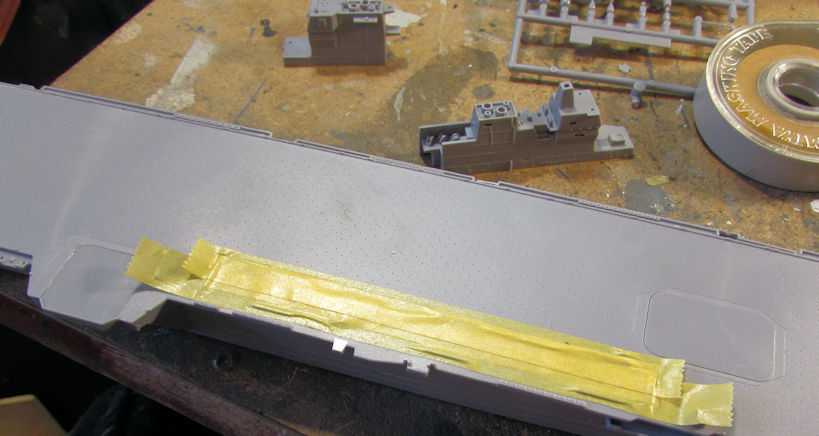

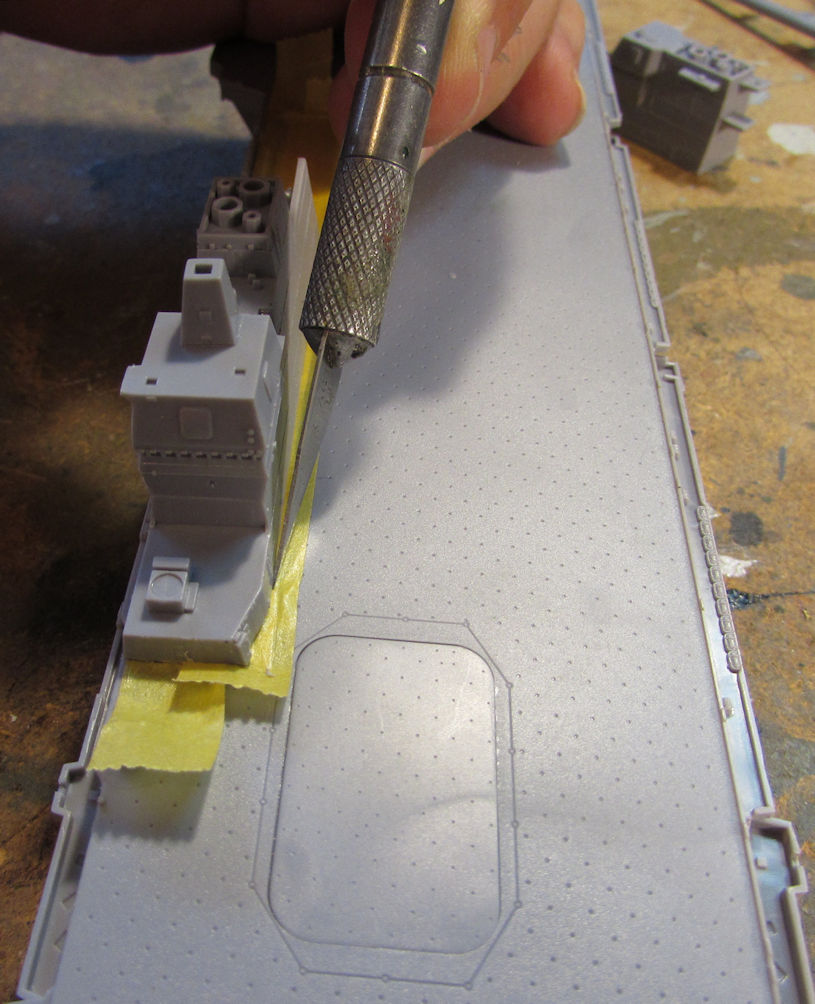

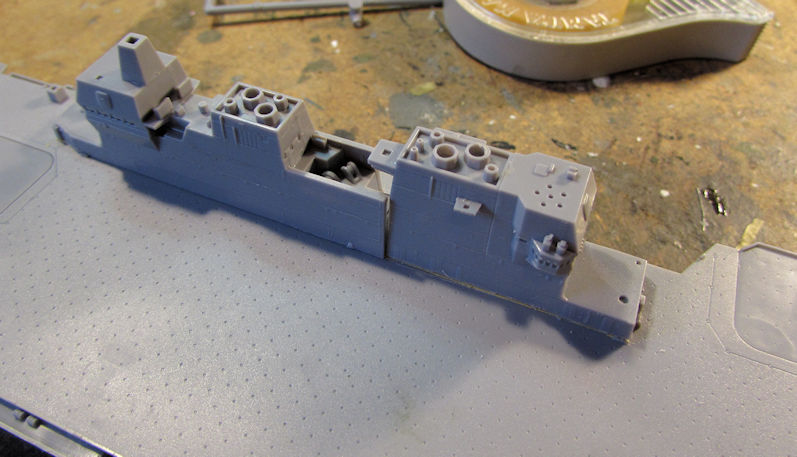

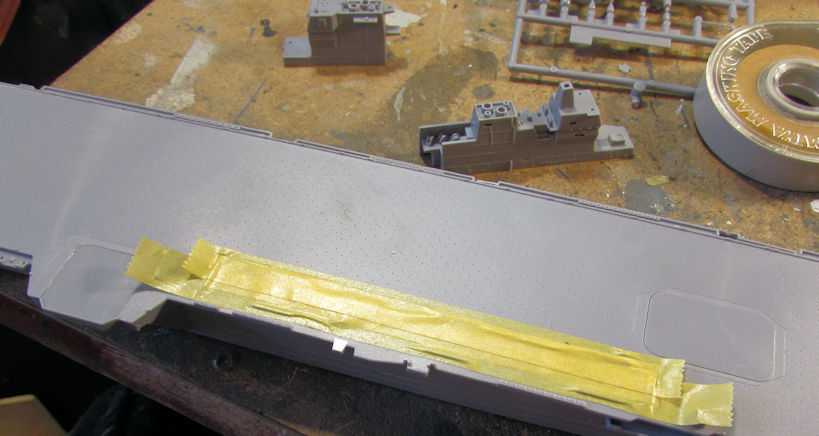

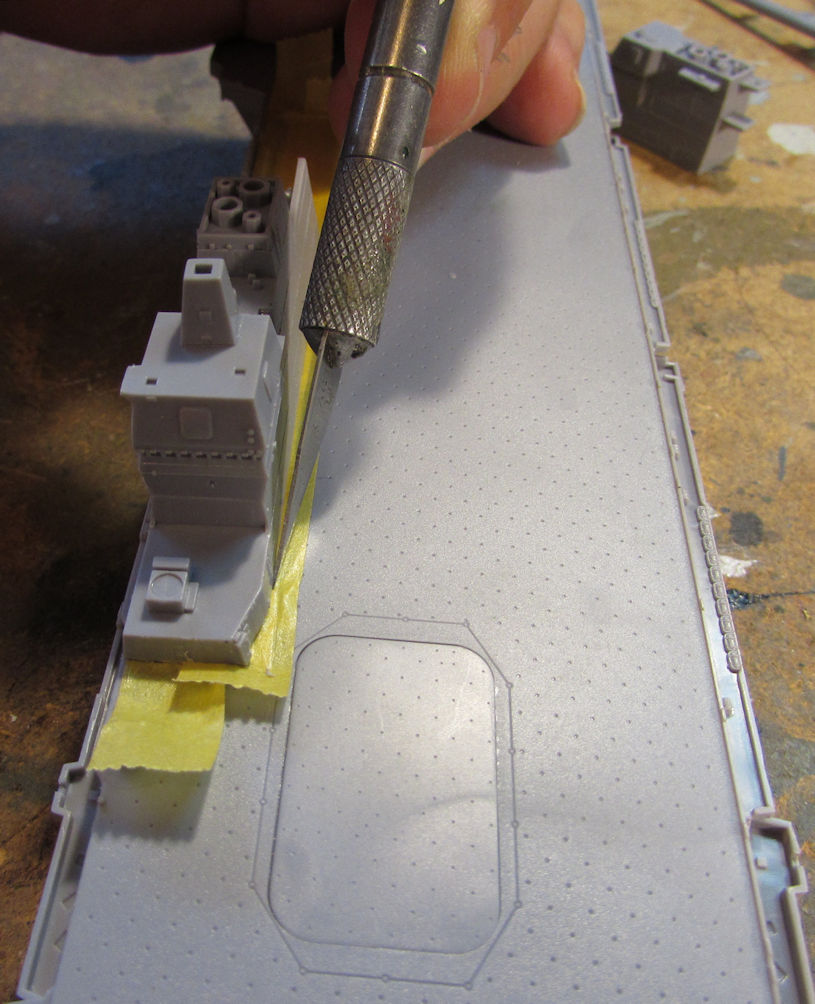

Speaking of ready to paint; I started to prepare the JMSDF Izumo for paint since almost all the assembly is done, except for detail parts. First, I wanted to mask off the area where the conning tower is supposed to go so when I shoot the deck, I won't get paint where the tower goes; allowing it to glue better later. Afterward, when I shoot the deck, I can then mask over the whole deck and shoot the rest of the hull and conning tower. I started by taping where the tower is supposed to go, burnishing it down as close as I can get it:

