Greg Kimsey

Well-known member

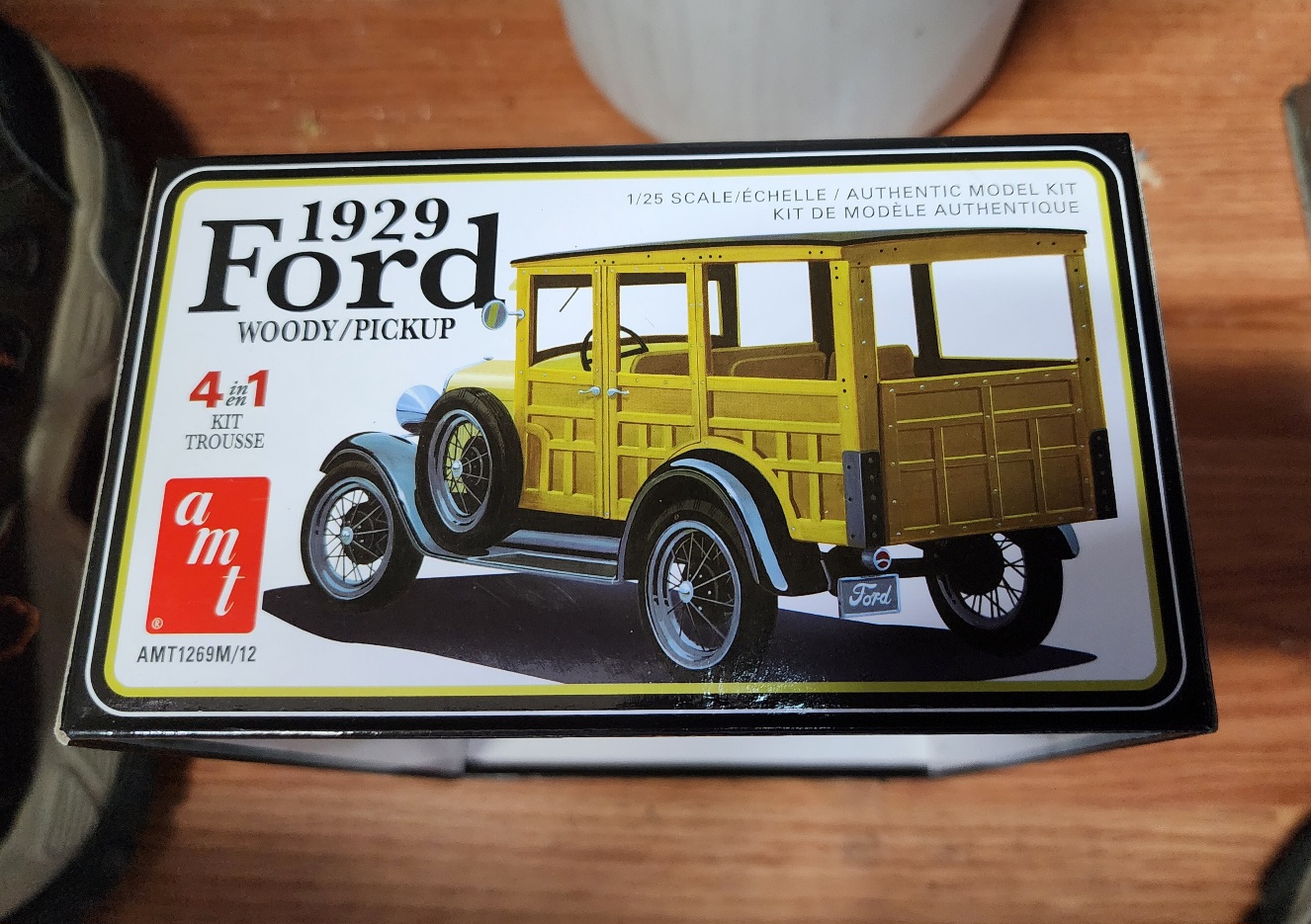

So, here is another for Bob, a 1929 Ford Woody. I am building this version:

I have to chassis primed and painted except for the wood grain bed bottom on the underside

