Greg Kimsey

Well-known member

My elderly friend, Bob, purchased this kit from me saying he wanted to try to build it. His Parkinsons was so bad that I say no way that could happen. It didn't. He brought it back and asked if I would build it. I always say yes. He is such a lonely old man.So I have taken a short break from my Israeli F-16 to do Bob a solid.

His requests were

Body- White

Interior- Teal

Hood detached.

Convertible.

Custom version, not stock

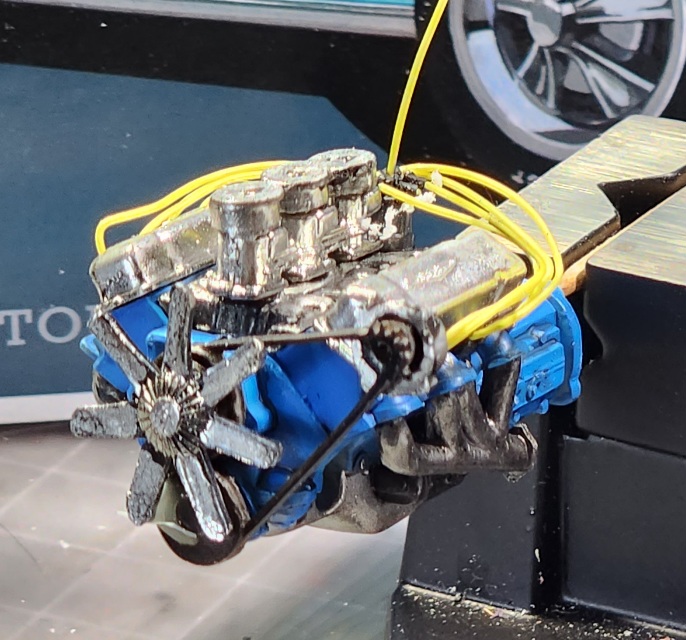

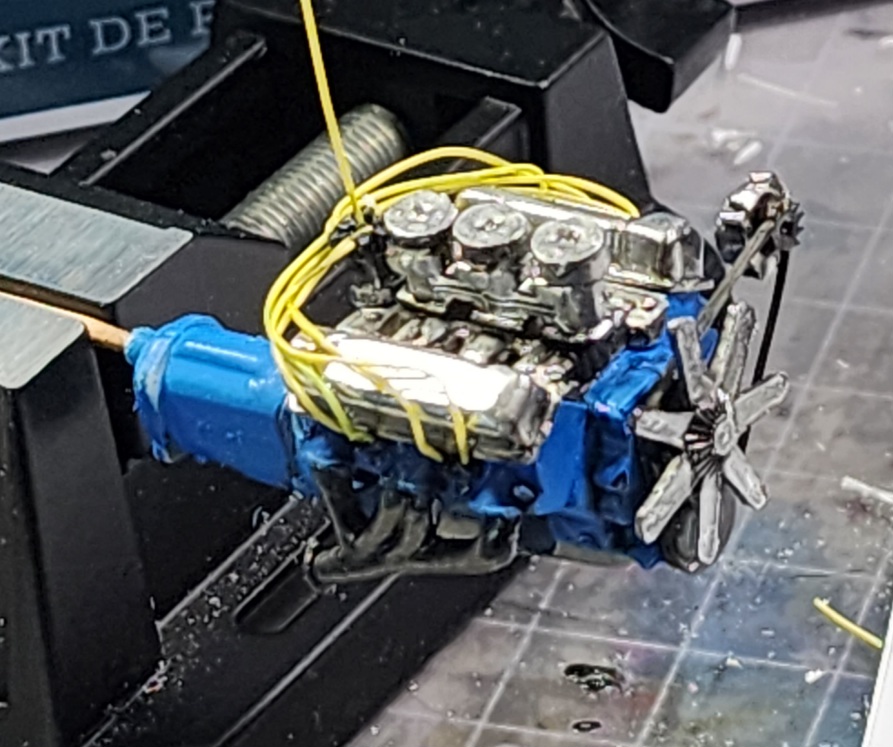

I am trying to make this as clean as I can (no glue fingerprints, smudges, etc). This might be the cleanest engine I have ever done.

I have always tried to make the sparkplug boots from one piece and cut a V at the bend, bend it and superglue. It has never worked out satisfactorily. This time I cut the boot into two tiny pieces with a 90 on one end and a 45 on the other, then slide the pieces onto the wire so the 45's meet to form a 90 degree boot. I gotta say, it worked out so well that I hate it took 50 years to try it.

I have all of the other parts primed for painting. More to come later!

His requests were

Body- White

Interior- Teal

Hood detached.

Convertible.

Custom version, not stock

I am trying to make this as clean as I can (no glue fingerprints, smudges, etc). This might be the cleanest engine I have ever done.

I have always tried to make the sparkplug boots from one piece and cut a V at the bend, bend it and superglue. It has never worked out satisfactorily. This time I cut the boot into two tiny pieces with a 90 on one end and a 45 on the other, then slide the pieces onto the wire so the 45's meet to form a 90 degree boot. I gotta say, it worked out so well that I hate it took 50 years to try it.

I have all of the other parts primed for painting. More to come later!