paddy

Well-known member

I have been pondering a model makers lathe for a while and i am sure i have broached the subject before because i remember Chris posting pictures of his collet based watchmakers lathe. Its one of those things i struggle with as i am not sure i would get the value from it. It may present opportunities that create value that i haven't thought of  and if its fun , it may not have to have a good output value

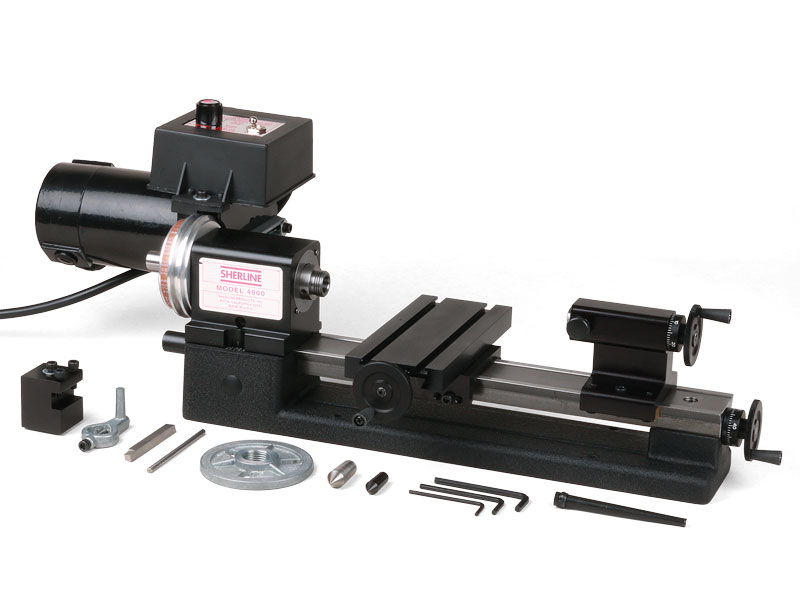

and if its fun , it may not have to have a good output value  I was looking at this but the details are sketchy so i have written to them to see if they have a user manual PDF that might throw some light on screw cutting pitch etc. Its a bit worrying if its a serious bit of kit that details like that are not included in the on line spec so lets see if they reply

I was looking at this but the details are sketchy so i have written to them to see if they have a user manual PDF that might throw some light on screw cutting pitch etc. Its a bit worrying if its a serious bit of kit that details like that are not included in the on line spec so lets see if they reply