I then positioned the conning tower parts one at a time and scored the tape around the edge of the tower:

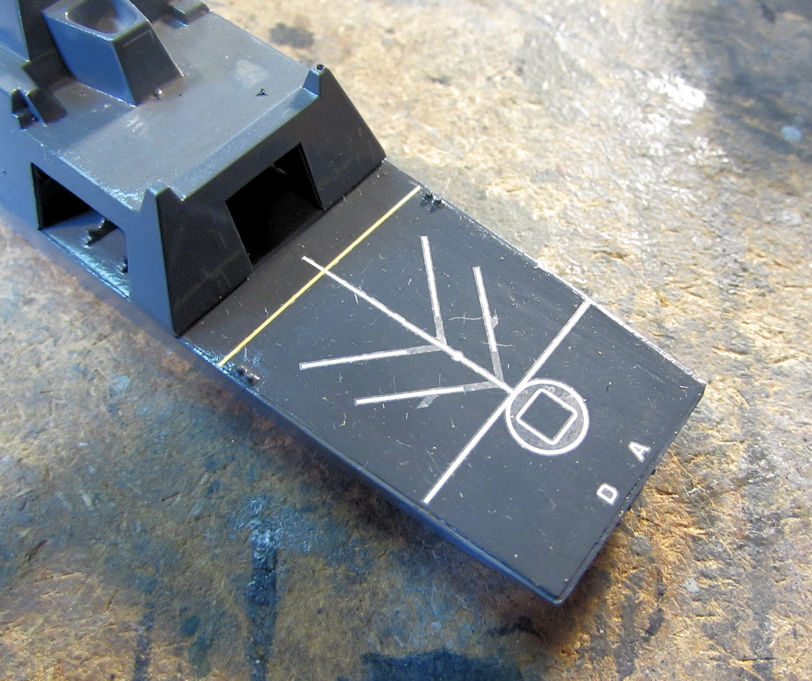

Afterward, I burnished it down again, and had a perfect covering for the tower area:

You can see that the area is almost perfectly covered. The rear tower part slipped a tiny bit:

Okay, that completes what I managed to get done so far. Hopefully this is a sign things are getting better for me. So, enjoy the tour and thanks all for looking in, comments are welcome.

I'll start with my one aircraft.

At my recent SoCal AMPS meeting, we had our annual "Four-Hour Build Challenge" where we were to choose an unbuilt, unstarted kit and build it over the course of the next four hours to see how far along we could get in that time. This was the second time we had done this challenge. The first time, most guys over-estimated how quickly they could finish something so almost nobody completed anything; except for three of us. I finished three models myself that time; all the way to the weathering stage.

This time I was far from that successful. I started with a simple bagged Airfix kit of a Saunders Roe experimental jet that had about 14 parts to it. I got the fuselage assembled first, then painted the pilot inside along with what could be seen of the cockpit:

No, you can't see the cockpit in that pic but I did it. Next I finished off all the wings and tail, then masked off the cockpit for painting. I shot it with a white paint; after fixing the damage that occurred after I dropped it on the way outside:

Then I dropped it again after painting so I had to wait till it dried and tried to sand out the damage to the paint. Some of it was apparently still wet since I found fingerprints on it afterward. After that dried, I tried again, only to damage the paint again. Okay, enough of that, I moved on to something else....

