jeaton01

Well-known member

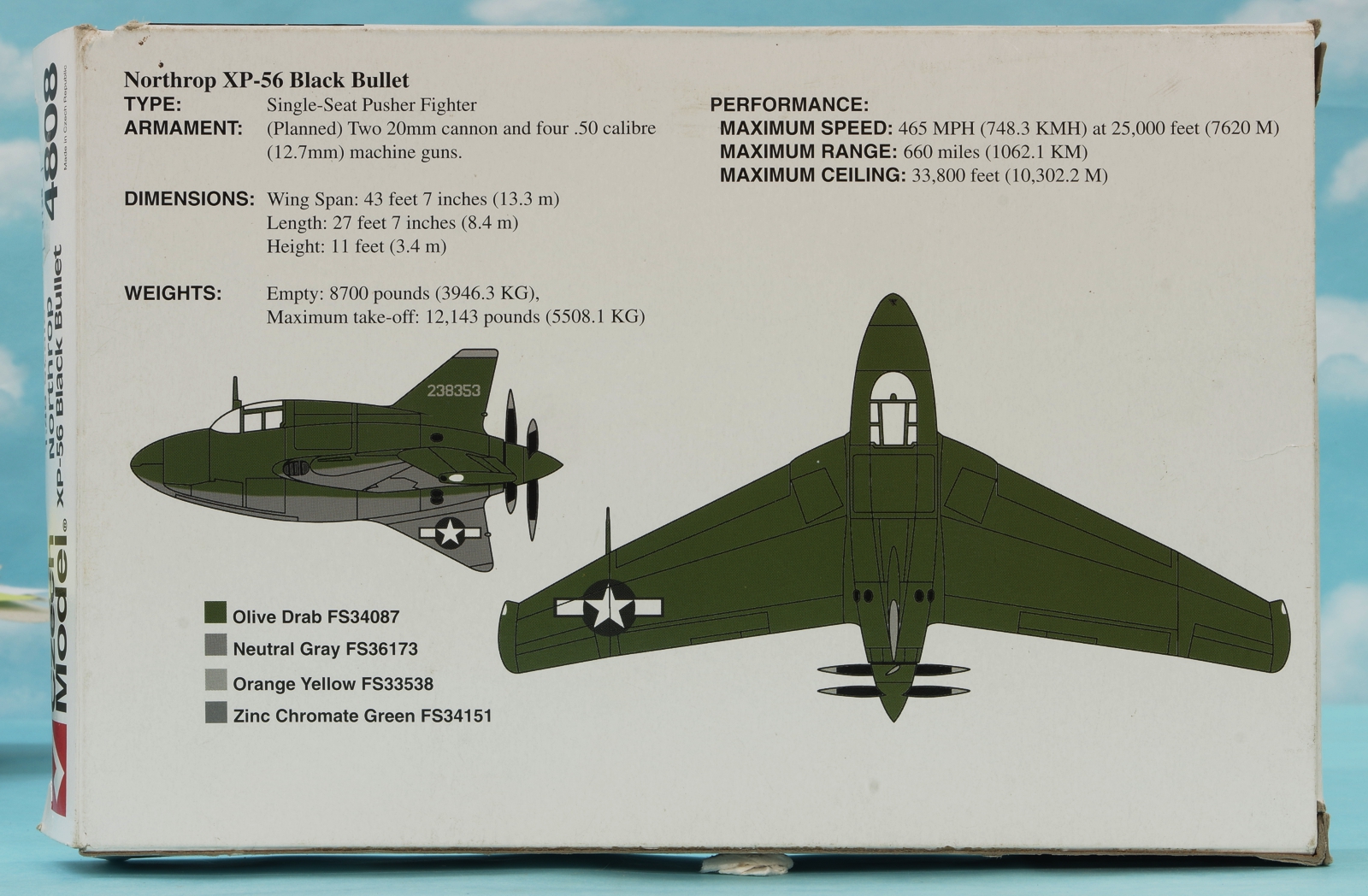

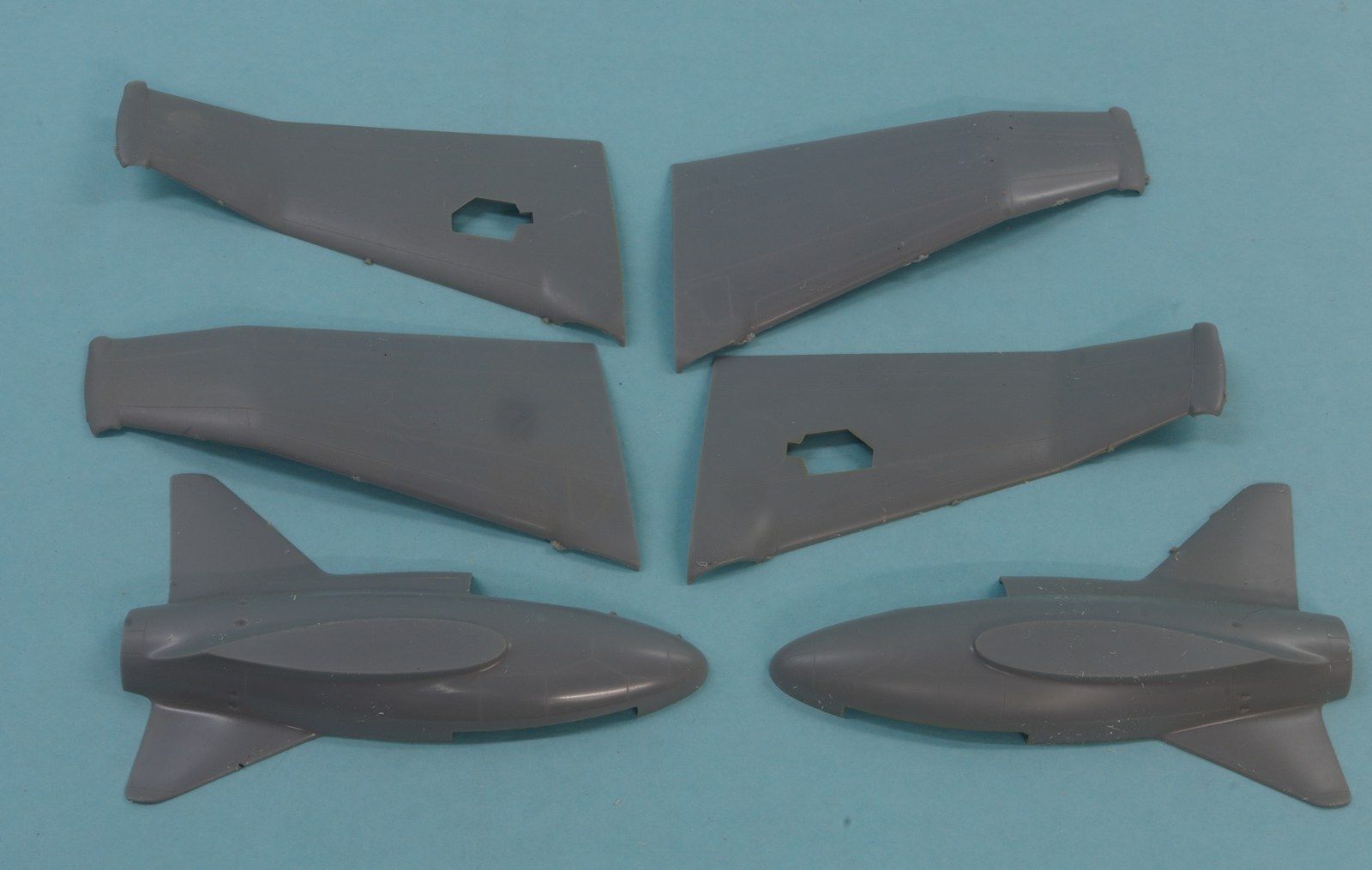