The cab is primed and I have the roof painted

The tires are done. I rounded off the backside of the spokes and made them smaller by using an Xacto knife

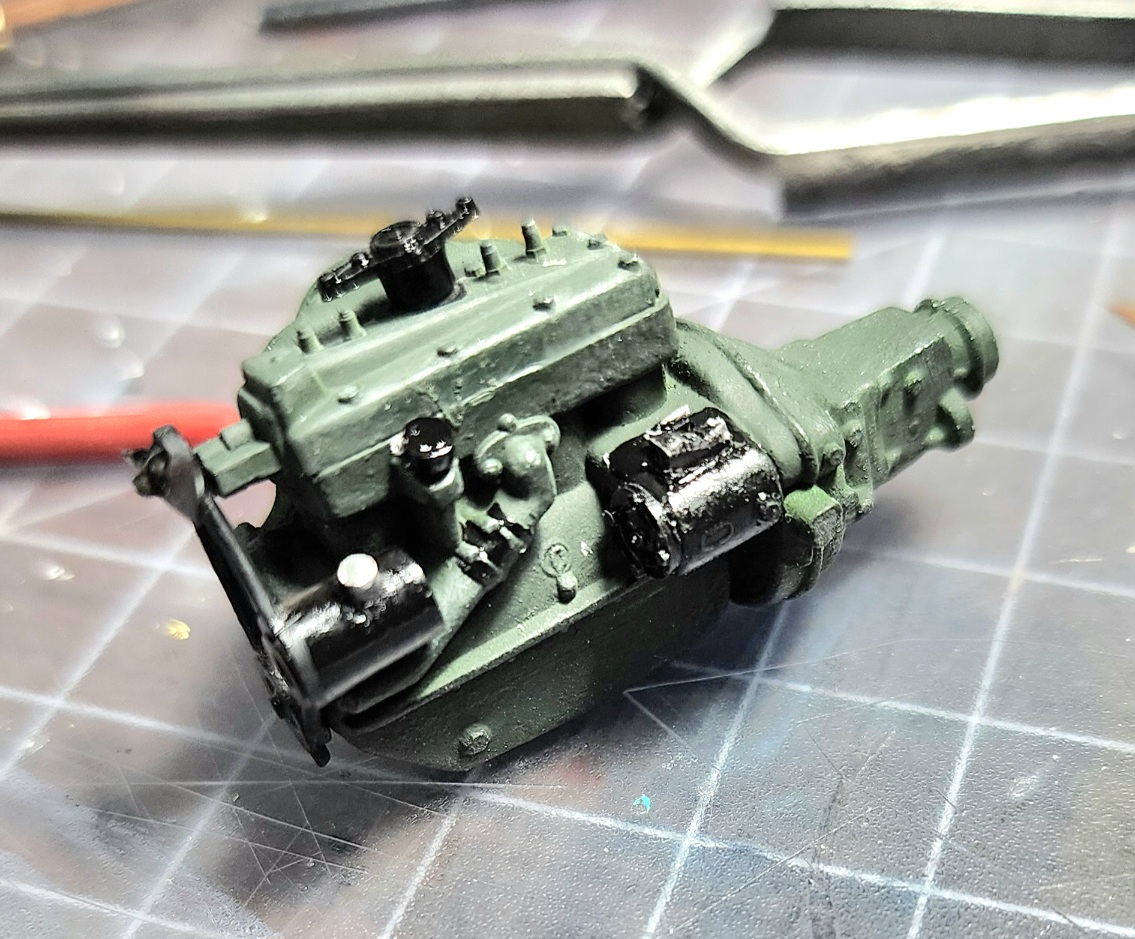

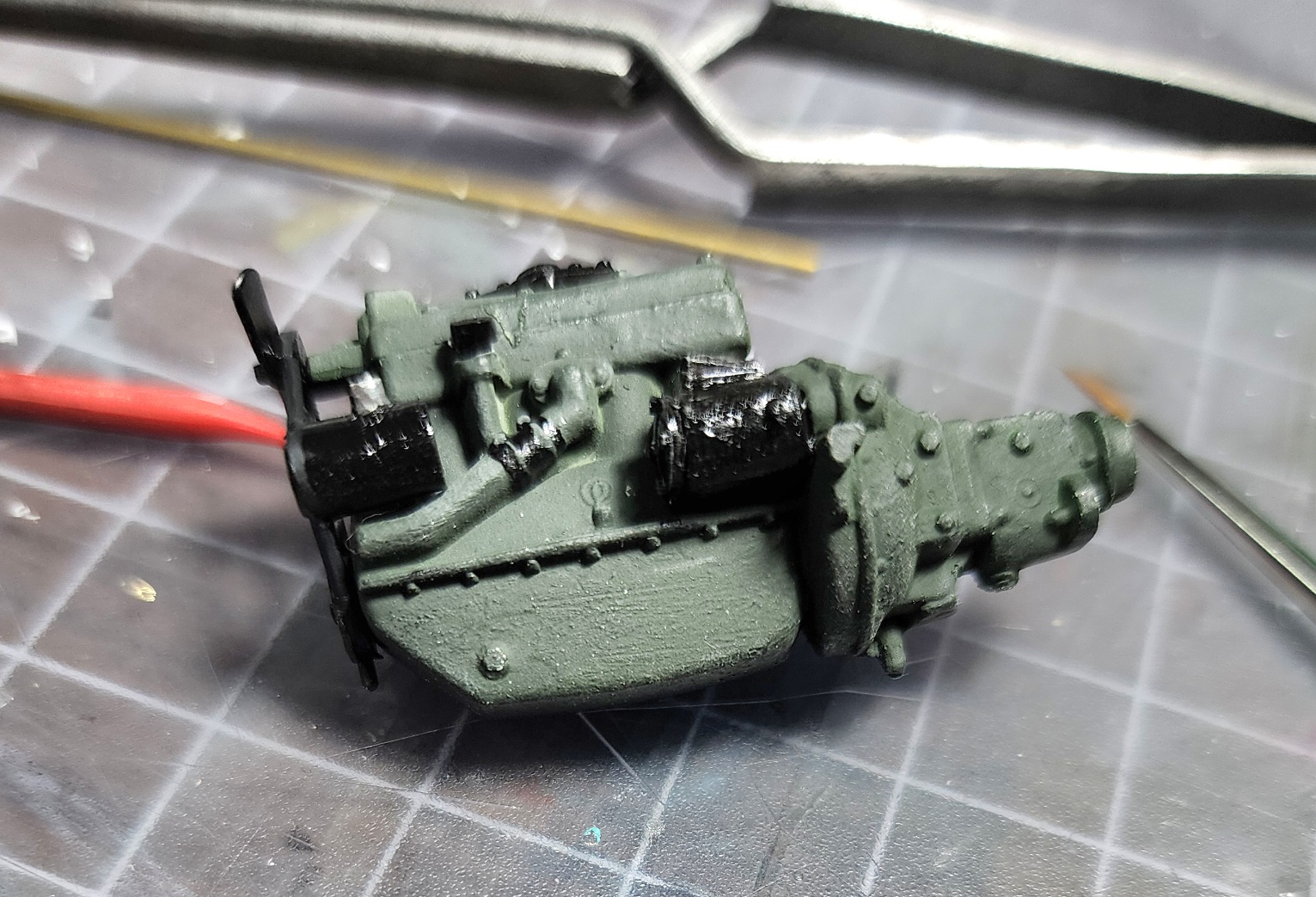

Now for the motor.. this is the sum total of parts for the entire engine. 4 pieces