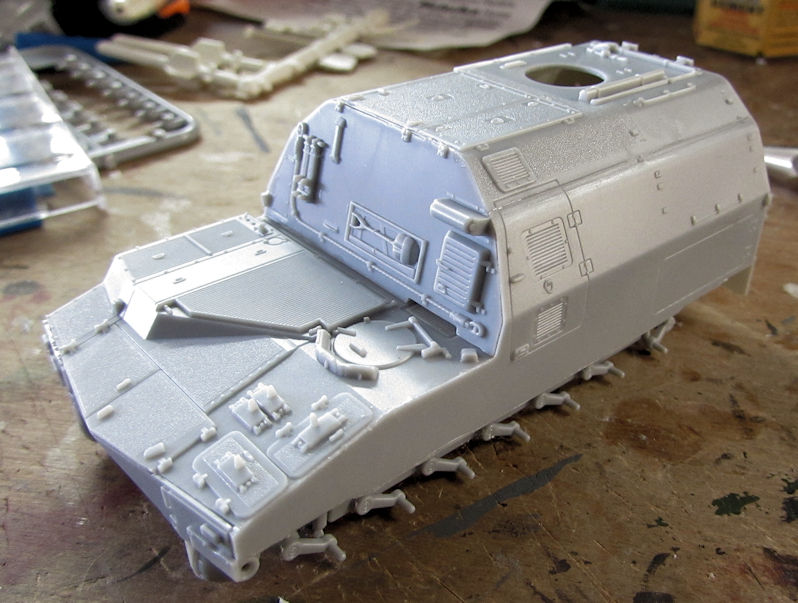

I pulled out an armor model and tried that. This was the Riich Models M-992 ammunition carrier for the M-109 Paladin. It should have been a simple build and started that way when I first assembled the main hull and superstructure. This was the result after 15 minutes:

I then tried to install the wheels and tracks. What a disaster! After fighting this for another 2.5 hours, I had this result; which doesn't show well all the gaps from poorly placed or missing indy links:

Part of the reason I had such difficulty with that was because I somehow managed to reverse some of the links near the end of the attempt to install them. That meant trying to find the reversed ones; pulling everything back off and trying to re-glue them all on again. I think I repeated that mistake at least three times before I finally got those tracks right. Finally, after all that and dinner break, I was too far gone to even try painting this so I gave up for the remaining 20 minutes of the time.

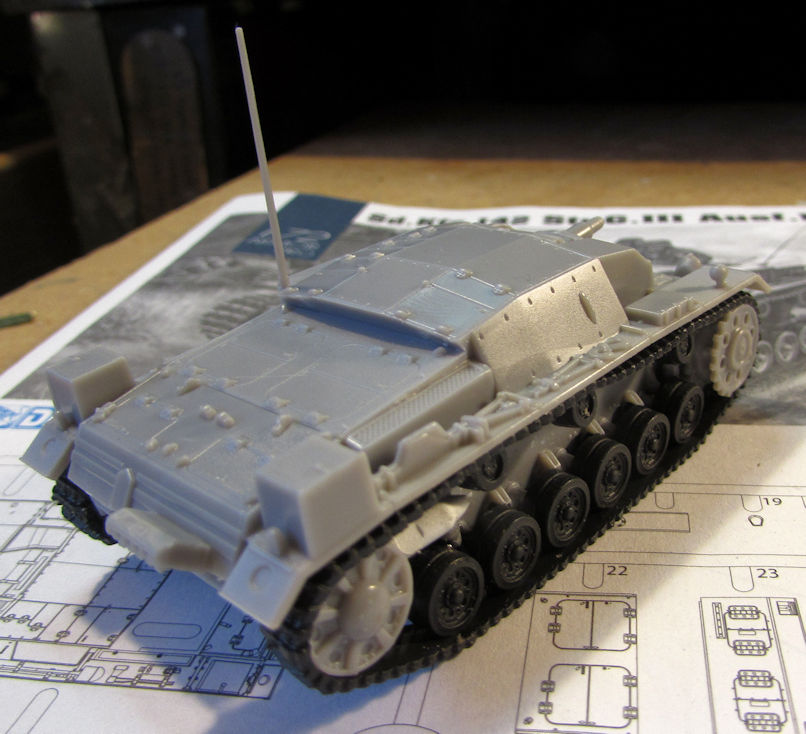

After the meeting, another friend and fellow AMPS member came up and offered me his 1/72 scale Dragon StuG he'd started for the build challenge. He had broken the rear idler since the tracks were too tight so he gave up on it. Since he had only done it for the challenge he didn't want to finish it since he doesn't normally do 1/72 scale armor. I accepted. Later when I got home I managed to get the rear idler glued on and then added the tracks. The other idler had been skewed as well so I adjusted it, and then added more glue to strengthen the bond more. Here it is after the repair:

The white pieces in front of the idlers are sprue scraps that I'd positioned in there to hold the wheels straight while the glue dried. Of course, that tall antenna has already become 'shortened' when this got knocked over; breaking the upper third off. Oh well....

Later on at home, I had a tough time getting the mojo up to work on anything. It seemed every time I tried to do something, I screwed it up so I was constantly walking out of my hobby room in disgust. It's a miracle I got anything done at all. After all that crap, I just simply pulled out some short-run models and went to work on them. After all I figured, if I'm gonna screw something up, it wouldn't be as noticeable as if it were done on a well-molded kit. Besides, there was something rather therapeutic about cleaning all the parts; sanding and test fitting over and over to figure out how best to make the parts fit.