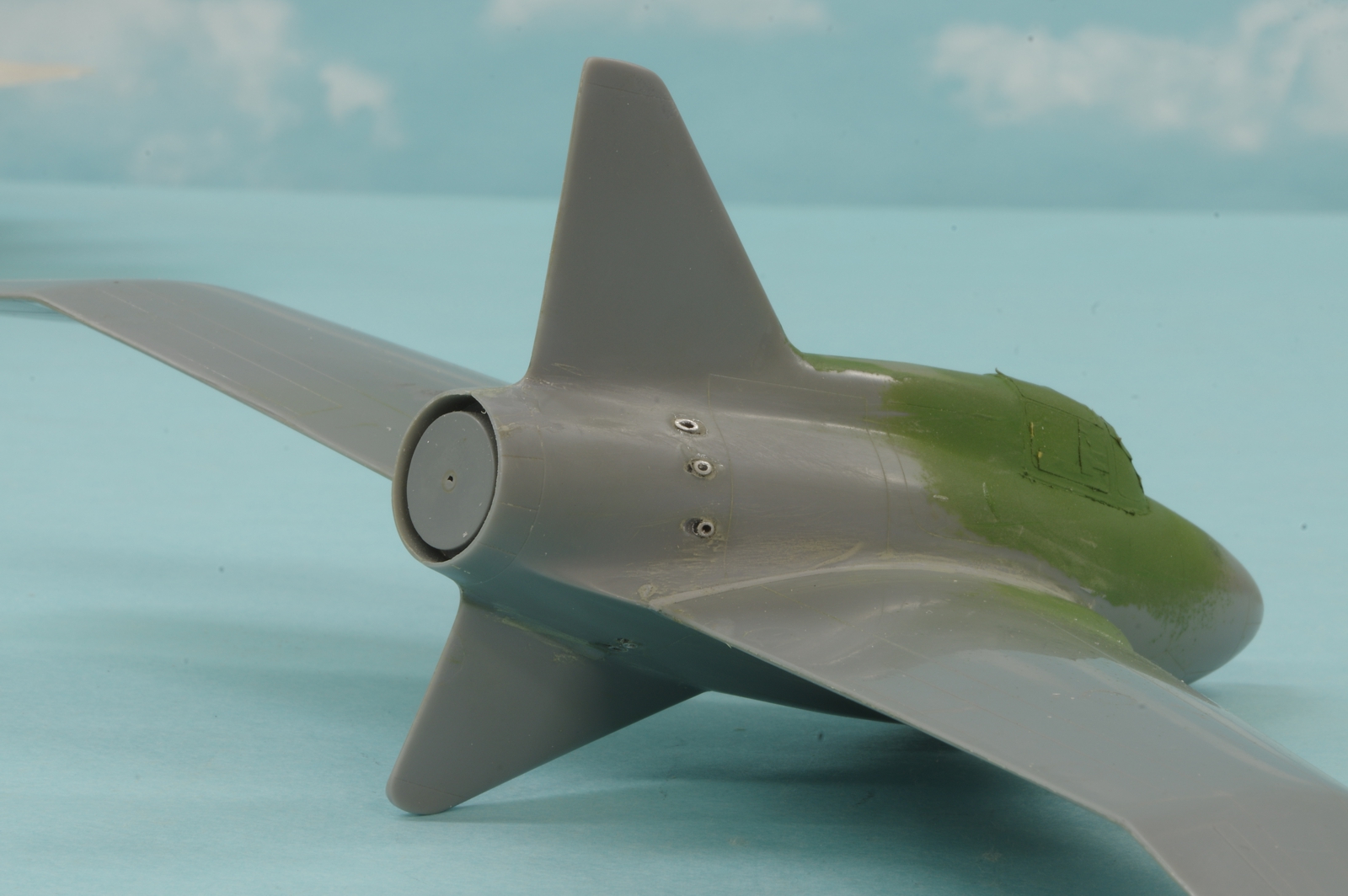

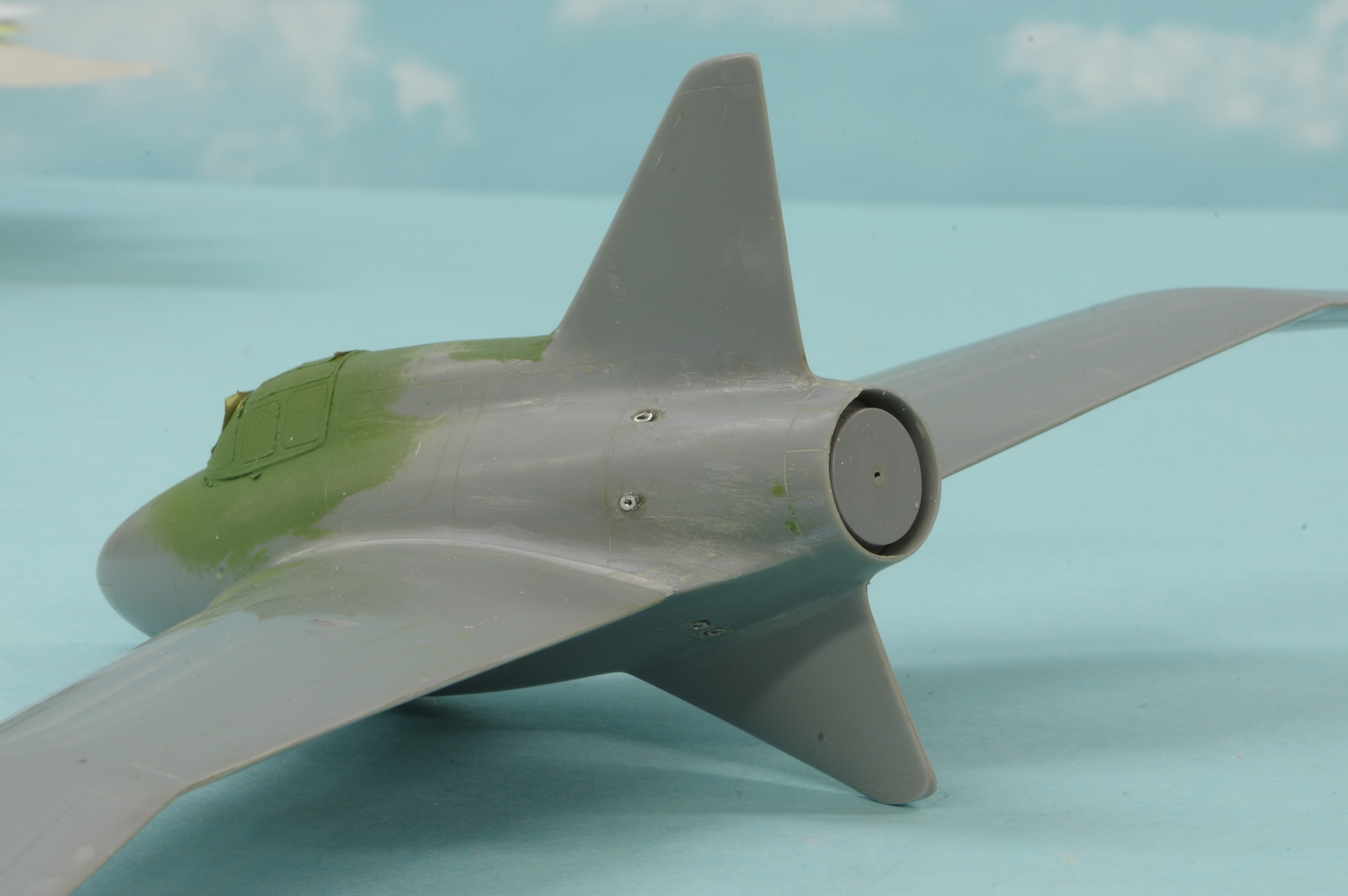

I started another X-Plane, one that I have had in the workshop pile for 10 years or so. It is the 1/48 Czech Models XP-56. It has resin detail parts and the rest is fairly good limited run injection moldings. Fit is very good so far but bring a rough file for the pour stubs.