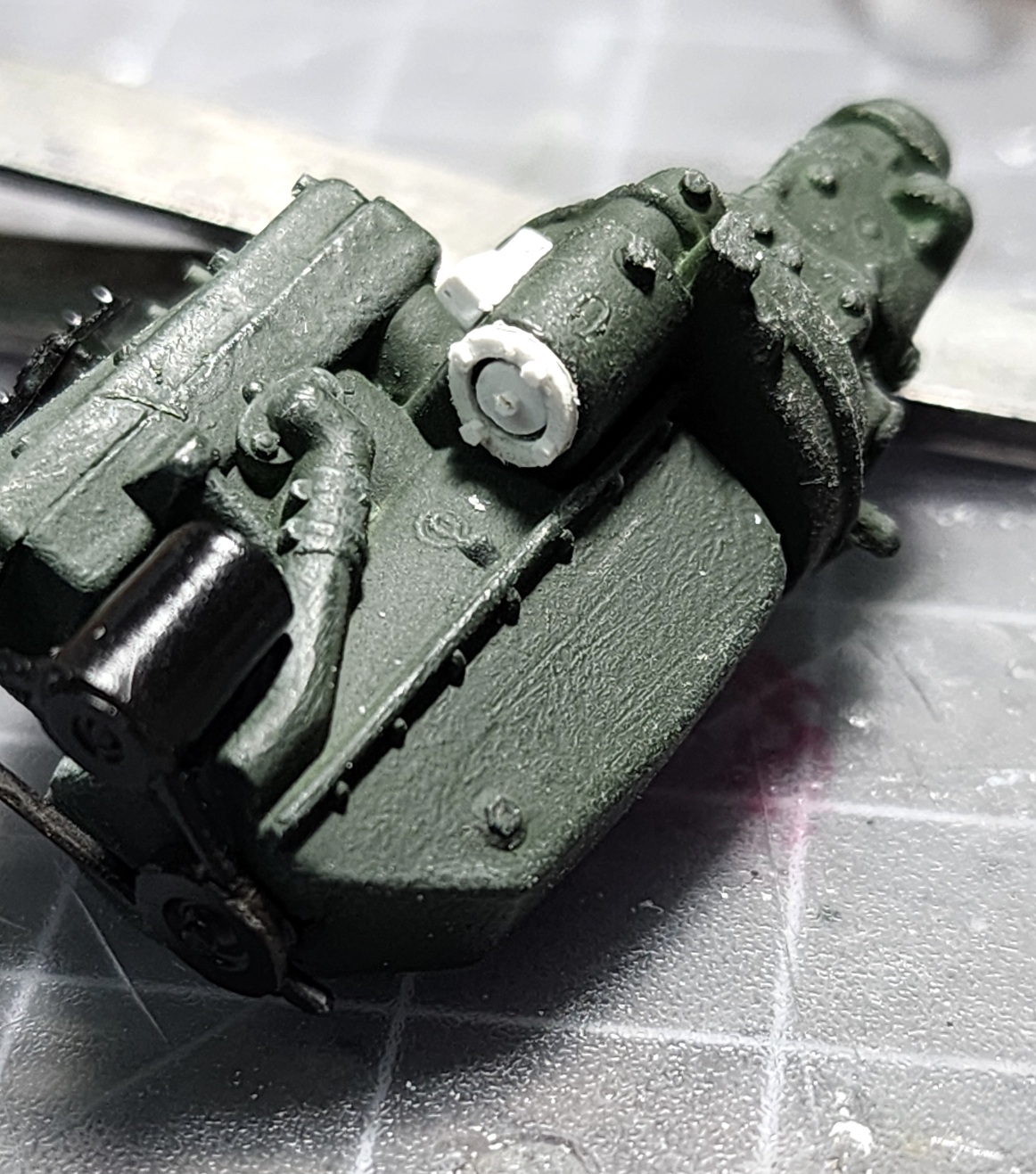

That really just won't do. I am detailing the starter here...

I even put a "fuse" on the starter which is right out in the open on top of the starter. I have some very good reference photos of this very model in the colors I need. The engine compartment is small and there aren't tons of wiring so it should be easy to replicate.

That is all I have so far. I think I am going to enjoy this one

I have to chassis primed and painted except for the wood grain bed bottom on the underside

The cab is primed and I have the roof painted

The tires are done. I rounded off the backside of the spokes and made them smaller by using an Xacto knife

Now for the motor.. this is the sum total of parts for the entire engine. 4 pieces

That really just won't do. I am detailing the starter here...

I even put a "fuse" on the starter which is right out in the open on top of the starter. I have some very good reference photos of this very model in the colors I need. The engine compartment is small and there aren't tons of wiring so it should be easy to replicate.

That is all I have so far. I think I am going to enjoy this one