The first little short run model I worked on was this little Military Wheels 1/72 scale Volkswagen 'pickup'. I started with the lower chassis and interior which I did not shoot pics of. I then went and assembled the main cab:

After building the rear cargo bed, I test fit that, the lower chassis and the front hood all together to see how this little beastie would look:

This also allowed me to see where the issues were. I worked on them and added the windows. I then got the body cemented down to the chassis; and added the roof rack; the fender and some other little fiddly bits. I also added some acrylic filler to the seams which needs to be re-done to fill the tiny holes there:

Moving on, I also started another Military Wheels Volkswagen; this one has a larger nose to increase the cargo space in the front. Again, I assembled the interior and the lower chassis but didn't shoot pics of it yet. The upper body was started though; and it was a bear to build due to being in five pieces with no attachment points. I got most of it assembled, leaving the nose off till later:

You can see how rough this was to assemble, given the crude glue joins from difficult, poorly molded parts. Still, I felt good doing this.

Later I test fit this and the nose to the chassis and interior:

What a schnozz on that little beetle! Here it is sitting next to the 'pickup' beetle:

Later I sanded it all as smooth as possible, and then used Mr. Surface on the remaining crevices that were left:

That's as far as I got on that one.

Moving on, I started another short-run kit; this time an ACE Russian BREM recovery vehicle based on the BMP I. I love doing ACE kits; it can be so relaxing doing the mind-numbing cleanup on all the parts. I started on the lower hull first:

I then test-fit the upper hull to it to see how well the lower hull was assembled:

I then found out that everything behind the turret had to be removed so I carved everything off and added the floor of the back work box on top of the bare area and clamped it down. I also added the armor plate over the turret ring:

I then found out I'd put in on sideways so I had to carve it off and turn it 90 degrees and re-cement it. Afterwards, I added the sides of that box and the hatches for the driver and TC:

While that was drying, I added the wheels and idlers to the lower hull:

That's as far as I got with that. I then pulled out the MACK Truck and decided to build the rear cargo bed for that. I couldn't go wrong there; after all it's just a box. Fortunately I was right:

I then decided to do more with this. I assembled the chassis:

Once that was dry, I installed the cab and the dry-fit the cargo bed:

This one will be getting the tilt. I assembled the tilt and added it to the bed to see how it fit:

Not bad. This is gonna look good. I am now ready to paint this.

Speaking of ready to paint; I started to prepare the JMSDF Izumo for paint since almost all the assembly is done, except for detail parts. First, I wanted to mask off the area where the conning tower is supposed to go so when I shoot the deck, I won't get paint where the tower goes; allowing it to glue better later. Afterward, when I shoot the deck, I can then mask over the whole deck and shoot the rest of the hull and conning tower. I started by taping where the tower is supposed to go, burnishing it down as close as I can get it:

I then positioned the conning tower parts one at a time and scored the tape around the edge of the tower:

Afterward, I burnished it down again, and had a perfect covering for the tower area:

You can see that the area is almost perfectly covered. The rear tower part slipped a tiny bit:

Okay, that completes what I managed to get done so far. Hopefully this is a sign things are getting better for me. So, enjoy the tour and thanks all for looking in, comments are welcome.

MM2CVS9

Active member

Speaking of ready to paint; I started to prepare the JMSDF Izumo for paint since almost all the assembly is done, except for detail parts. First, I wanted to mask off the area where the conning tower is supposed to go so when I shoot the deck, I won't get paint where the tower goes; allowing it to glue better later. Afterward, when I shoot the deck, I can then mask over the whole deck and shoot the rest of the hull and conning tower. I started by taping where the tower is supposed to go, burnishing it down as close as I can get it:

I then positioned the conning tower parts one at a time and scored the tape around the edge of the tower:

Afterward, I burnished it down again, and had a perfect covering for the tower area:

You can see that the area is almost perfectly covered. The rear tower part slipped a tiny bit:

Okay, that completes what I managed to get done so far. Hopefully this is a sign things are getting better for me. So, enjoy the tour and thanks all for looking in, comments are welcome.

Great tip on masking for the Izumo.

EJ

Duke Maddog

Well-known member

Thanks guys! Your comments and compliments are most motivating.

Iambrb, I'm trying my friend!

Iambrb, I'm trying my friend!

Duke Maddog

Well-known member

Thanks Kenny! This machine is running quite rough right now. I wish I could smooth things out and get some of these things finished!

Similar threads

- Replies

- 7

- Views

- 377

- Replies

- 1

- Views

- 291

- Replies

- 37

- Views

- 2K

- Replies

- 18

- Views

- 718

...liking very much the job camo

...liking very much the job camo