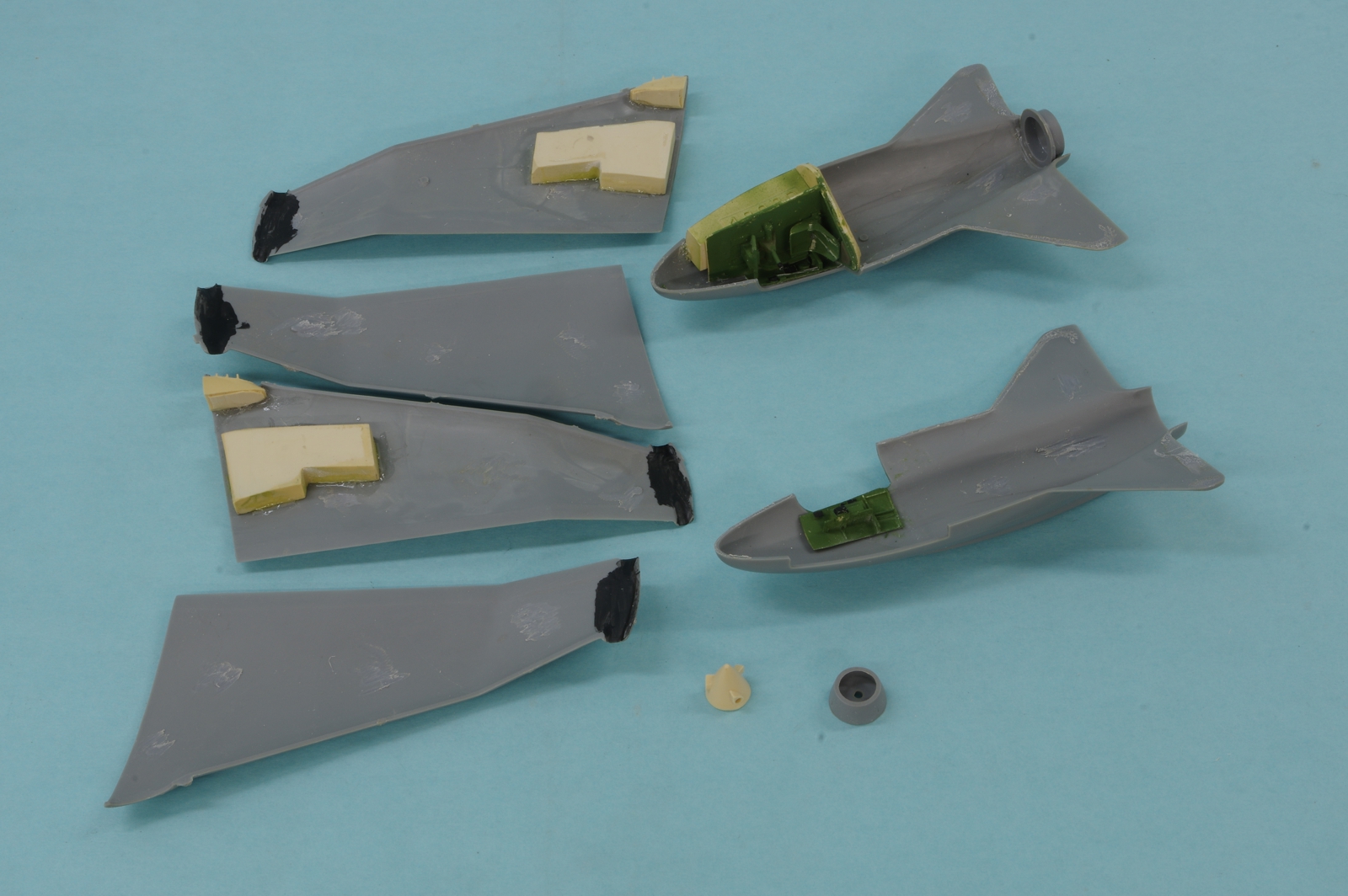

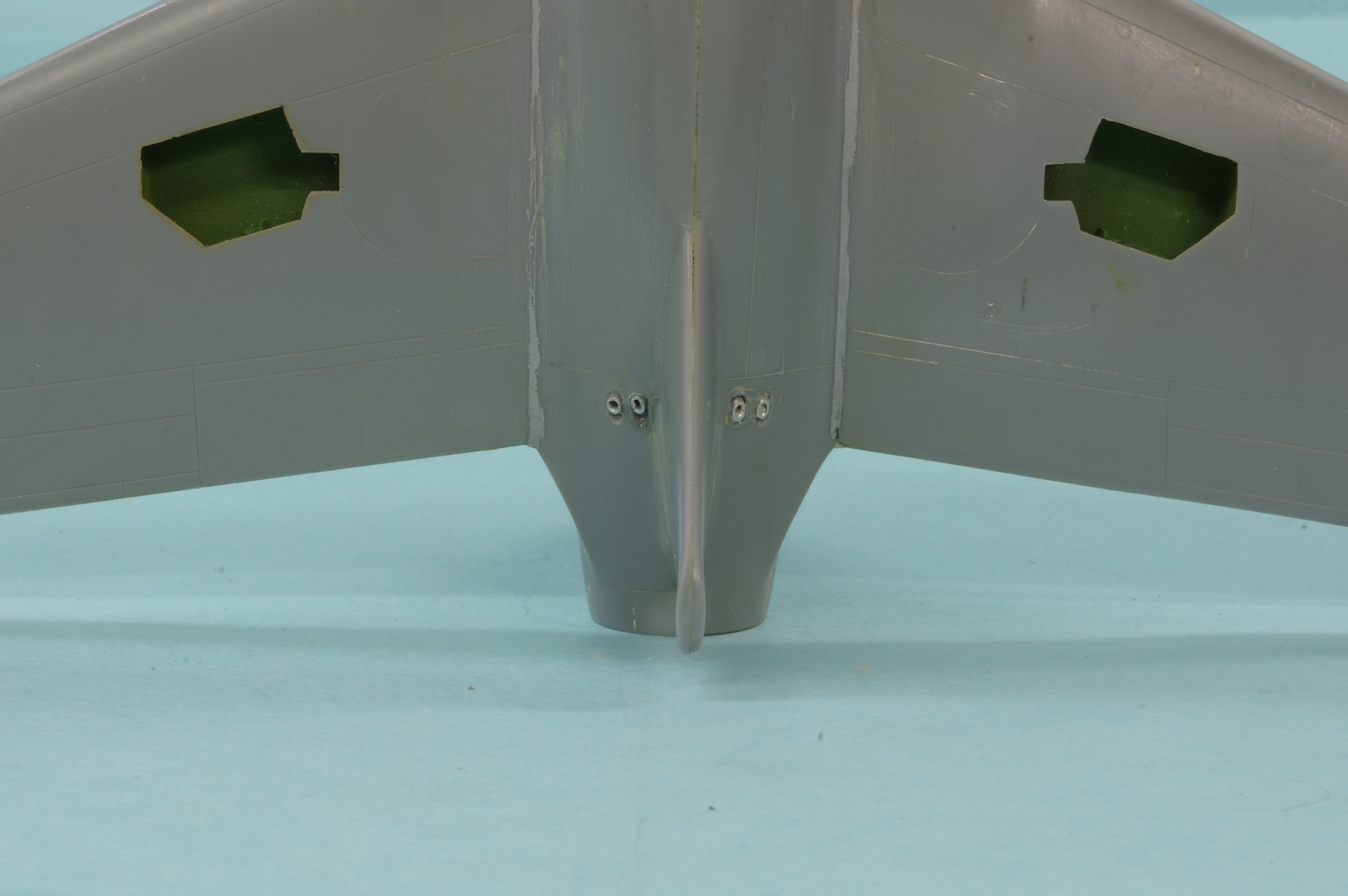

The cockpit tub positioning wasn't too bad and it locks the nosewheel bay in place. The main gear bays fit well once all of the pour remnants were belt sanded down to flush with the perimeters. I painted the cockpit interior green as well as the gear bays. The inside of the tip venturies were painted flat black but it might have been good to put some sheet plastic in there to block the see through. I installed the wings to the fuselage halves and taped the assembly together to check for any ballast requirements but the model appears to be balanced well to stay on the nosewheel without any. I didn't install two subpanels that fit at an angle to the main panel as it looked like getting them in the right spot was going to be difficult and they would be hard to see anyway. There were no instrument panel decals in the kit but there is sufficient detail on the panels for some drybrushing.