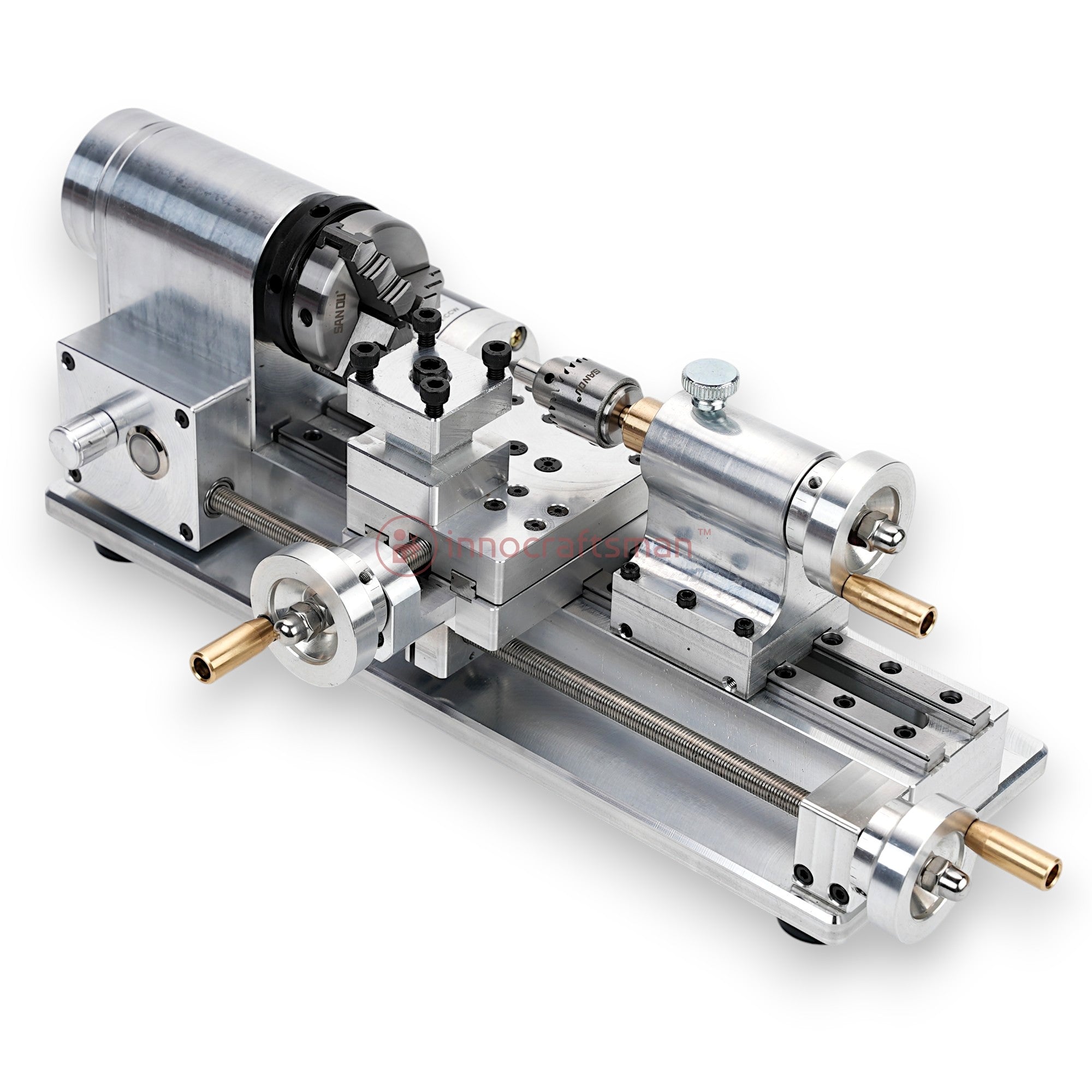

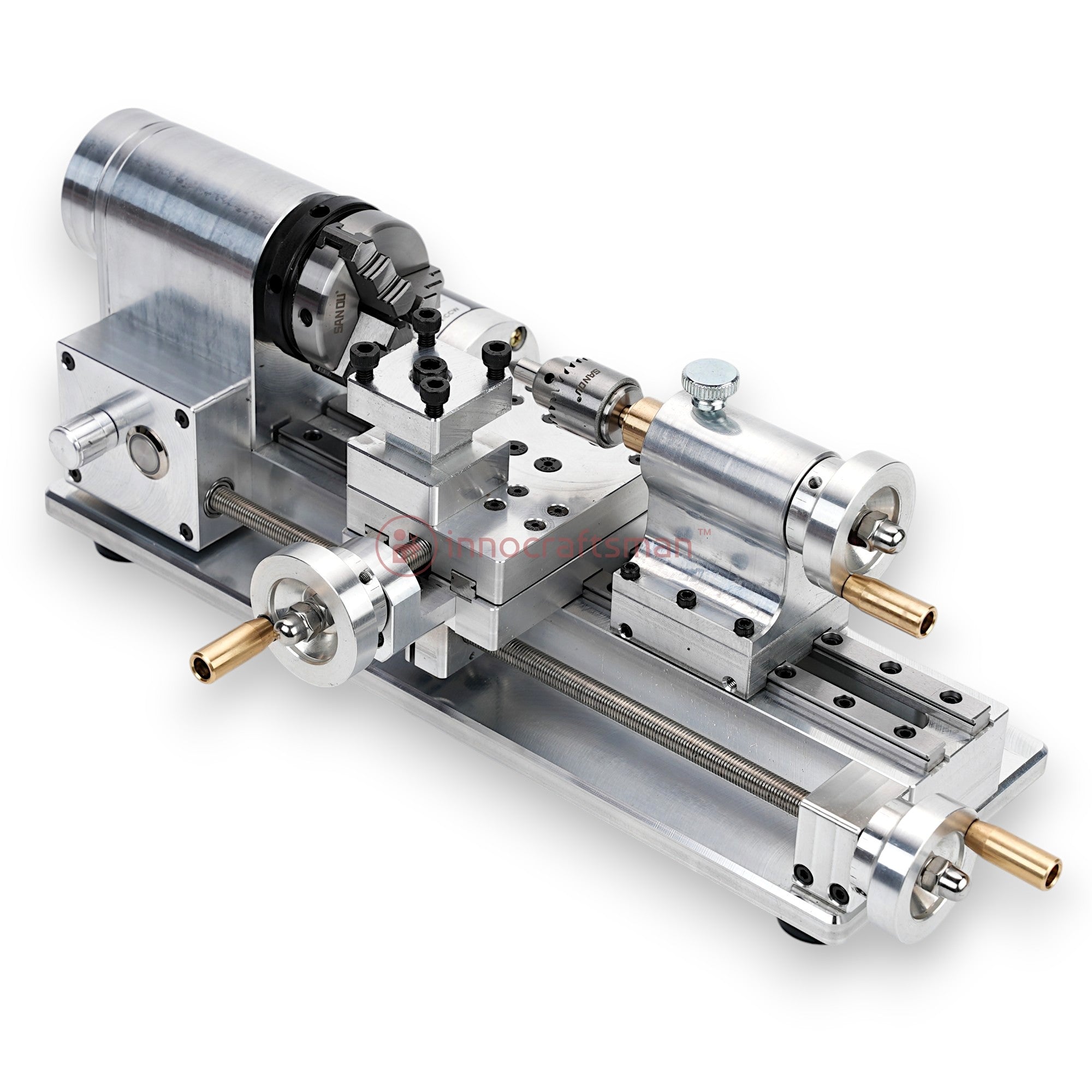

innocraftsman.com

innocraftsman.com

I was also looking at the CNC lathe/milling machine but i dont think the Chinese have the reliability reputation to warrant the extra expense. Strangely i cant find any reviews of their lathe on the web either but i would guess even if it was faulty from the box you would have little redress.

The other problem with machine tools is.....i would guess that if the mini lathe is £500 then you would need another £500 to equip it to be usable....taps, dies, running centres, tools, steady, die holders etc .

I will update if i hear back from these people.

Mini Metal Lathe 80W

Introducing a compact yet functional DIY mini lathe, where every component is crafted from premium materials using CNC machinery for maximum precision. This lathe is perfect for crafting detailed models and intricate parts, making it ideal for creating watch parts, jewelry, and other fine...

I was also looking at the CNC lathe/milling machine but i dont think the Chinese have the reliability reputation to warrant the extra expense. Strangely i cant find any reviews of their lathe on the web either but i would guess even if it was faulty from the box you would have little redress.

The other problem with machine tools is.....i would guess that if the mini lathe is £500 then you would need another £500 to equip it to be usable....taps, dies, running centres, tools, steady, die holders etc .

I will update if i hear back from these people.