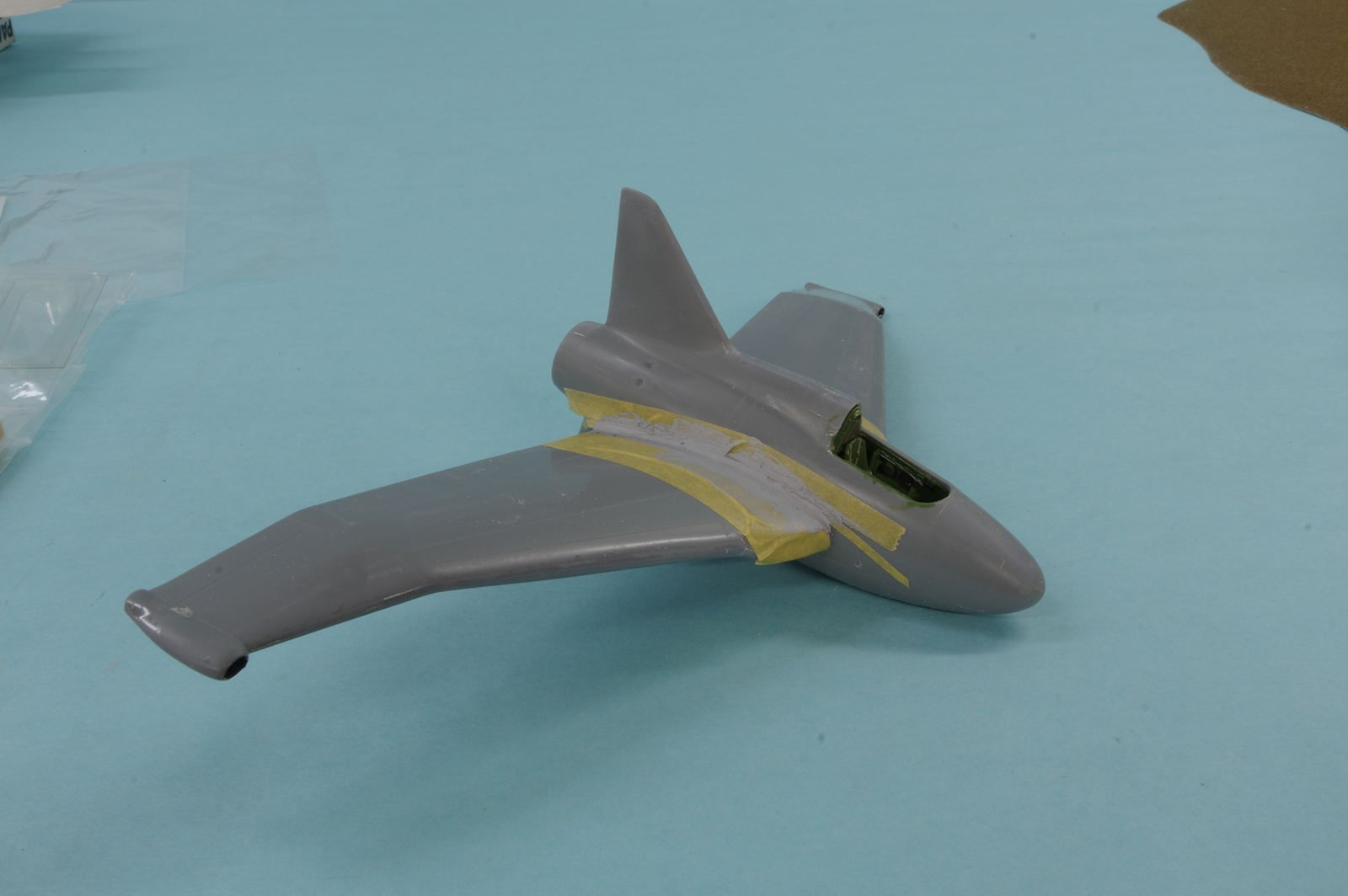

The wing to fuselage joins needed some work due to the fuselage mating detail being a little too wide in the vertical dimension. A large exacto blade shaped to a curve scraped things into a close shape followed by a rough file and some Tamiya Putty. The putty was held to a narrow area by Tamiya Tape applied on both sides of the problem areas.

The vacuform canopy fitted nicely, I cut it close with Tamiya nippers and did the final shaping with a low powered Dremel like tool from Harbor Freight. I used a 2 inch carborundum wheel running at the lowest speed so that process wasn't too exciting. I took photos of the canopy and scaled them to size in Corel Draw, outputted a dxf file and cut them in a Silhouette Cameo vinyl cutter. Once masked some interior green was sprayed on for the interior color.

1/16 aluminum tubing was inserted into holes drilled at an angle in the depressions the kit had for the exhaust and glued in with CA. I should have roughed up the outside of the tubing first as that gives the tubing some tooth for the CA but I forgot. That made it so I couldn't be as aggressive as I would have liked to be when I hollowed out the tubing. Before hollowing the tubing out I clipped the stubs off at an angle and filed them down flush with the fuselage skin.

The cockpit tub positioning wasn't too bad and it locks the nosewheel bay in place. The main gear bays fit well once all of the pour remnants were belt sanded down to flush with the perimeters. I painted the cockpit interior green as well as the gear bays. The inside of the tip venturies were painted flat black but it might have been good to put some sheet plastic in there to block the see through. I installed the wings to the fuselage halves and taped the assembly together to check for any ballast requirements but the model appears to be balanced well to stay on the nosewheel without any. I didn't install two subpanels that fit at an angle to the main panel as it looked like getting them in the right spot was going to be difficult and they would be hard to see anyway. There were no instrument panel decals in the kit but there is sufficient detail on the panels for some drybrushing.

The wing to fuselage joins needed some work due to the fuselage mating detail being a little too wide in the vertical dimension. A large exacto blade shaped to a curve scraped things into a close shape followed by a rough file and some Tamiya Putty. The putty was held to a narrow area by Tamiya Tape applied on both sides of the problem areas.

The vacuform canopy fitted nicely, I cut it close with Tamiya nippers and did the final shaping with a low powered Dremel like tool from Harbor Freight. I used a 2 inch carborundum wheel running at the lowest speed so that process wasn't too exciting. I took photos of the canopy and scaled them to size in Corel Draw, outputted a dxf file and cut them in a Silhouette Cameo vinyl cutter. Once masked some interior green was sprayed on for the interior color.

1/16 aluminum tubing was inserted into holes drilled at an angle in the depressions the kit had for the exhaust and glued in with CA. I should have roughed up the outside of the tubing first as that gives the tubing some tooth for the CA but I forgot. That made it so I couldn't be as aggressive as I would have liked to be when I hollowed out the tubing. Before hollowing the tubing out I clipped the stubs off at an angle and filed them down flush with the fuselage skin.

Last edited: